A kind of LED white light fluorescent powder and preparation method thereof

A fluorescent powder and white light technology, applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of low color rendering index and poor color reproduction, and achieve good repeatability, high yield and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 0.1 mmol 1,4-bis(imidazol-1-yl)benzene, 0.2 mmol 2,2'-dimethoxy-4,4'-biphenyldicarboxylic acid, 0.1 mmol manganese nitrate and 0.1 mmol europium nitrate in In a mixed solvent of 3mL acetonitrile, 6mL dimethylformamide and 6mL water, stir at room temperature to form a mixed solution A, then reflux the above mixed solution A at 75°C for 6 hours to obtain a mixed solution B, and then mix the mixed solution B was placed in a 25 mL hydrothermal reaction kettle, heated for 48 hours under solvothermal conditions of 160°C, and then cooled to room temperature at a rate of 5°C / hour to obtain the white light phosphor.

[0019] The structures of the above compounds were then characterized.

[0020] The phosphors were then subjected to structural characterization.

[0021] The X-ray diffraction data of the phosphor powder is on the Bruker Smart Apex CCD surface probe diffractometer, using MoK α Radiation (λ = 0.71073 Å), collected in ω-scan mode and corrected for Lp facto...

Embodiment 2

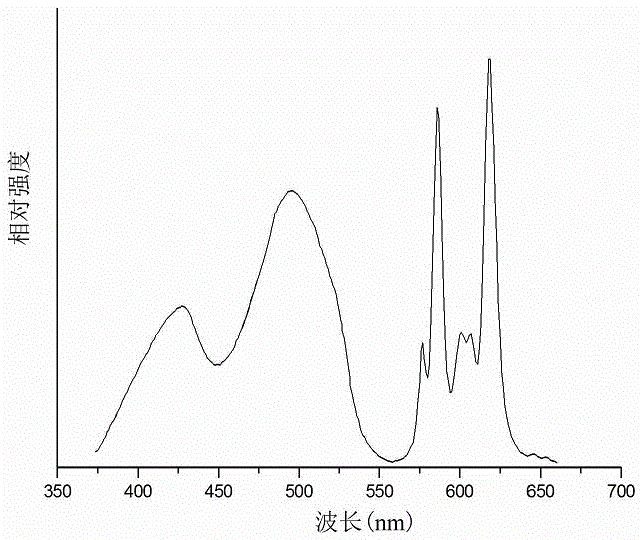

[0024] Dissolve 0.1 mmol 1,4-bis(imidazol-1-yl)benzene, 0.2 mmol 2,2'-dimethoxy-4,4'-biphenyldicarboxylic acid, 0.1 mmol manganese nitrate and 0.1 mmol europium nitrate in In a mixed solvent of 3mL acetonitrile, 6mL dimethylformamide and 6mL water, stir at room temperature to form a mixed solution A, then reflux the above mixed solution A at 75°C for 6 hours to obtain a mixed solution B, and then mix the mixed solution B was placed in a 25 mL hydrothermal reaction kettle, heated for 24 hours under solvothermal conditions of 180°C, and then cooled to room temperature at a rate of 4°C / hour to obtain the white light phosphor. The fluorescence spectrogram of this embodiment is as shown in Embodiment 1.

Embodiment 3

[0026] Dissolve 0.1 mmol 1,4-bis(imidazol-1-yl)benzene, 0.2 mmol 2,2'-dimethoxy-4,4'-biphenyldicarboxylic acid, 0.1 mmol manganese nitrate and 0.1 mmol europium nitrate in In a mixed solvent of 3mL acetonitrile, 6mL dimethylformamide and 6mL water, stir at room temperature to form a mixed solution A, then reflux the above mixed solution A at 75°C for 6 hours to obtain a mixed solution B, and then mix the mixed solution B was placed in a 25 mL hydrothermal reaction kettle, heated for 36 hours under solvothermal conditions of 170°C, and then cooled to room temperature at 2°C / hour to obtain the white light phosphor. The fluorescence spectrogram of this embodiment is as shown in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com