Extrusion device and method for producing variable-section seamless pipe

A technology of extrusion device and extrusion method, which is applied in the field of metal extrusion, can solve the problems of large extrusion force, poor stability and uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

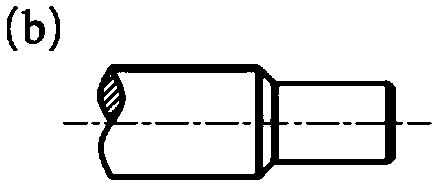

[0068] Extrusion forming of 7075 aluminum alloy variable section seamless pipe thickened inside the end.

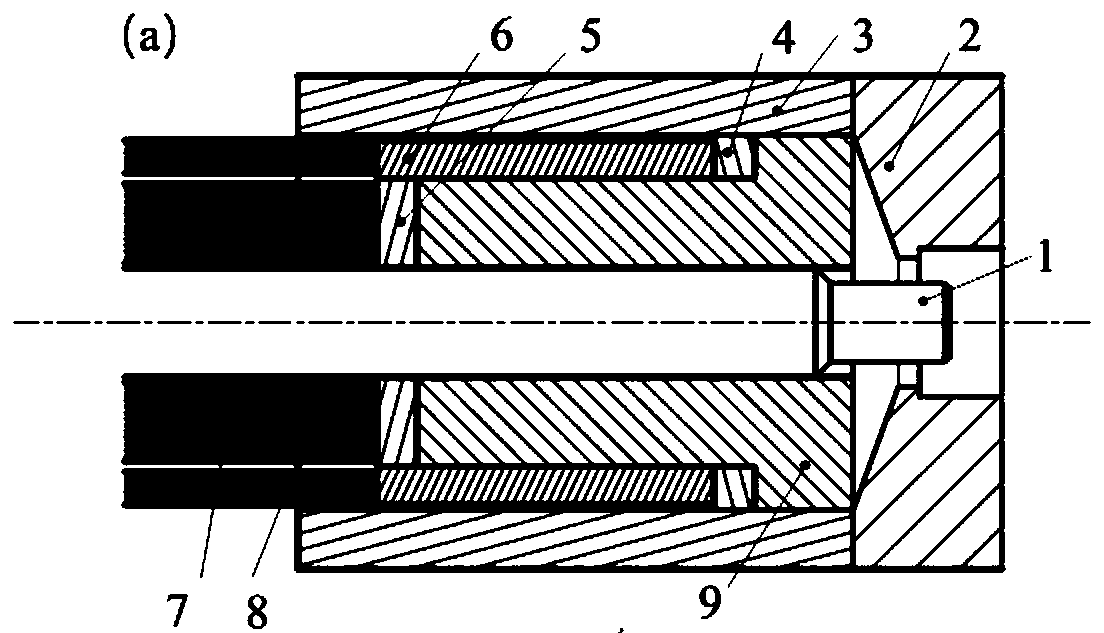

[0069] In conjunction with accompanying drawing 2, the extrusion method of the 7075 aluminum alloy variable cross-section seamless pipe thickened in the end is specifically described as follows:

[0070] Preheat the extrusion needle 1, extrusion die 2, extrusion outer cylinder 3 and auxiliary cylinder 6 to 430°C. Use 65% of No. 52 cylinder oil, 25% of rAK-1 accumulator graphite powder and 10% tin oil ester salt to be made into lubricant to extrude pin 1, extrude outer cylinder 3 inwall, extrude die 2 inwall and The inner wall of the auxiliary cylinder 6 is fully lubricated.

[0071] The 7075 aluminum alloy billet 9 with the outer step is perforated in advance by machining, preheated to 450°C, and loaded into the extrusion outer cylinder 3, and the extrusion needle 1 is passed through the pre-processed inner hole of the 7075 aluminum alloy billet 9, so that The extrusion...

Embodiment 2

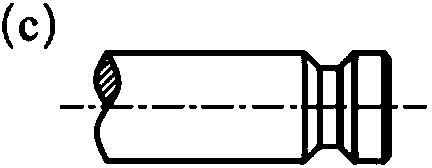

[0078] Extrusion forming of AZ91 magnesium alloy variable cross-section seamless pipe with external thickening at the end.

[0079] In conjunction with accompanying drawing 3, the extruding method of the AZ91 magnesium alloy variable cross-section seamless pipe with external thickening at the end is specifically described as follows:

[0080] Preheat the extrusion needle 1, extrusion die 2, extrusion outer cylinder 3 and auxiliary cylinder 6 to 250°C. Use the lubricant made of 50% No. 52 cylinder oil and 50% rAK-1 battery graphite powder to fully lubricate the extrusion needle 1, the inner wall of the extruded outer cylinder 3, the inner wall of the extrusion die 2 and the inner wall of the auxiliary cylinder 6.

[0081] The AZ91 magnesium alloy billet 9 with external steps is perforated in advance by machining, preheated to 380°C, and then loaded into the extrusion outer cylinder 3, and the extrusion needle 1 is passed through the pre-processed inner hole of the AZ91 magnesiu...

Embodiment 3

[0088] Extrusion forming of 2A12 aluminum alloy variable cross-section seamless pipe with thickened inside end and thickened middle.

[0089] In conjunction with accompanying drawing 4, the extrusion method of the 2A12 aluminum alloy variable cross-section seamless pipe that is thickened in the end and thickened in the middle is specifically described as follows:

[0090] Preheat the extrusion needle 1, extrusion die 2, extrusion outer cylinder 3 and auxiliary cylinder 6 to 380°C. Use 65% of No. 52 cylinder oil, 25% of rAK-1 accumulator graphite powder and 10% tin oil ester salt to be made into lubricant to extrude pin 1, extrude outer cylinder 3 inwall, extrude die 2 inwall and The inner wall of the auxiliary cylinder 6 is fully lubricated.

[0091] Pre-punching the 2A12 aluminum alloy billet 9 with a stepped exterior is machined, preheated to 400°C and then loaded into the extrusion outer cylinder 3, and the extrusion needle 1 is passed through the pre-processed inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com