Energy-saving environment-friendly efficient hot blast cupola

An energy-saving and environment-friendly cupola technology, which is applied in the field of metallurgical casting for smelting metals, can solve problems such as low hot air temperature, failure to keep up with social development, and increased coke consumption, and achieve high purity, high practicability, promotion value, and transformation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

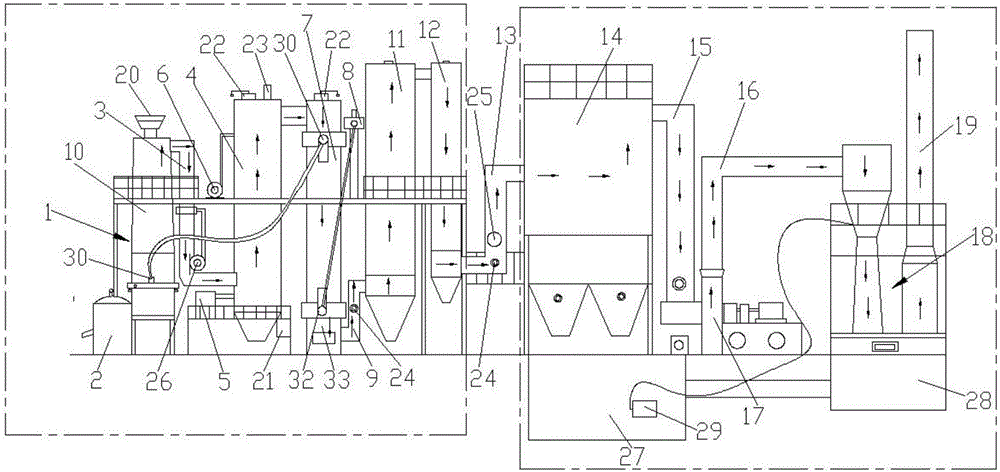

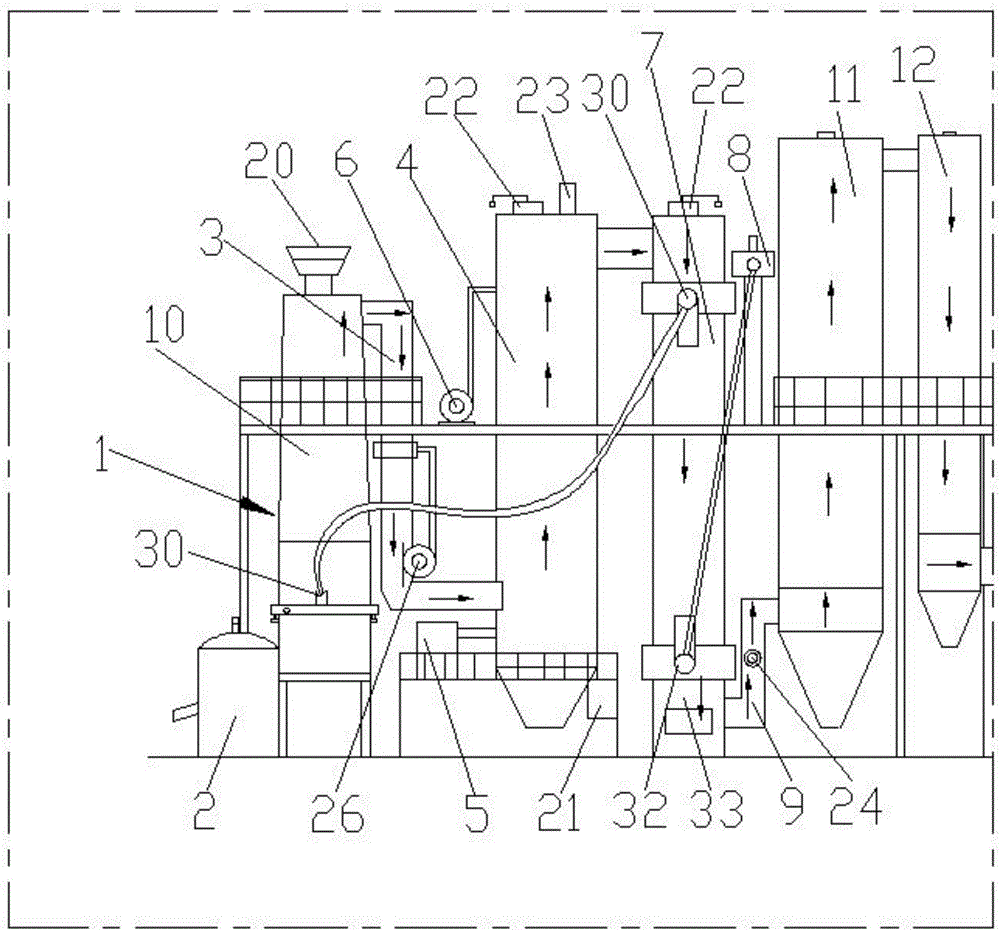

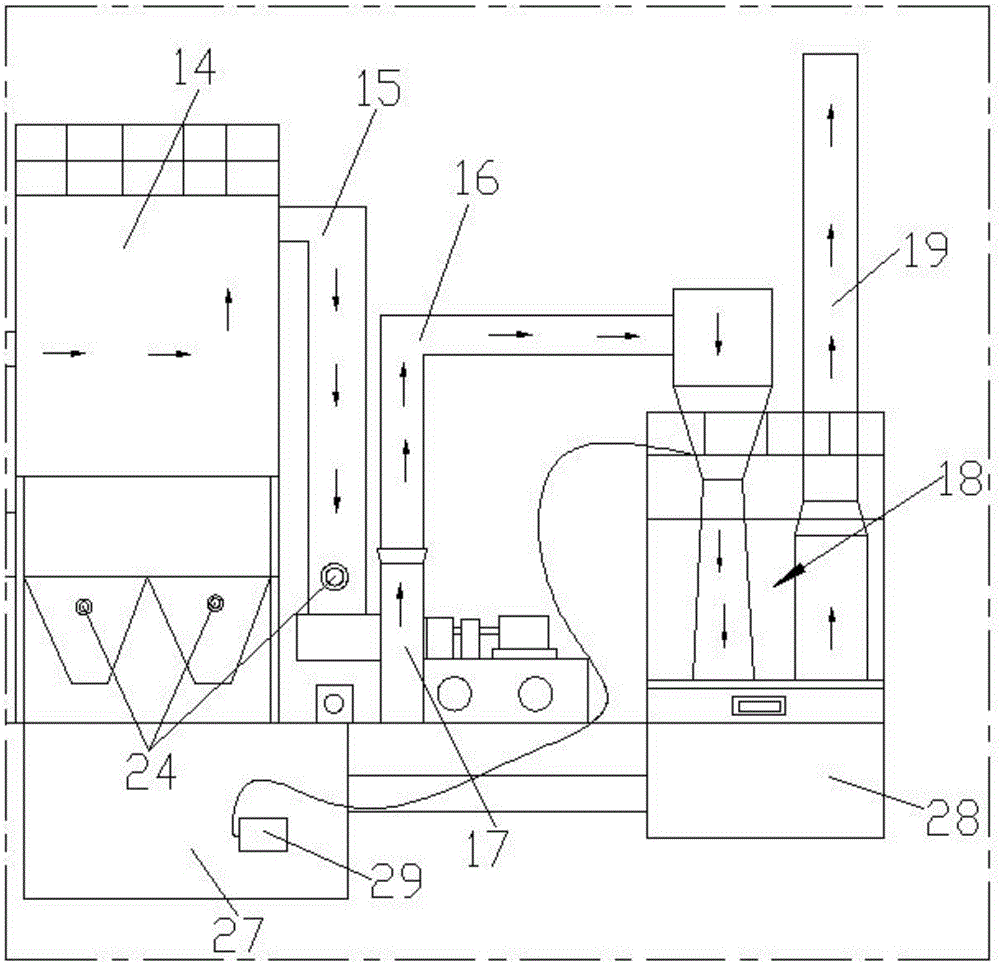

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] as attached Figure 1-3 The shown energy-saving and environment-friendly high-efficiency hot blast cupola of the present invention includes a smelting device and a waste gas treatment device connected to each other; the smelting device includes a cupola 1, a front bag 2, a first flue gas pipe 3, and a combustion chamber 4. Preheating furnace 5, cold air blower 6, heat exchanger 7, blower 8 and second flue gas pipe 9; the cupola 1 is provided with a hot air inlet 30; the cupola 1 upper end is provided with a feed port 20 , the lower end communicates with the front bag 2; the cupola 1 includes a flue gas chamber 10; the side of the flue gas chamber 10 communicates with the lower part of the combustion chamber 4 through the first flue gas pipe 3; the lower part of the combustion chamber 4 is provided There is a preheating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com