A high-speed plastic circular weaving machine

A circular loom and plastic technology, applied in circular looms, looms, textiles, etc., can solve the problems of easy degumming, low operating speed, and low temperature resistance, and achieve low temperature rise, stable operation, and increased production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

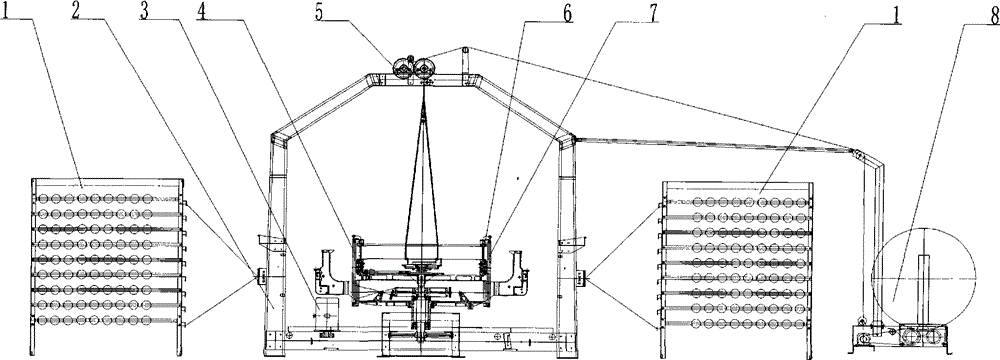

[0029] Example 1: as figure 1 As shown, a high-speed plastic circular loom includes an outer support (2), front and rear warp support (1), a lifting device (5), a cloth rolling device (8), a main engine transmission device (3), a weaving and opening device ( 4), the whole shuttle device (16), the door ring (6), the rolling track device (7). The outer bracket is arranged outside the main machine, the front and rear warp wire brackets are respectively arranged at the front and rear of the outer bracket, the lifting device is arranged on the top of the main machine and supported by the outer bracket, and the cloth winding device is arranged in the front part of the rear warp wire bracket.

Embodiment 2

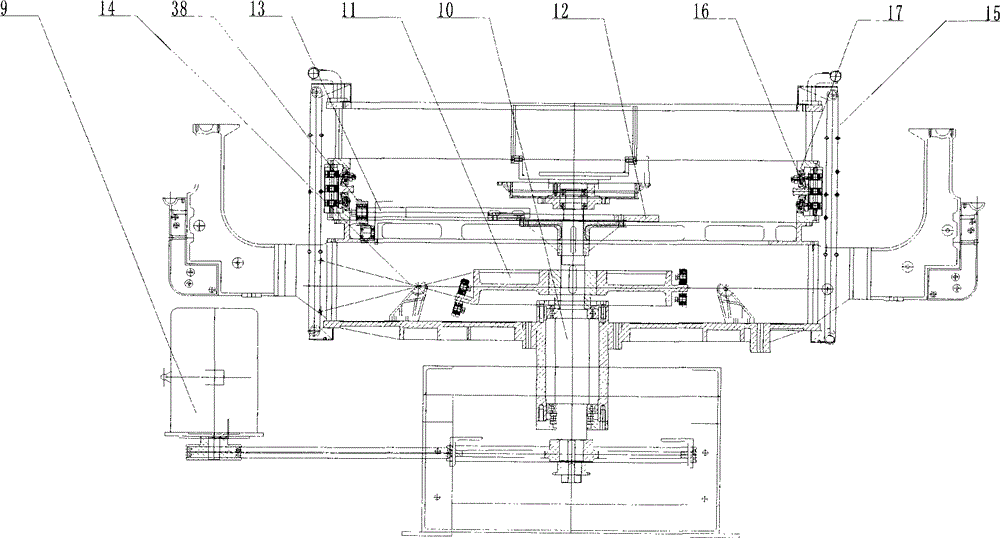

[0030] Example 2: as figure 2 As shown in the figure, the shuttle body is in the shape of a boat, and the rear part is provided with a rear roller (19). In addition, the whole shuttle is subjected to the centrifugal force outward during the movement, and there is a certain distance between the positioning wheel and the warp, so the woven product will not be damaged. Two or more conical positioning shuttle wheels (17) are installed on the inner side of the shuttle body, respectively. The positioning shuttle wheel is characterized by a wheel shaft (39) in the middle, and a concentric or eccentric mounting hole (40) in the wheel shaft. The axle is provided with more than one bearing (41), the outer bearing is provided with a steel sleeve (42), the outer steel sleeve is cast with a colloidal molding (43), and its conical angle is in rolling contact with the inclined plane steps on the inner plane of the upper and lower door rings. Because the upper and lower tapered rollers and ...

