Heat-conducting oil heating roller

A technology of heating roller and heat transfer oil, applied in the direction of roller, metal processing equipment, metal rolling, etc., can solve the bad influence of the straightness of the roll surface, reduce the effective use width of the roll surface, and cannot meet the high requirements of the rolling process of the battery pole piece. Accuracy requirements and other issues, to achieve the effect of increasing the effective use width, improving heating energy efficiency, and reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

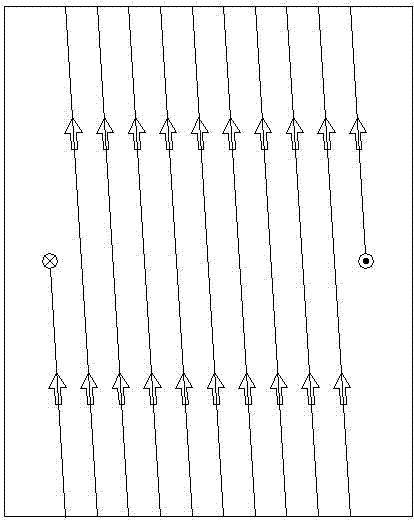

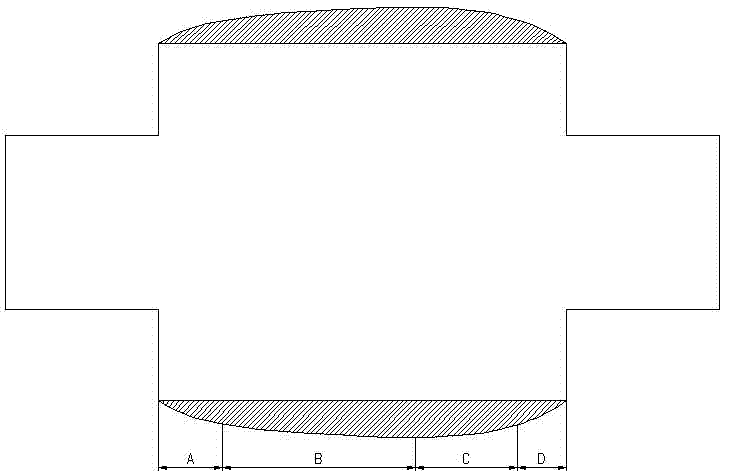

[0016] See attached figure 1 , 2 , the existing heat conduction oil heating roller is a single-inlet and single-outlet circulating oil circuit, and the temperature of the oil inlet end is slightly higher than that of the oil outlet end relative to the width of the roll surface, so there will be a relatively large convexity between the roll surfaces B and C , and A and D, B and C are not equal, which will have a negative impact on the straightness of the roll surface and cannot meet the high-precision requirements of the battery pole piece rolling process; in addition, due to the relatively large heat dissipation area on both ends of the roll shaft, the The temperature at both ends of the surface will be relatively low, the thermal expansion will be small, and the roll surface sag width A and D sections will be wider, thereby reducing the effective use width of the roll surface.

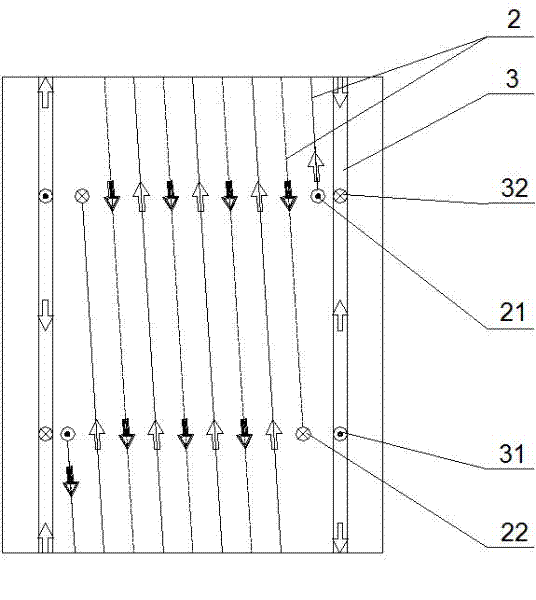

[0017] See attached image 3 , the structure of a specific embodiment of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com