Processing device for household metal fittings and processing method thereof

A technology of metal fittings and processing devices, which is applied in the direction of metal processing equipment, auxiliary devices, grinding drive devices, etc., can solve the problems of increasing procedures, increasing costs, cumbersome and repetitive operations, etc., to facilitate centralized processing, prevent health problems, and achieve Polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

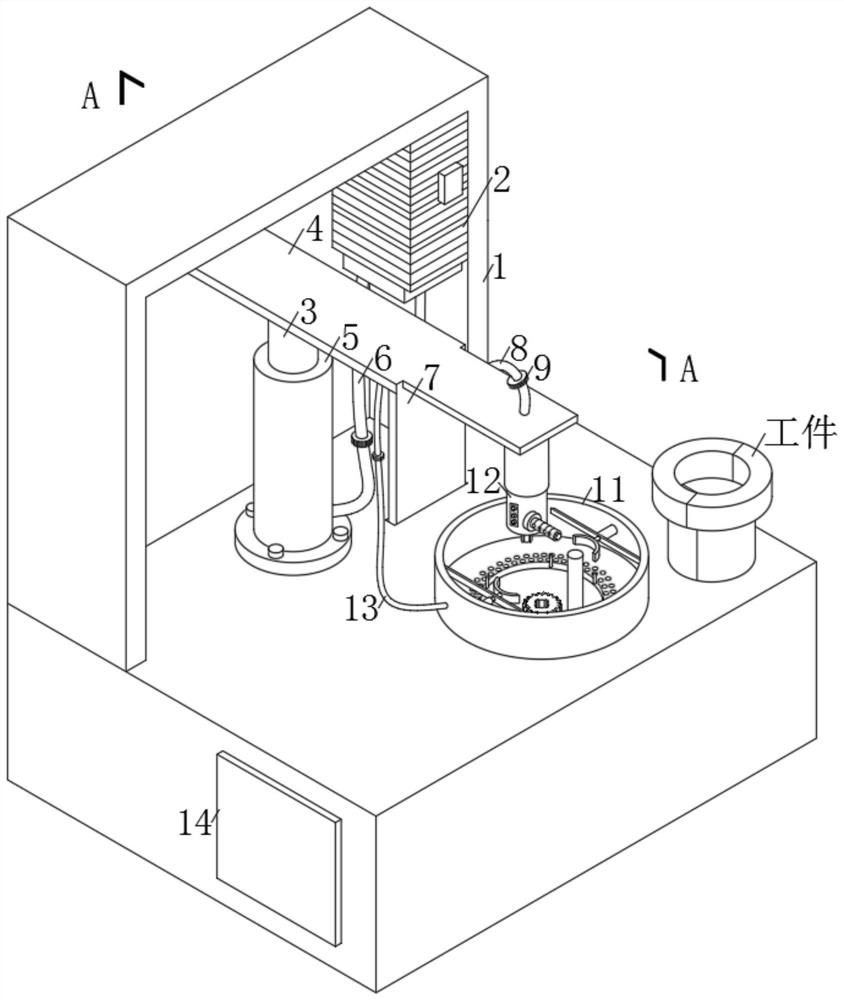

[0028] refer to figure 1 - Figure 4 The embodiments of a processing device for household metal fittings and a processing method thereof of the present invention will be further described.

