A launching mechanism and a method for controllable continuous firing

A launch mechanism and pipeline technology, applied in the direction of the launch device, etc., can solve the problem of not being able to launch multiple balls in succession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

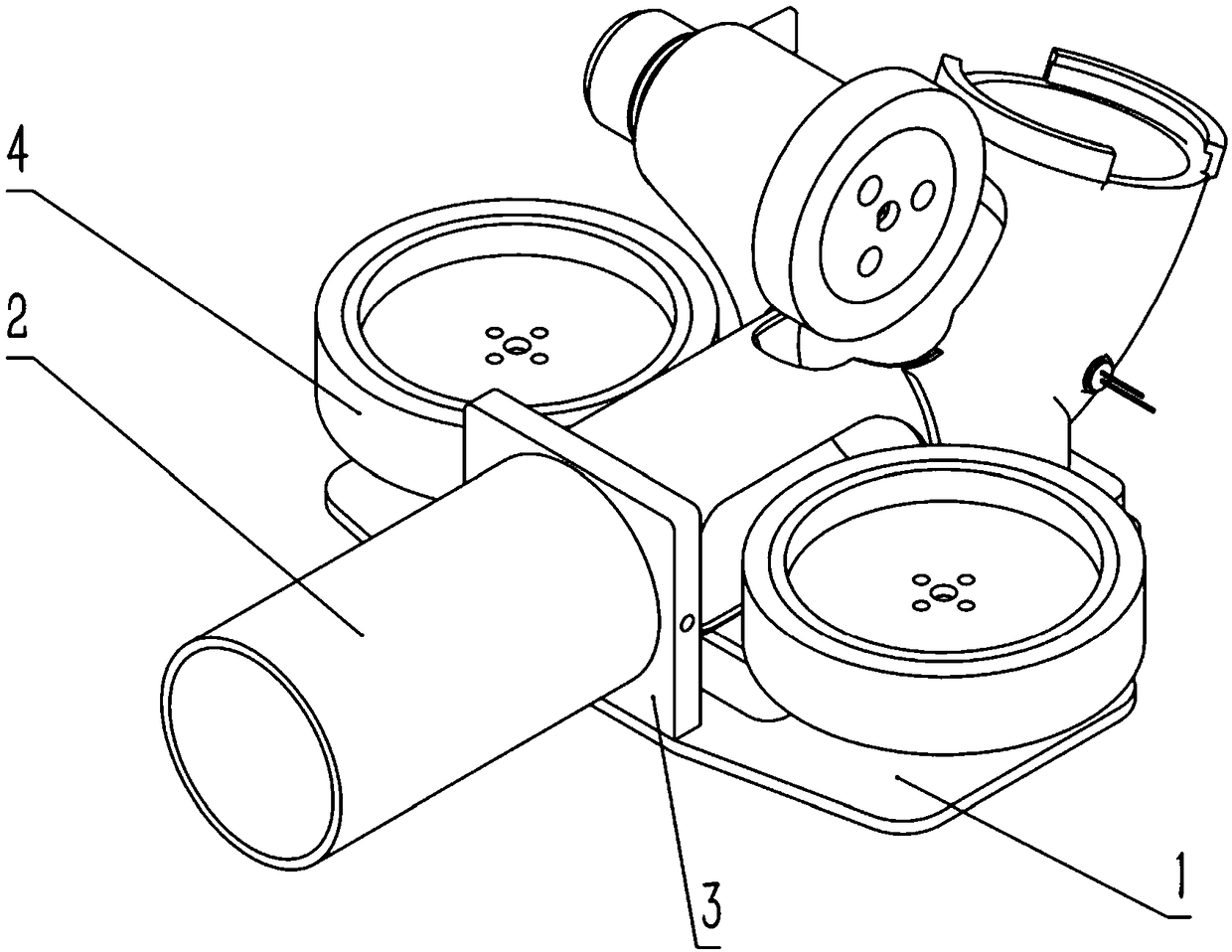

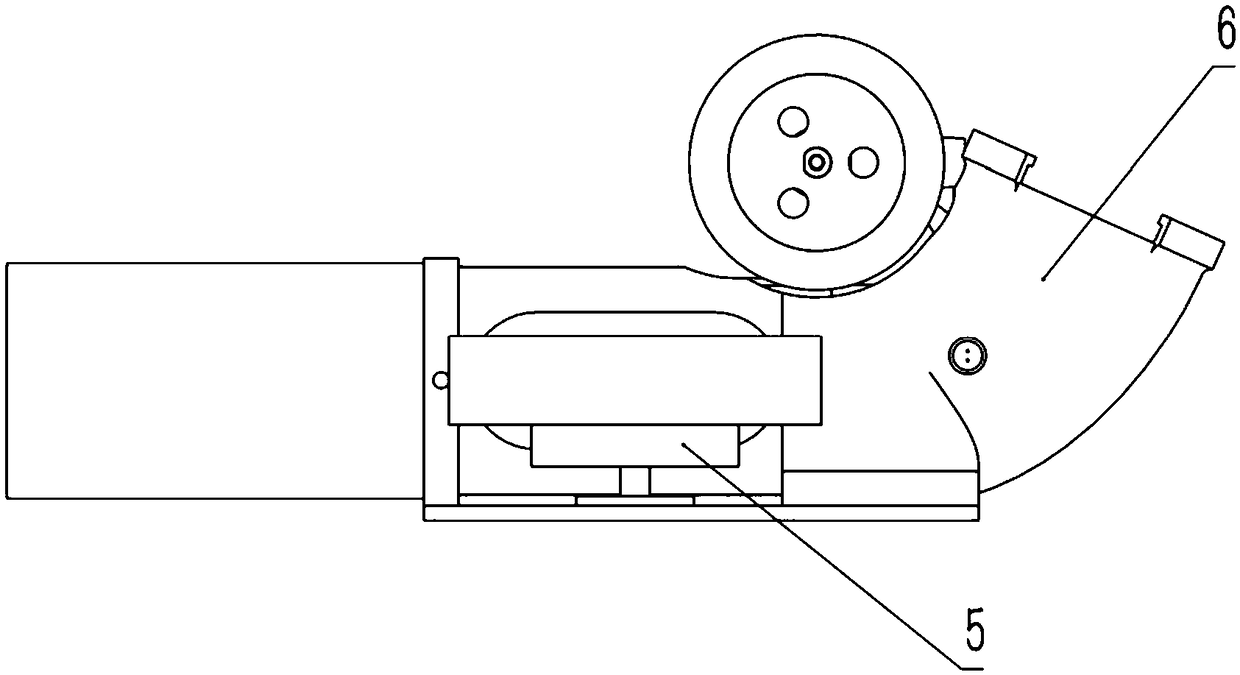

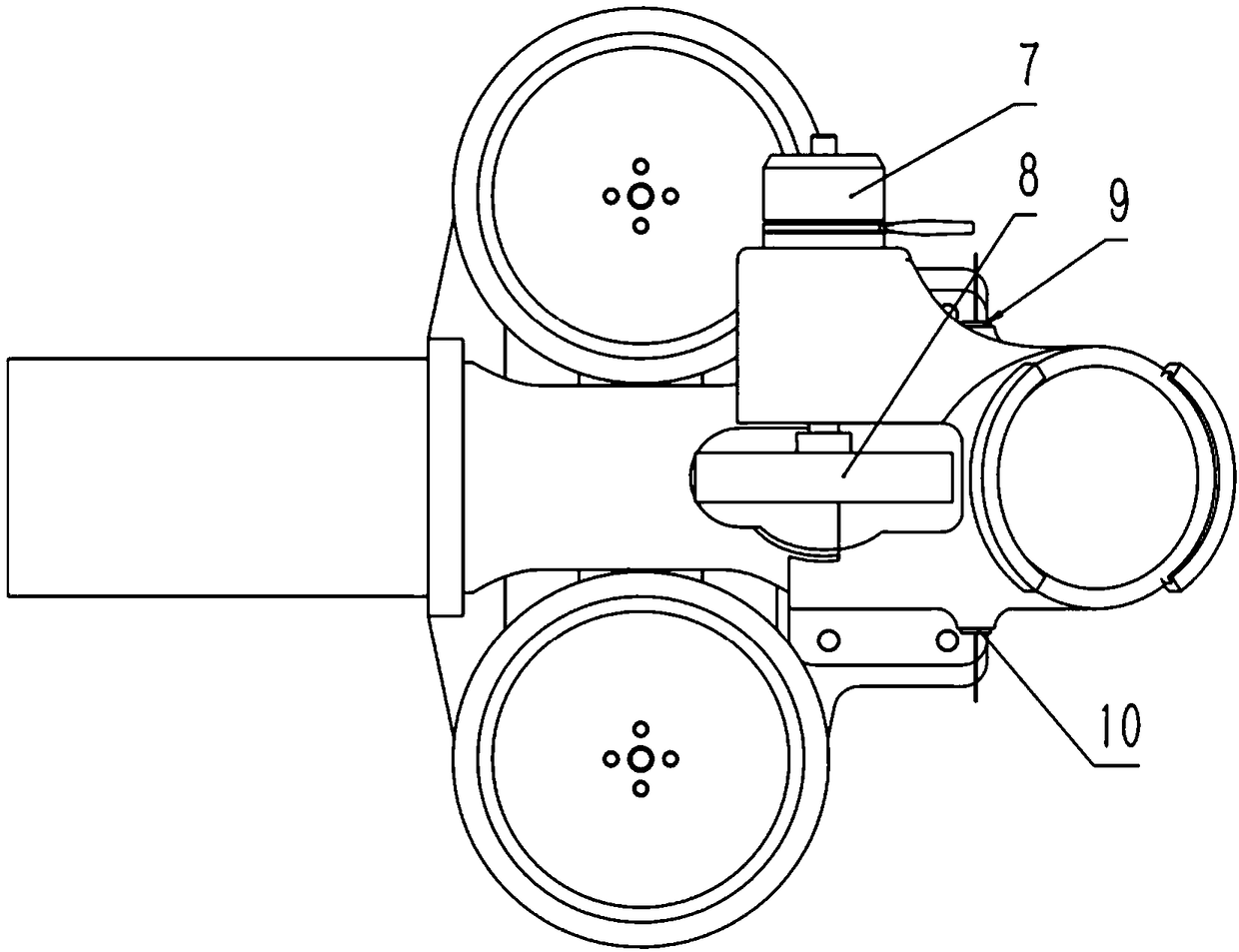

[0025] Such as Figure 1-3 As shown, in the embodiment of the present invention, a kind of controllable burst firing mechanism is provided, comprising a load-bearing base plate 1, a launch pipe 2, a launch friction wheel 4, a brushless motor 5, a bomb delivery pipe 6, a dial friction wheel 8 and Brushless geared motor7. The launching pipeline 2, the brushless motor 5 and the bullet feeding pipeline 6 are installed on the bearing base plate 1

[0026] The launching pipeline 2 passes through the pipeline fixing part 3, and is fixed with set screws on the side of the pipeline fixing part 3, and the bottom of the pipeline fixing part 3 is fastened on the bearing base plate 1 by screws.

[0027] The launch friction wheel 4 is interference-set on the brushless motor 5, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com