High-speed plastic circular loom without shuttle roller track

A circular loom and track technology, applied in circular looms, looms, textiles, etc., can solve the problems of low speed and limit the speed of plastic circular looms, and achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

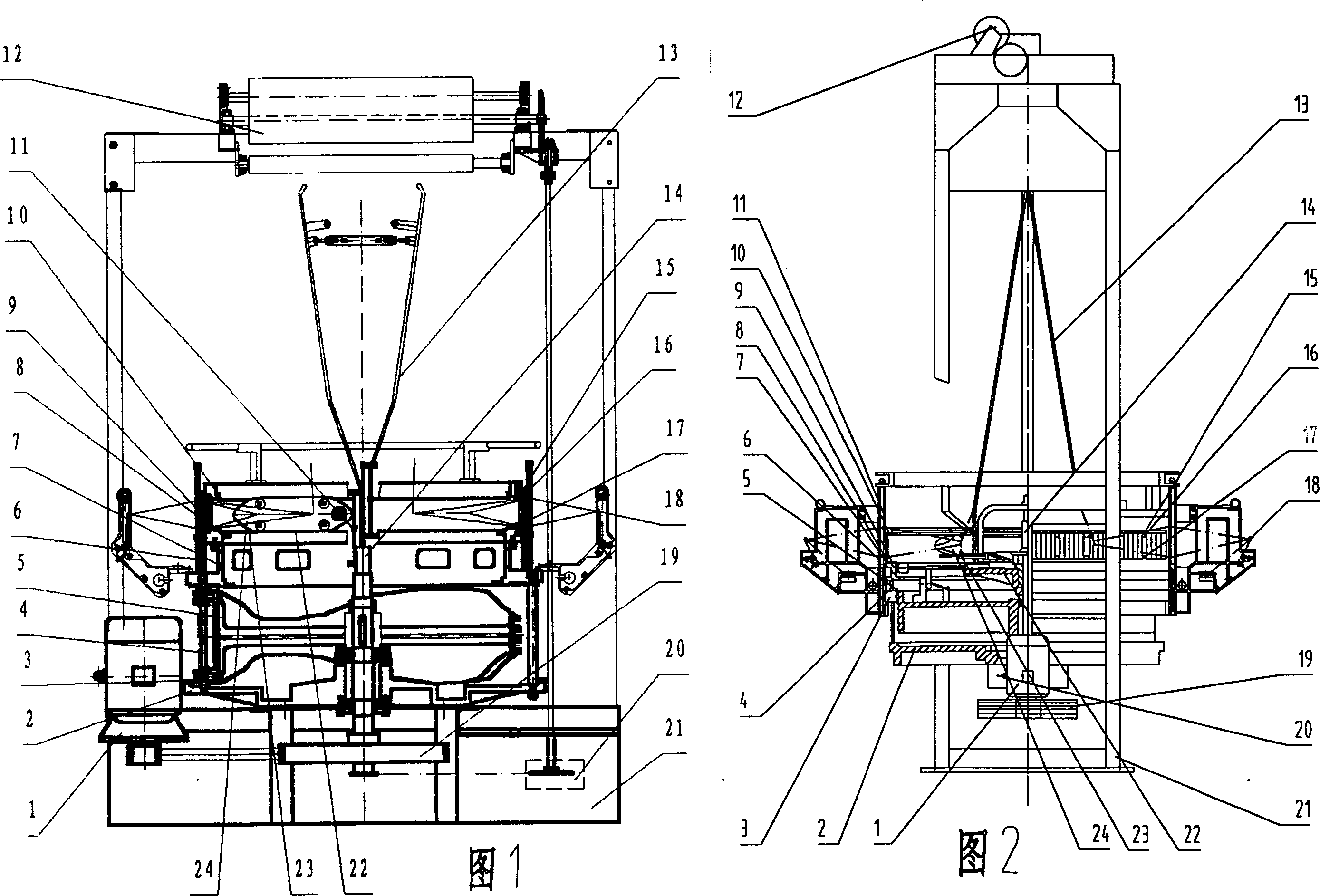

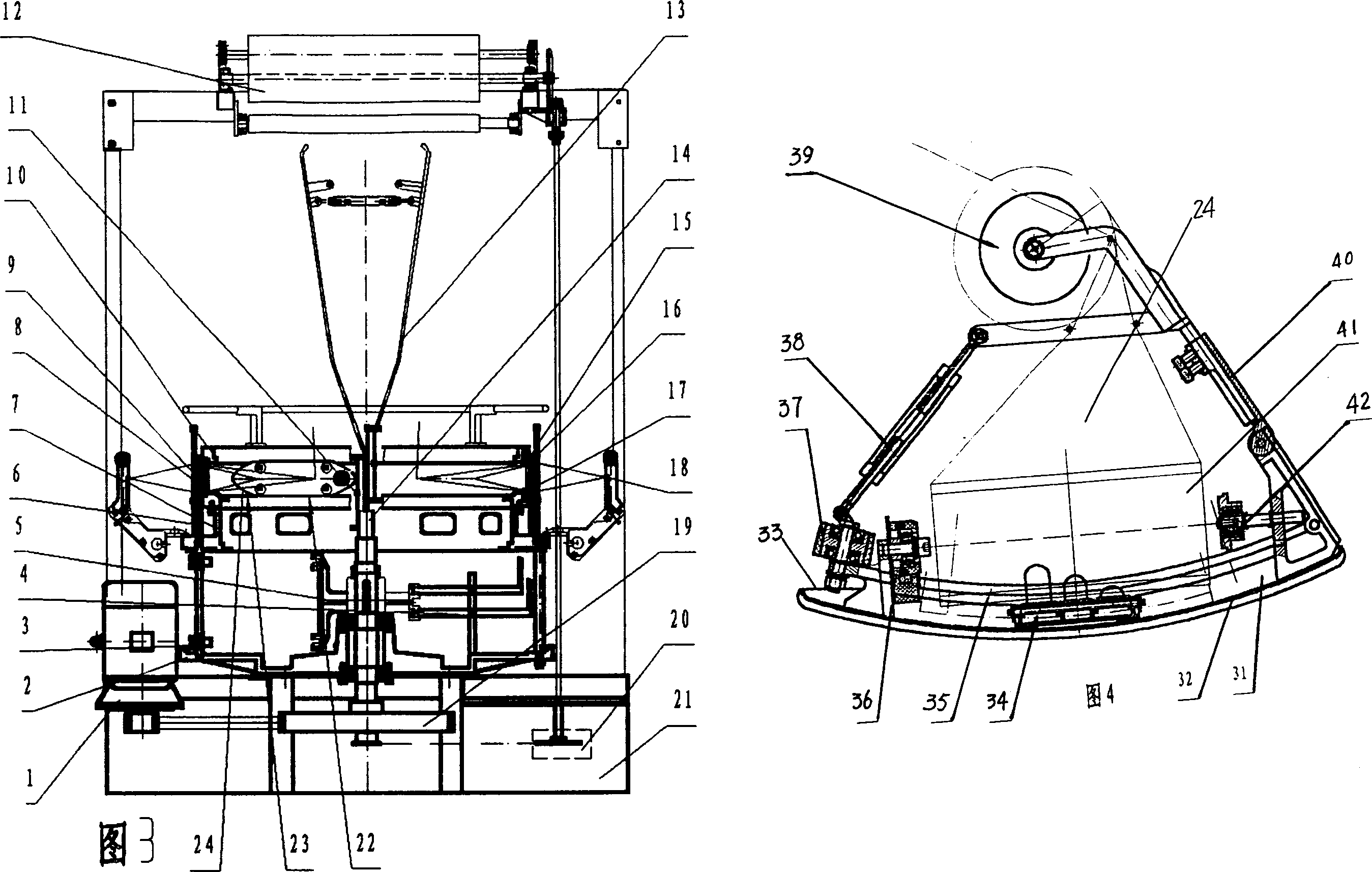

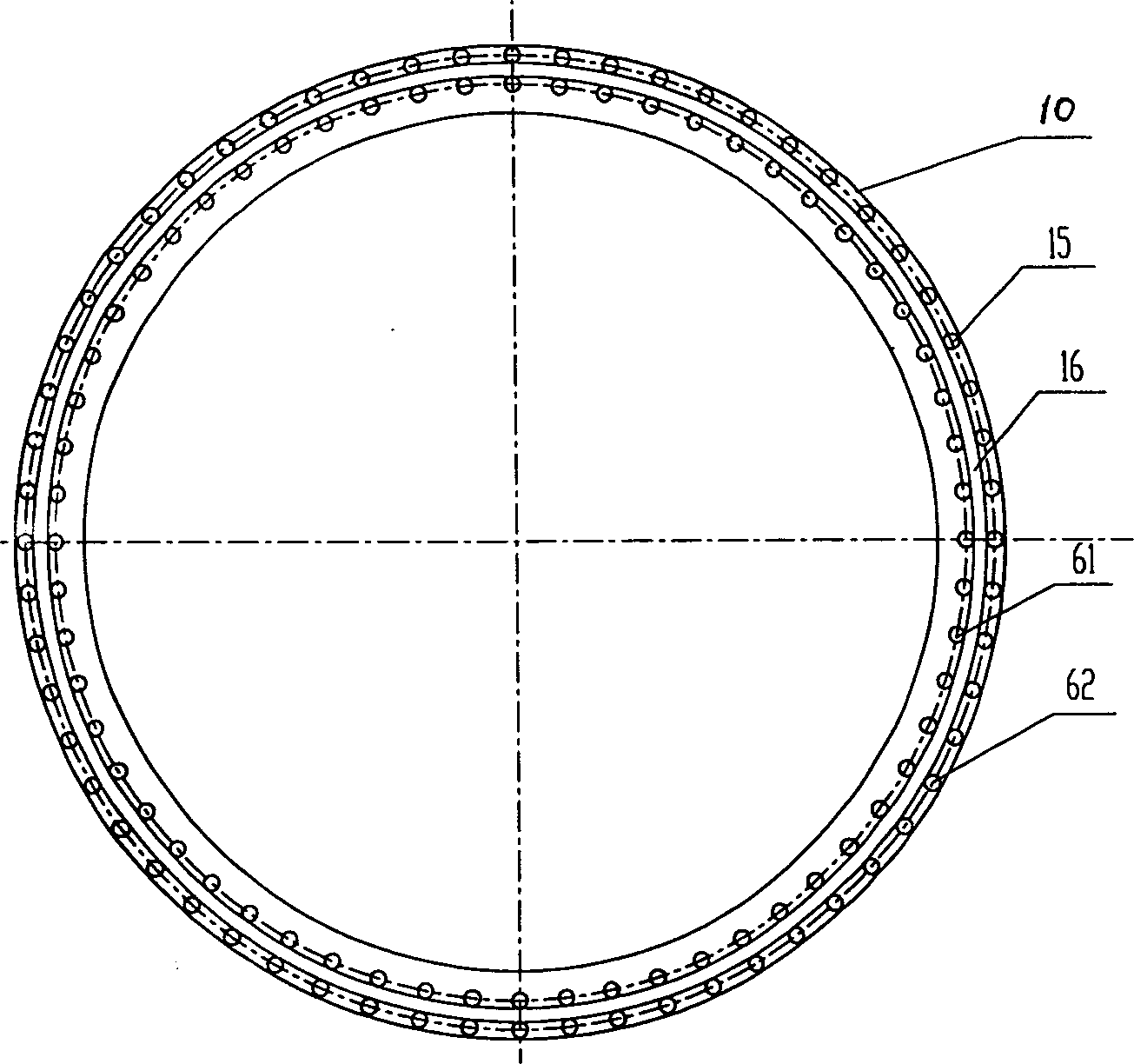

[0025] Referring to Figure 1, Figure 2, Figure 3, the main engine of the present invention is composed of a motor (1), a chassis (2), a slider (3), a slider guide column (4) or a connecting rod (4), a cam (5) or a small Cam (5), slide bar (6) or brown belt (6), middle ring (7), buckle door (8), lower door ring (9), upper door ring (10), brown frame (11) or brown wire (11), lifting device (12), expander (13), main shaft (14), jumper (18), drive belt (19), speed change mechanism (20), chassis (21), turntable (22) , Shuttle thruster (23), shuttle (24) and electrical control device. The basic structures in Figure 1, Figure 2, and Figure 3 are the same. The difference in individual components is that the slider (6) and the brown frame (11) in Figure 1 are the brown belt (6) and the brown wire (11) in Figure 2 , And comparing Figure 1 with Figure 3, the slider guide post (4) and cam (5) in Figure 1 are the connecting rod (4) and the small cam (5) in Figure 3, and the rest of the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com