Method and system for monitoring the operation of a carbonaceous block roasting plant

A roasting and block technology, applied in the direction of lighting and heating equipment, furnace, furnace safety device, etc., can solve the problem that the overall adjustment system cannot detect and clean, and achieve the effect of avoiding calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

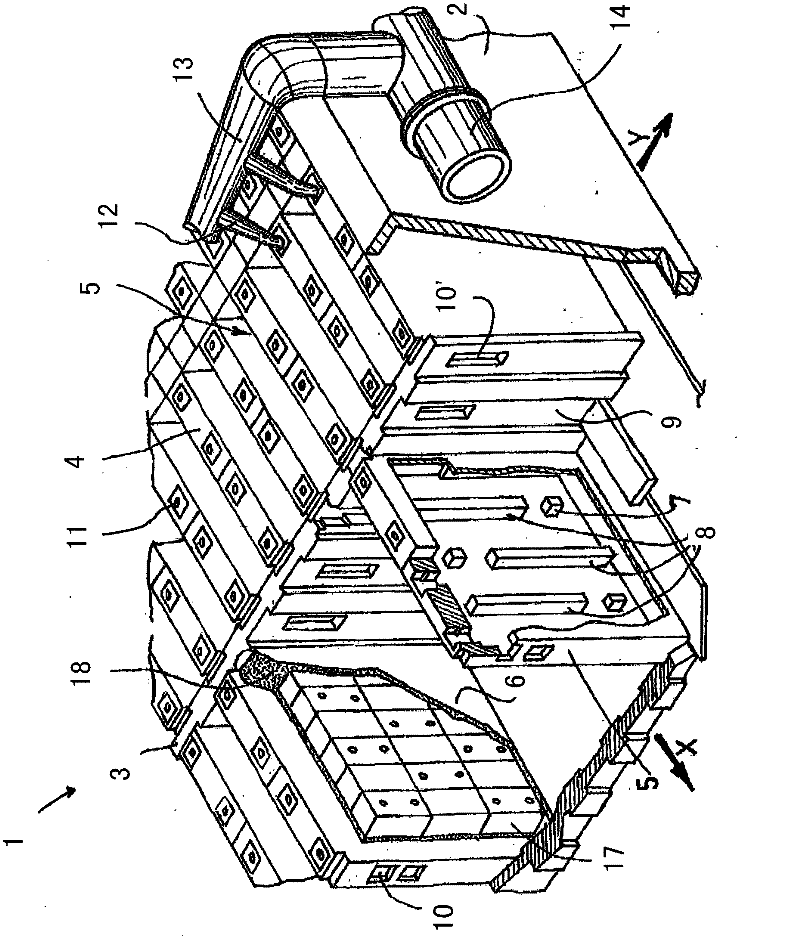

[0074] The anode roasting equipment includes a rotary heat source furnace 1 . The following detailed description relates to the practice of the invention on equipment comprising chamber furnaces, such as Figure 1-3 The device shown in . However, the invention is not limited to this type of furnace. In particular, the invention is also applicable to installations comprising furnaces without intermediate transverse walls between the end walls.

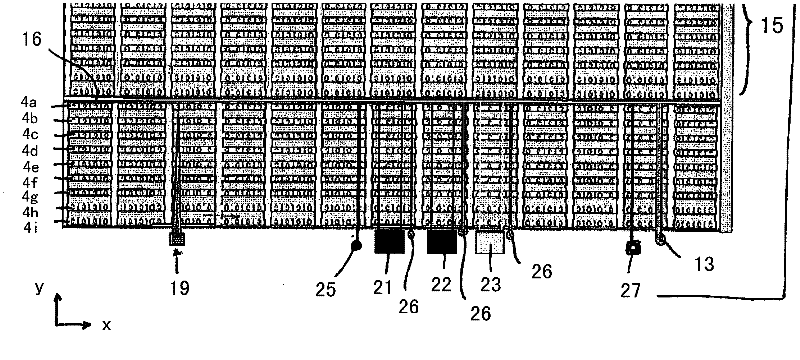

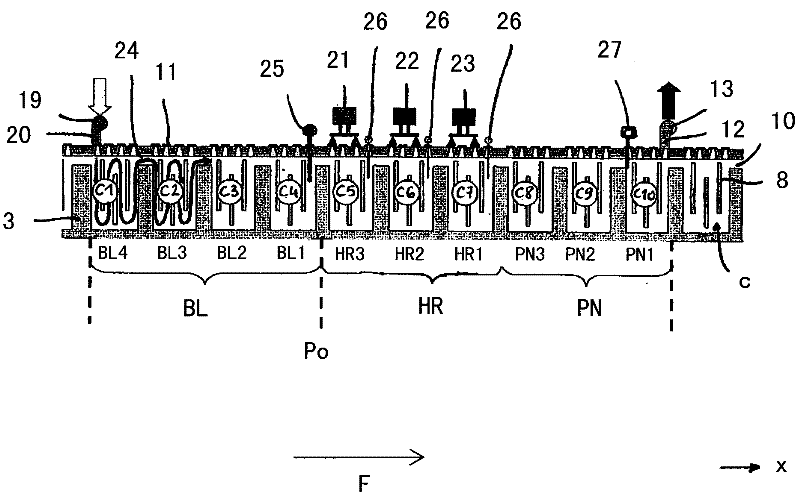

[0075] The furnace 1 comprises a thermally insulating enclosure 2 of substantially parallelepiped form, relative to which a longitudinal direction X and a transverse direction Y are defined. In the enclosure 2, a transverse wall 3 is placed enclosing a cavity C continuous in the X direction. In each chamber C, hollow space walls 4 are placed in longitudinal direction, forming long cells 5 between each other. Therefore, each cavity C includes a plurality of partition walls 4a to 4i, such as figure 2 shown in .

[0076] The partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com