Patents

Literature

32results about How to "Inhibits the formation of deposits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

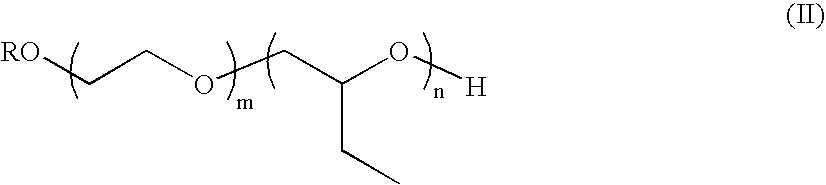

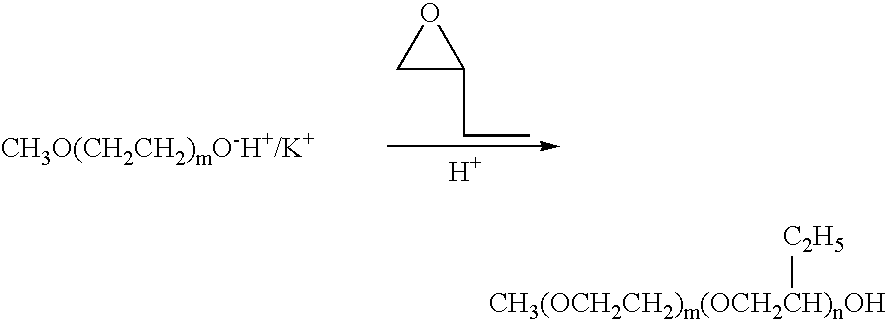

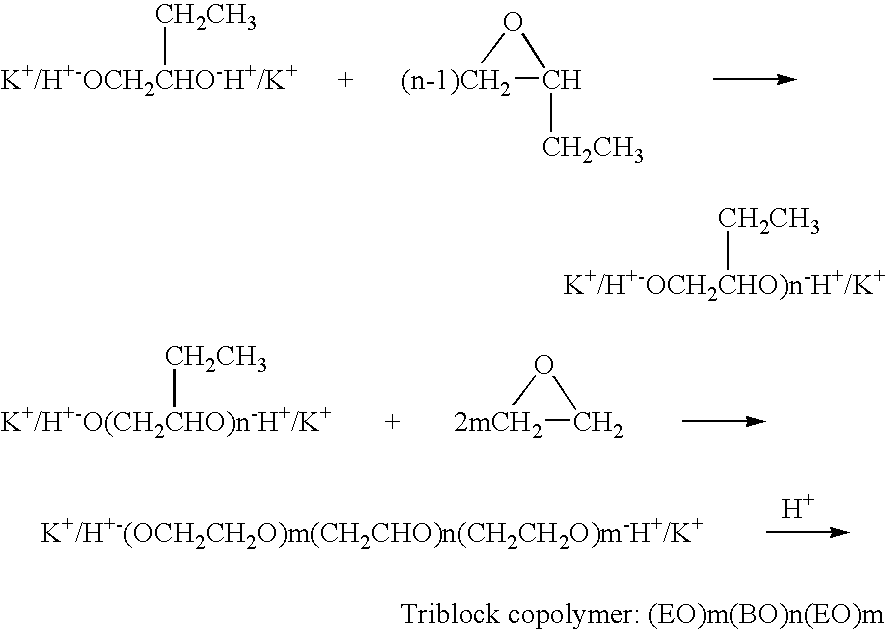

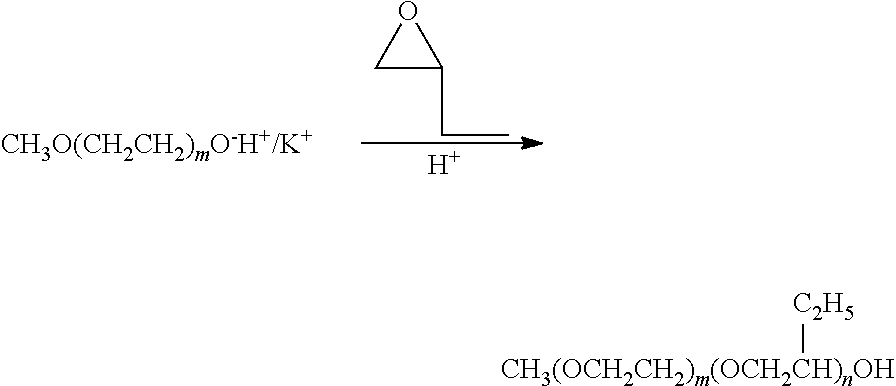

Use of PEO-PBO block copolymers in ophthalmic compositions

The use of poly(oxyethylene)-poly(oxybutylene) block copolymers in pharmaceutical compositions useful for modifying the surfaces of contact lenses and other medical devices is disclosed. The present invention is based in-part on a discovery that this class of compounds is particularly efficient in wetting hydrophobic surfaces, such as the surfaces of silicone hydrogel contact lenses and other types of ophthalmic lenses. Such compounds are also useful for cleaning purposes. The use of the compounds as surfactants in various types of compositions for treating contact lenses therefore represents a preferred embodiment of the present invention.

