Forming die for prefabricated reinforced concrete

A technology for reinforced concrete and forming molds, applied in molds, manufacturing tools, ceramic forming machines, etc., can solve problems affecting the vibration of steel bars in the forming space and hinder the combination of steel bars and concrete, so as to avoid uneven distribution of steel bars and avoid displacement and bending , Guarantee the effect of bending bearing capacity and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

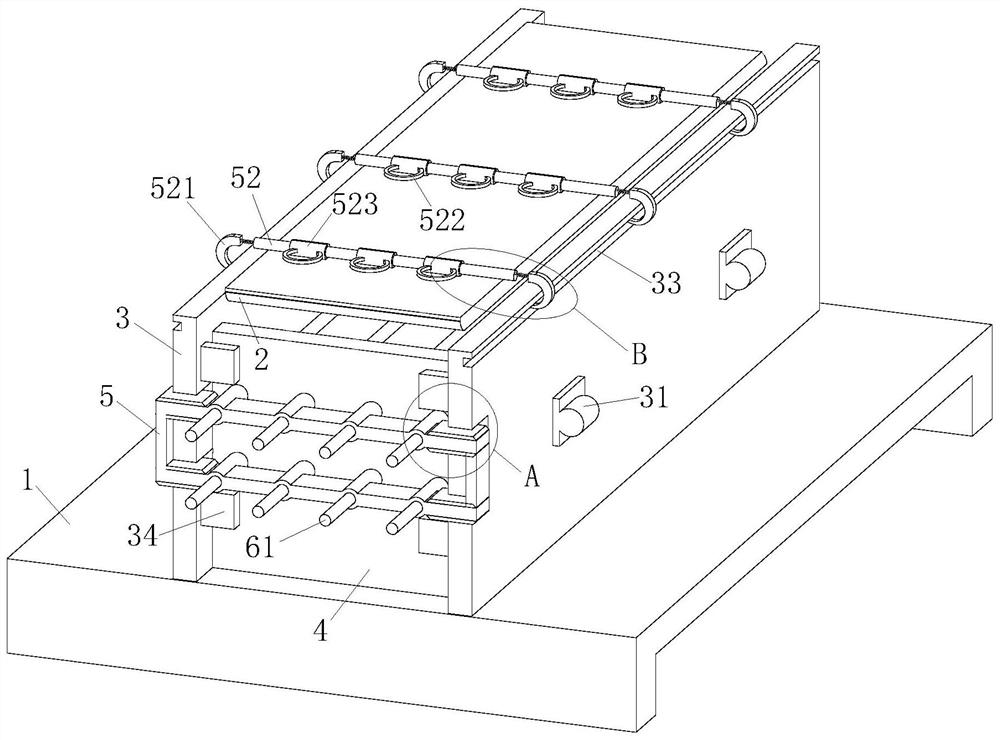

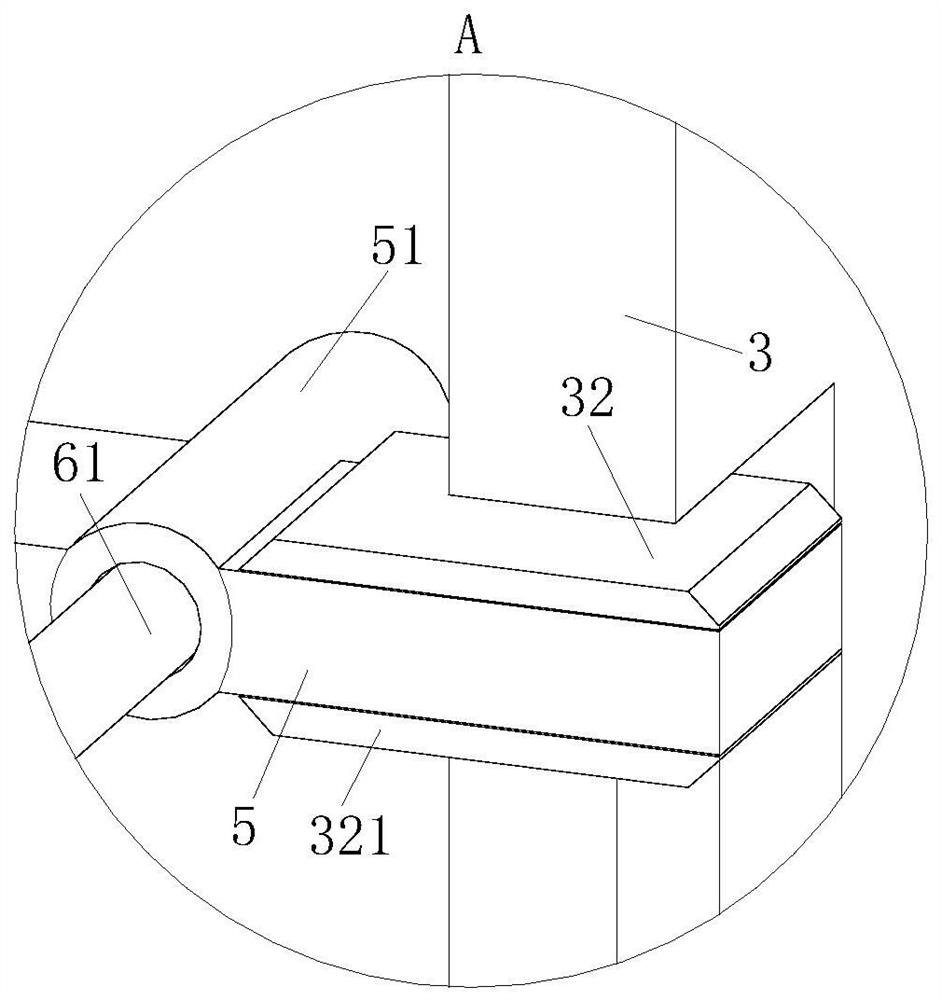

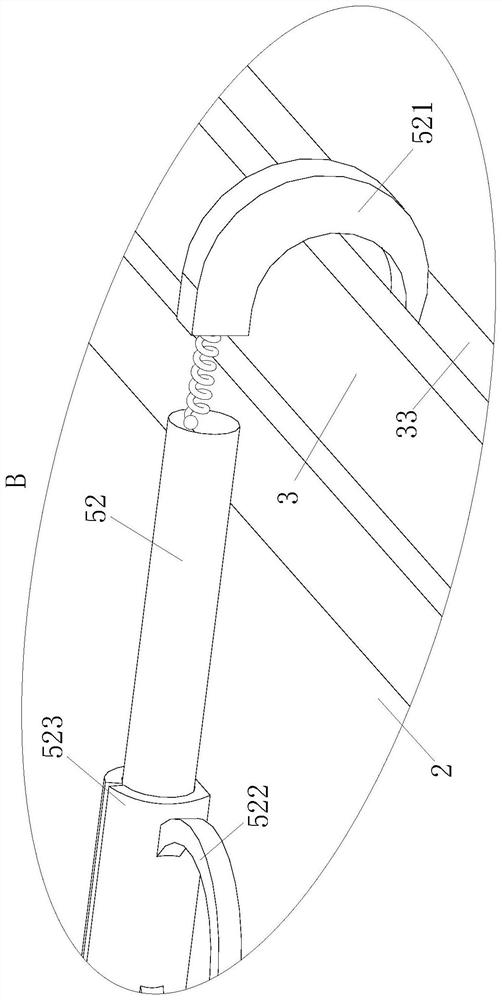

[0032] like Figures 1 to 8 As shown, a forming mold for prefabricated reinforced concrete according to the present invention includes a bottom formwork 1, an upper formwork 2, a side formwork 3, an end formwork 4 and a fixed frame 5, and the upper surface of the bottom formwork 1 is installed with parallel Two side templates 3, and the initial installation state of the two side templates 3 is a vertical state; the two end templates 4 are vertically slidably installed on the upper surface of the bottom template 1, and between the initial state of the two side templates 3 Vertical contact; the opposite surface of the side template 3 is evenly provided with a limit block 34 near the edges of both sides, and the limit block 34 is used to limit the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com