Magnetic weft insertion method of circular knitting machine

A circular knitting machine and magnetic technology, applied in circular looms, looms, textiles, etc., can solve the problems of weaving yarn damage, the influence of the application field expansion of weaving products, and the limitation of yarn types, so as to avoid friction and extrusion , increase mechanical properties, expand the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

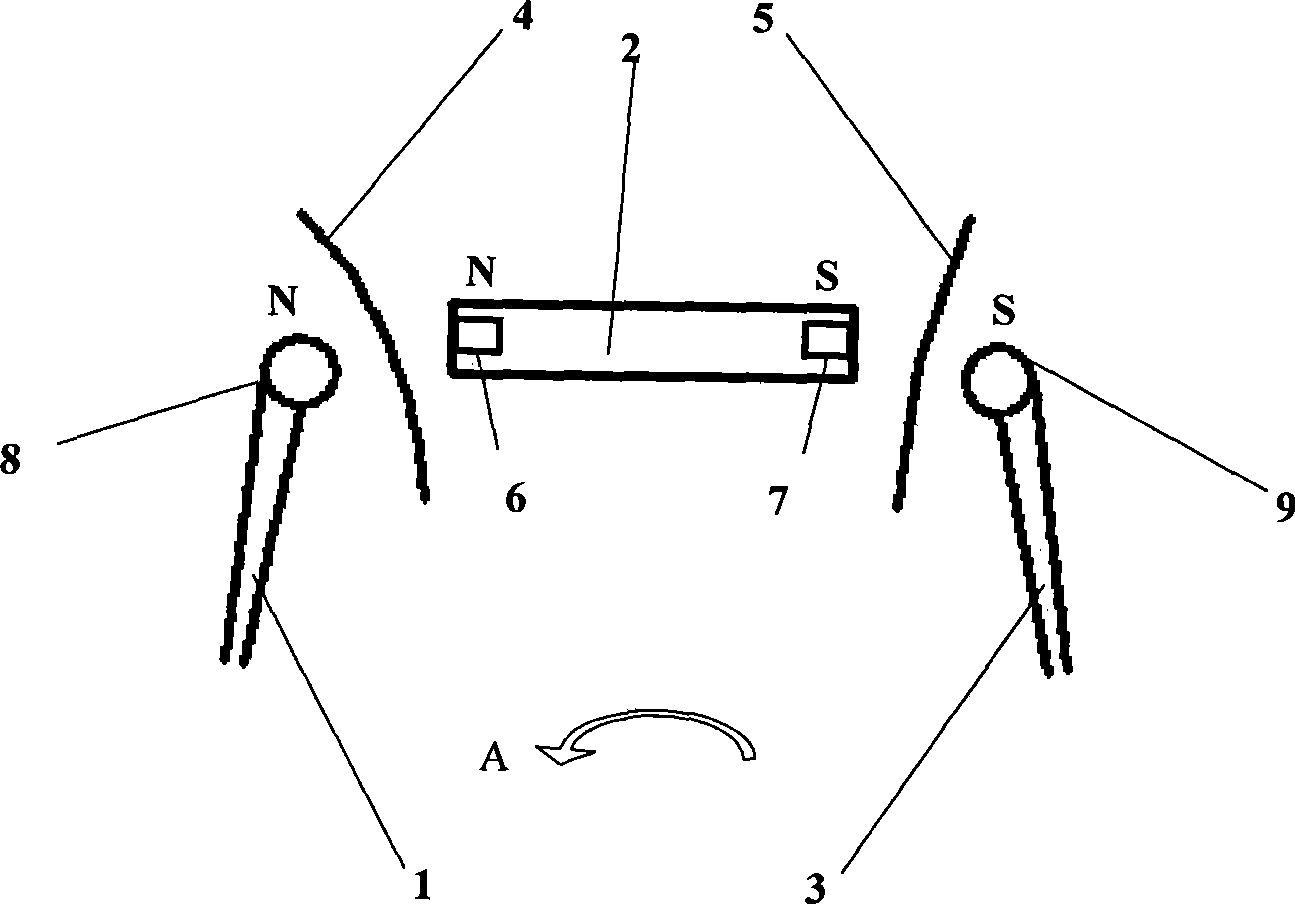

[0009] figure 1 It is a schematic diagram of the weft insertion device of the magnetic circular knitting machine according to the embodiment of the present invention. figure 1 Among them, a permanent magnet 6,7 is respectively installed on both sides of the weft shuttle boat 2, and the magnet 6 on one side of the advancing direction is installed as N pole outwards, and then the other side magnet 7 is installed S pole outwards. Using the principle of same-sex repulsion, a magnet 8 is installed at the position where the shuttle bar 1 is originally in contact with the weft shuttle ship 2, and the N pole of the magnet 8 is facing the weft shuttle ship 2, and the shuttle pusher 3 is originally in contact with the weft shuttle ship. A piece of S pole is installed toward the magnet 9 of weft yarn shuttle boat 2. Thereby make the both sides of weft yarn shuttle boat 2 keep a certain distance with shuttle pusher 3 and shuttle bar 1 all the time, and warp yarn 4,5 can pass through at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com