Non-contact circular weaving machine directly driven through electromagnetism

A non-contact circular loom technology, applied to circular looms, looms, textiles, etc., can solve problems such as complex structure, large frictional resistance, and loud noise, and achieve stable and reliable operation, reduce frictional resistance, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

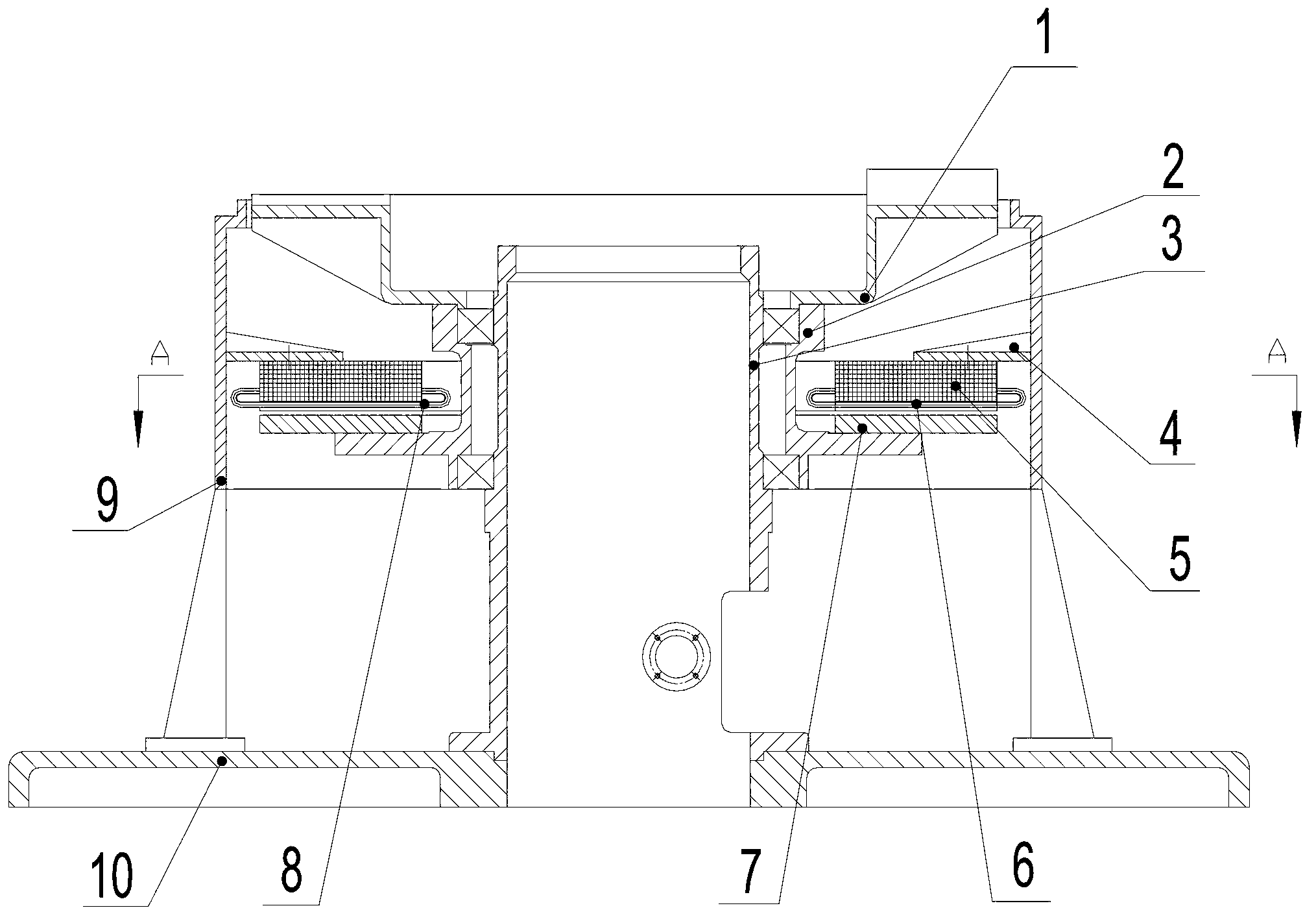

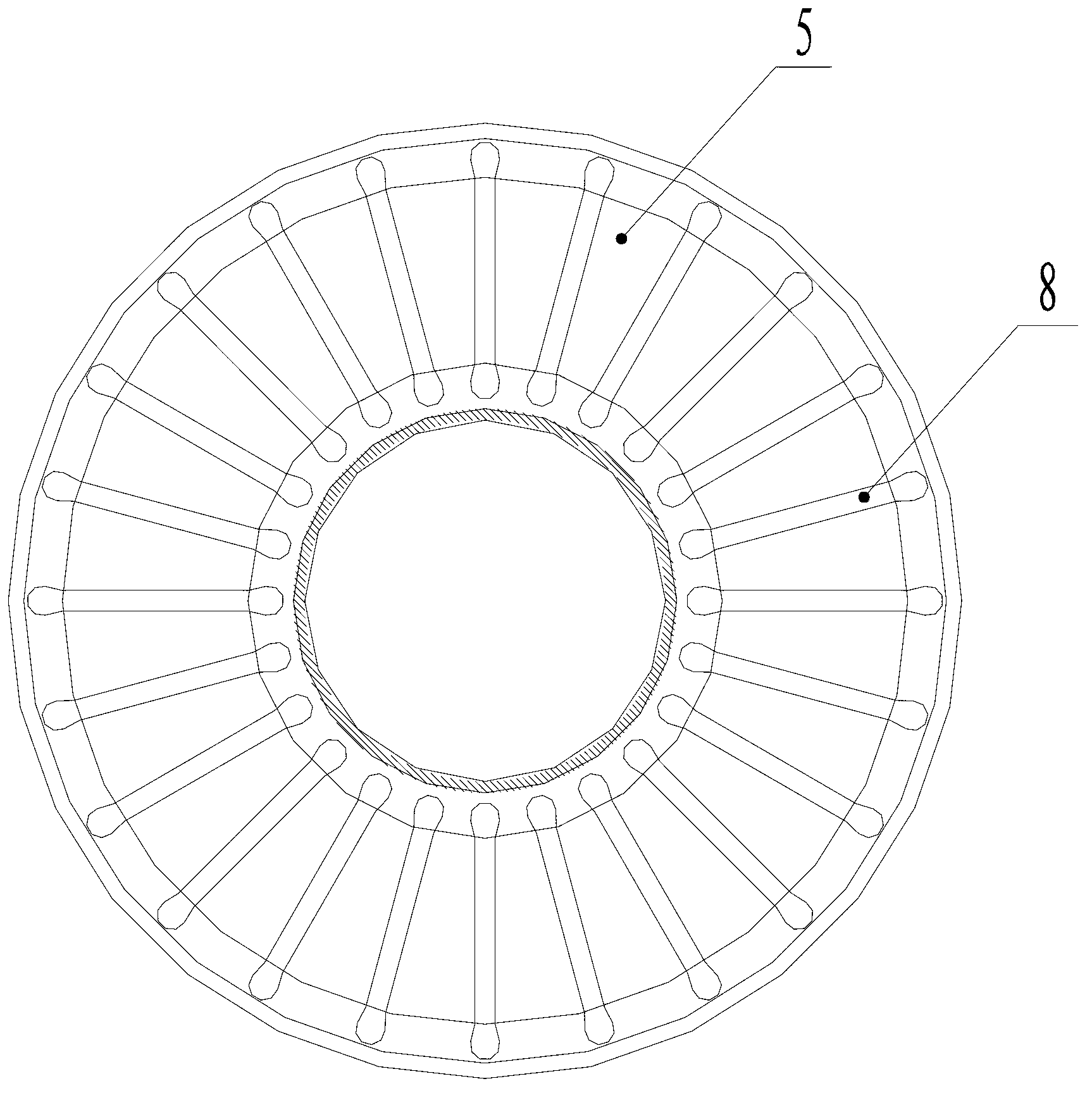

[0017] Such as figure 1 and figure 2 As shown, the circular loom directly driven by the non-contact electromagnetic includes a chassis 10, a central column 3 and a ring sleeve 9, and the central column 3 and the ring sleeve 9 are respectively connected and fixed to the chassis 10, and the center column 3 and the ring sleeve 9 are connected and fixed. There is a shuttle bed 1 between them, the shuttle bed 1 is connected with the center column 3 through the bearing seat 2 and can rotate around the center column 3, and a direct drive planar motor for driving the shuttle bed 1 to rotate around the center column 3 is provided under the shuttle bed 1 , the planar motor is composed of a stator 5 and a rotor 7, the stator 5 is connected and fixed with the ring sleeve 9 through the mounting bracket 4, and the rotor 7 is connected and fixed with the shuttle bed 1 through the bearing seat 2. The stator 5 is provided with a plurality of wire slots 8, the wire slots 8 are embedded with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com