Three-shuttle circular weaving machine for high pressure resistant large-caliber hose fabric

A large-diameter, high-pressure-resistant technology, applied to circular looms, looms, textiles, etc., can solve the problems of insufficient weaving layer, unstable weft density, complex structure, etc., achieve more warp positions, improve operation stability, The effect of increasing the pulling distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

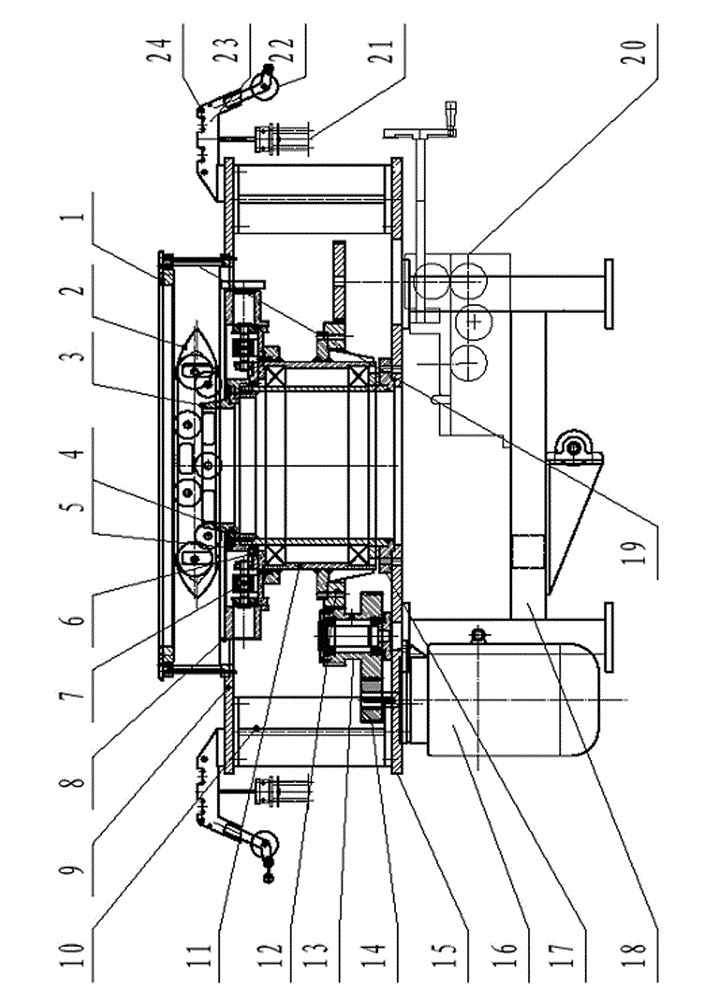

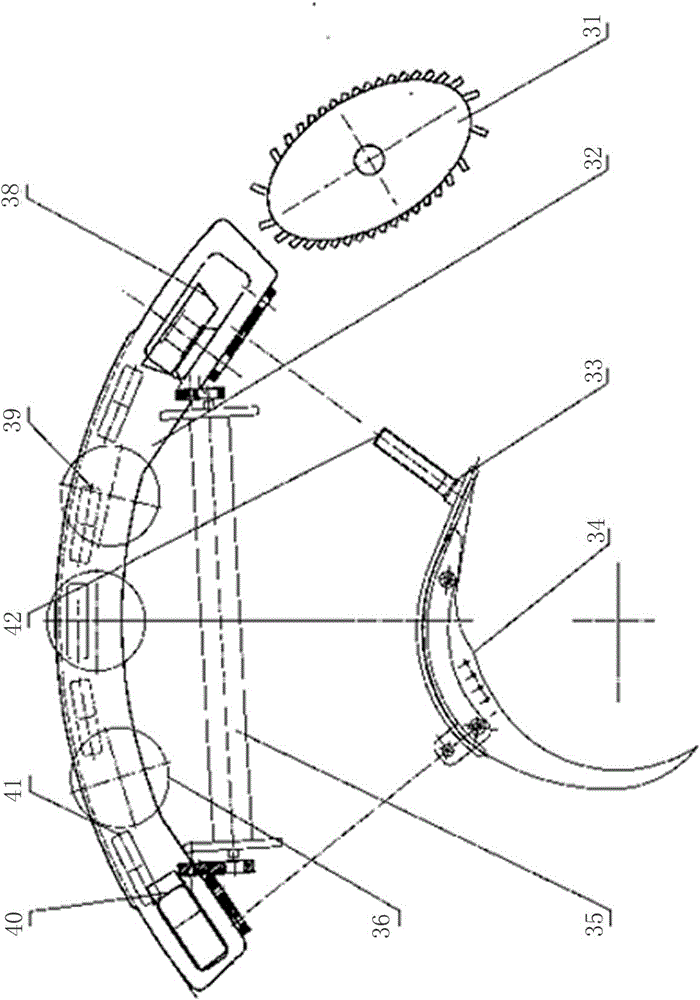

[0022] like Figure 1 to Figure 4 As shown, a three-shuttle circular loom for high-pressure resistant large-diameter hose fabrics of the present invention includes a body support device, a transmission device, a weaving device and a motor 16, and the transmission device and the weaving device are fixed on the body support device;

