Automatic glass cleaning machine for manufacturing curved glass of automobile side window

A technology for automatic cleaning machine and curved glass, which is applied to the cleaning method using gas flow, the cleaning method using tools, the cleaning method using liquid, etc., which can solve the problem of poor hot water recovery and temperature control effect, and cumbersome and time-consuming adjustment methods. , large market demand and other problems, to avoid the dislocation of glass movement, easy to debug equipment, and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

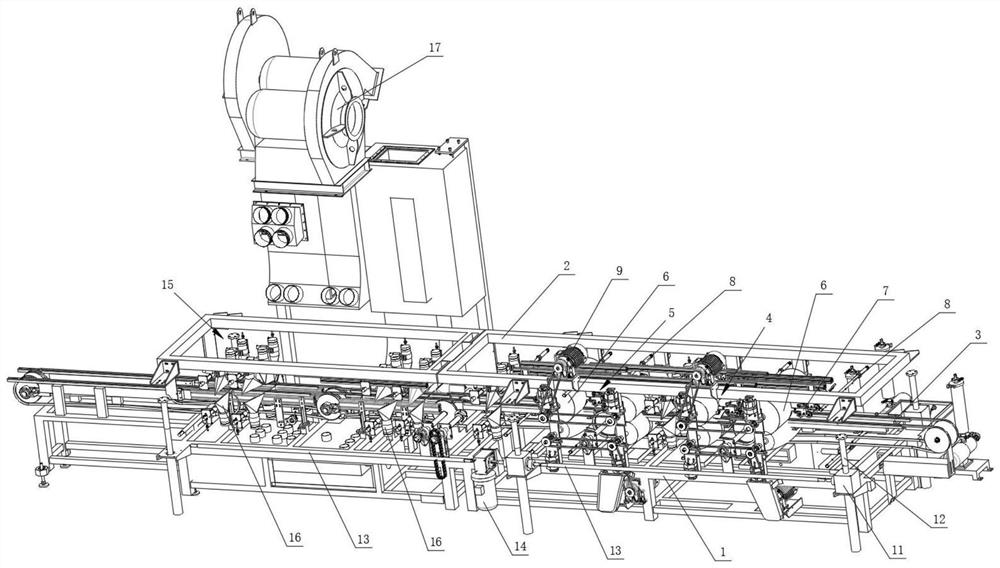

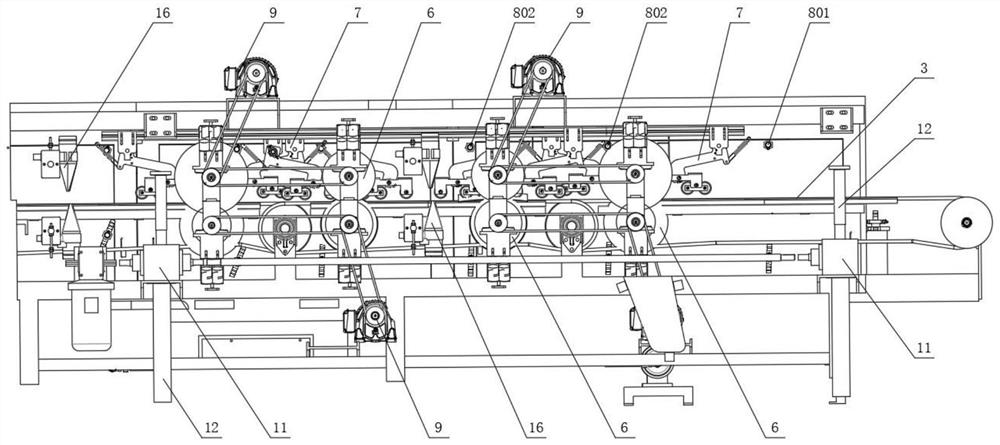

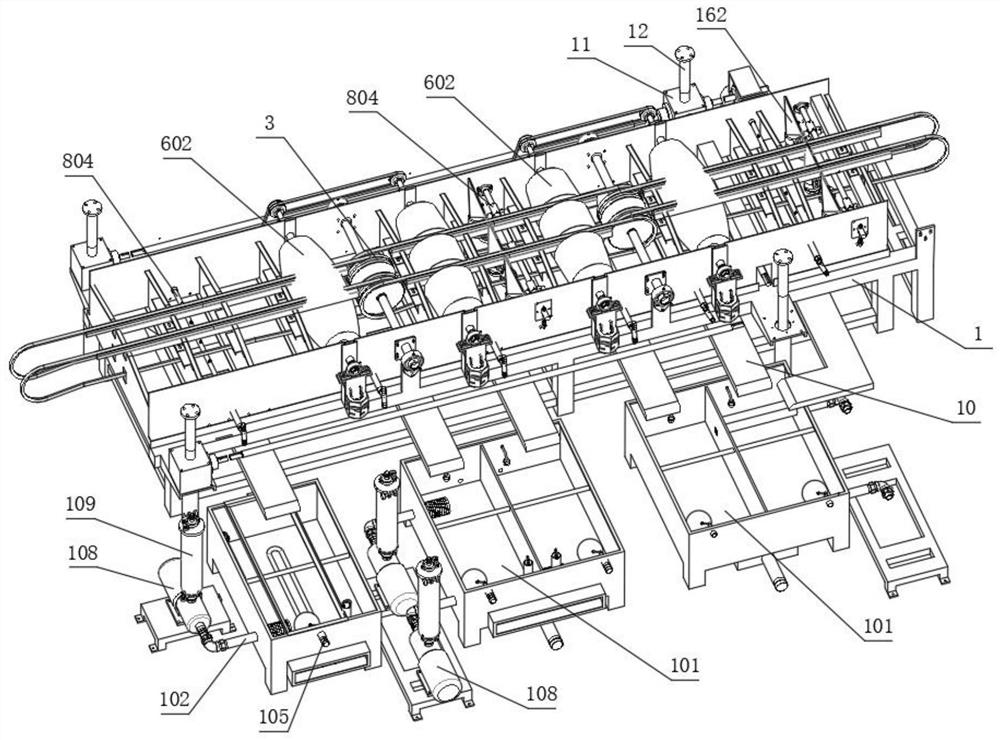

[0045] see Figures 1 to 9 , a glass automatic cleaning machine for the manufacture of curved surface glass for automobile side windows, comprising a lower frame 1 and an upper frame 2 that is adjustable up and down relative to the lower frame 1, the movable upper frame 2 can provide a larger working space for the installation of the cleaning mechanism, and is convenient The operator debugs the equipment; the middle part of the lower shelf 1 is provided with a transmission mechanism 3, along the transmission direction along the transmission mechanism 3, a primary cleaning unit 4 and a secondary cleaning unit 5 are arranged in sequence, and the cleaning of the secondary cleaning unit 5 The force is greater than that of the primary cleaning unit 4, and the primary cleaning unit 4 can remove larger foreign matter particles first, so as to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com