Owner:ALCON INC

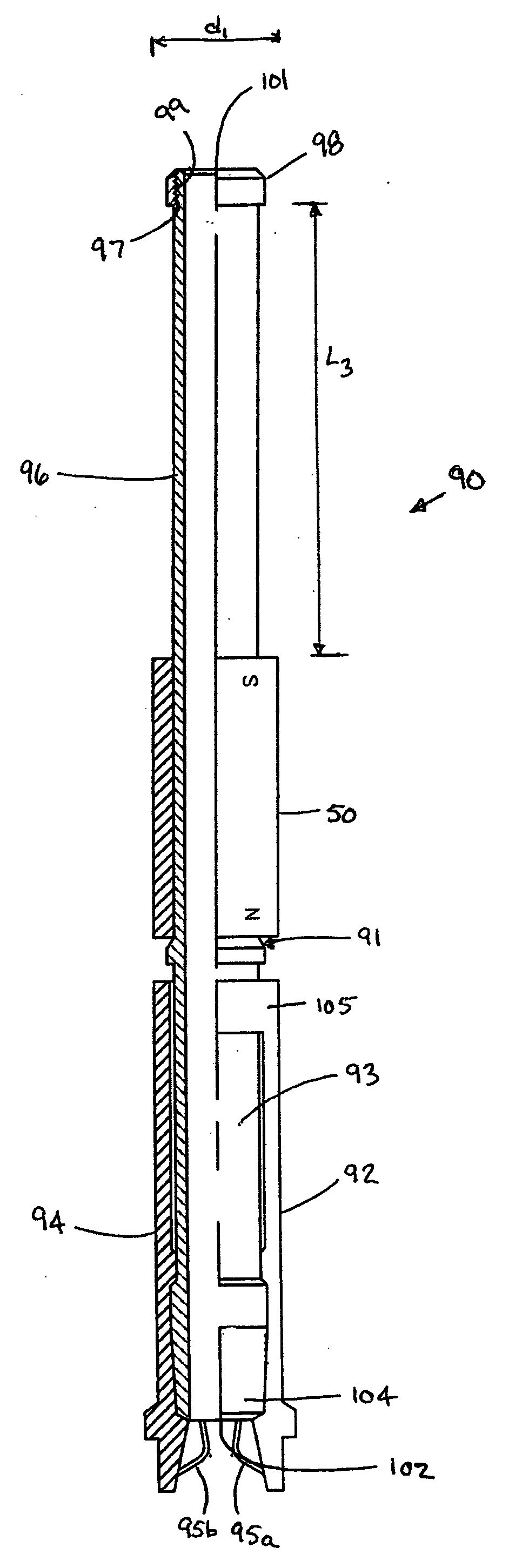

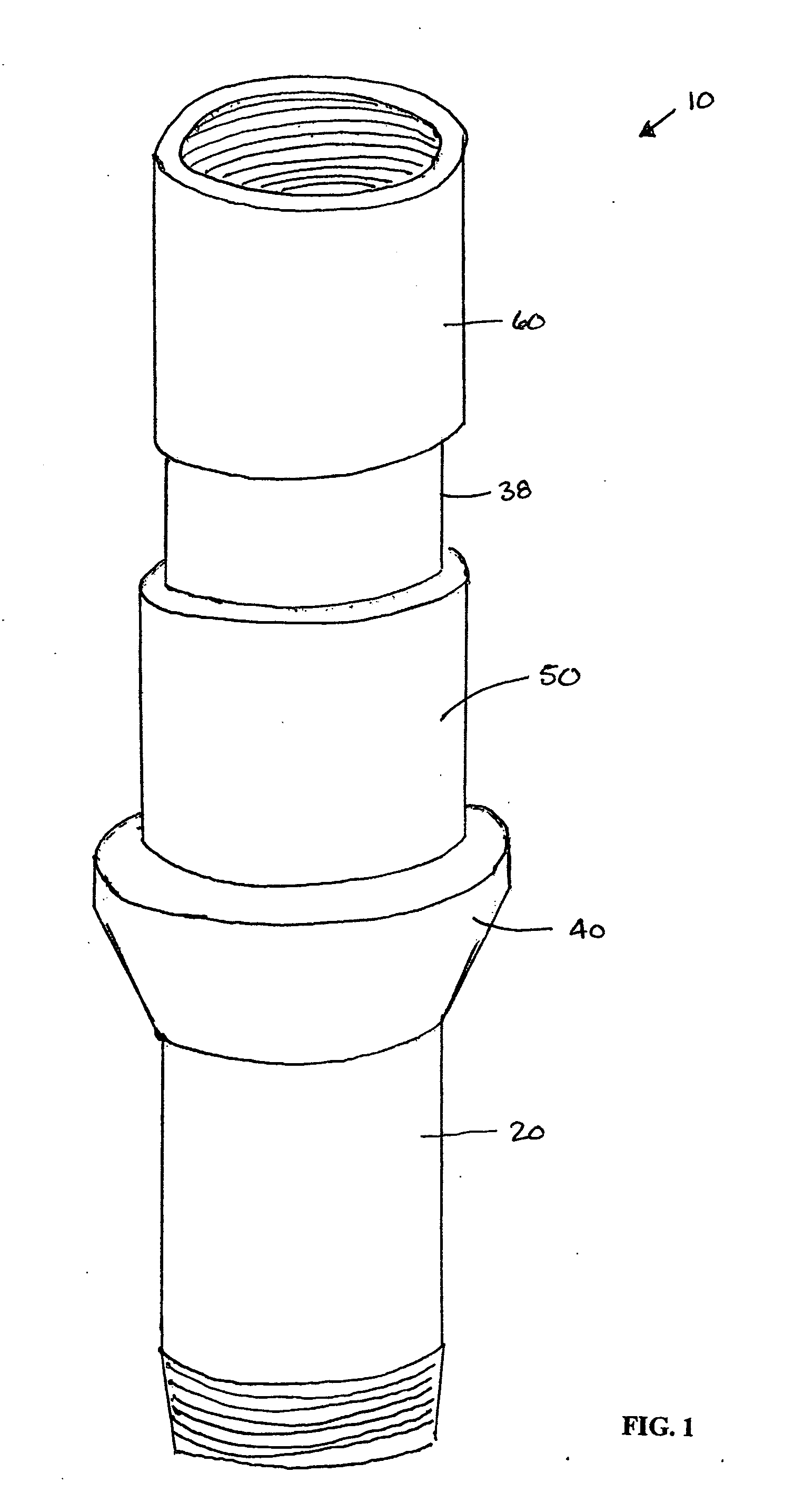

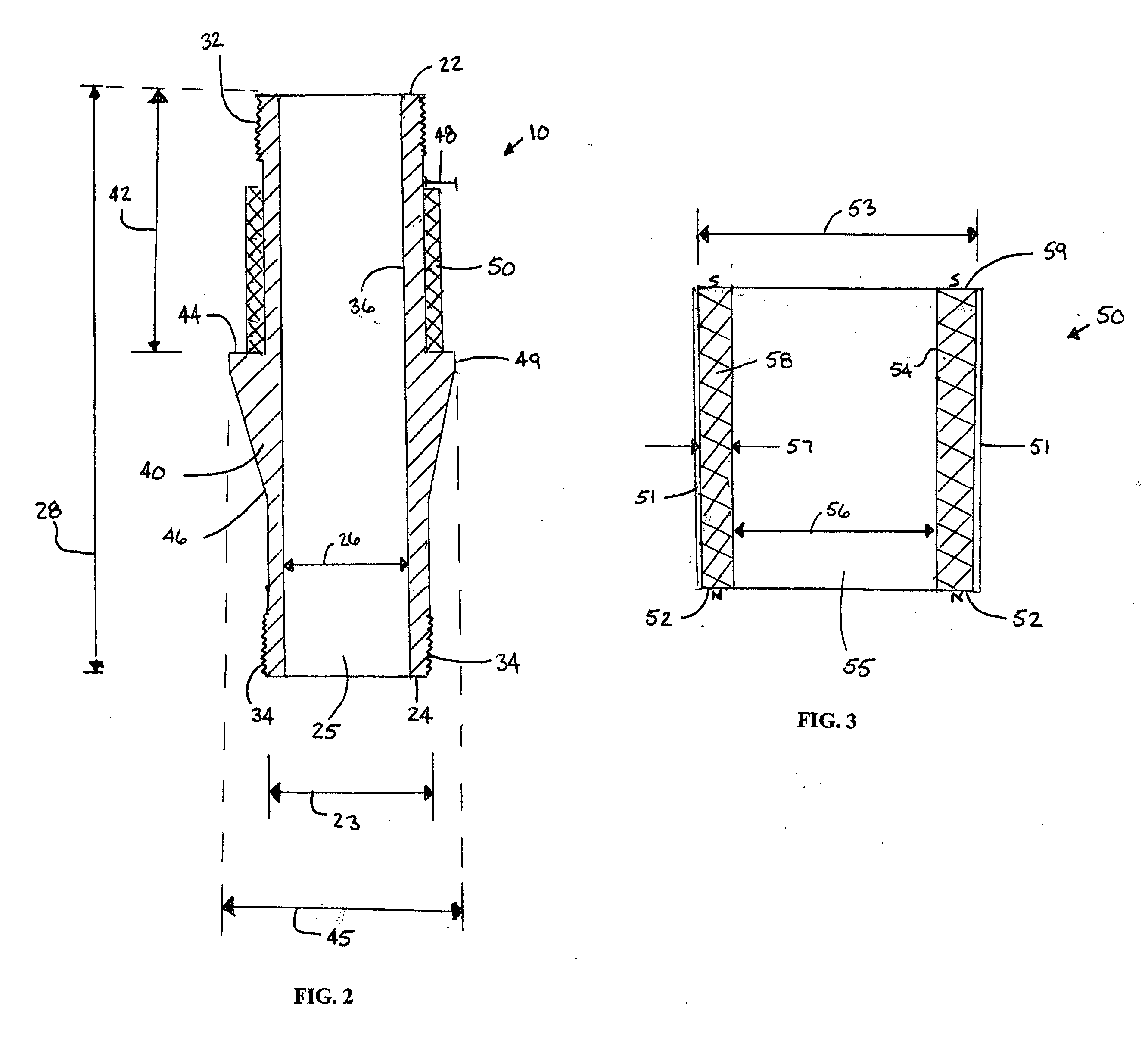

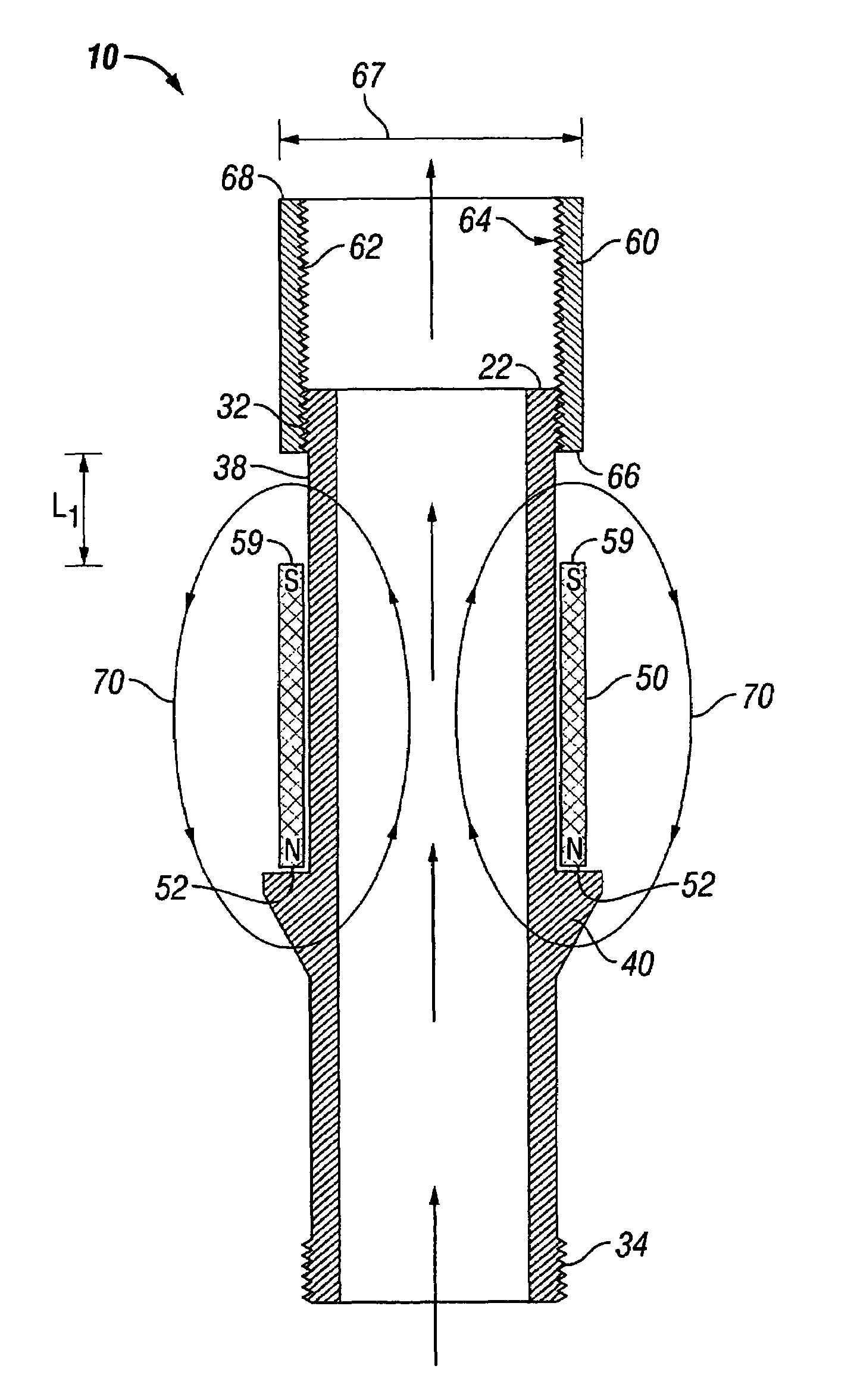

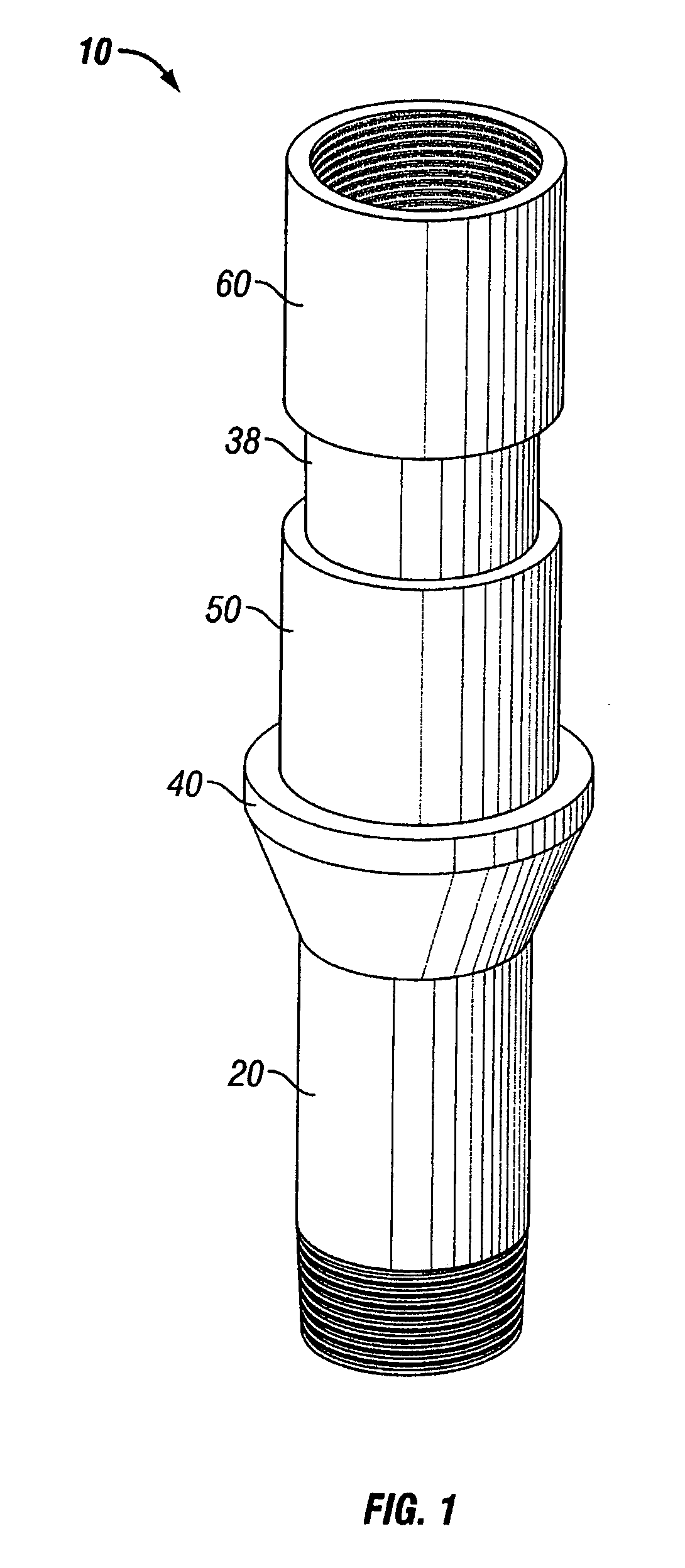

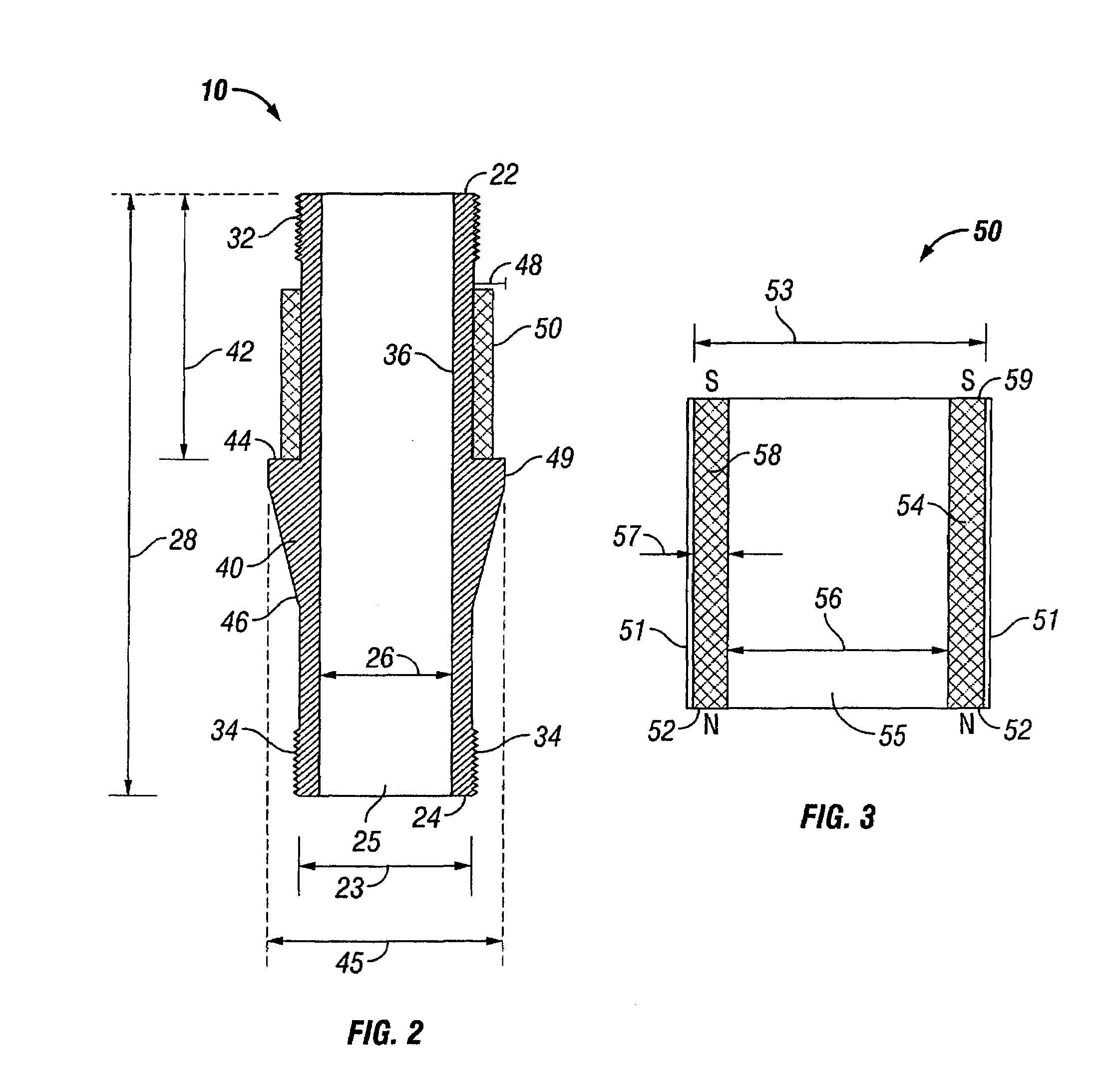

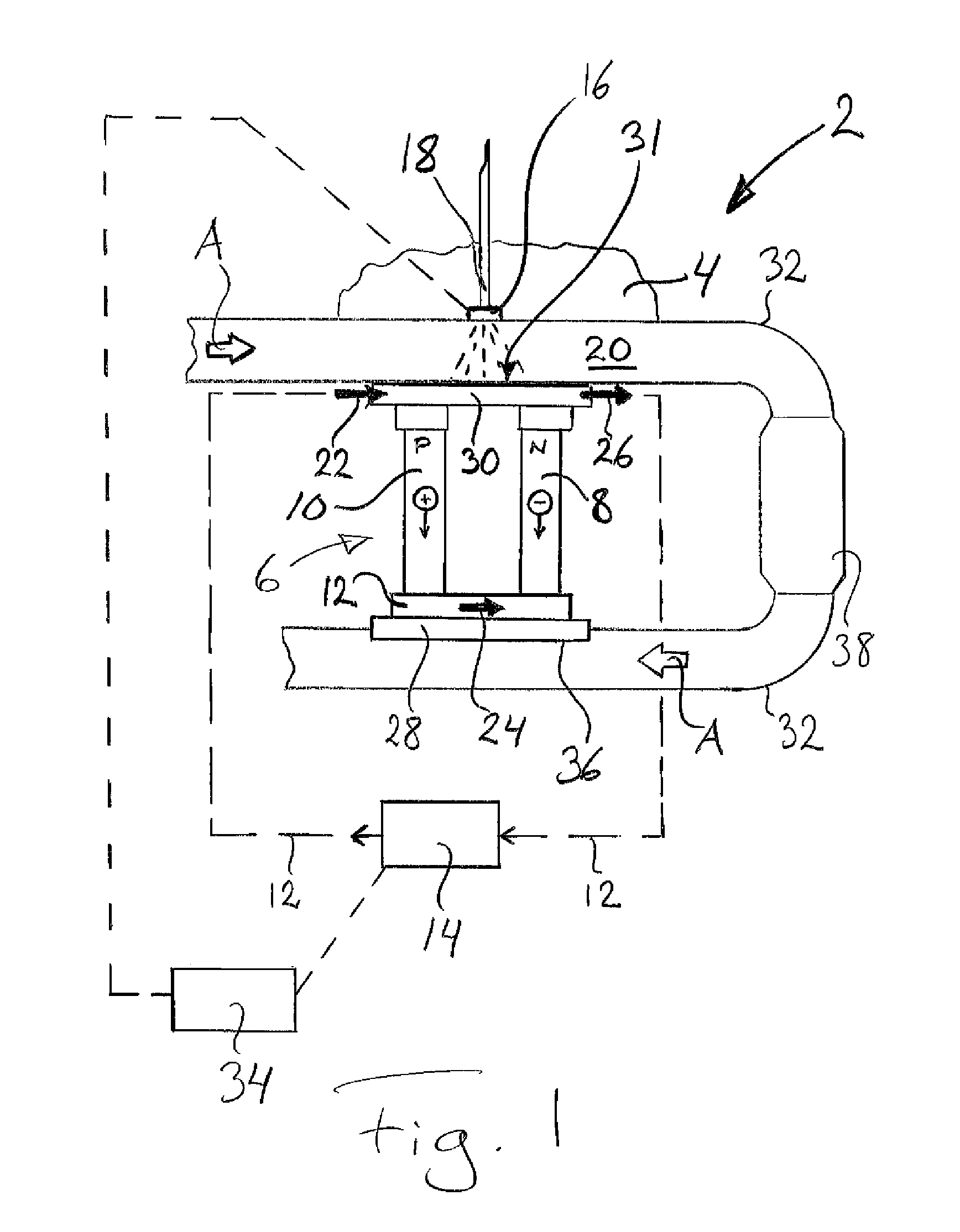

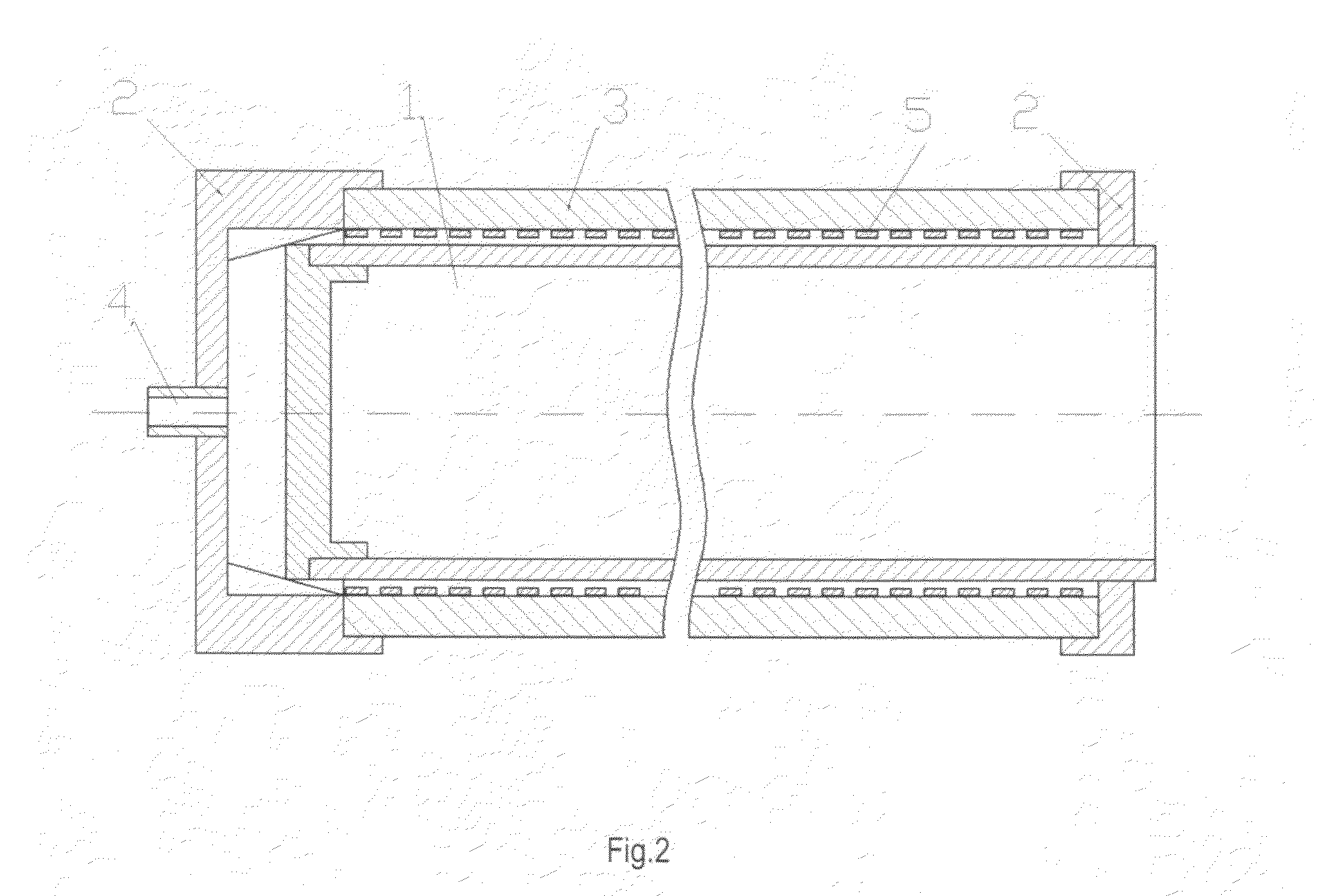

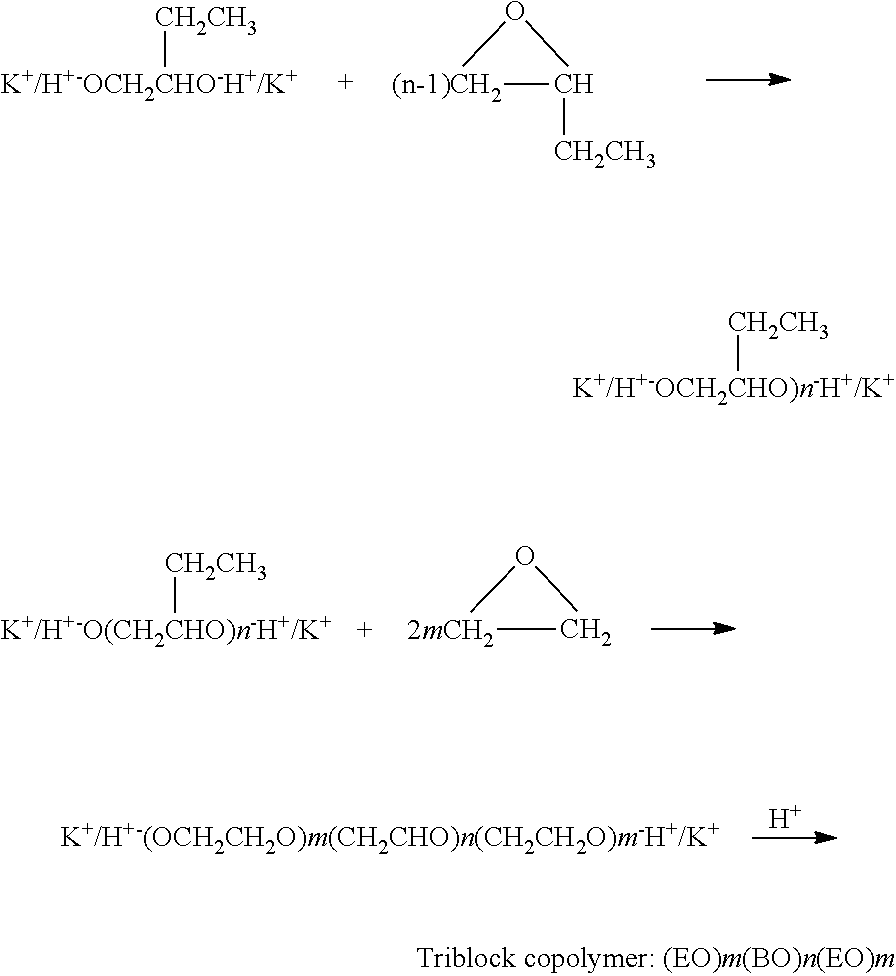

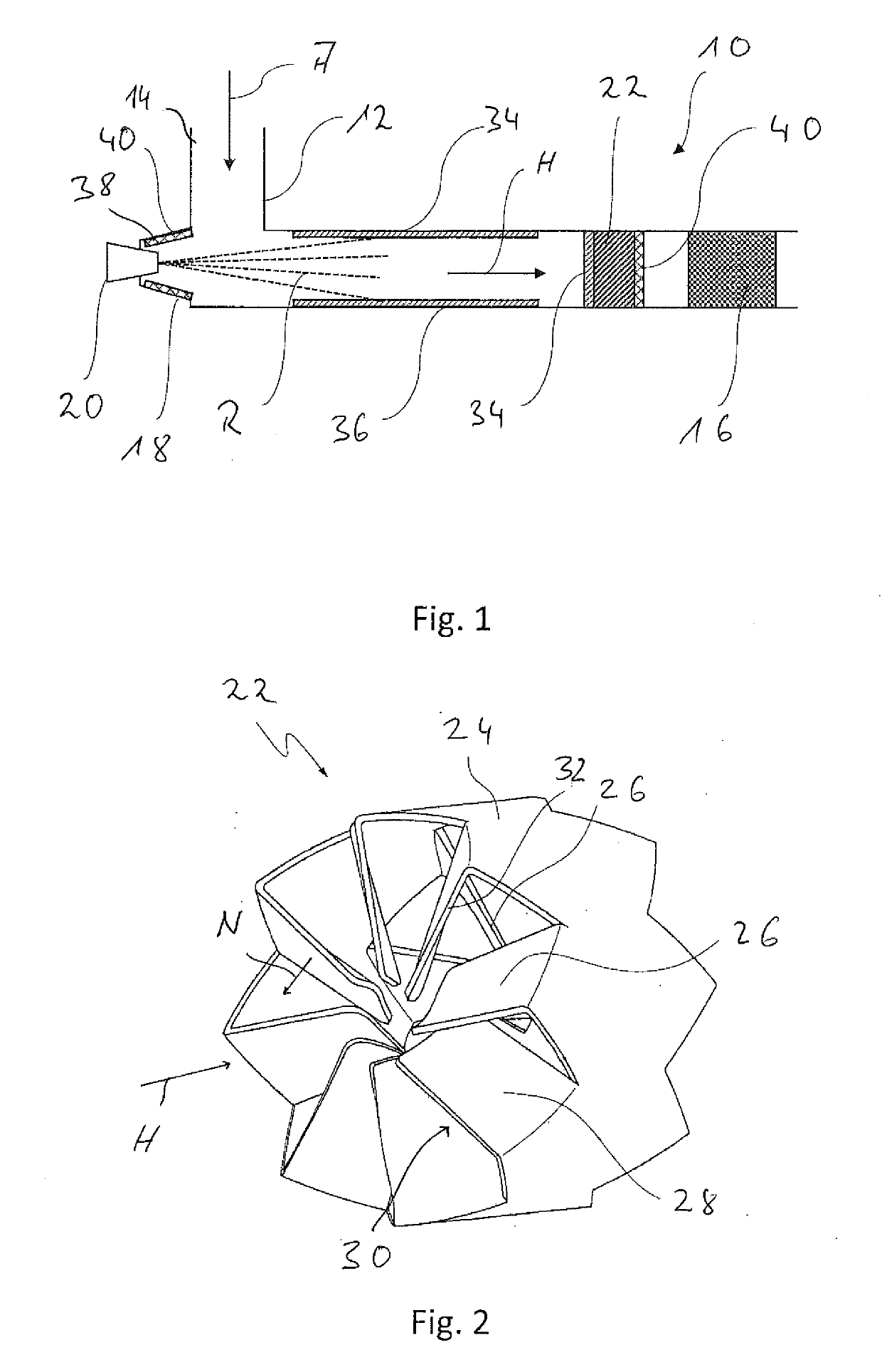

Magnetic assemblies for deposit prevention

InactiveUS20060048941A1Easy to installInhibits the formation of depositsCleaning apparatusWater/sewage treatment by magnetic/electric fieldsMagnetic polesEngineering

An apparatus and method for controlling and / or minimizing the formation or accumulation of unwanted deposits on the inside of fluid flow paths by employing at various locations along the path an assembly of permanent magnets oriented such that the fluid flow is preferably from the North magnetic pole to the South magnetic pole.

