Method and apparatus specially adapted for measuring weft yarn in circular loom

A technology for circular looms and measuring methods, which is applied in circular looms, looms, textiles, and papermaking, and can solve problems such as increasing yarn, jamming and disconnection, and increasing assembly line costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

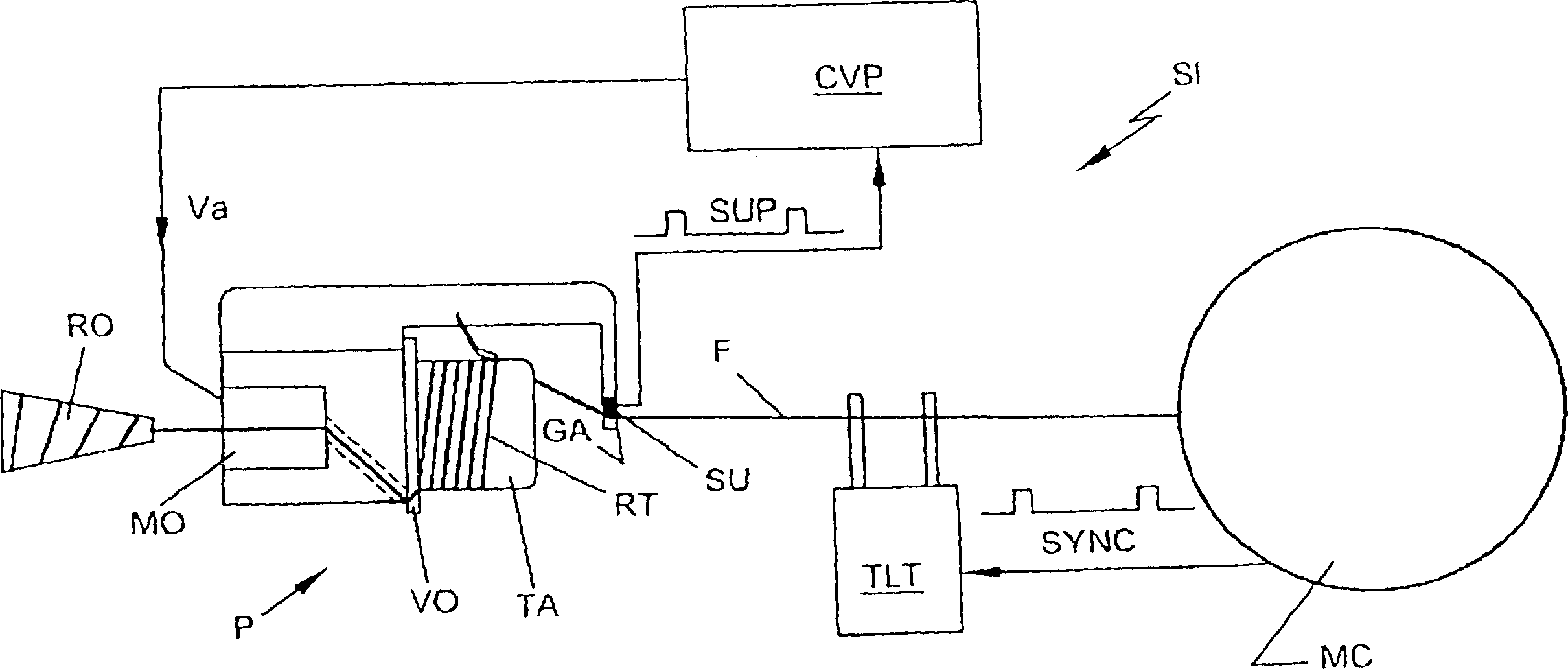

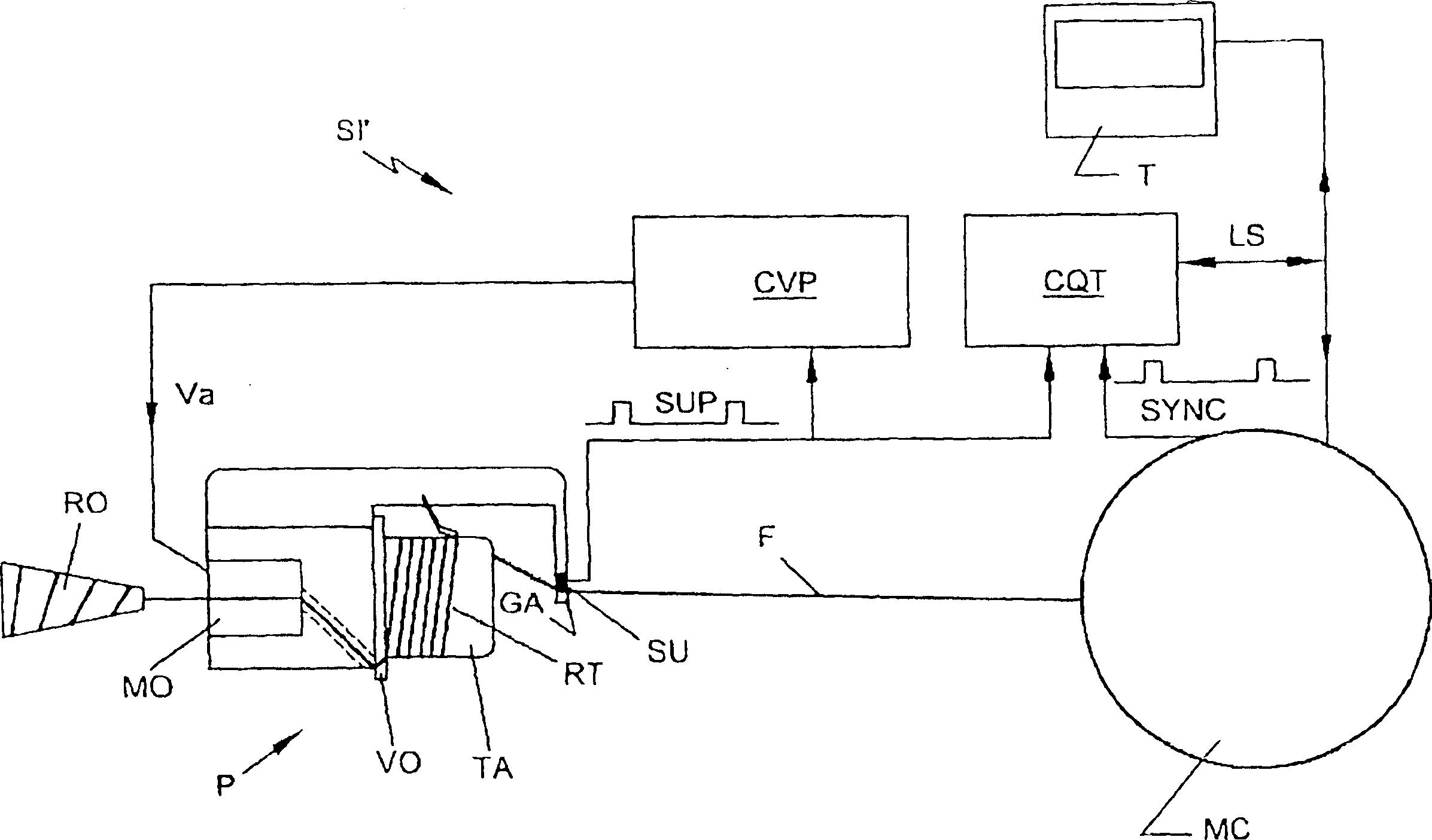

[0018] start referencing figure 1 , the designation MC generally designates an electronic circular loom, while the designation SI designates the amount of weft yarn (in cm) used to introduce the weft yarn F into the loom MC and to loosen it on each drop to form the knitted fabric. know the system.

[0019] The system SI generally consists of a weft thread guide P with a fixed drum TA, on which a fishing spool-like support is wound with a plurality of turns of the yarn F, which is released from the yarn axis RO and constitutes a yarn reserve RT, which support is composed of a The motor MO associated with the rotating disc VO placed at the base of the drum is driven.