Embodiment 3

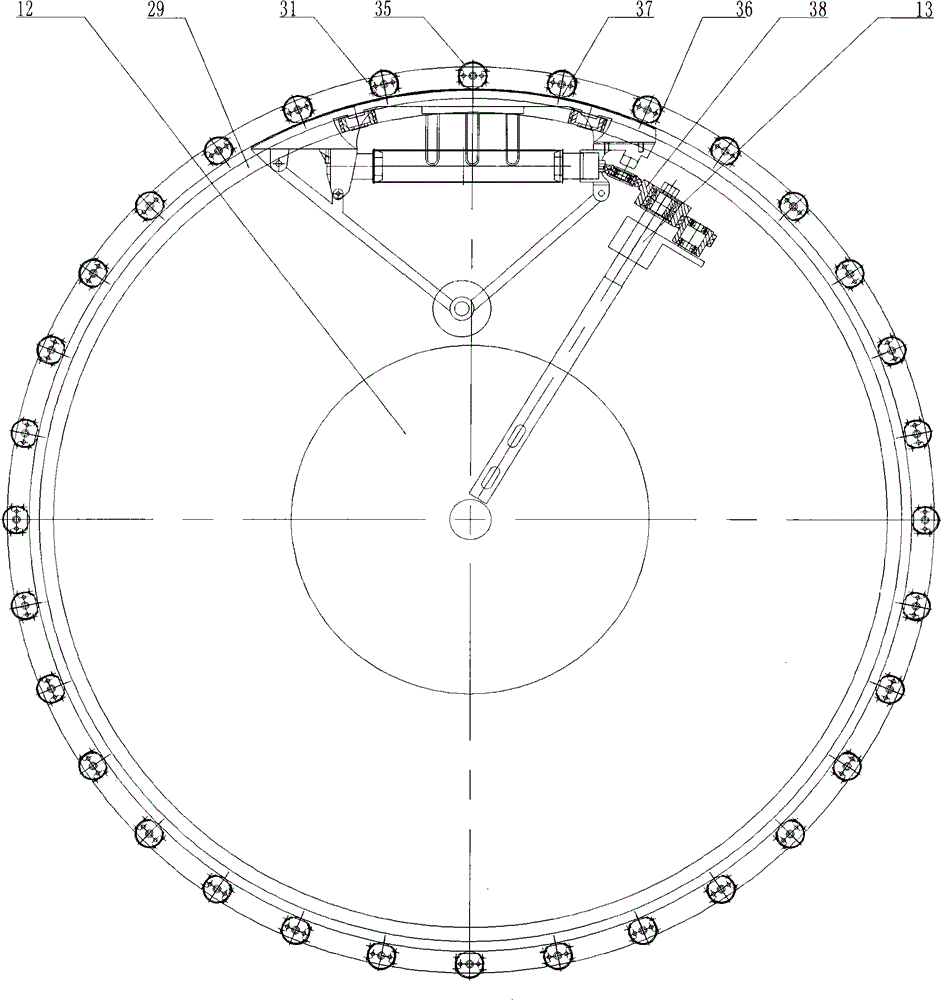

[0031] Example 3: as image 3 As shown, on the inner plane of the upper and lower door rings, there are inclined plane steps (29) that conform to the opening angle of the warp threads, and on the outer plane of the upper and lower door rings are more than 24 roller shafts (30), and the two ends of the roller shafts are fixed On the upper and lower door rings, two or more track rollers (31) are arranged on the roller shaft to form a roller group, each roller is provided with more than one bearing (32), and the bearing is provided with a steel sleeve (33), the steel sleeve A colloid (34) is casted outside, and a roller sheath (35) or a guard post (36) is arranged outside the roller to keep a certain distance from the roller. The roller sheath and the roller are concentric and fixed in the middle of the upper and lower door rings. There is a C-shaped port (37) on the vertical side of the circumference, so that the circumference of the roller is exposed to the outside. The above 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com