Owner:PIPELINE PROTECTION GLOBAL LLC +1

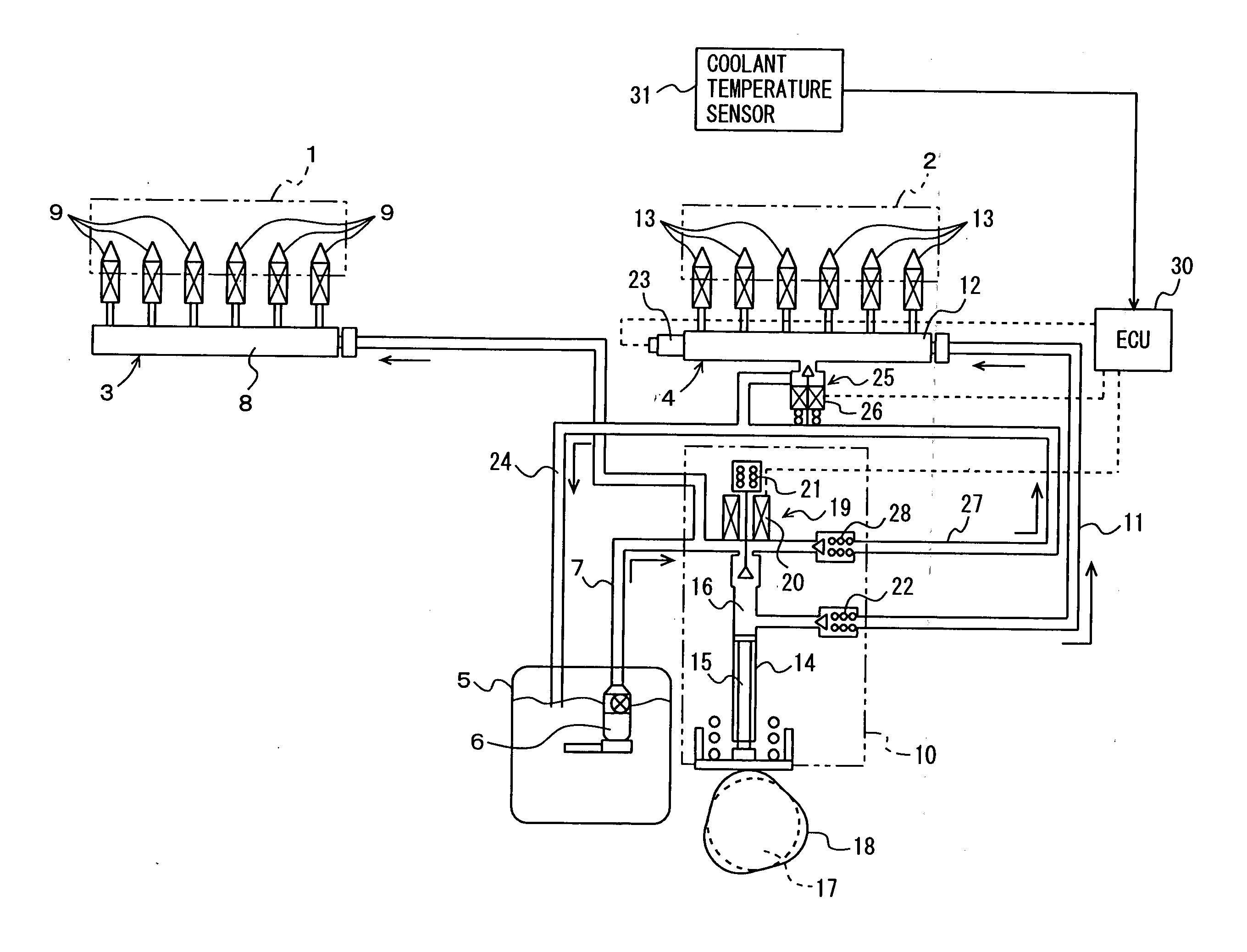

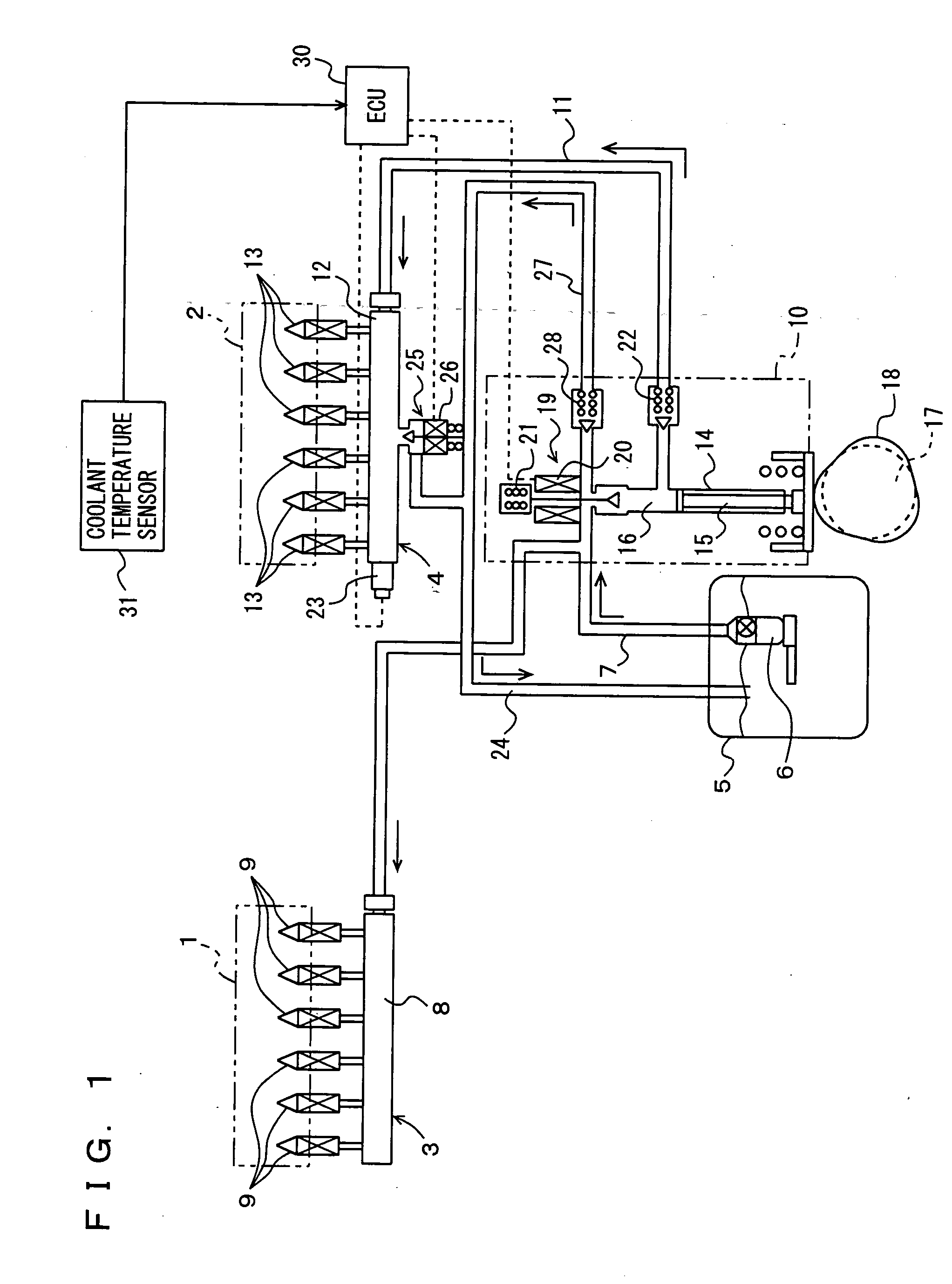

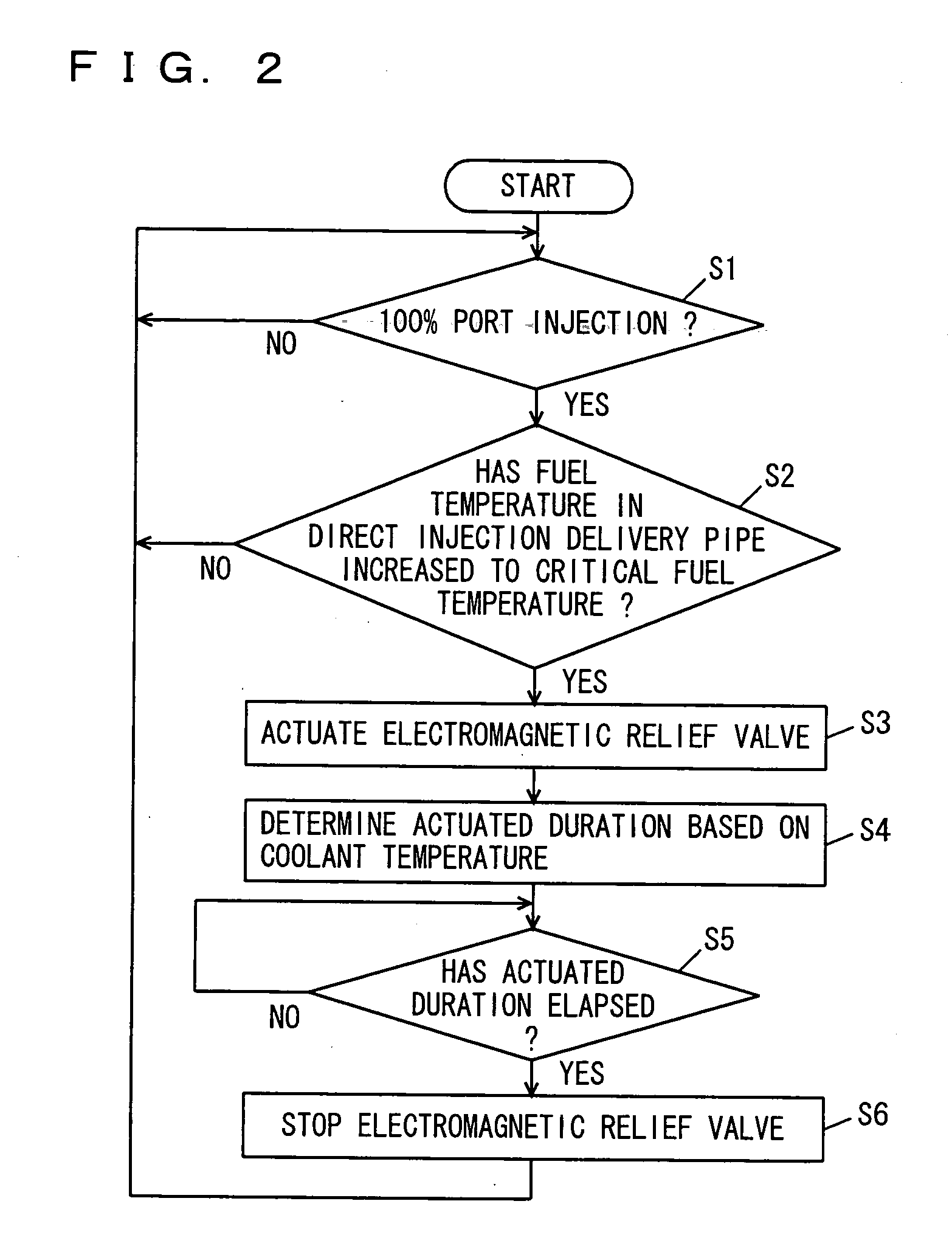

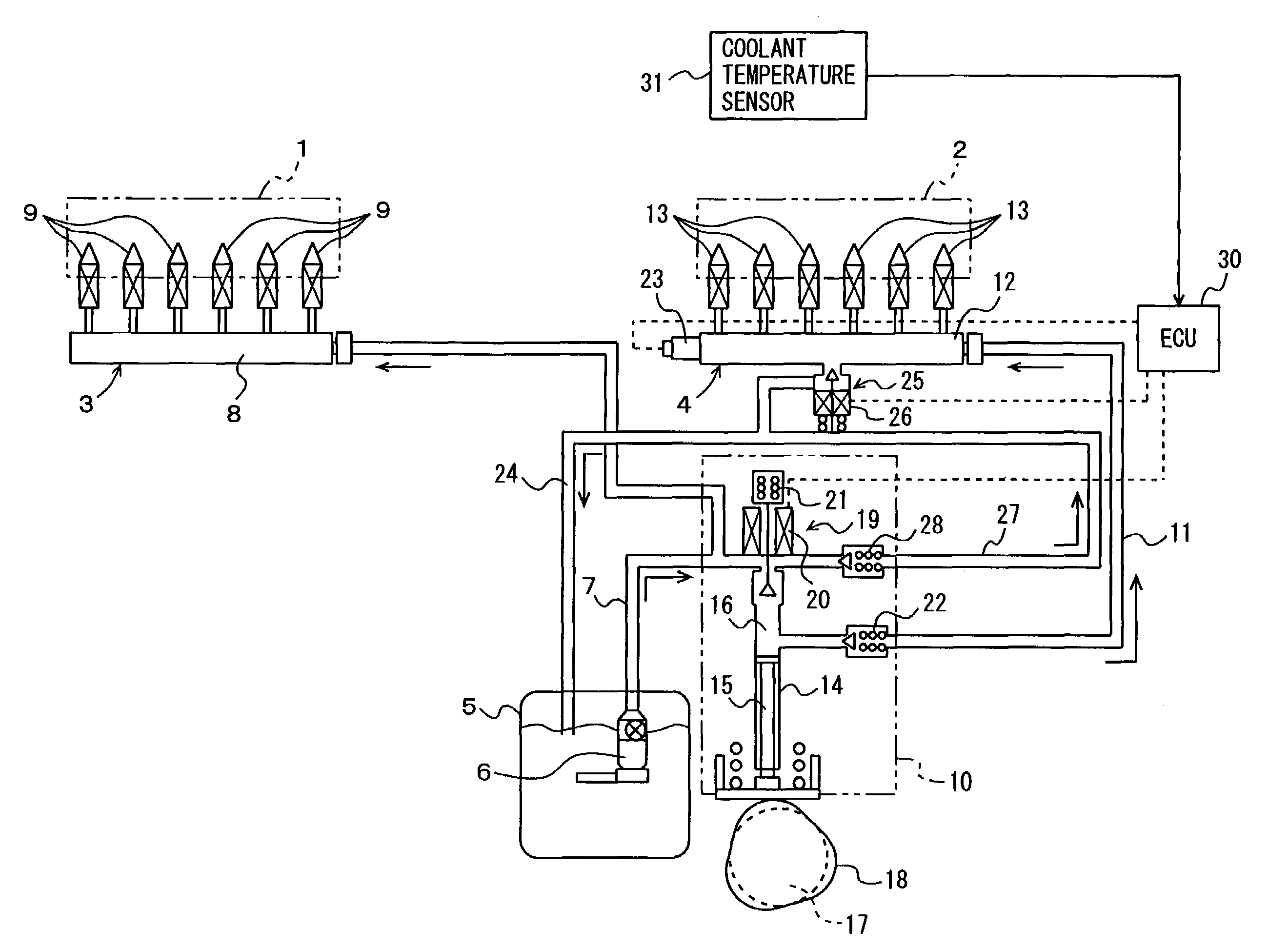

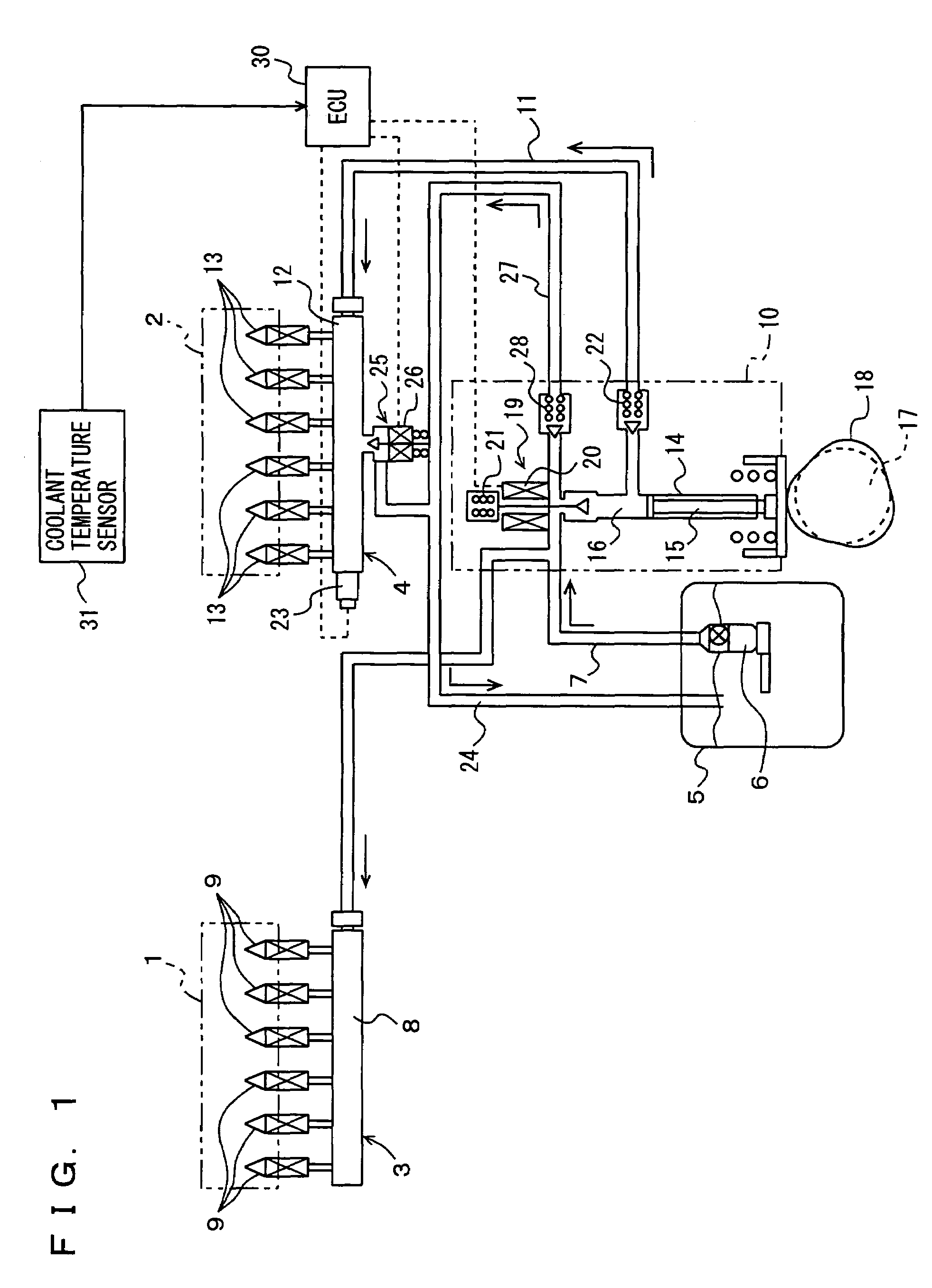

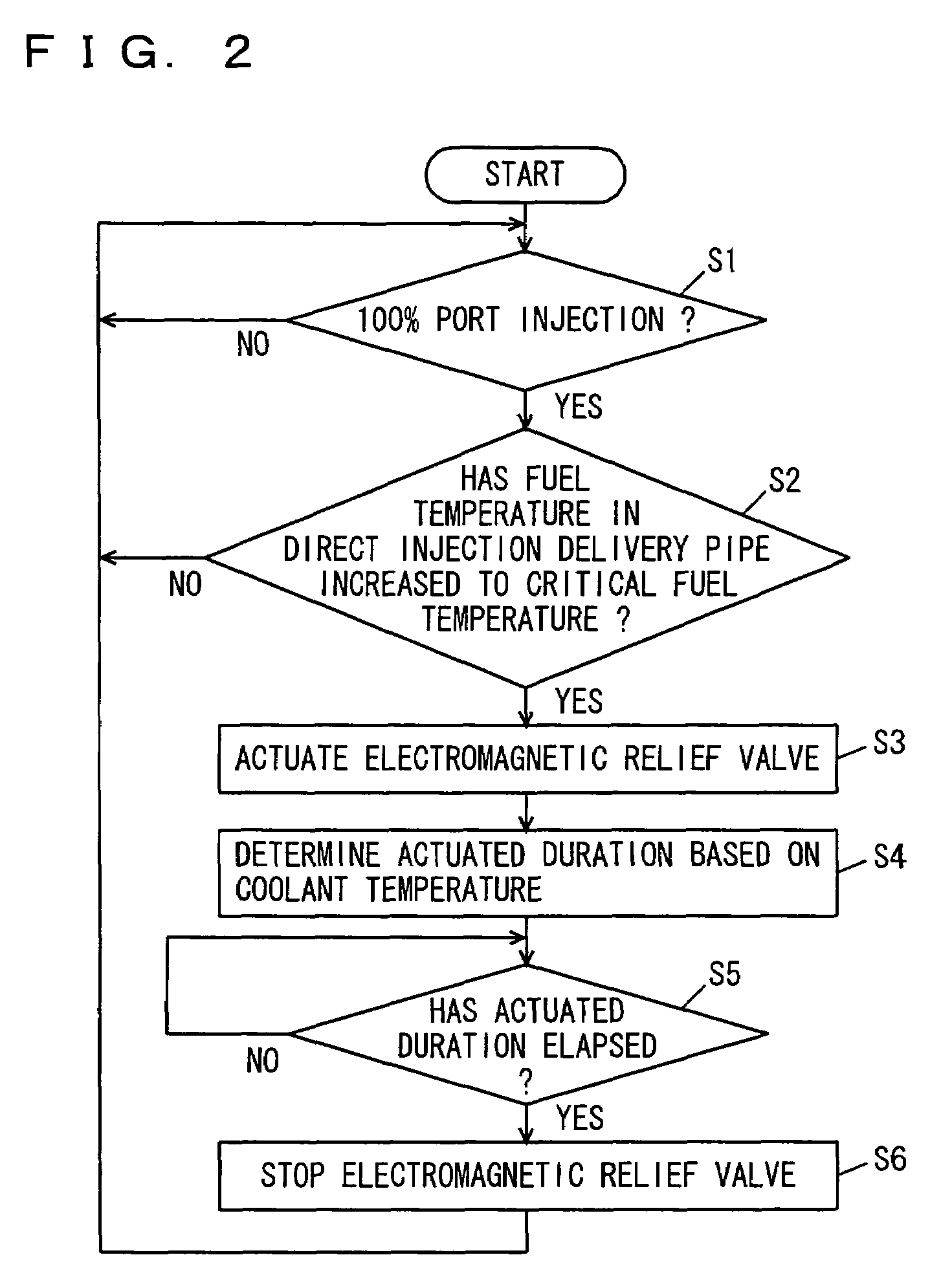

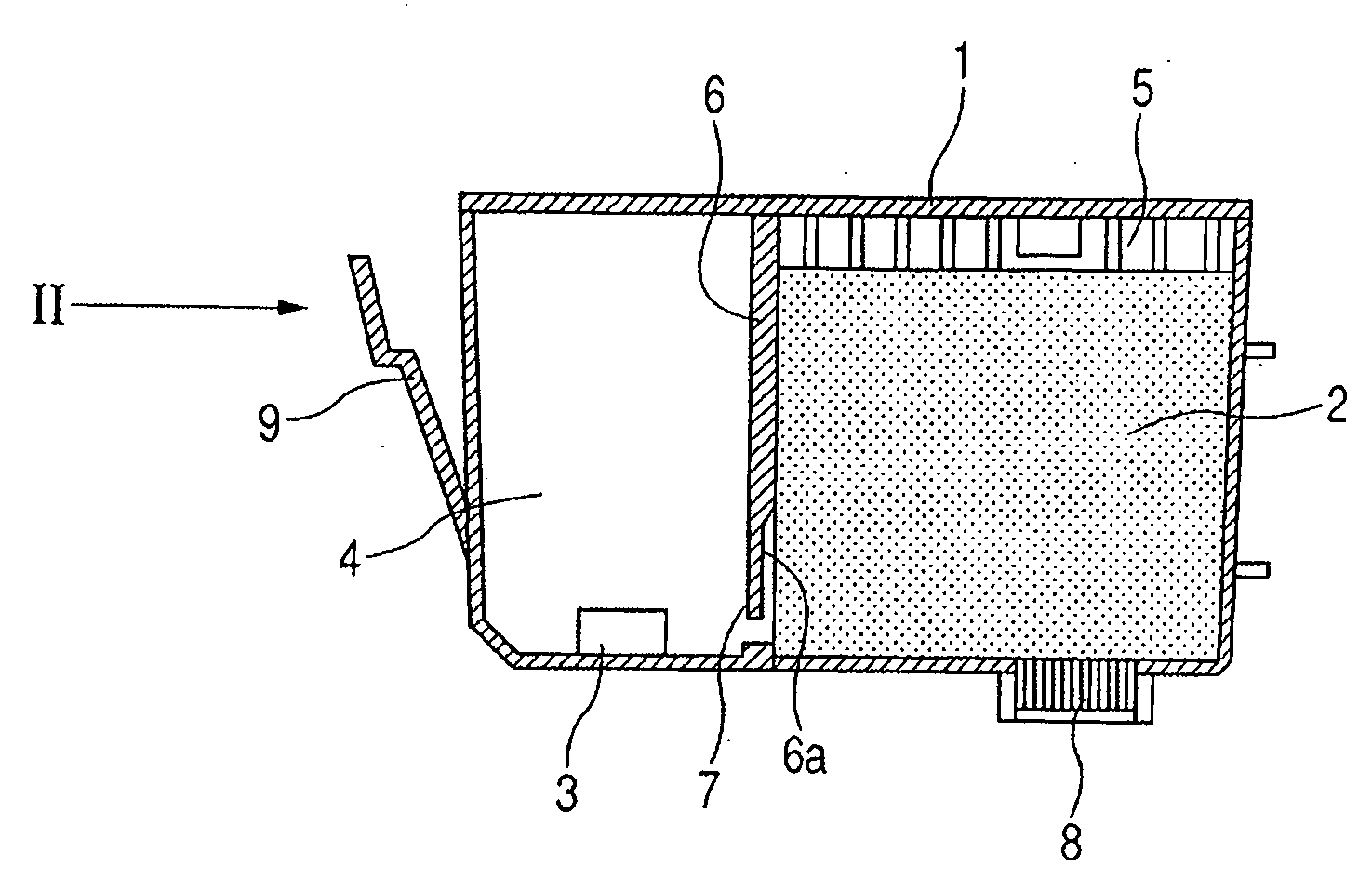

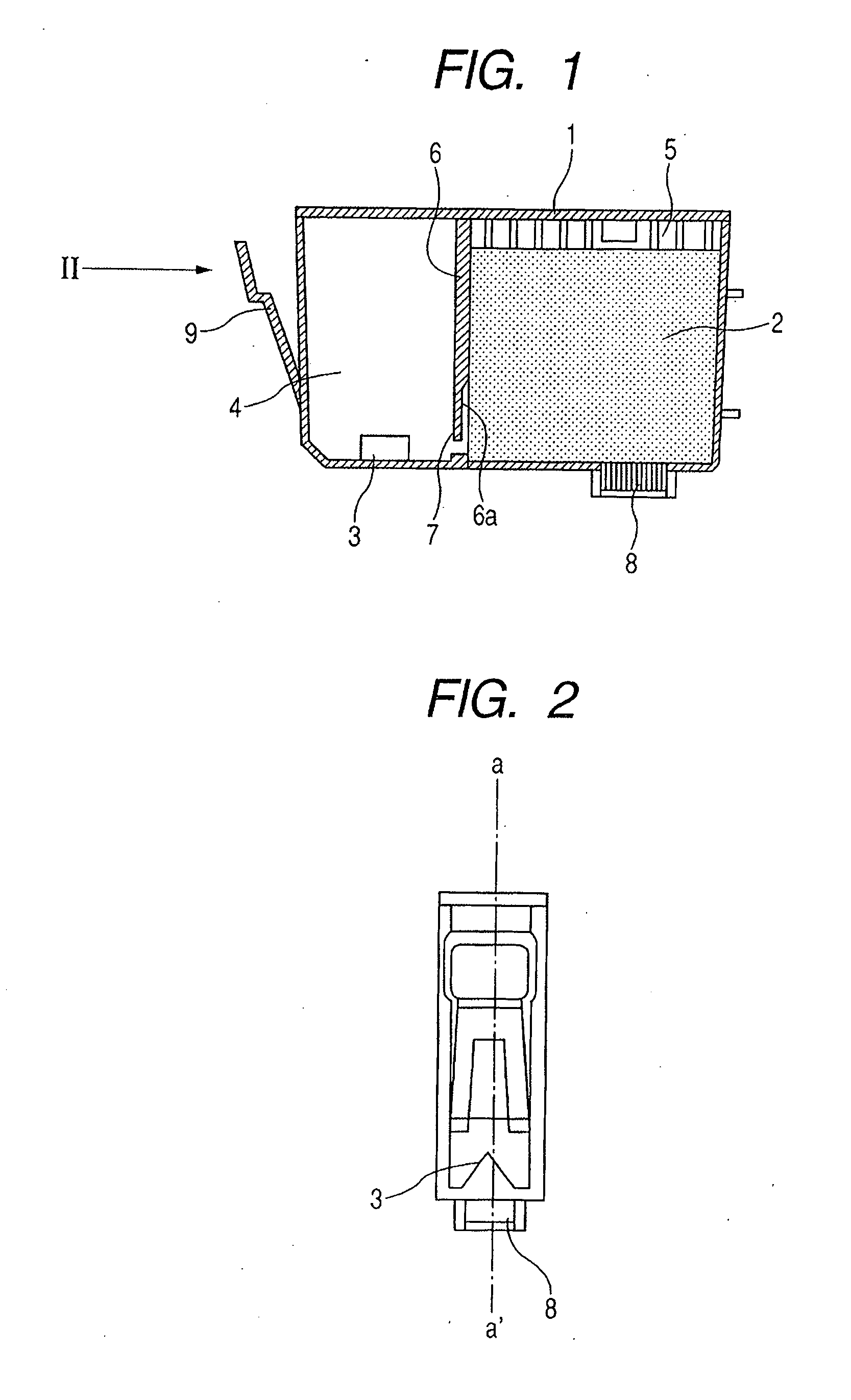

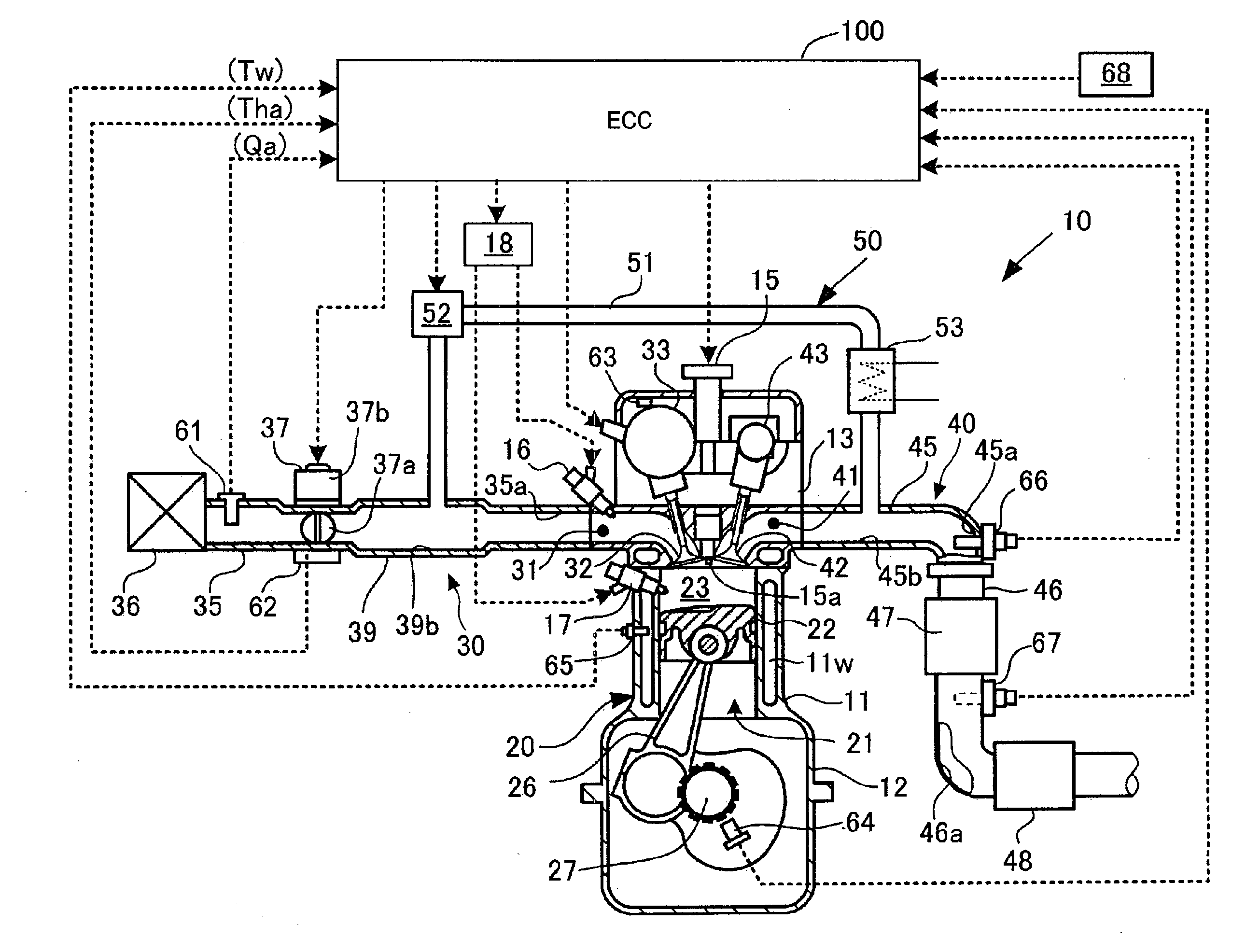

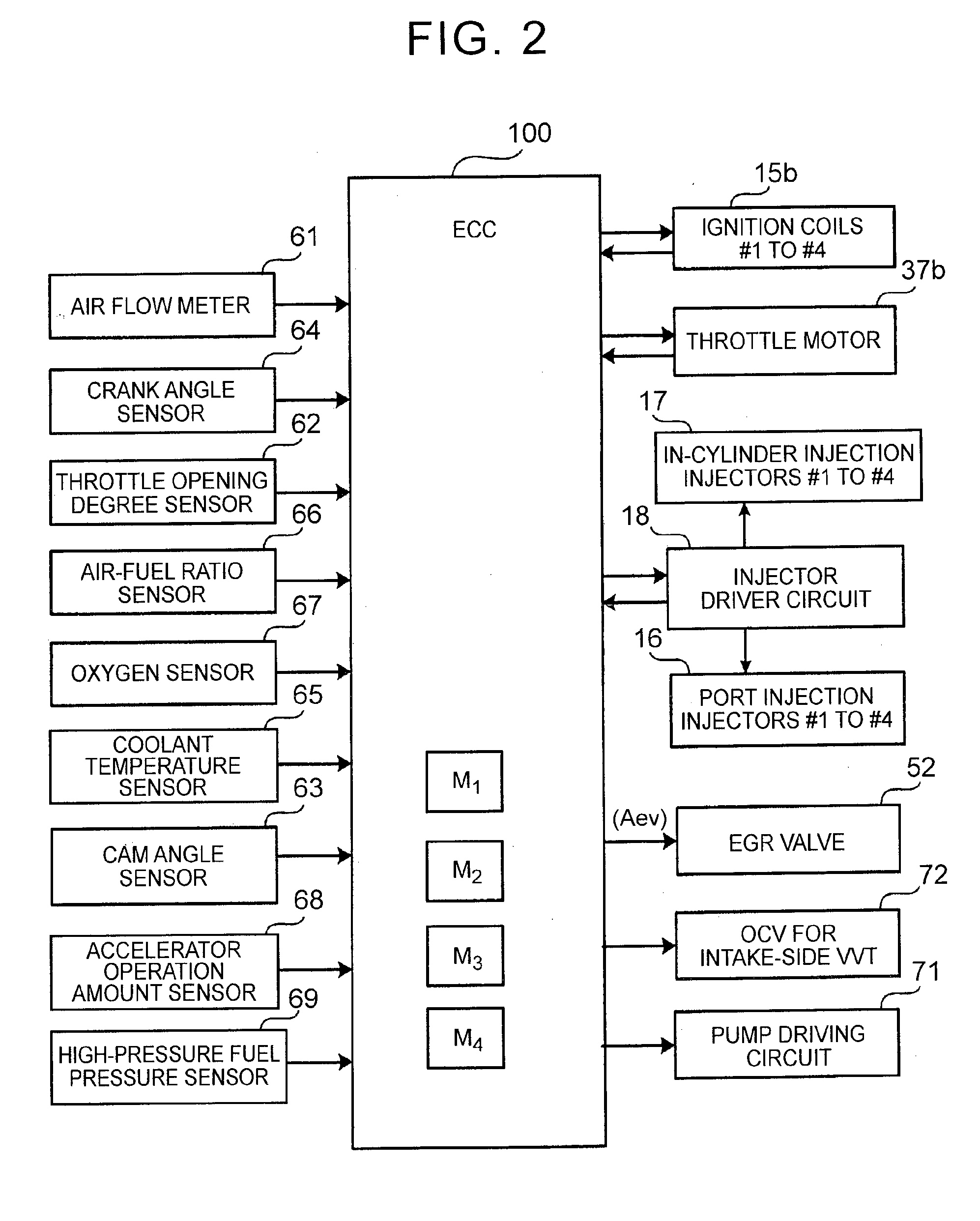

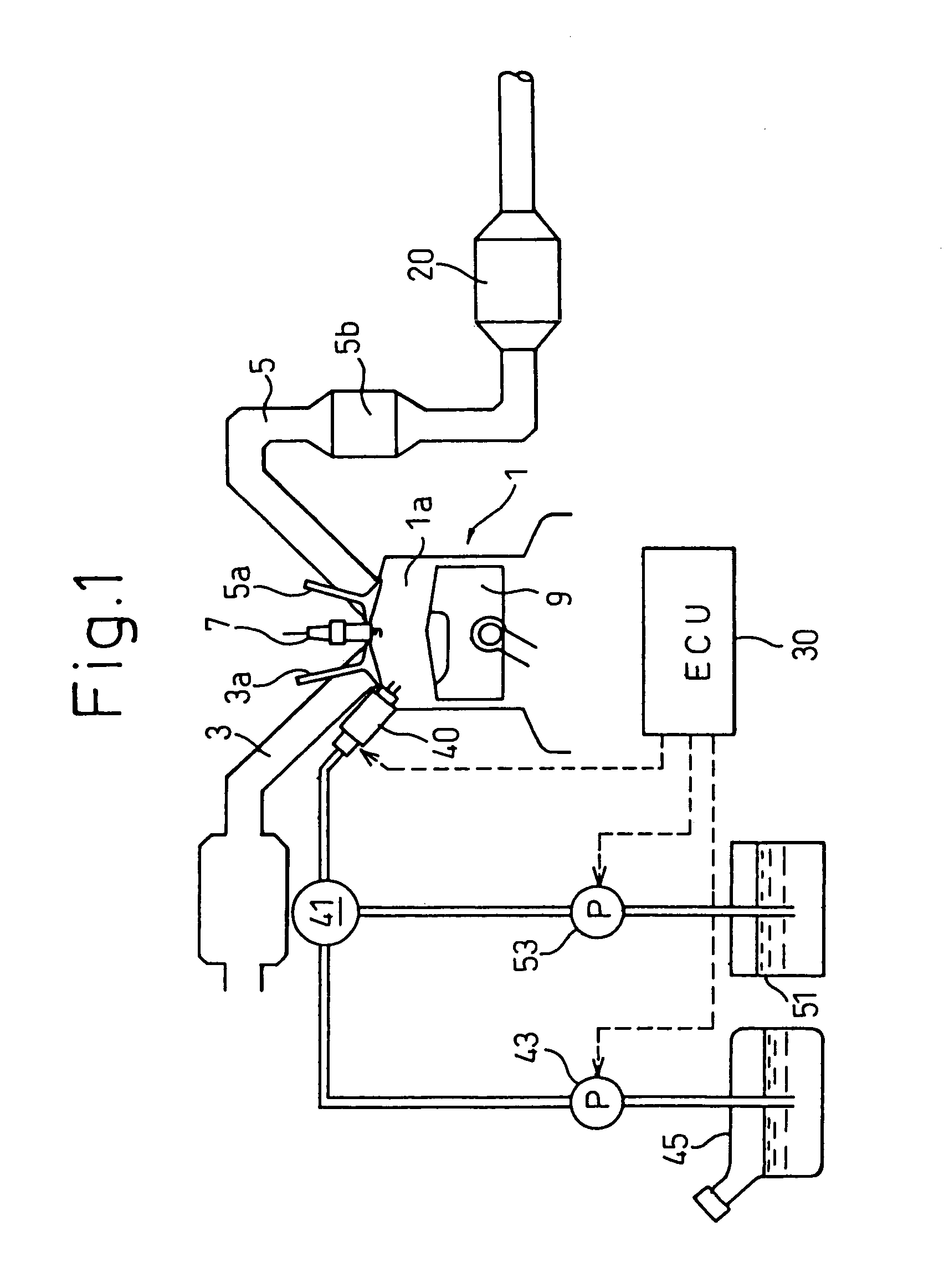

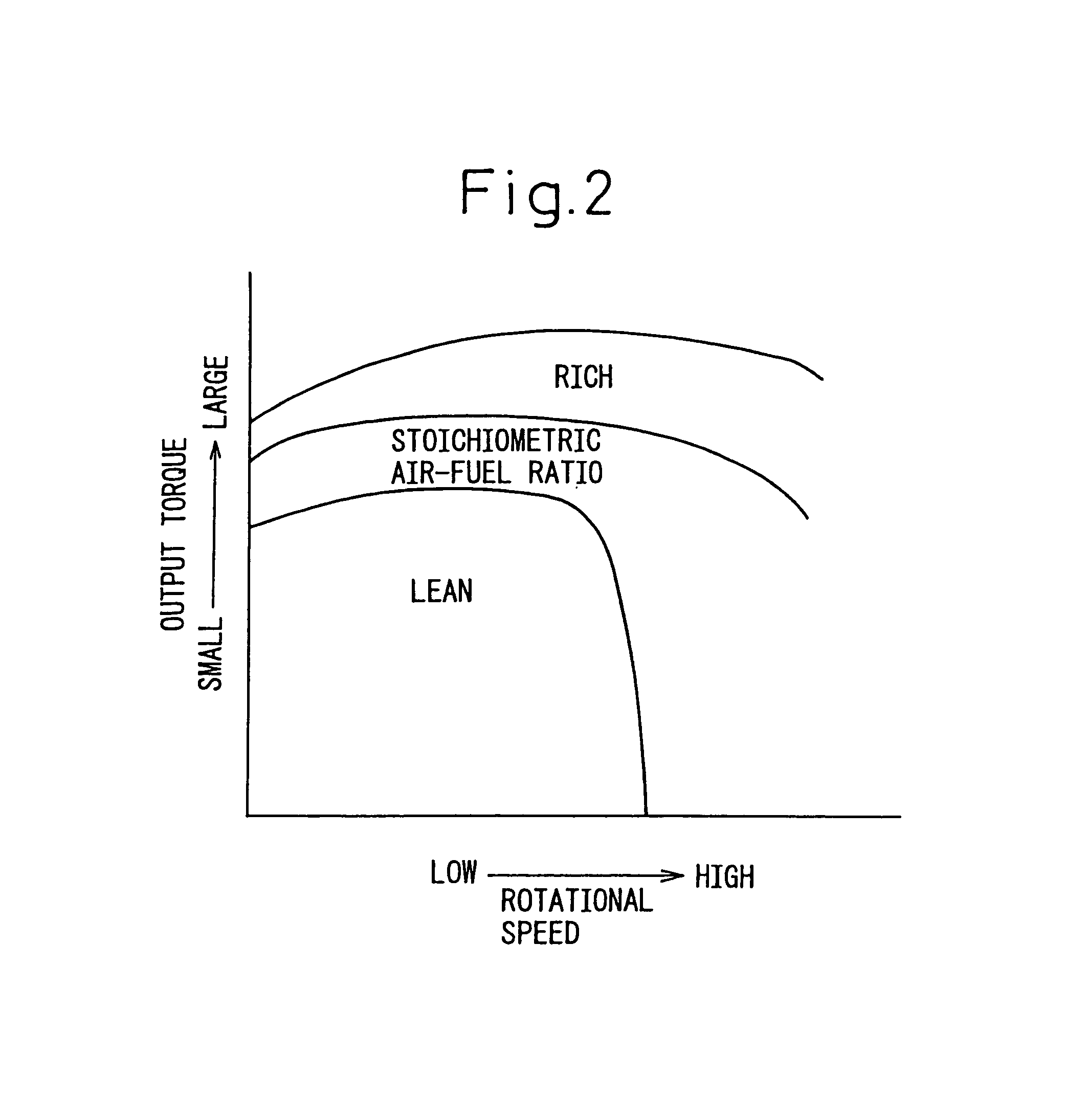

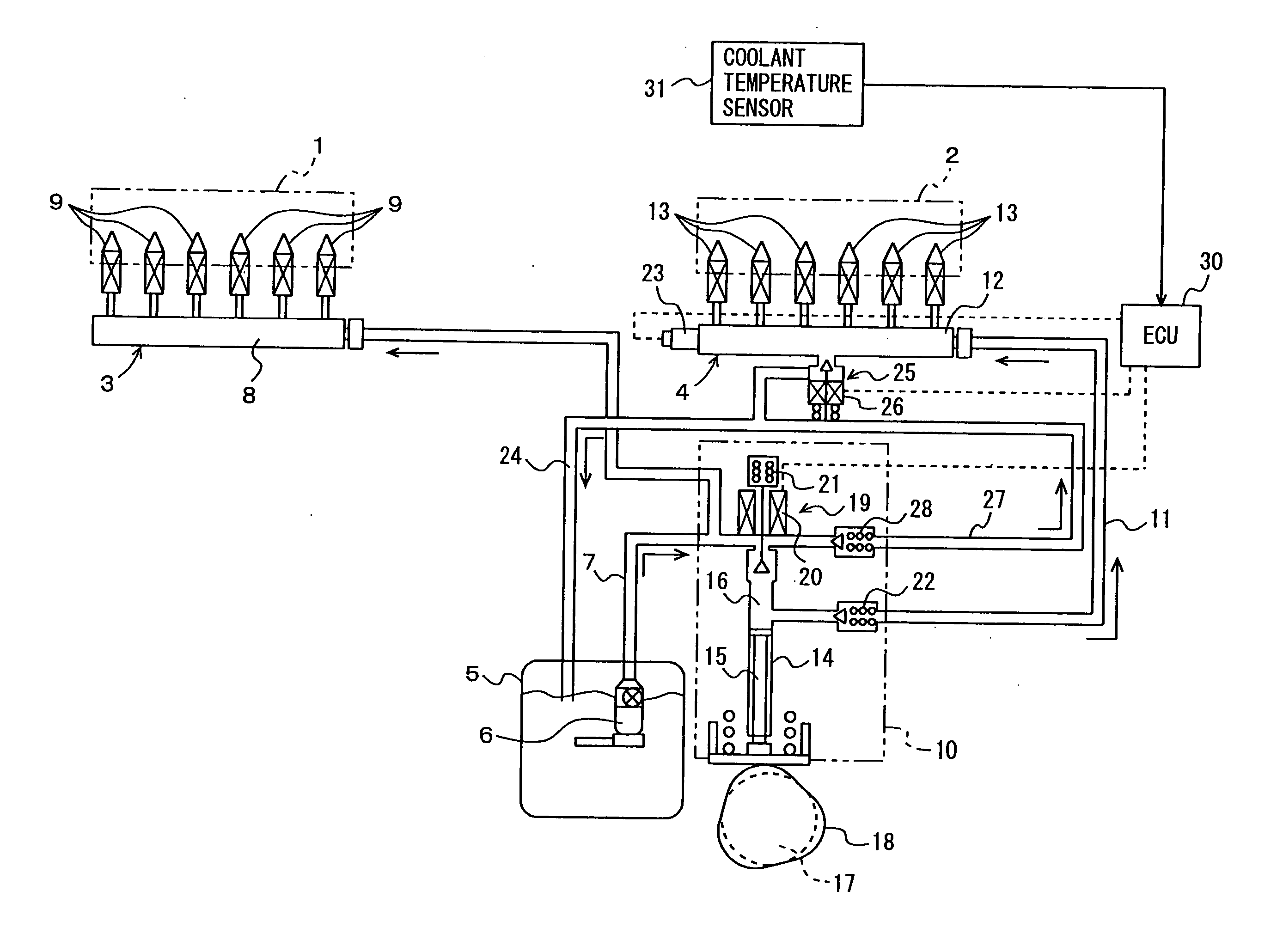

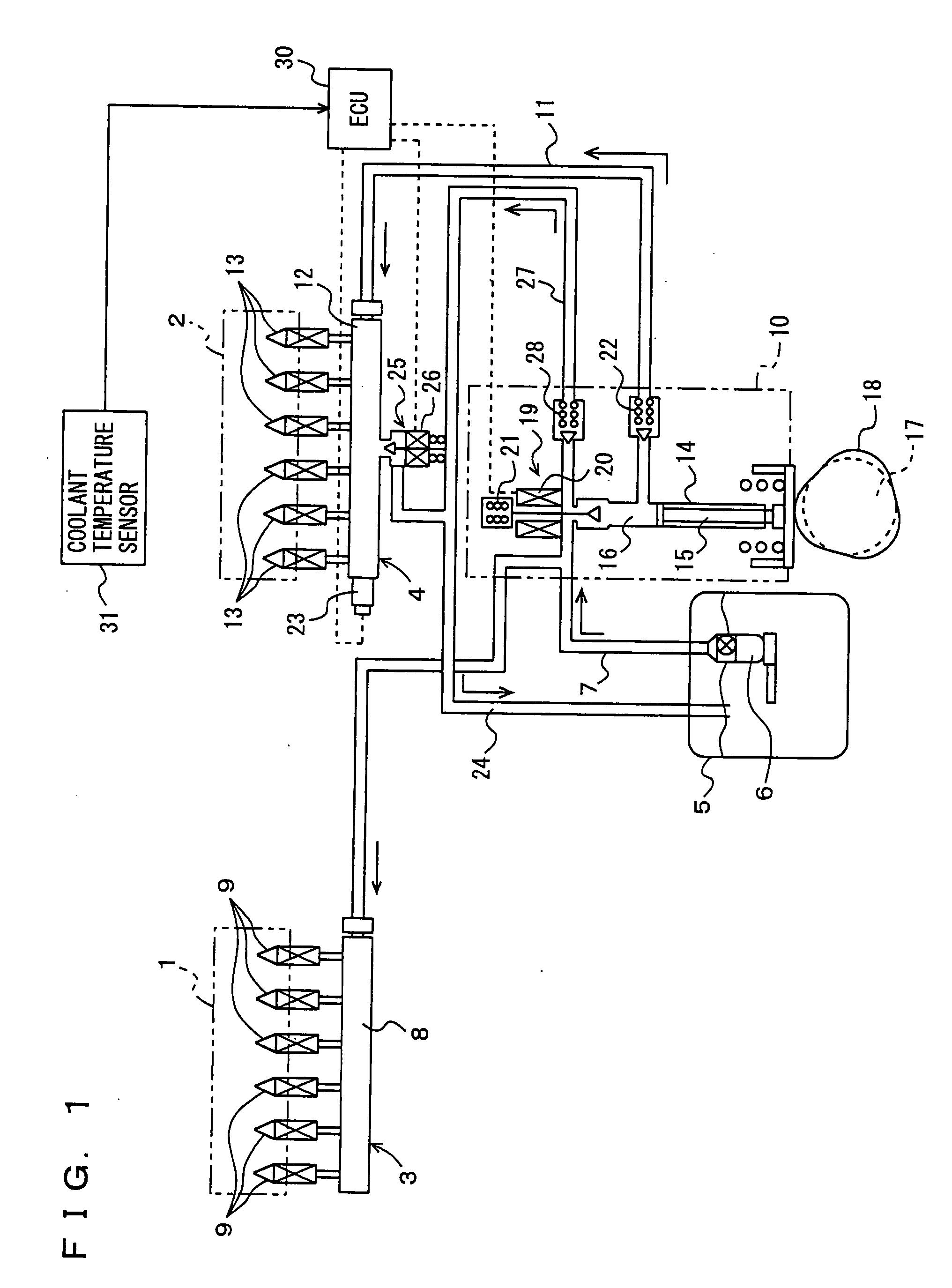

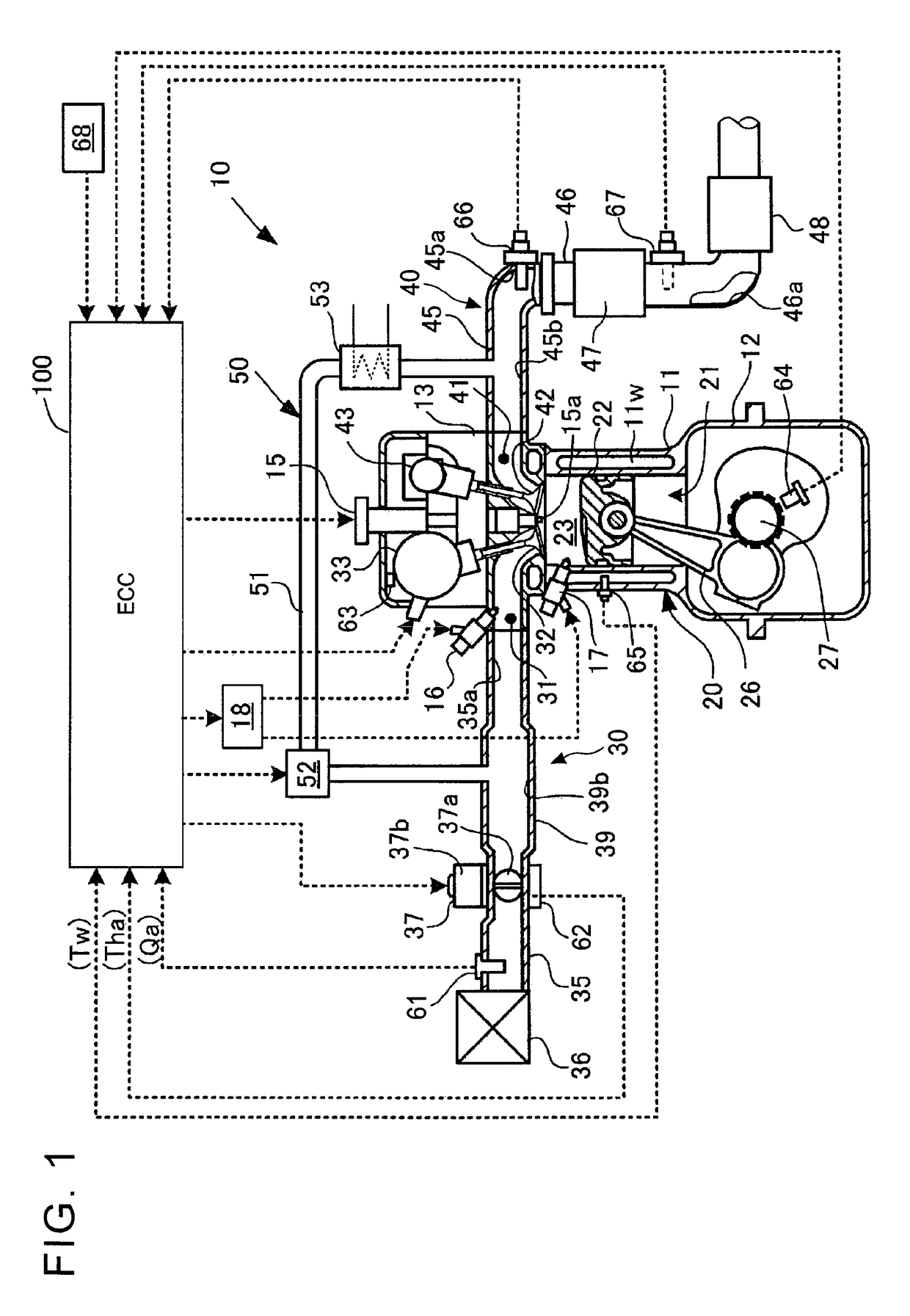

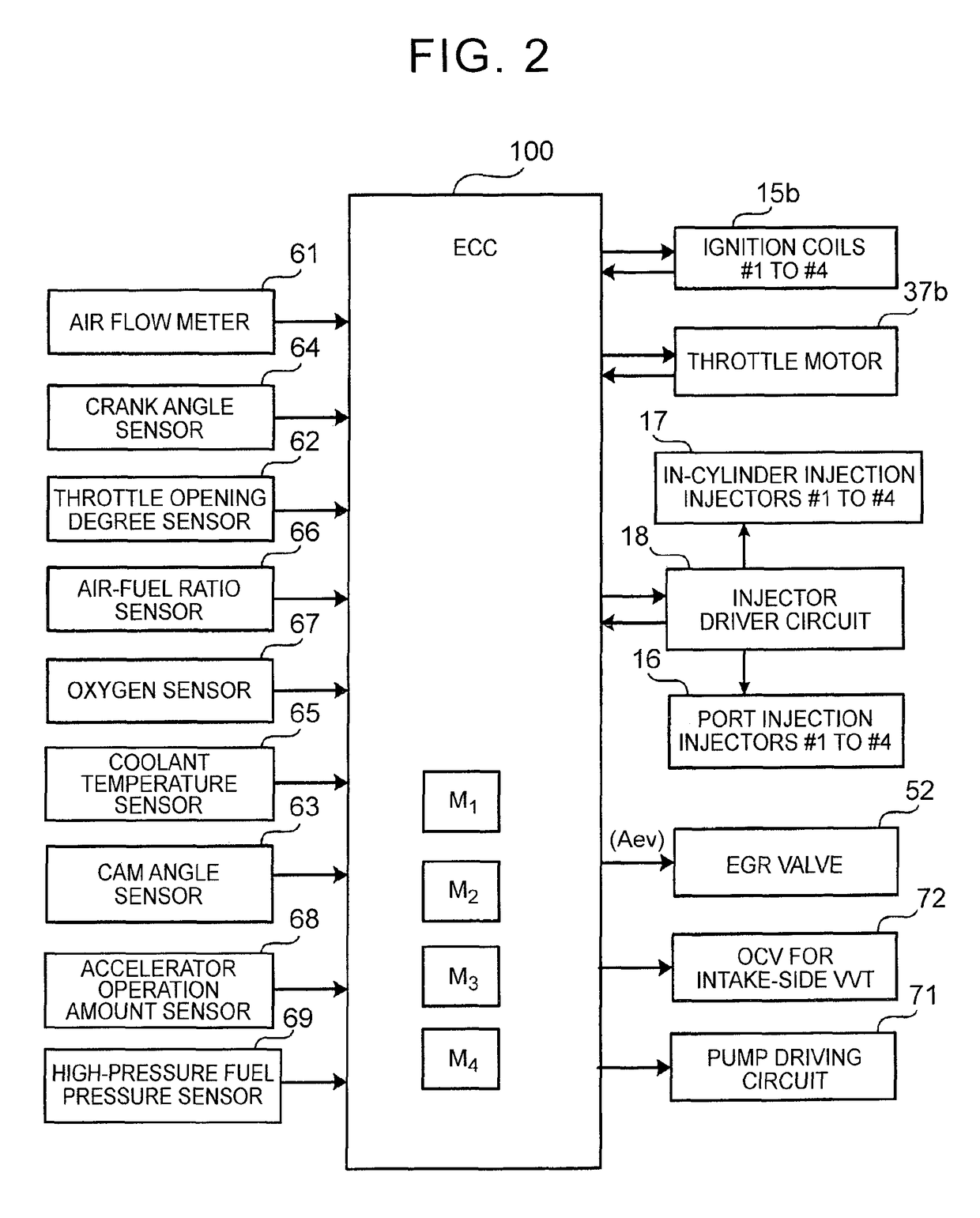

Fuel supply apparatus for internal combustion engine

InactiveUS20060075992A1Suppress mutationImprove the state of combustionElectrical controlInternal combustion piston enginesHigh pressureCoolant temperature

The engine ECU executes a program including the step of detecting an engine coolant temperature, the step of detecting an engine speed and an engine load, the step of estimating a temperature at a tip end of an in-cylinder injector based on the engine coolant temperature, the engine speed and the engine load, and, when the temperature at the tip end is greater than a guaranteed temperature, the step of calculating a drive duty of a high-pressure fuel pump that ensures a decrease of the temperature at the tip end of the in-cylinder injector to the guaranteed temperature, and the step of controlling the high-pressure fuel pump using the drive duty.

Owner:TOYOTA JIDOSHA KK

Fuel supply apparatus for internal combustion engine

