Spiral acceleration-type electromagnetic gun system and obtaining method thereof

A helical acceleration, electromagnetic gun technology, applied in the field of electromagnetic launch, electromagnetic gun, to achieve the effect of simplifying the control system, high efficiency, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 pic 1, application system 1 specific Embodiment approach

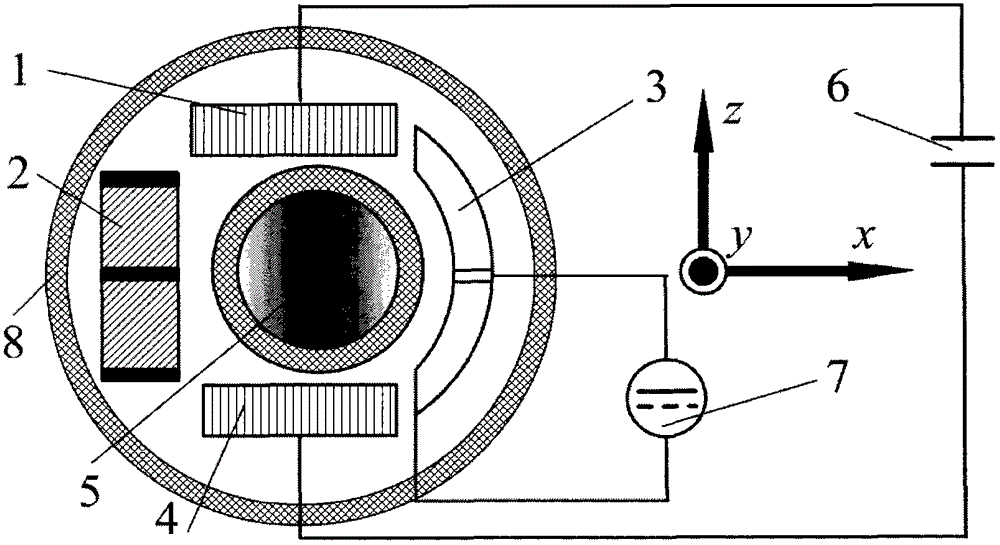

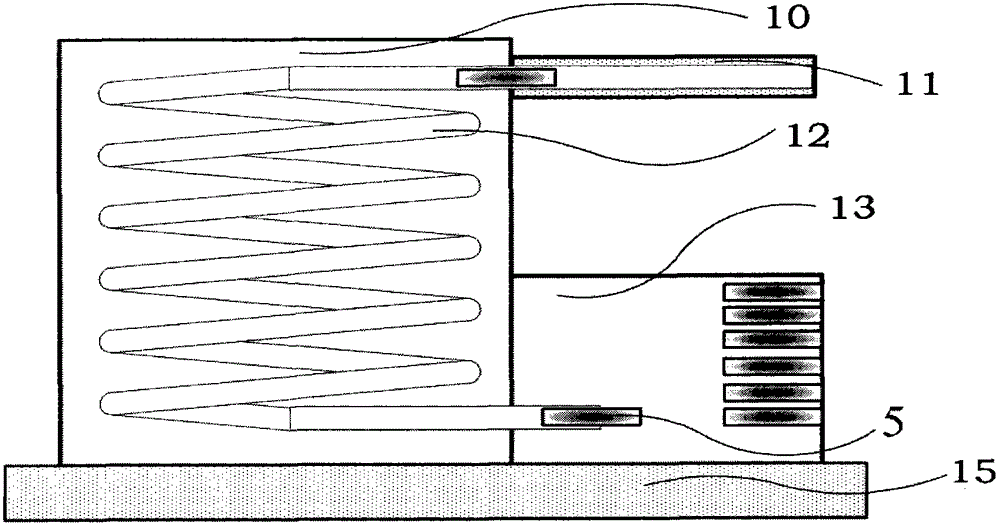

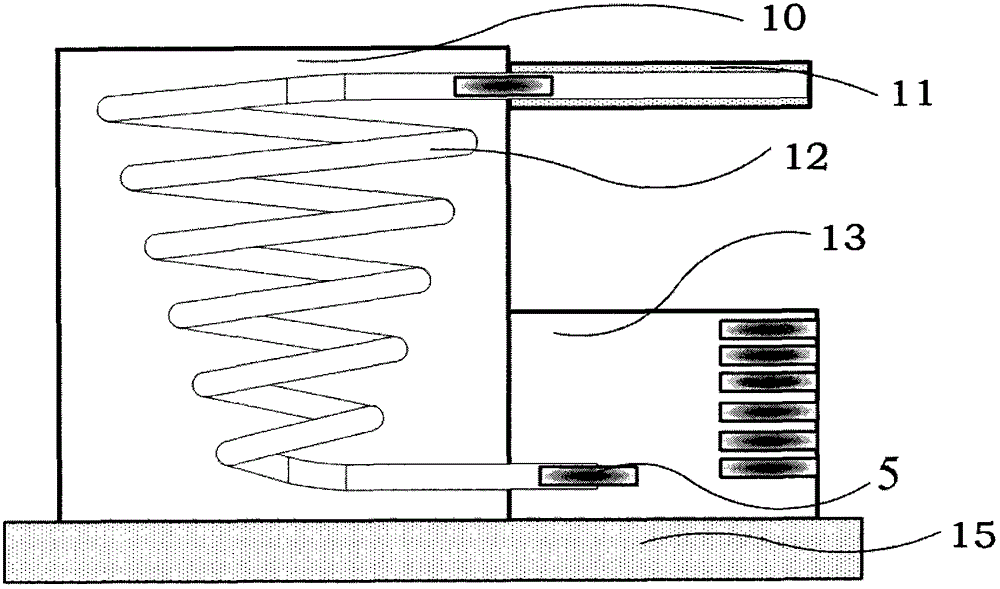

[0034] Example as figure 1 It shows that the present invention is applied to a specific implementation of a shipborne artillery system: a cross section of a spiral electromagnetic gun barrel with high exit velocity and continuous shooting that can be loaded on a ship. 1 and 4 in the figure are upper and lower symmetrical superconducting electromagnetic propulsion windings, which provide the propulsion required for the acceleration of the projectile under the excitation of the pulse power supply; 5 in the figure is the projectile, and its shell is made of massive high-temperature superconducting material. The internal filling is high-strength composite material or alloy material; Figure 2 shows the permanent magnet guide rail, which can generate figure 1 The strong magnetic field gradients in the z and x directions of the coordinates, and then produce electromagnetic coupling with the superconducting shell of the projectile shown in Figure 5, relying on the magnetic field gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com