Uniform material distributing and discharging device capable of preventing materials from being blocked

A technology of unloading device and uniform distribution is applied in the field of unloading device and uniform distribution, which can solve the problems of high labor intensity, high safety hazard, and increased density in cleaning, so as to eliminate labor intensity and safety hazard, and eliminate the angle of repose. , the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

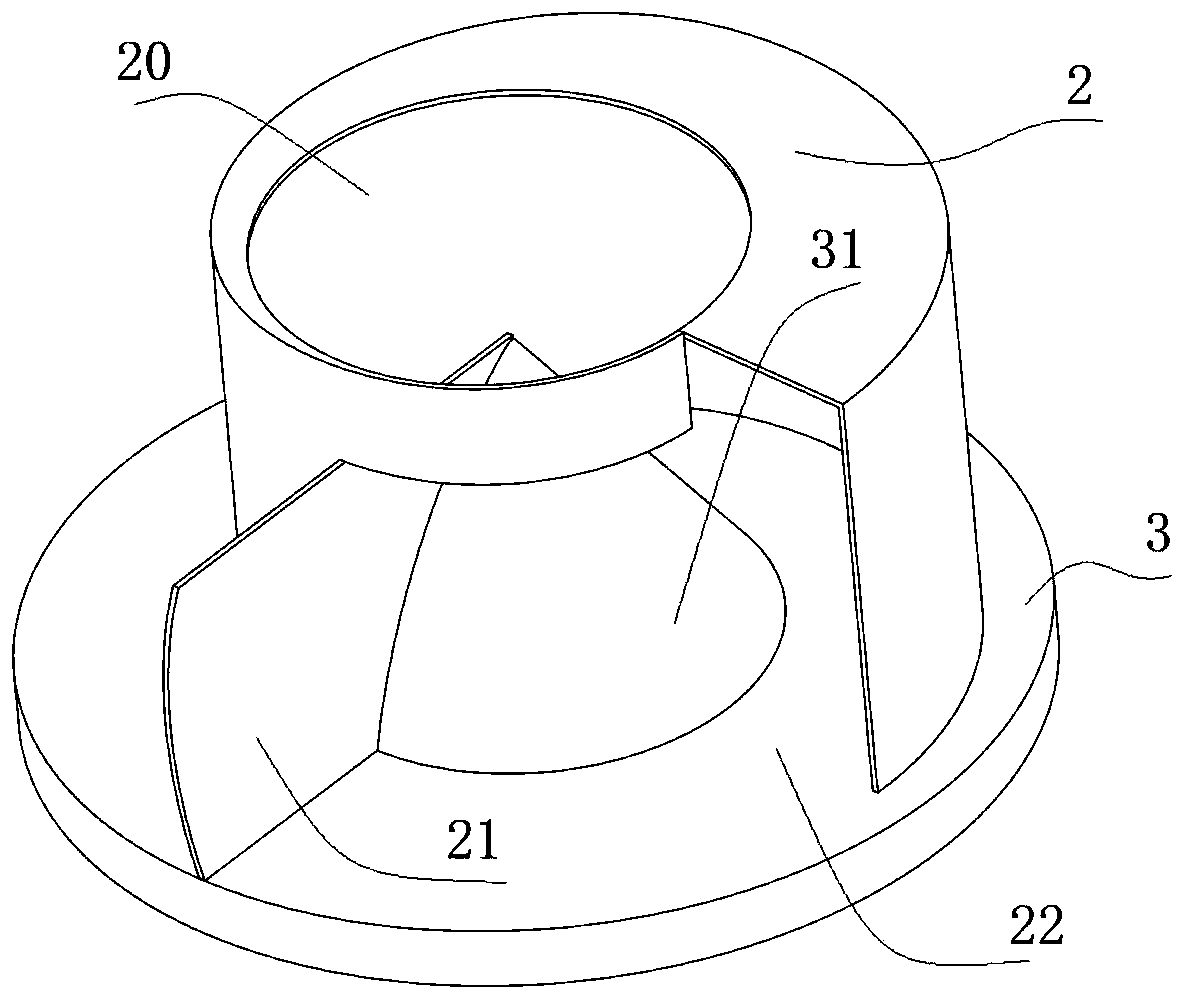

[0026] Such as Figure 1 to Figure 4 As shown, a uniform material distribution and unloading device for preventing material clogging includes a cloth body 2, which is provided with a feed port 20, the upper end of the cloth body 2 is connected to the material receiving body 1, and the bottom end is fixed on the carrier. material disc 3. The material enters the device of the present invention through the receiving body 1 , specifically, the bottom of the receiving body 1 is connected to the cloth body 2 , and after the material is fed from the receiving body 1 , it enters the cloth body 2 through the feeding port 20 .