InactiveUS7263973B2Suppress mutationImprove the state of combustionElectrical controlInternal combustion piston enginesExternal combustion engineHigh pressure

The engine ECU executes a program including the step of detecting an engine coolant temperature, the step of detecting an engine speed and an engine load, the step of estimating a temperature at a tip end of an in-cylinder injector based on the engine coolant temperature, the engine speed and the engine load, and, when the temperature at the tip end is greater than a guaranteed temperature, the step of calculating a drive duty of a high-pressure fuel pump that ensures a decrease of the temperature at the tip end of the in-cylinder injector to the guaranteed temperature, and the step of controlling the high-pressure fuel pump using the drive duty.

Owner:TOYOTA JIDOSHA KK

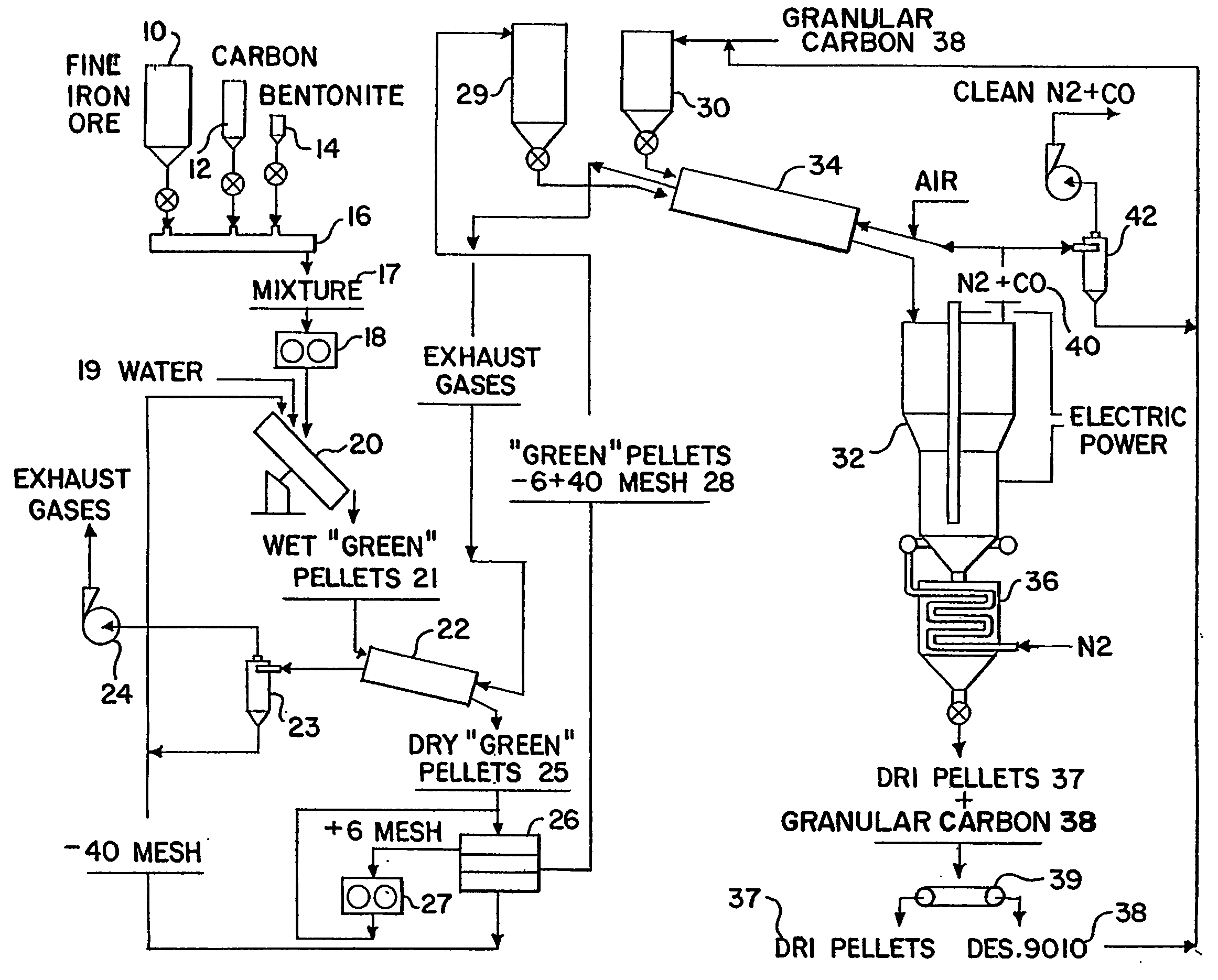

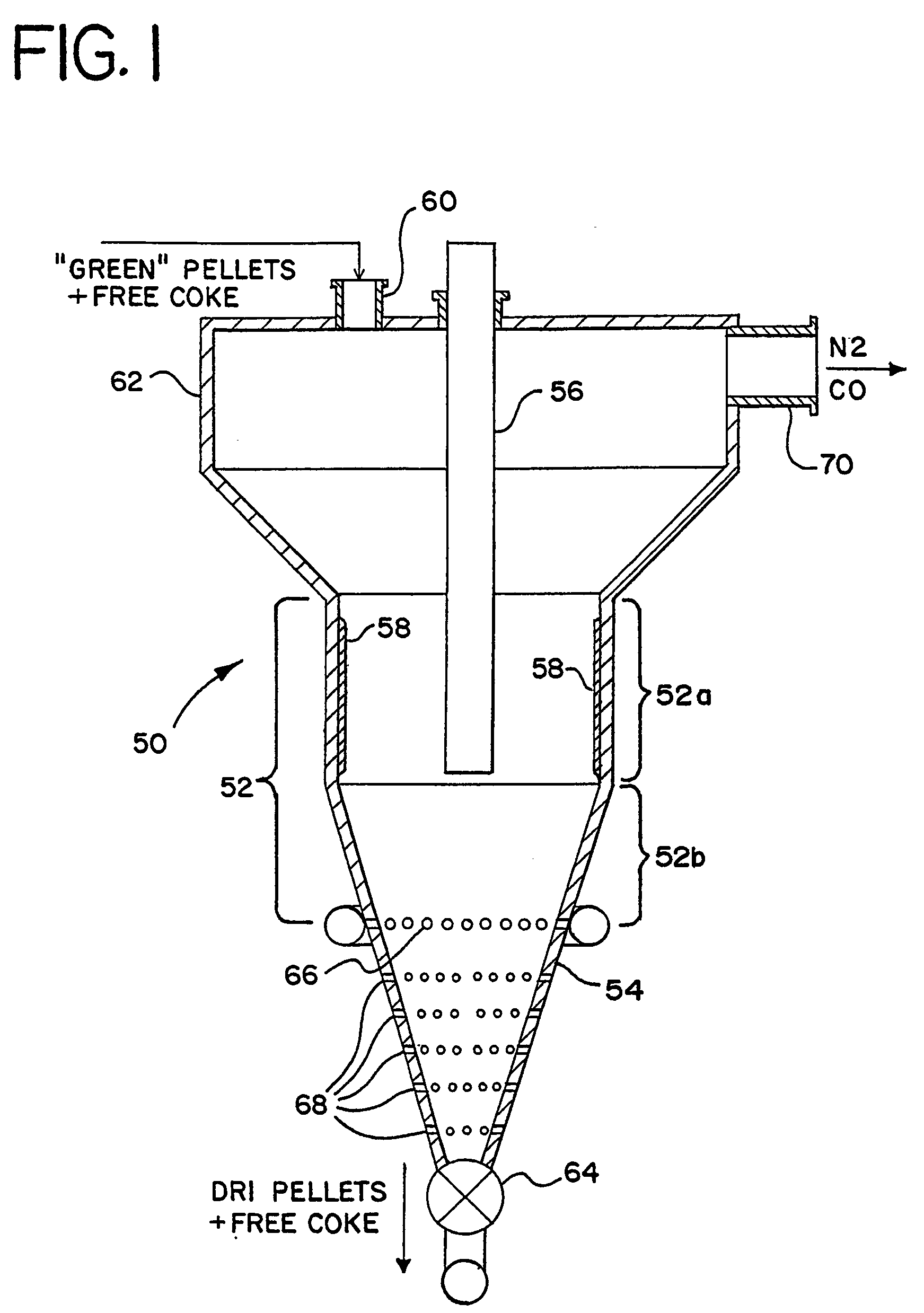

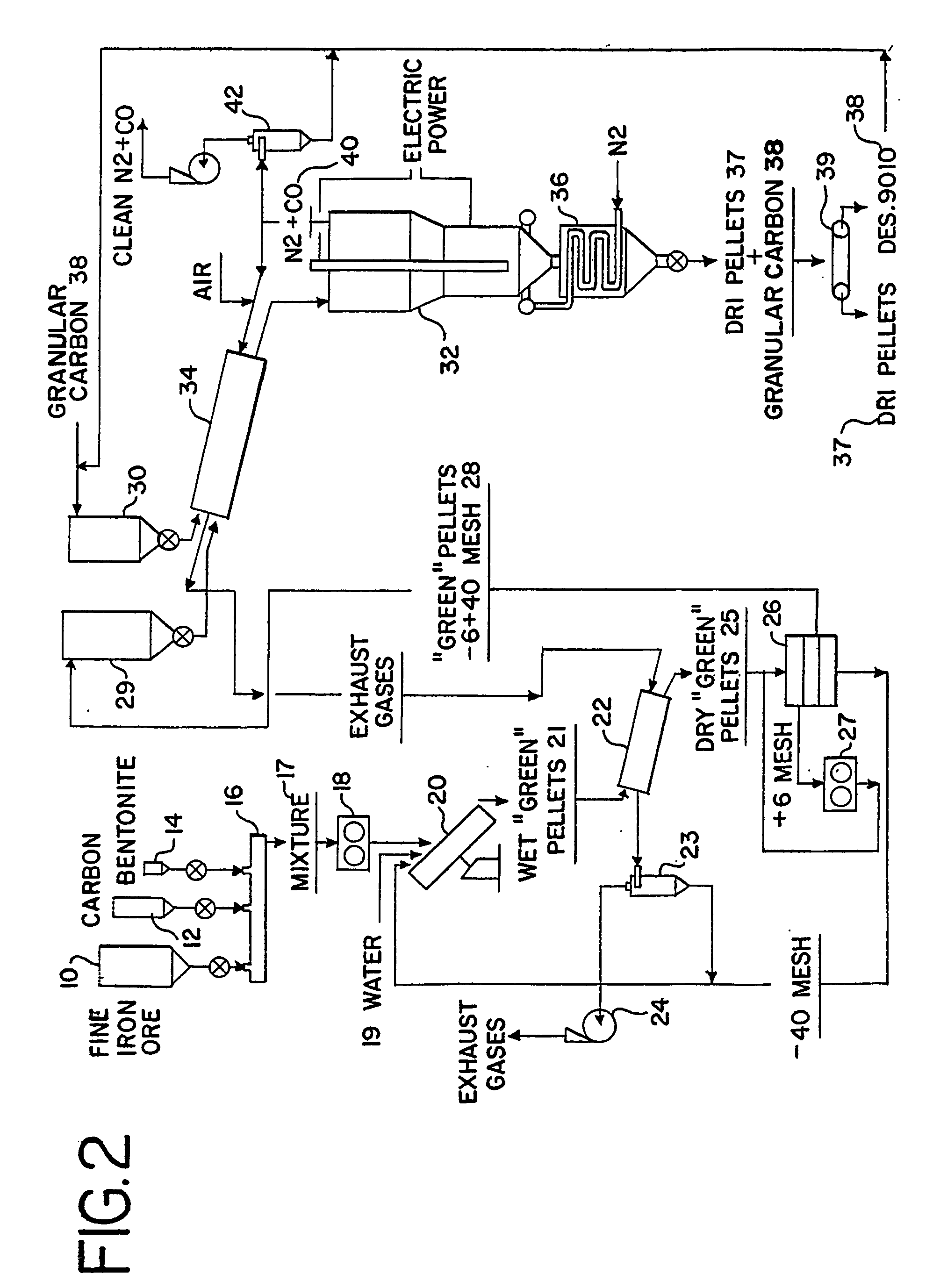

Process and apparatus for the direct reduction of iron oxides in an electrothermal fluidized bed and resultant product

InactiveUS20050092130A1Avoid particle agglomerationInhibits the formation of depositsMaintainance of heating chambersCharge manipulationVolatilesFluidized bed

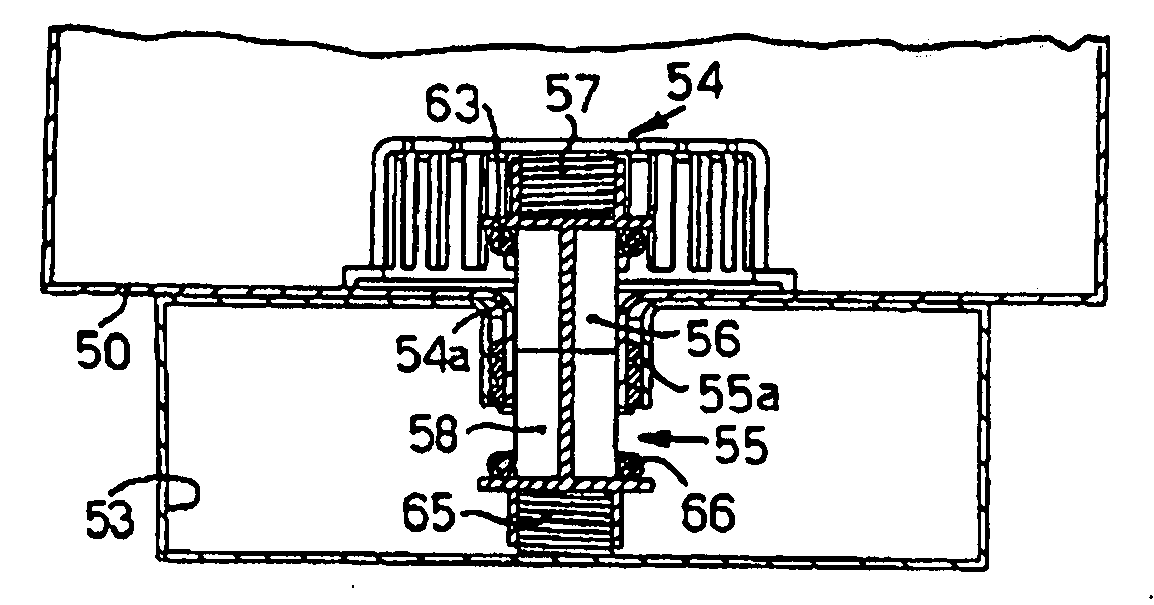

A method and an apparatus (50) for producing direct reduced iron (37) from dry pellets (25) composed of iron oxide and carbonaceous material. A mixture of pellets (25) and free coke particles (38) with weight relation from 3:1 to 5:1 is fed into the top of an electrothermal fluidized bed (32) that is fluidized by nitrogen. By exposing pellets (25) in the