Plastic woven bag circular weaving machine with automatically adhered lining film

A plastic woven bag and lining film technology, applied to circular looms, looms, textiles, etc., can solve the problems of low production efficiency, large space occupied by equipment, high production cost, etc., and achieve high production efficiency and small equipment footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

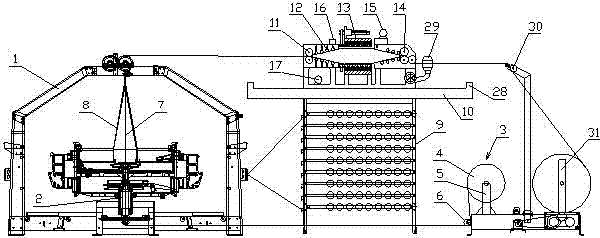

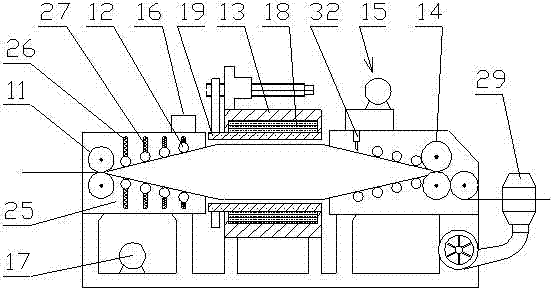

[0019] exist figure 1 In the illustrated embodiment 1, a circular loom for automatically bonding plastic woven bags with an inner lining film includes a plastic woven bag circular loom mainframe, a creel and a winding device, and the main shaft 2 of the mainframe 1 is a hollow structure, The hollow structure is provided with a film tube, and one side of the host is provided with a film release frame 3. The film release frame includes a reel 4, a support frame 5 and a rotating roller 6. The EVA / PC double-layer plastic film is arranged on the film release frame. 7. Through the rotating roller and the film-passing tube, it penetrates into the barrel cloth 8 on the upper part of the main machine; the said creel 9 is provided with a guide rail 10, the guide rail is arranged on the top of the creel frame, and the two ends of the guide rail are provided with limit devices 28. There is an inner lining film bonding device, and a walking mechanism is arranged between the inner lining fi...

Embodiment 2

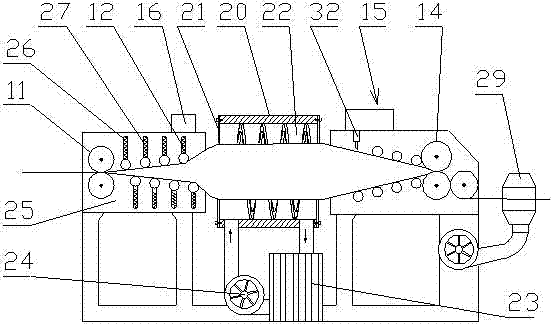

[0021] The traveling mechanism of Embodiment 2 includes a synchronous motor arranged at one end of the guide rail, the synchronous motor is provided with a driving wheel, the other end of the guide rail is provided with a synchronous wheel, and a synchronous belt is arranged between the driving wheel of the synchronous motor and the synchronous wheel. , the lining film bonding device is connected with the synchronous belt. The heating device is a hot air heating cylinder, and the hot air heating cylinder includes a cylinder body 20, a sealing cover 21, a spiral air duct 22, a heating element 23 and a blower 24 (see image 3 ), the sealing cover is located at both ends of the hot air heating cylinder, the spiral air duct is arranged in the cylinder, and the blower, the heating element and the spiral air duct form a hot air circulation loop. The two sides of the feeding end of the lining film bonding device are provided with mounting plates, and the upper and lower parts of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com