[0023] The body supporting device comprises frame 18, large base plate 15, center seat 17, seat ring 9, pressure ring cover 5 and nozzle seat 4, is provided with large base plate 15 on the frame 18, is provided with center seat 17 on the large base plate 15, and center Both sides of the upper end of the seat 17 are provided with a pressure ring sleeve 5, the pressure ring sleeve 5 is provided with a nozzle seat 4, and both sides of the nozzle seat 4 are provided with a seat ring 9;

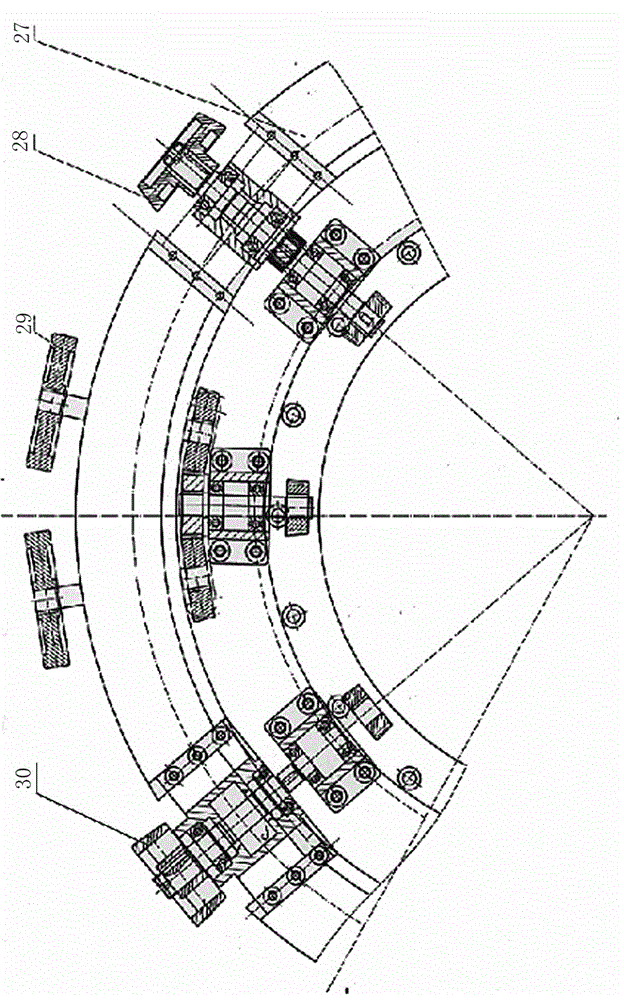

[0024] The transmission device comprises a transition gear assembly 13, a driving gear 12, a shuttle bed bearing seat 11, a shuttle bed assembly 8, a transmission gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com