electrothermal fluidized bed (32) to temperatures of between approximately 850-1,100° C. for an average period of between approximately 15-60 minutes, the volatiles are removed and the pellets (25) metallized. Reduced pellets (37) mixed with free coke (38) are discharged from the bottom of fluidized bed (32) and cooled. The reduced iron pellets (37) are physically separated from any free coke (38) and the free coke (38) is recycled back into the fluidized bed (32).

Owner:GOLBERGER WILLIAM M +1

Magnetic assemblies for deposit prevention and methods of use

InactiveUS7353873B2Easy to installInhibits the formation of depositsCleaning apparatusWater/sewage treatment by magnetic/electric fieldsMagnetic polesBiomedical engineering

An apparatus and method for controlling and / or minimizing the formation or accumulation of unwanted deposits on the inside of fluid flow paths by employing at various locations along the path an assembly of permanent magnets oriented such that the fluid flow is preferably from the North magnetic pole to the South magnetic pole.

Owner:PIPELINE PROTECTION GLOBAL LLC +1

Ink cartridge

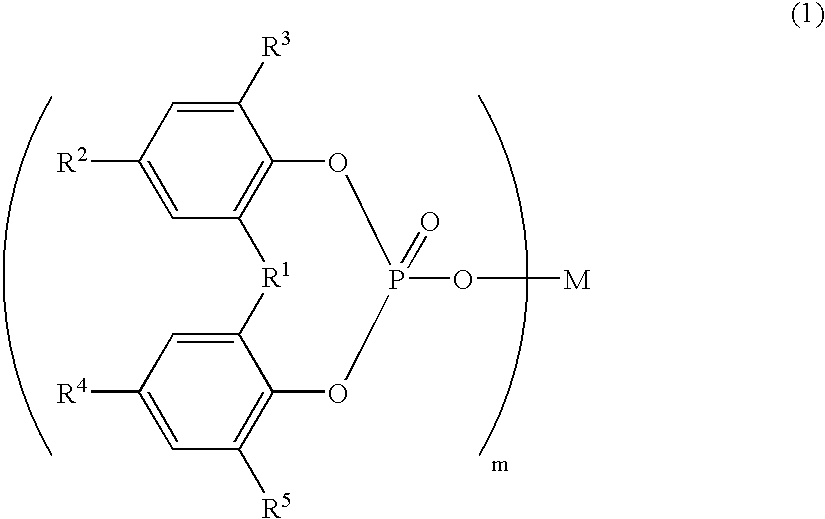

InactiveUS20080021170A1Reduce interactionPrint quality defectPrintingPhosphoric Acid EstersHydrotalcite

An ink cartridge for an ink jet recording apparatus is formed by a material including an propylene homopolymer and a nucleating agent containing a specified organic phosphoric acid ester compound. The material advantageously contains a nucleating agent of from 0.01 to 1.0 part by mass with respect to 100 parts by mass of polypropylene, and hydrotalcite as a neutralizing agent.