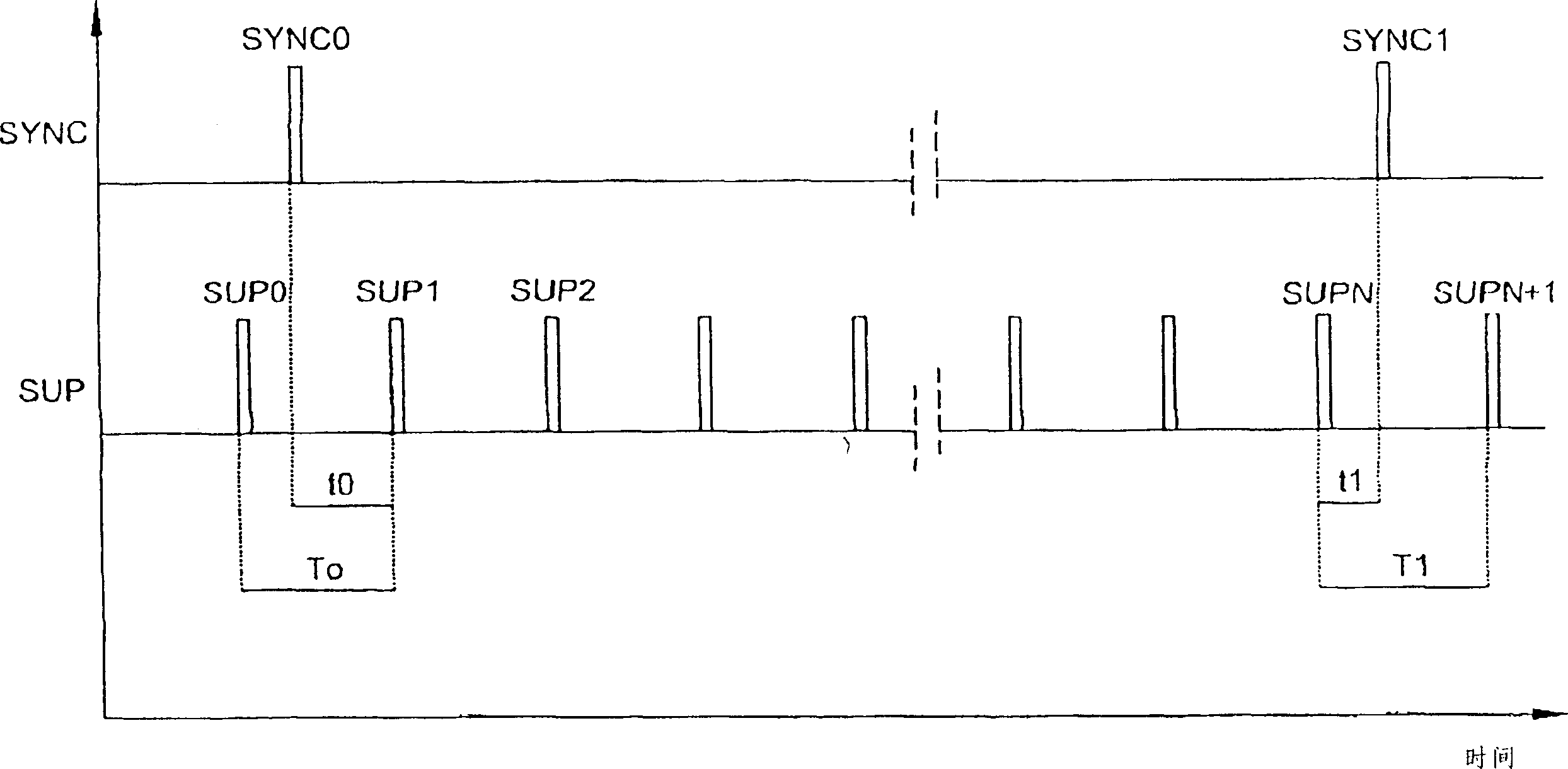

[0020] At the end of the drum TA, the thread guide P comprises a terminal thread guide ring GA, which is associated with an output sensor SU, which is usually able to provide a pulse signal SUP according to an electronic voltage, as long as the unwound weft thread F surrounds the thread One full turn of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com