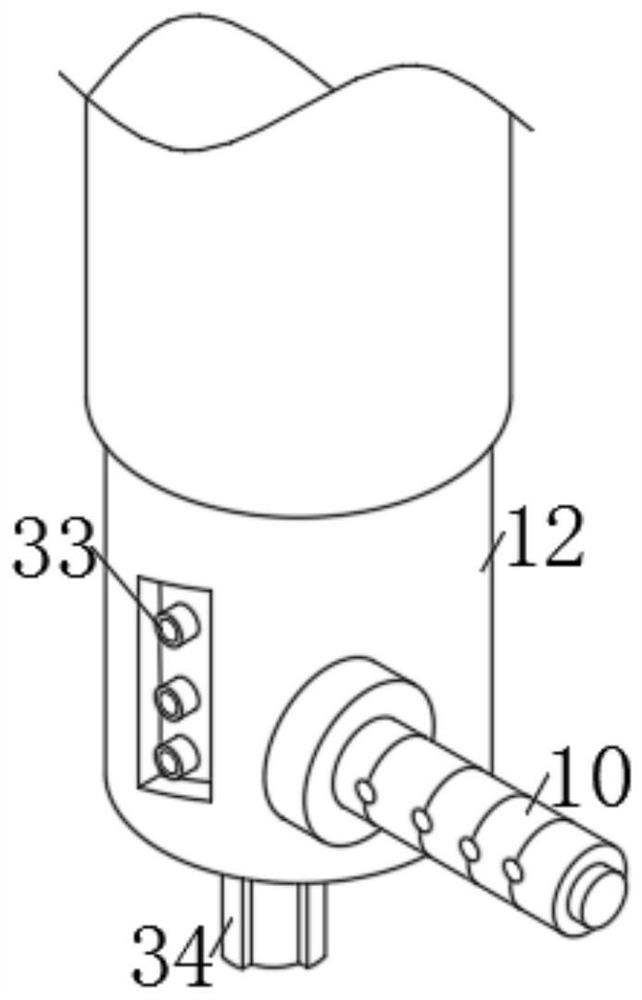

[0029] See figure 1 and figure 2 , A processing device for household metal fittings, characterized in that it includes a device base 1, a grinding rod 19, a placement frame 11 and a welding head 10, and also includes:

[0030] The device base 1, the placing frame 11 is rotatably mounted on the upper side of the device base 1, and the welding head 10 is located just above the center of the placing frame 11;

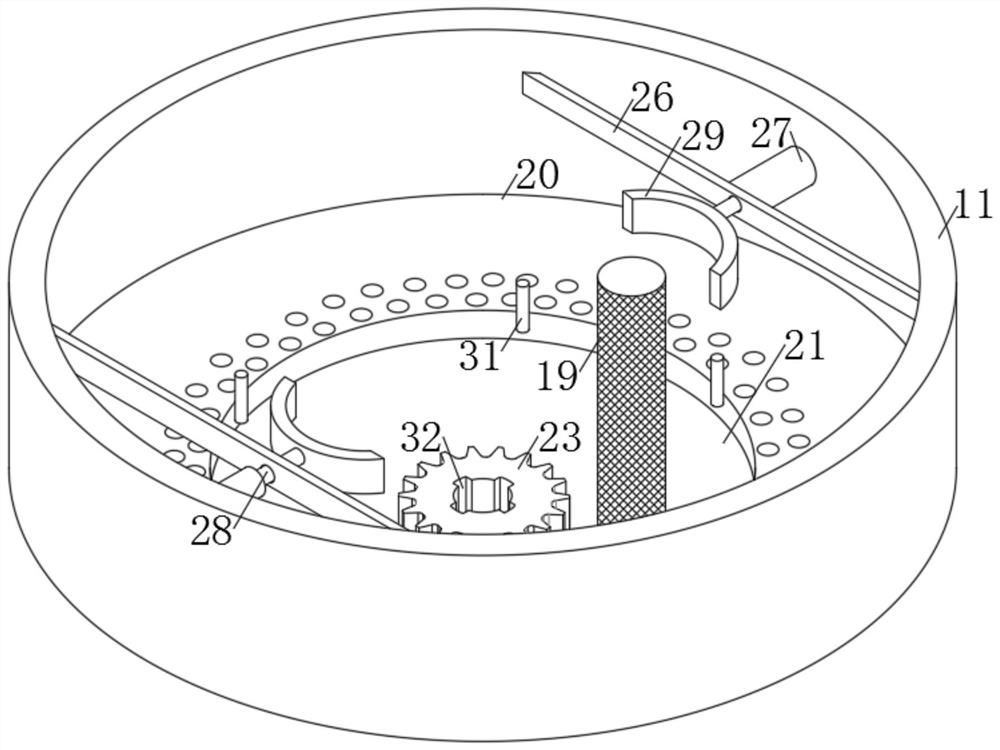

[0031] A rotating member, the rotating member includes a first rotating mechanism and a second rotating mechanism, the first rotating mechanism includes a driving gear 23, a rotating gear 25 and an internal gear 22, and the driving gear 23 is connected with a power source that drives it to rotate along the axis. The power source is the motor 24, the driving gear 23 rotates and gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com