Owner:CANON KK

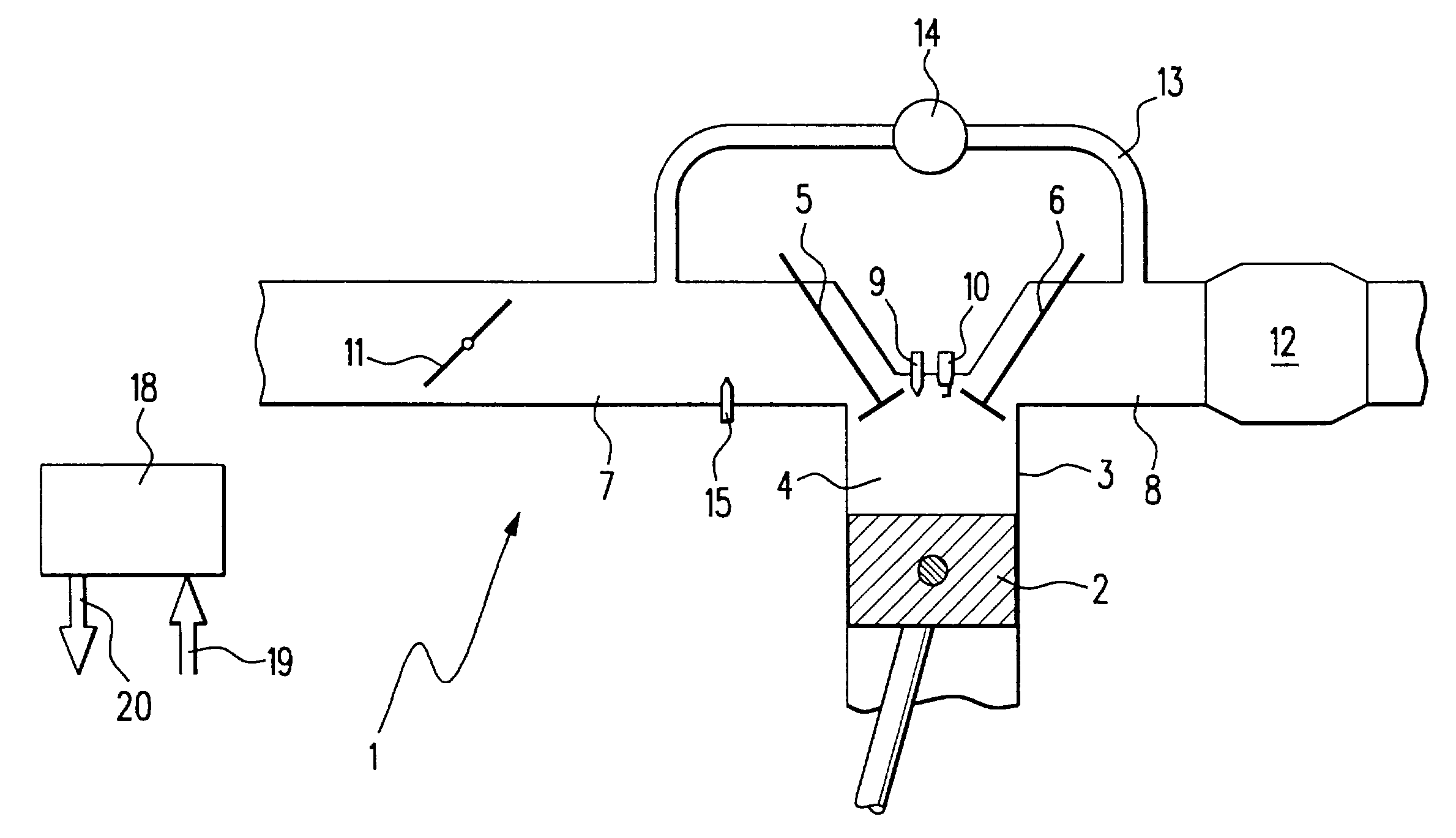

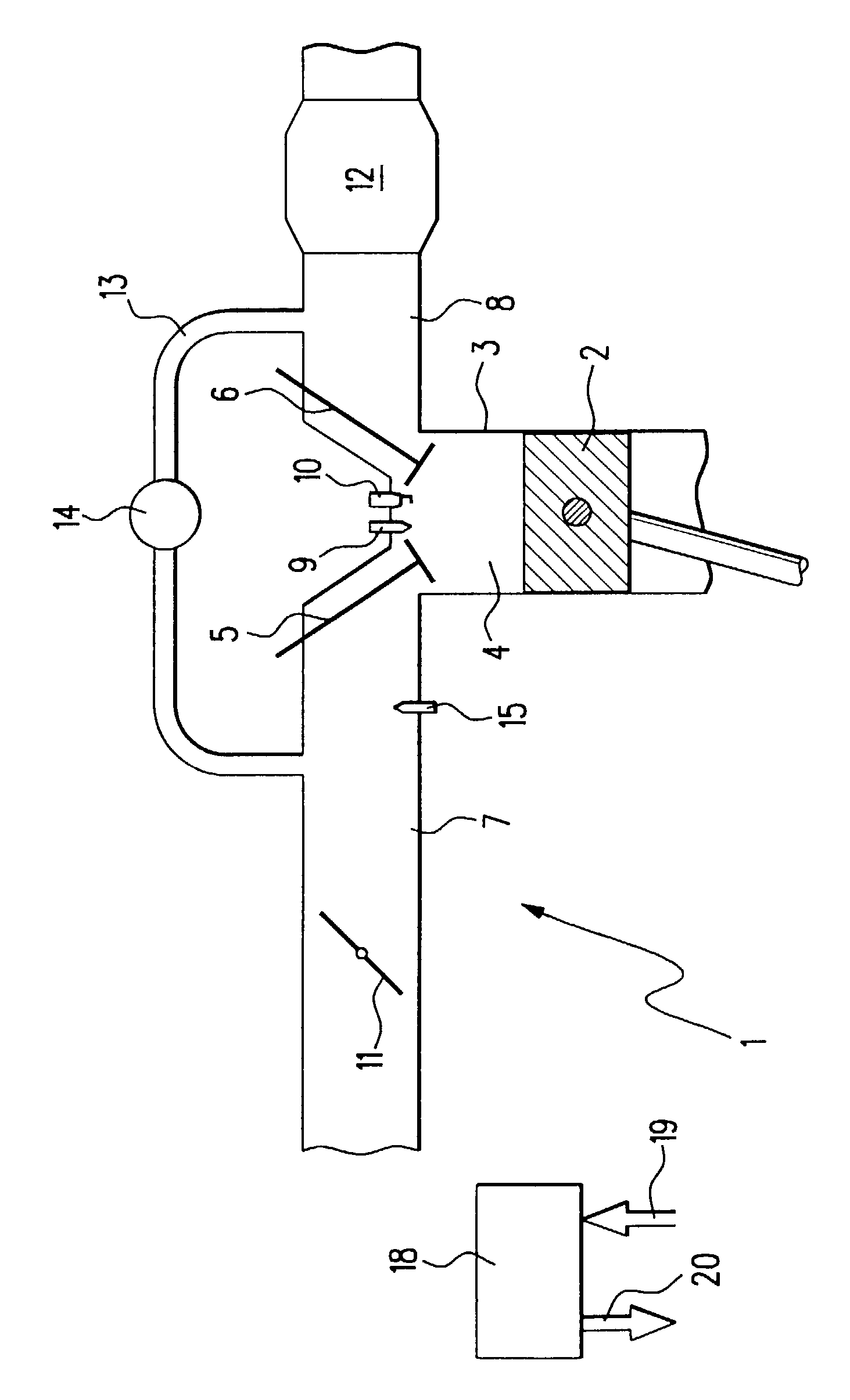

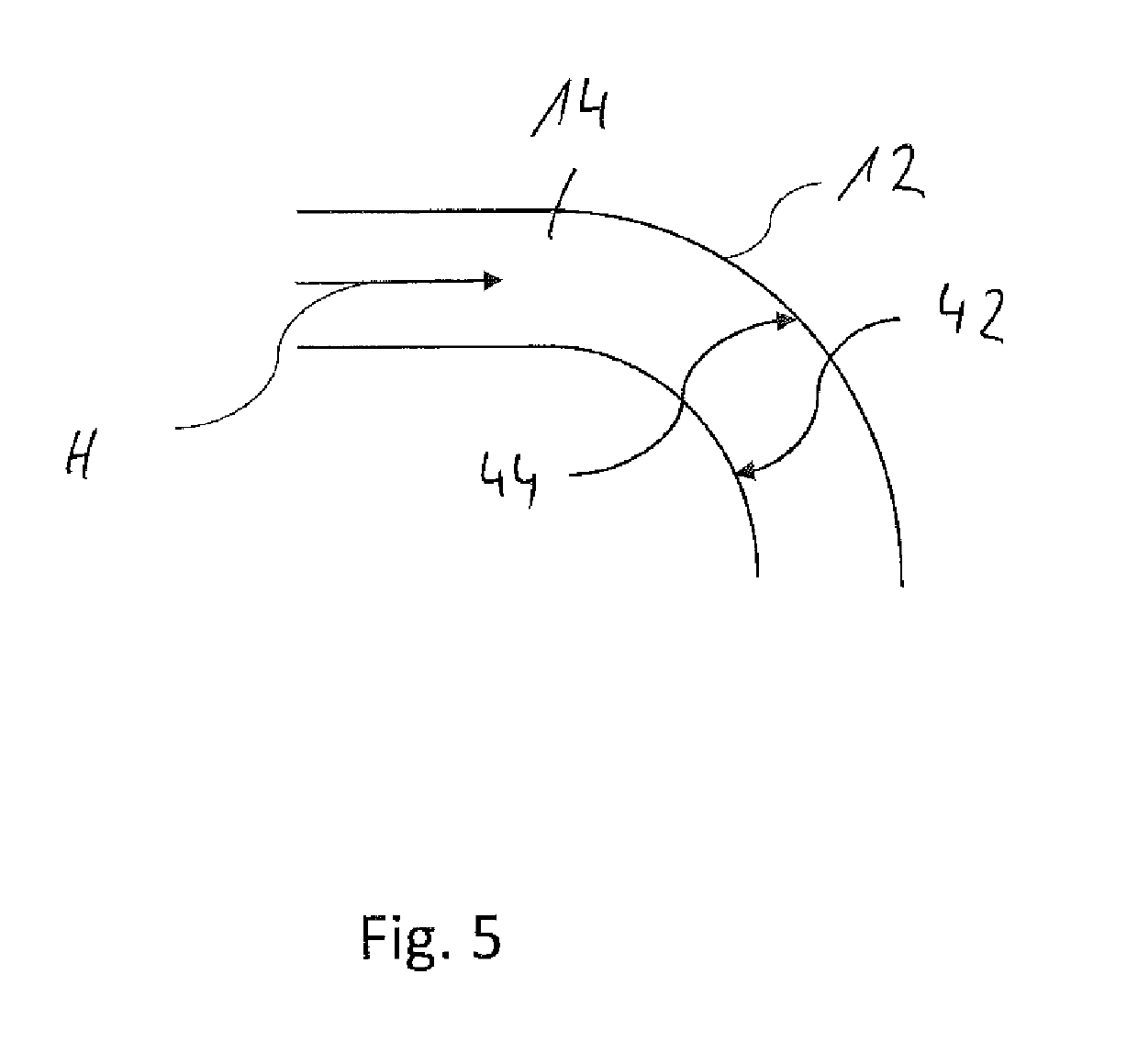

Fuel injection system for internal combustion engines with gasoline direct injection, which includes optional injection into the intake tube, and method for operating it

InactiveUS6971364B2Reduce fuel consumptionInhibition formationAnalogue computers for vehiclesElectrical controlGasoline direct injectionExternal combustion engine

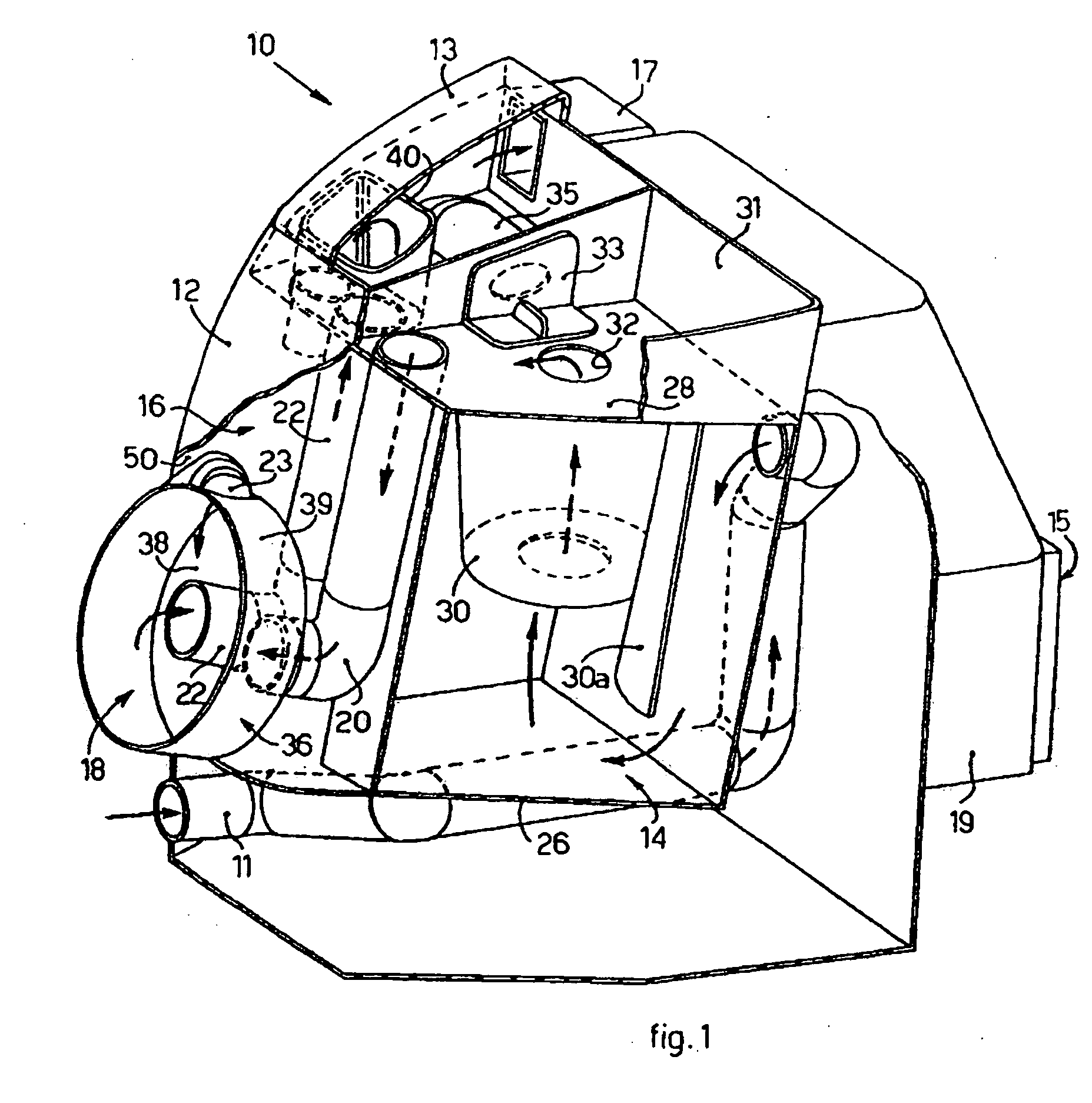

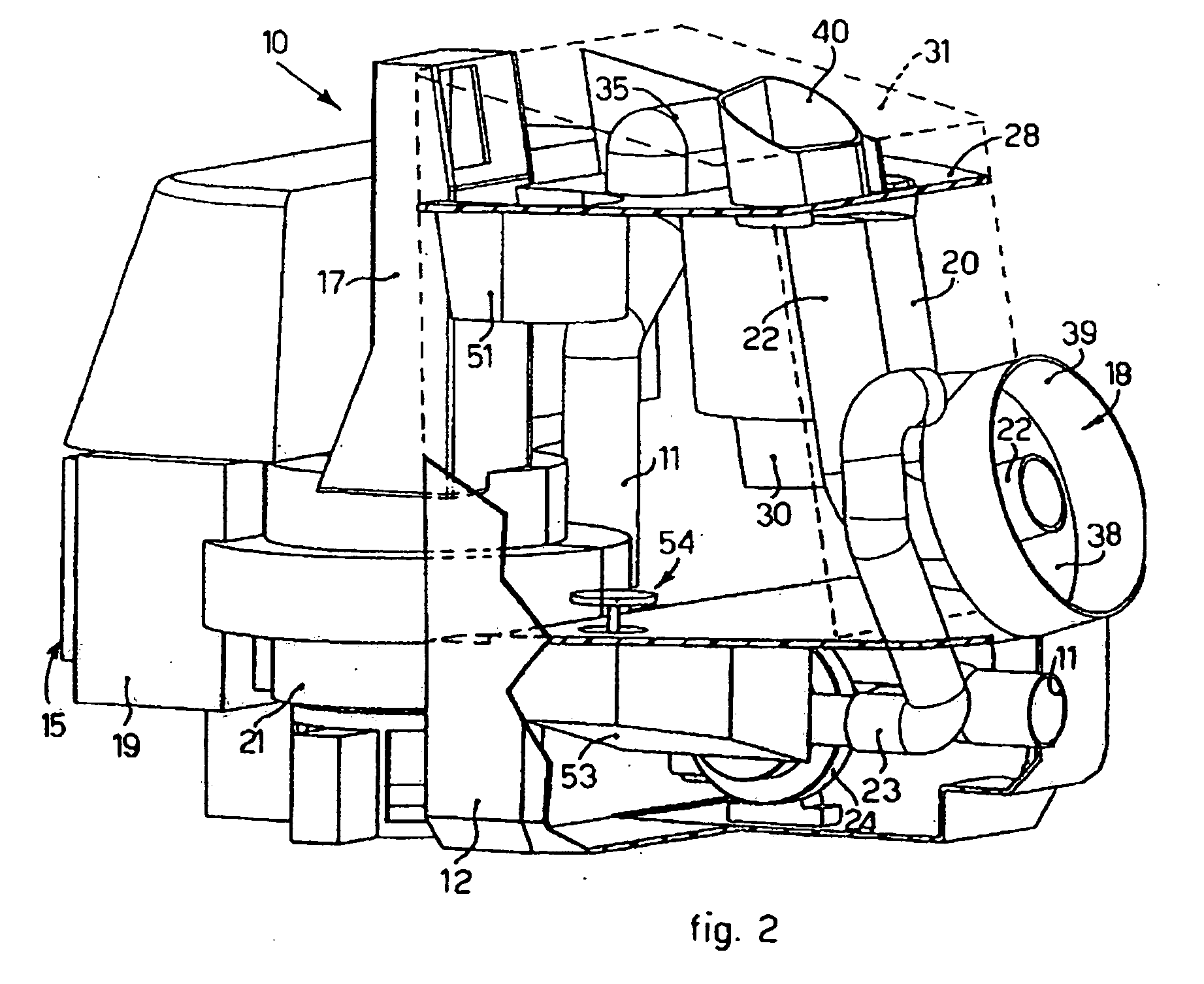

A fuel injection system for GDI internal combustion engines, which has a second injection valve in the intake tube, and a method for operating this fuel injection system. By injecting fuel into the intake tube at intervals by means of the second injection valve, the formation of deposits in the intake tube and on the inlet valve, which are produced due to the recirculation of exhaust gas through the exhaust recirculation tube, can be prevented and possibly existing deposits can be broken down.

Owner:ROBERT BOSCH GMBH

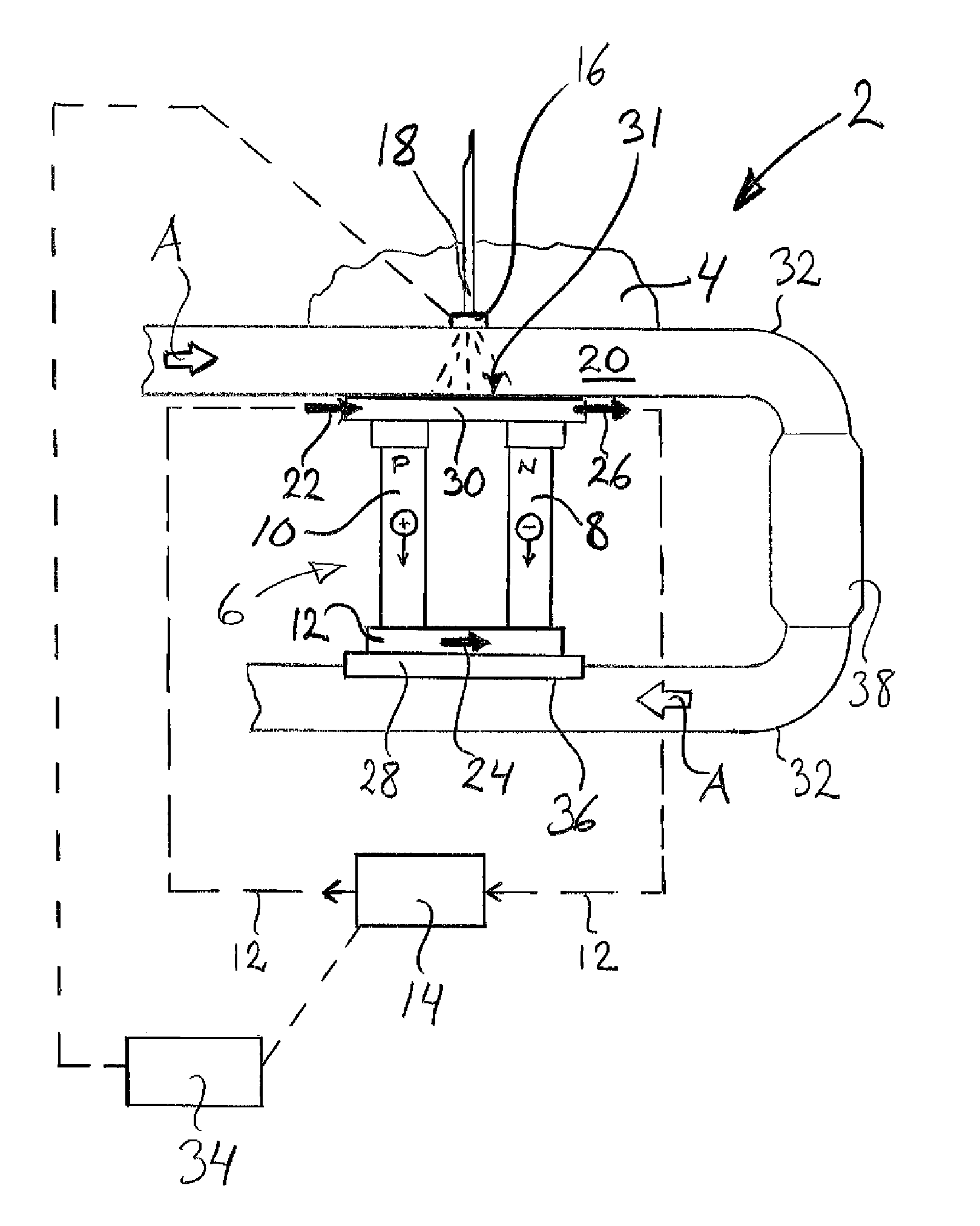

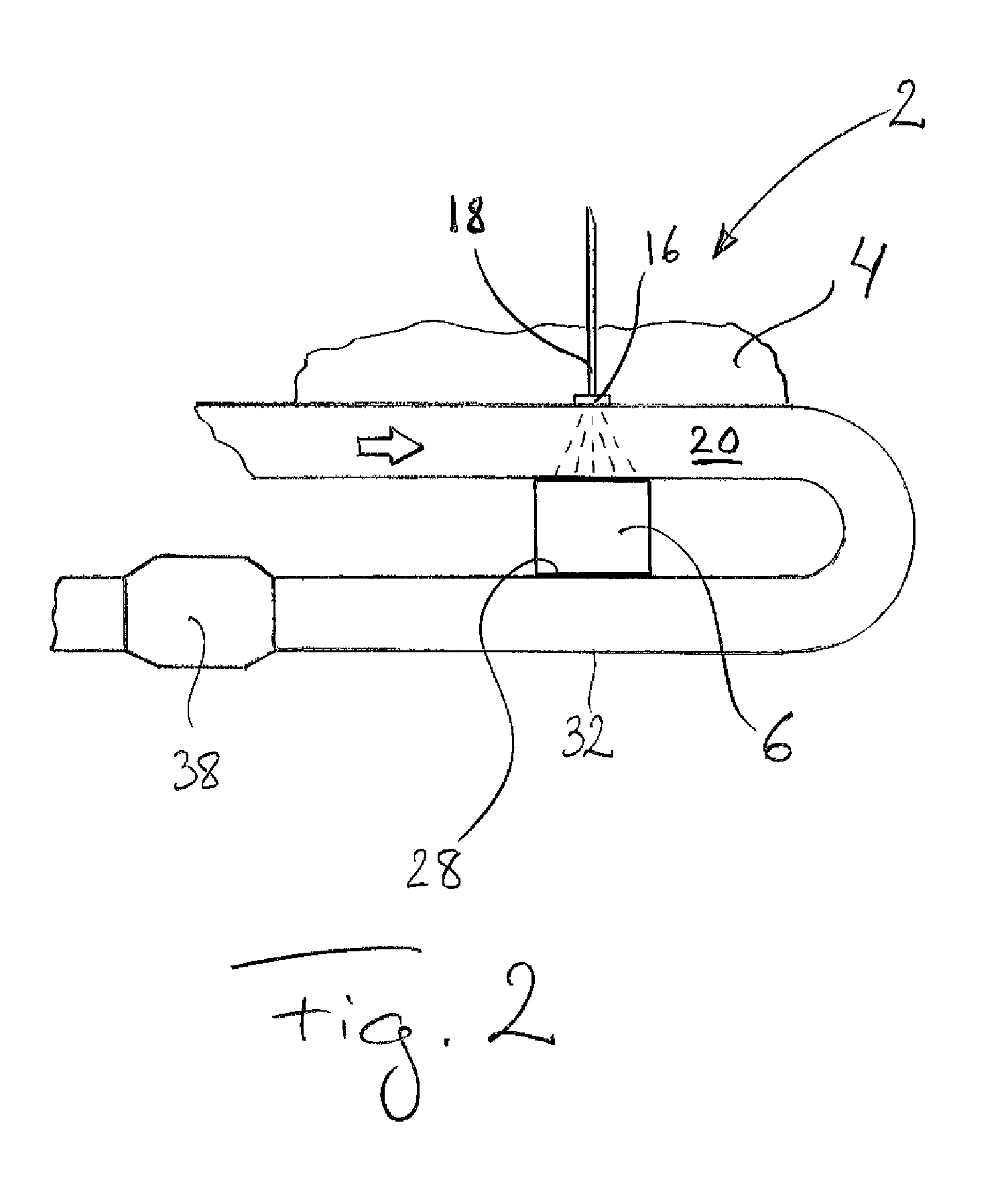

Exhaust post-treatment device and method for a vehicle, with a reductant vaporising surface being warmed by a Peltier element

