A system and method for increasing the degree of concentration in a mechanical vapor recompression system

A mechanical vapor, recompression technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

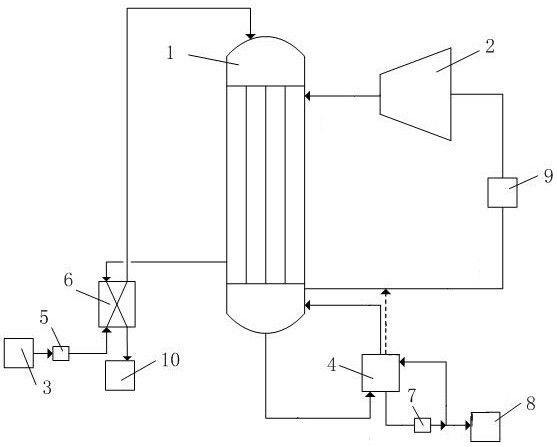

[0037] A system capable of improving the concentration degree of a mechanical vapor recompression system includes an evaporator 1, a compressor 2, a supplementary heater 4 and a discharge pump 7, and the outlet of the concentrated material at the bottom of the evaporator 1 is connected to the supplementary heater 4 are connected through pipelines; the vapor phase outlet at the upper part of the supplementary heater 4 is connected with the vapor phase inlet at the bottom of the evaporator 1 through pipelines; the evaporator 1 is connected with the inlet of the compressor 2 through pipelines, and the outlet of the compressor 2 is connected with the evaporator 1. The shell-side steam inlet is connected through a pipeline; the re-concentrated material outlet at the bottom of the supplementary heater 4 is connected with the discharge pump 7 through a pipeline. Heater 4 is connected, and all the way is connected with product storage tank 8 through pipeline as discharge.

[0038]Furt...

Embodiment 2

[0046] A method for improving the concentration degree of a mechanical vapor recompression system, the technical solution flow is as follows:

[0047] When the mechanical vapor recompression system needs supplementary heat from the outside because the heat dissipation loss is greater than the work done by the compressor 2, the concentrated material outlet at the bottom of the evaporator 1 is connected to the heat supplement 4, and the concentrated material in the evaporator 1 enters the heat supplement 4 After heating, it becomes a vapor-liquid two-phase; after the vapor-liquid two-phase separation, the vapor phase enters the evaporation system as the supplementary heat of the mechanical vapor recompression evaporation system, and enters the compressor 2 together with the secondary steam generated by the evaporator 1, After being compressed and heated up, it is used as the heat source of the evaporator 1; after being further heated and concentrated by the supplementary heater 4...

Embodiment 3

[0059] Attached below figure 1 , compare and illustrate the existing mechanical vapor recompression evaporation system heat supplement scheme and the new method proposed by the present invention:

[0060] The heat supplement method of the existing traditional mechanical vapor recompression system: when the heat dissipation loss of the mechanical vapor recompression system is greater than the work done by the vapor compressor 2, and the supplementary heat needs to be provided by the outside world, the steam inlet of the shell side of the compressor 2 and the evaporator 1 A steam branch pipe is set on the connected pipeline, which is used to input the supplementary steam from the outside into the 1 shell side of the evaporator to supplement the heat loss of the system and ensure the normal operation of the system.

[0061] figure 1 It is a schematic flowchart of a system and method proposed by the present invention that can increase the concentration degree of the mechanical va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com