[0027] The cloth body 2 is of an involute structure, and its cylinder is gradually enlarged along the radial direction of the material-carrying disk 3 , and a cloth opening 22 is formed at the largest opening of the cylinder. It can be seen that the cylinder body of the material distribution body 2 is not completely closed, and the cylinder body is gradually en...

Embodiment 2

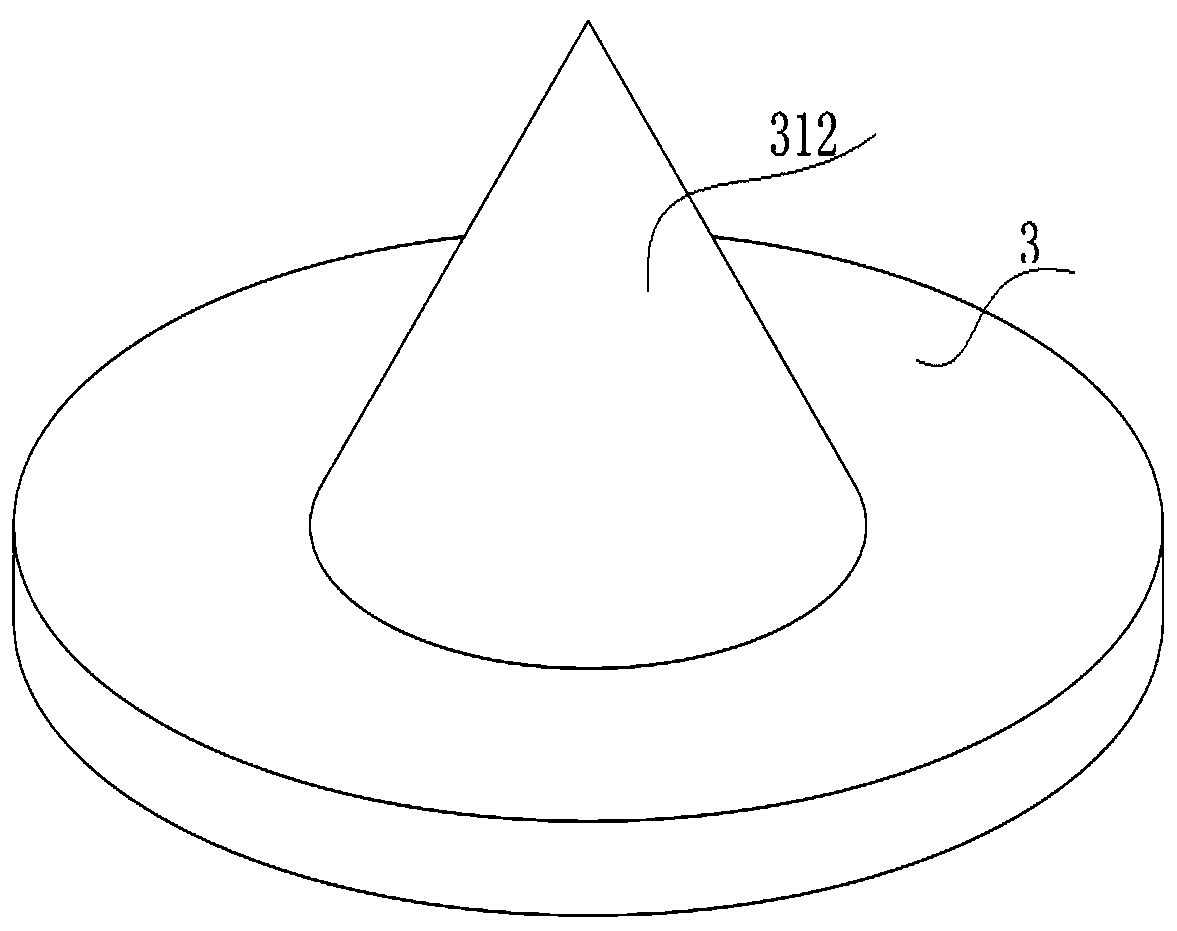

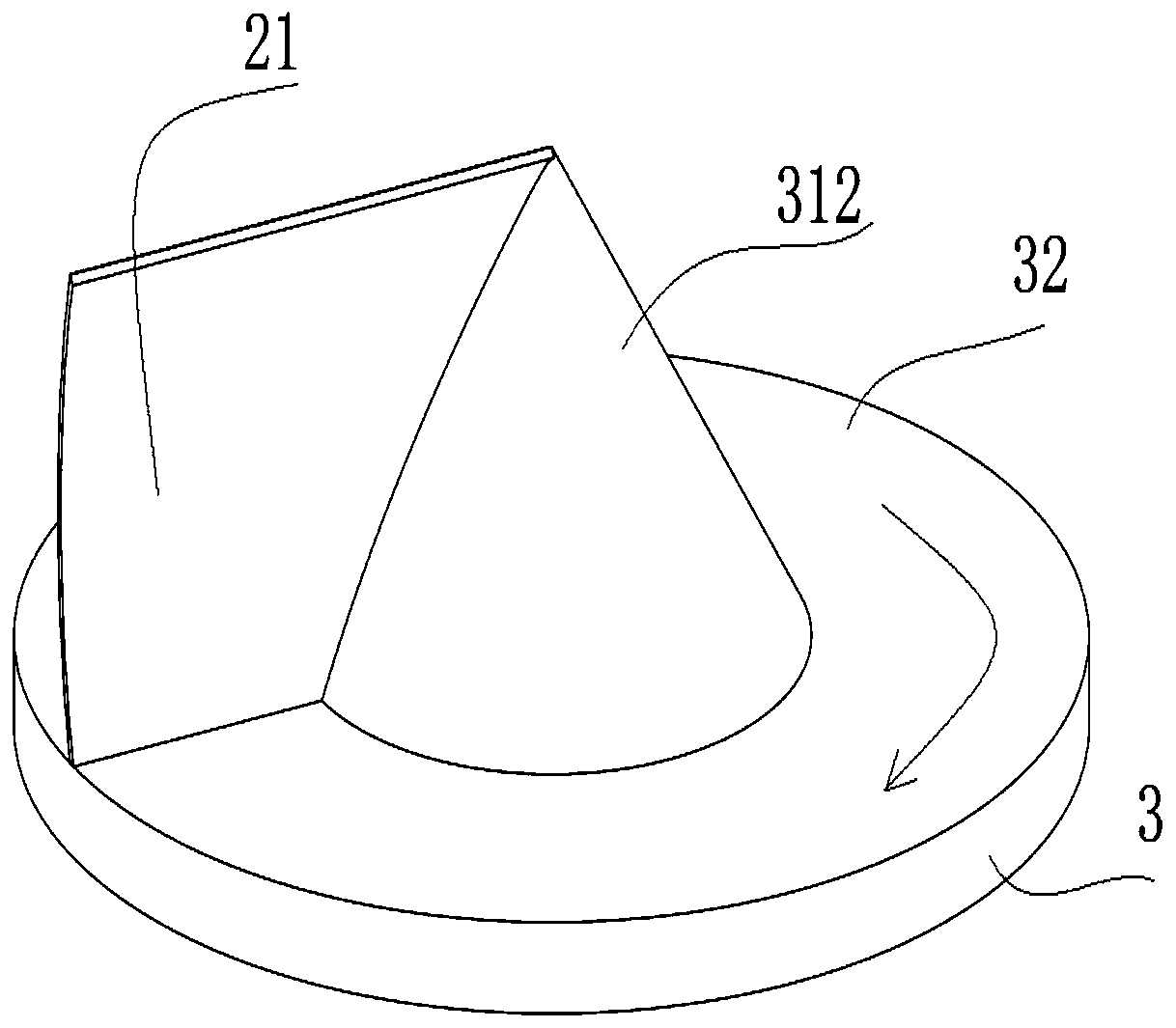

[0036] To improve the material receiving structure (31) of the device of the present invention, the material receiving structure (31) can also be a cylindrical structure (311) according to factors such as the type and nature of the material. Such as Figure 5 As shown, the cylindrical structure ( 311 ) has an axial cross-sectional diameter ≥ the diameter of the feed inlet 20 , and its height is consistent with the height of the discharge baffle 21 . The unloading baffle (21) sticks to the cylindrical structure (311) and the disk surface (32) of the loading disc (3), forming a scraping structure during the rotation of the loading disc (3).

[0037] In order to prevent materials from accumulating on the top of the cylindrical structure (311), the cylindrical structure (311) can be set as a closed combination with a cylinder at the bottom and a cone at the top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com