InactiveUS9062582B2Reduce nitrogen oxides presentReducing nitrogen oxides presentInternal combustion piston enginesExhaust apparatusThermal energyNitrogen oxides

An exhaust post-treatment device (2) for a vehicle (4) for reducing nitrogen oxides present in the exhaust gases (20) of the vehicle (4) by supply of liquid reducing agent (18) to the exhaust gases (20) in an exhaust pipe (32). The device (2) locally warms a surface (31) within the exhaust pipe (32) by a Peltier element (6) by using thermal energy from the exhaust gases (20) to vaporize liquid reducing agent (18) which reaches the surface (31), thereby avoiding the formation of deposits of reducing agent within the exhaust pipe (32). Also a method for post-treatment of exhaust gases from vehicles with an exhaust post-treatment device (2) including a Peltier element (6).

Owner:SCANIA CV AB

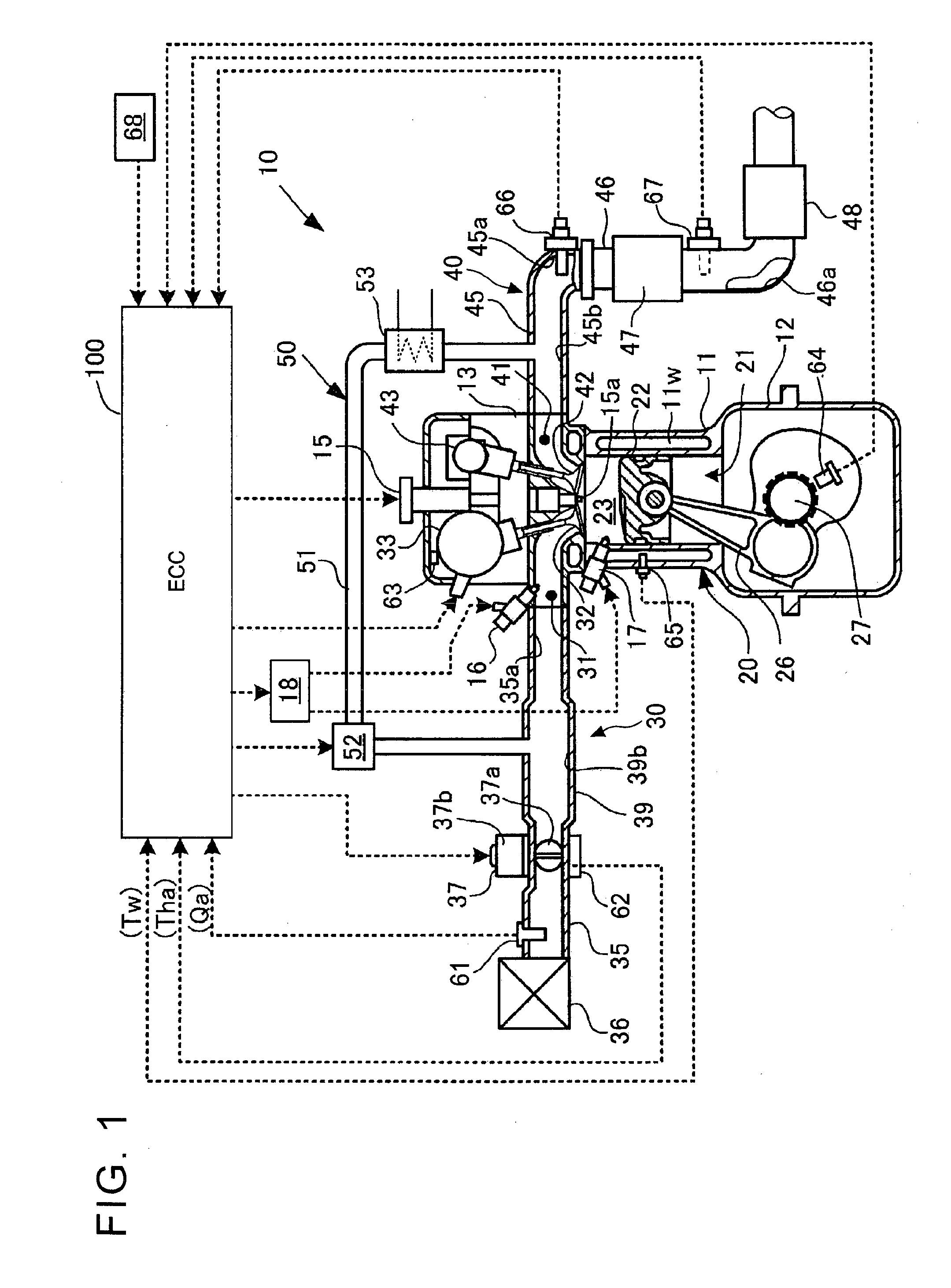

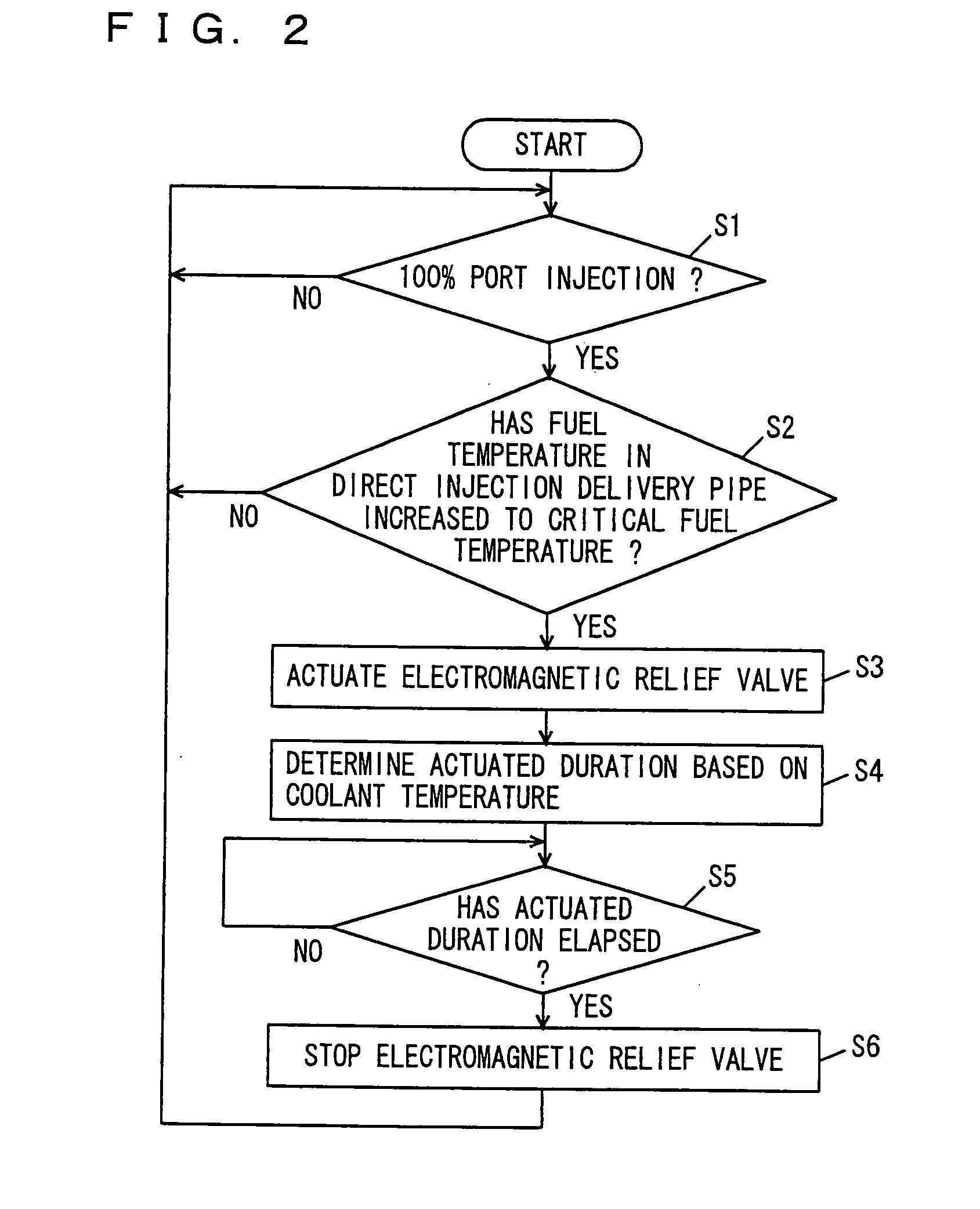

Control device and control method for internal combustion engine

ActiveUS20150267634A1Inhibits the formation of depositsImprove cooling effectElectrical controlInternal combustion piston enginesInjectorEngineering

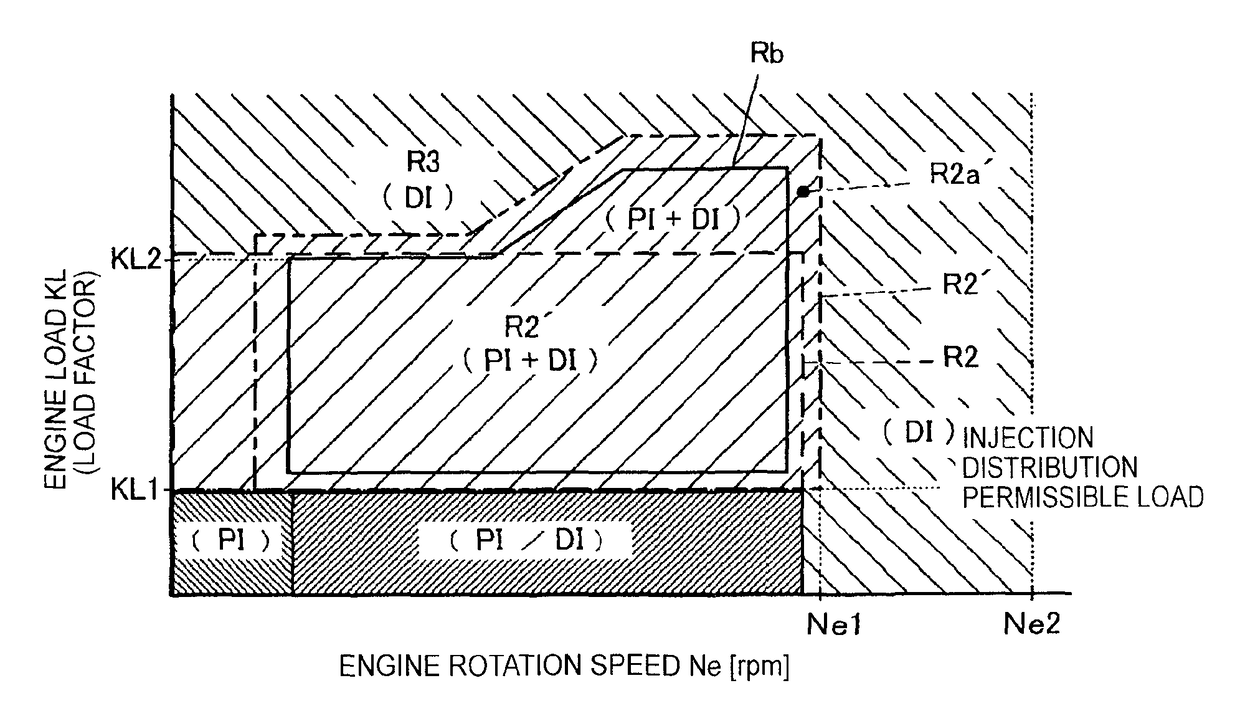

A control device for an internal combustion engine includes: an EGR control unit executing open / close control over an EGR valve on the basis of an operating state of the engine; and a fuel injection control unit carrying out at least one of port injection and in-cylinder direct injection by operating at least one of a port injection injector and an in-cylinder direct injection injector on the basis of the engine operating state. The fuel injection control unit sets an EGR non-operation in-cylinder direct injection region, in which the port injection is stopped and the in-cylinder direct injection is carried out while the EGR valve is closed, within an operation range of the engine, and sets part of an EGR operation port injection permissible region, in which at least the port injection is carried out while the EGR valve is open, within the EGR non-operation in-cylinder direct injection region.

Owner:TOYOTA JIDOSHA KK

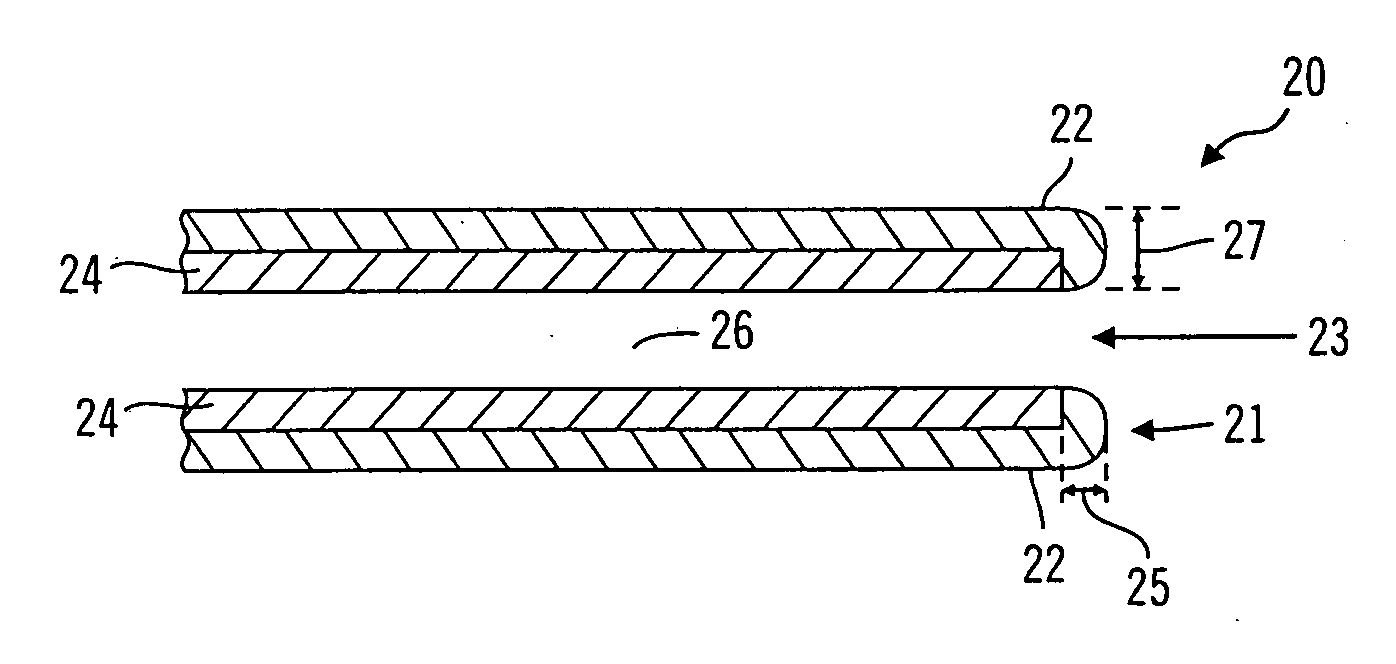

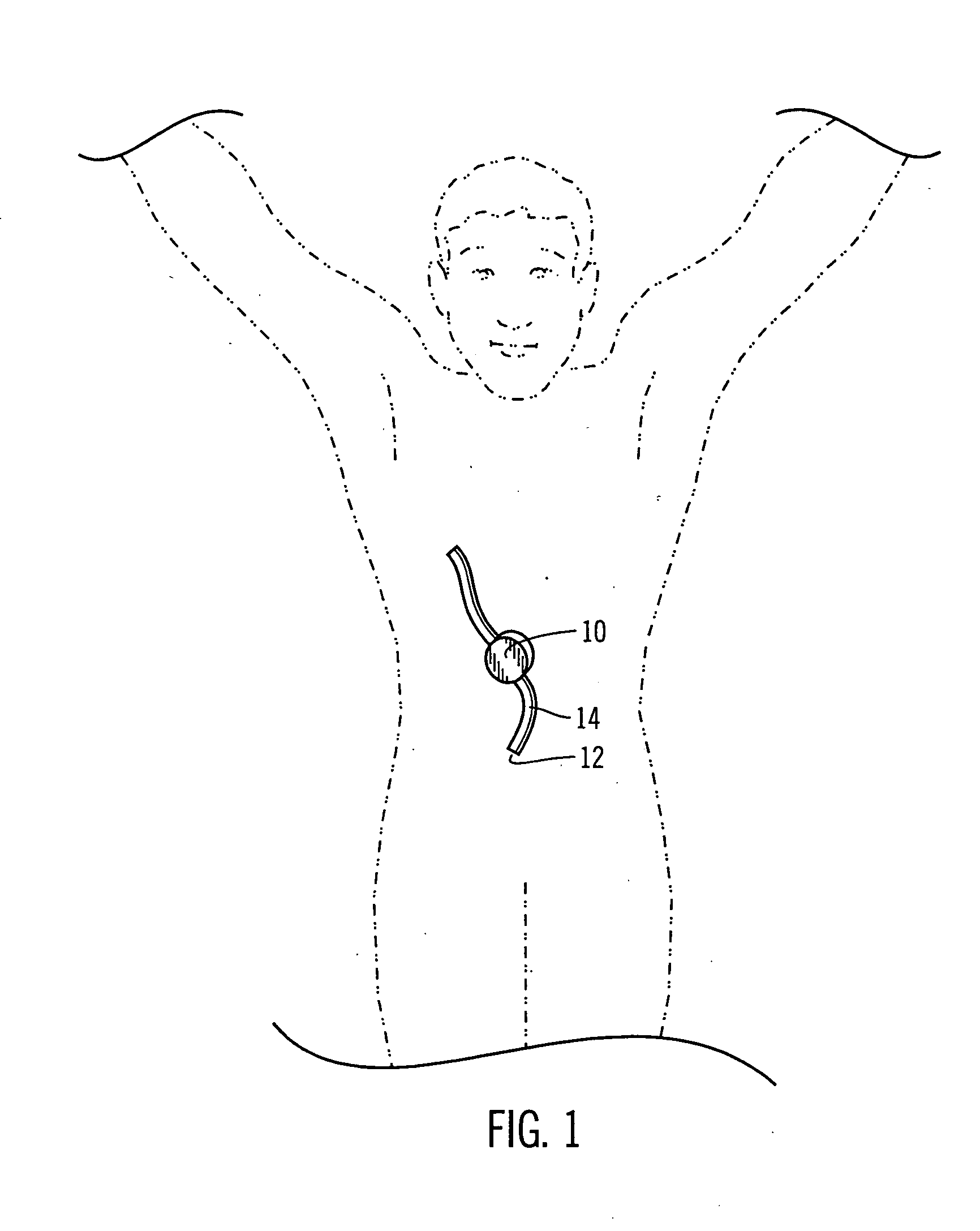

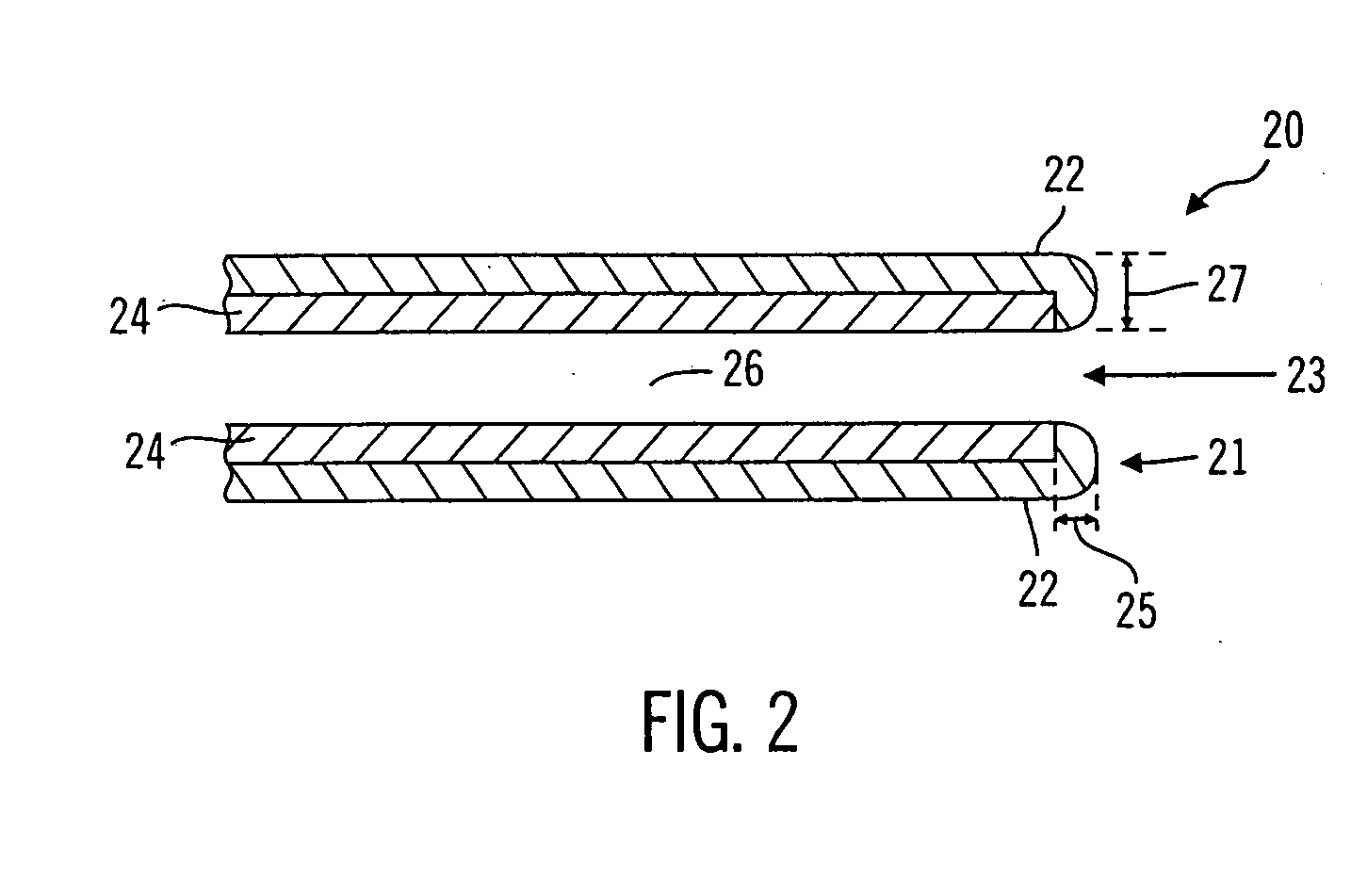

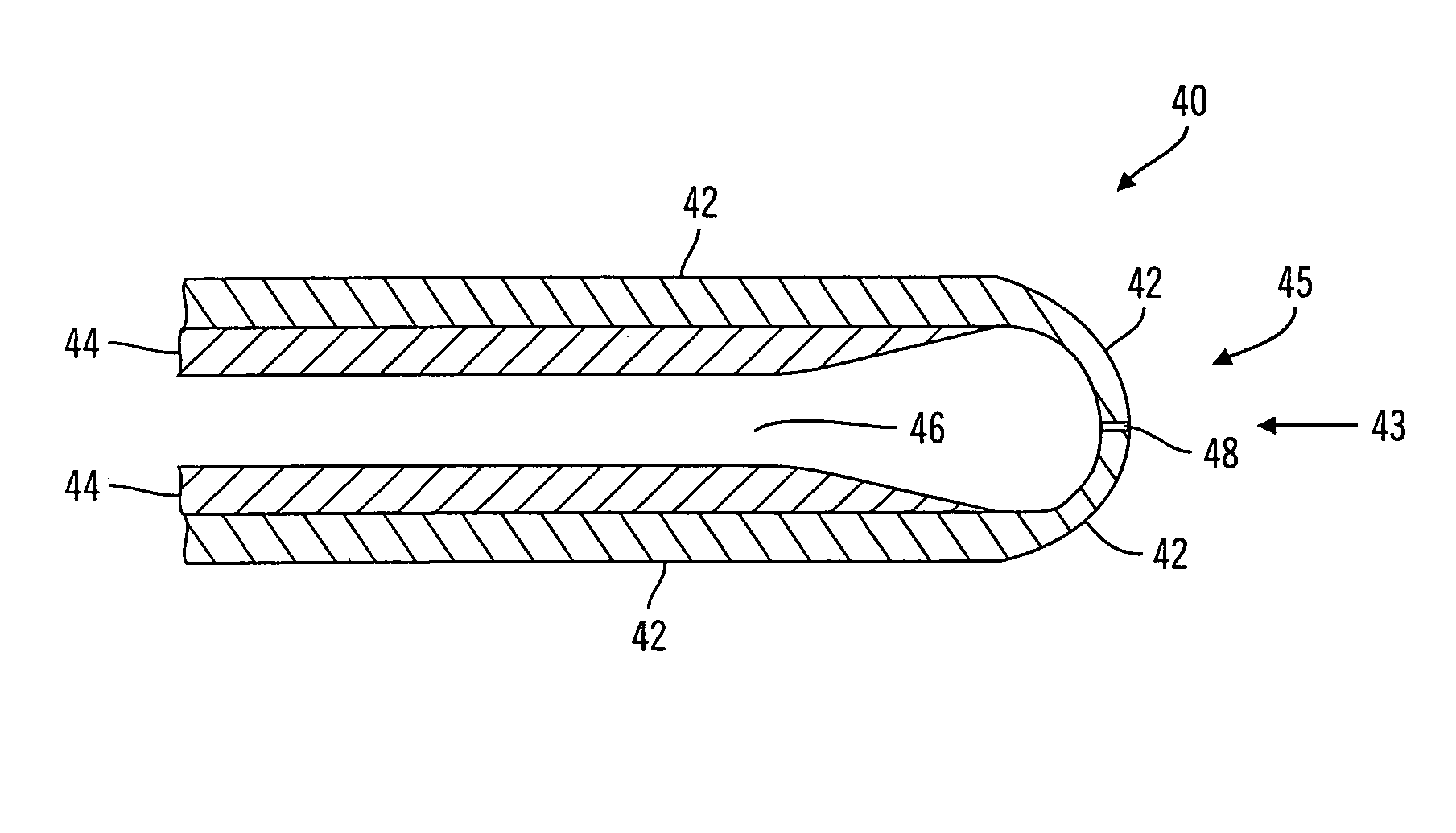

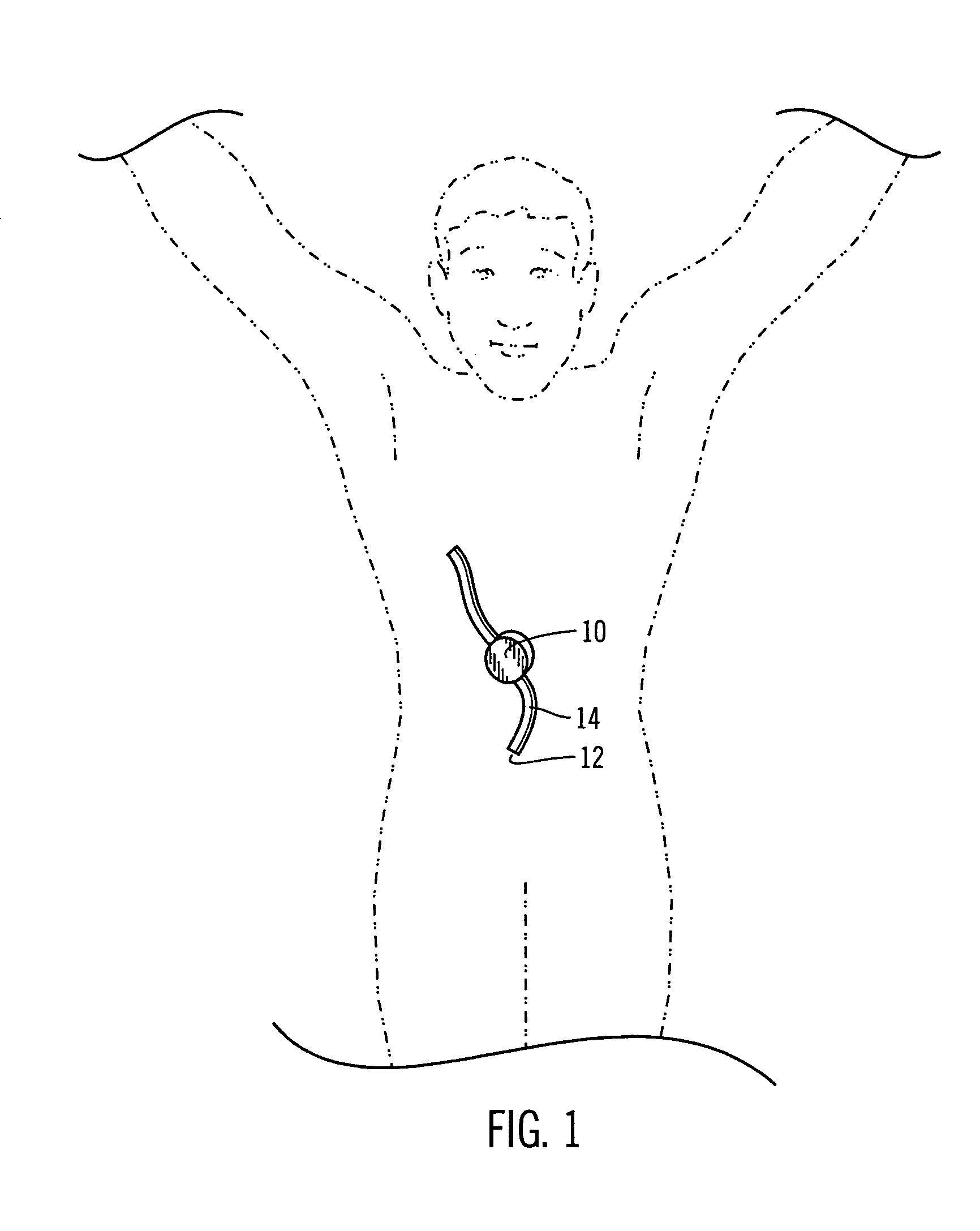

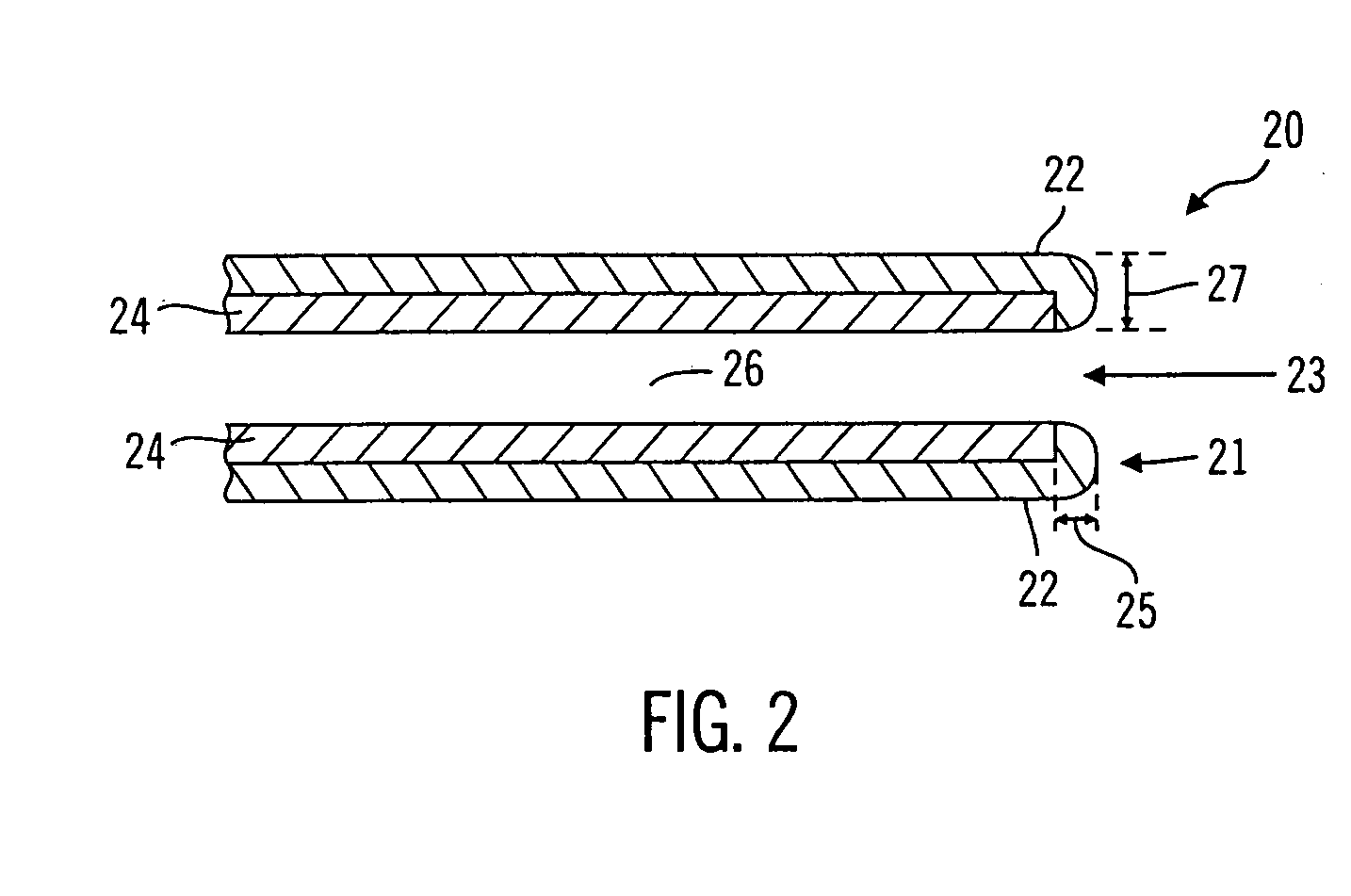

Barrier catheter apparatus and method

ActiveUS20050021001A1Inhibited DiffusionInhibits the formation of depositsSurgeryDilatorsBody fluidRisk stroke

A catheter for use in delivery or withdrawal of a formulation, wherein the catheter has an outer layer comprising a bio-compatible material and a barrier layer comprising a material that provides a more effective barrier than the outer layer against inward and outward diffusion of substances that may cause destabilization of the formulation. The outer surface of the barrier layer contacts at least a portion of the inner surface of the outer layer. The catheter may include a flared distal end tip to aid in the release, during a bolus delivery or catheter flush, of any obstruction situated at the distal end tip of the catheter. The larger cross-sectional area at the flared distal end tip minimizes the chances that any obstruction that develops at the distal end tip will be sufficient to hinder the flow of the formulation within the lumen of the catheter. The catheter may also include a slit valve at the distal end tip which has one or more and, preferably a plurality of slits that may be elastically extended to an open position by the expulsion of the formulation during an IIP pump stroke. During the interval between IIP pump strokes, the slits return to a closed position and hinder the inflow of body fluid into the distal end tip.

Owner:MEDTRONIC MIMIMED INC

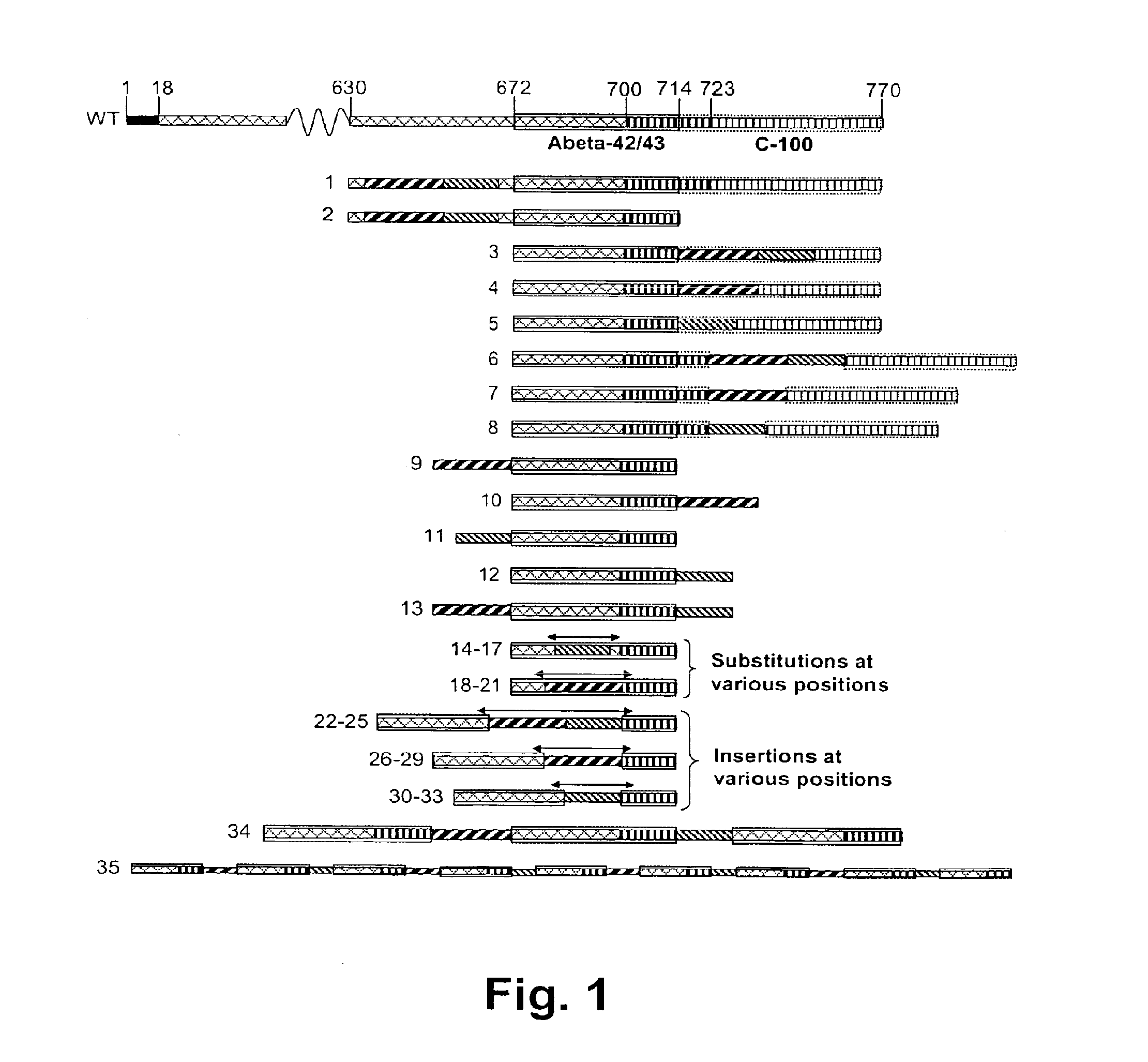

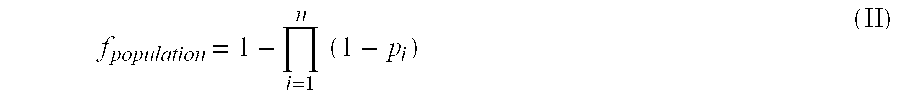

Novel method for down-regulation of amyloid

InactiveUS20070041945A1Strong immune responseInhibits the formation of depositsFungiBacteriaAntiendomysial antibodiesIn vivo

A method for in vivo down-regulation of amyloid protein in an animal, including a human being, the method comprising effecting presentation to the animal's immune system of an immunogenically effective amount of at least one amyloidogenic polypeptide or subsequence thereof which has been formulated so that immunization of the animal with the amyloidgenic polypeptide or subsequence thereof induces production of antibodies against the amyloidogenic polypeptide, and / or at least one analogue of the amyloidogenic polypeptide wherein is introduced at least one modification in the amino acid sequence of the amyloidogenic polypeptide which has as a result the immunization of the animal with the analogue induces production of antibodies against the amyloidogenic polypeptide.

Owner:H LUNDBECK AS

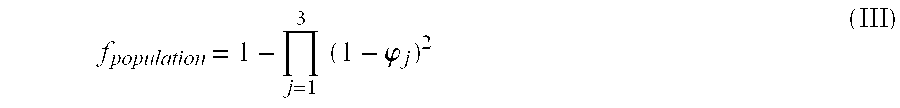

Method of purifying exhaust gas of an internal combustion engine

InactiveUS7047726B2Reduce consumptionReduce the numberElectrical controlNon-fuel substance addition to fuelExternal combustion engineSulfur

A NOx occluding and reducing catalyst 20 is provided in an exhaust gas passage of an engine to occlude the NOx in the exhaust gas of a lean air-fuel ratio. The engine is provided with an injector for directly injecting the fuel into the combustion chamber, and the fuel fed by a fuel pump into a common rail with pressure is injected. The additive containing a sulfur-solidifying agent that forms a solid sulfate upon the reaction with sulfur in the fuel due to combustion, is injected into the common rail from a tank due to a pump, and is supplied into the combustion chamber through the injector together with the fuel. When the condition of the atmosphere of the NOx occluding and reducing catalyst is the one where the NOx in the exhaust gas is little absorbed, the ECU adjusts the discharge amount of the pump, and decreases the amount of the additive injected into the common rail or interrupts the injection. This decreases the consumption of the sulfur-solidifying agent.

Owner:TOYOTA JIDOSHA KK

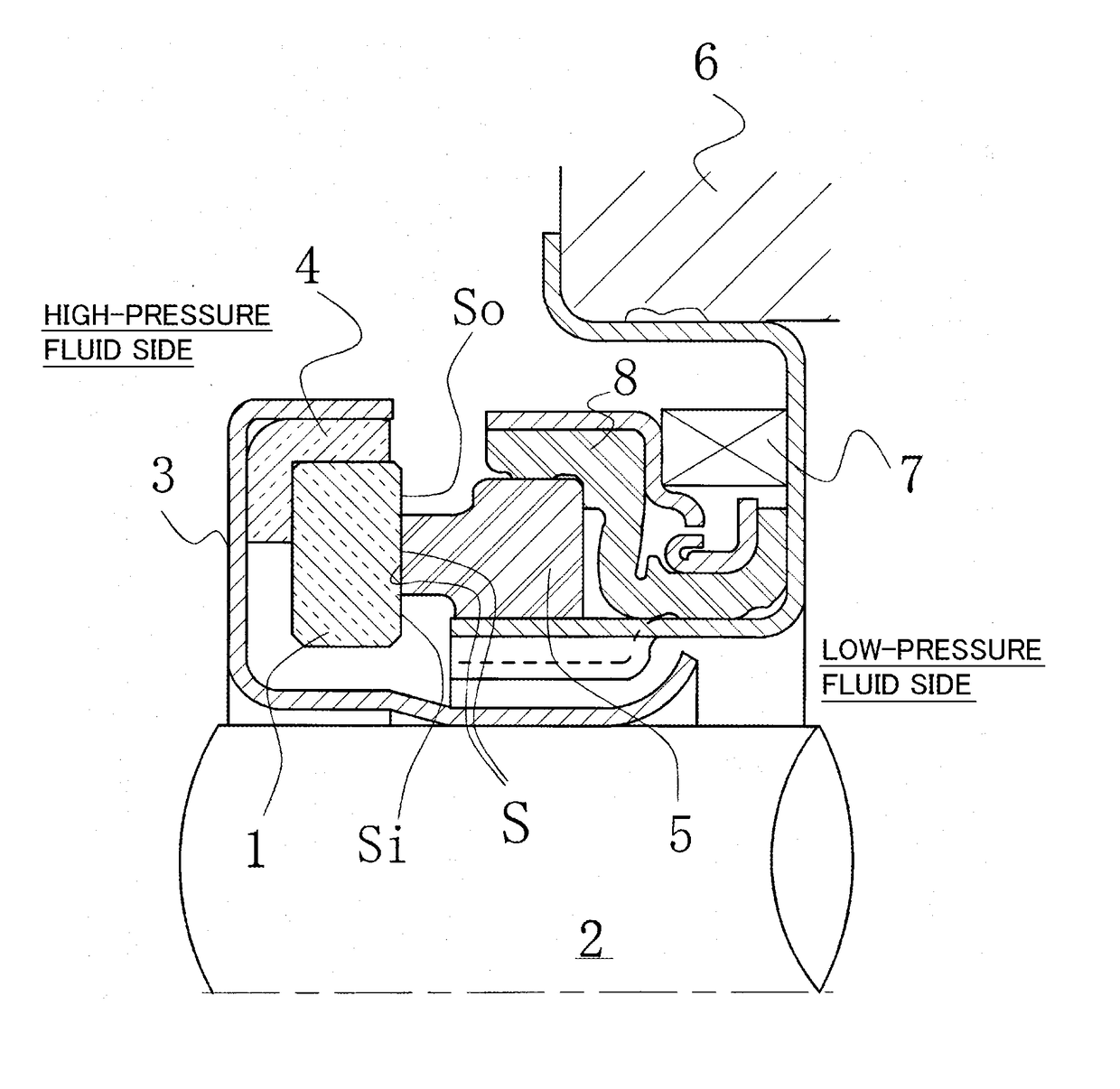

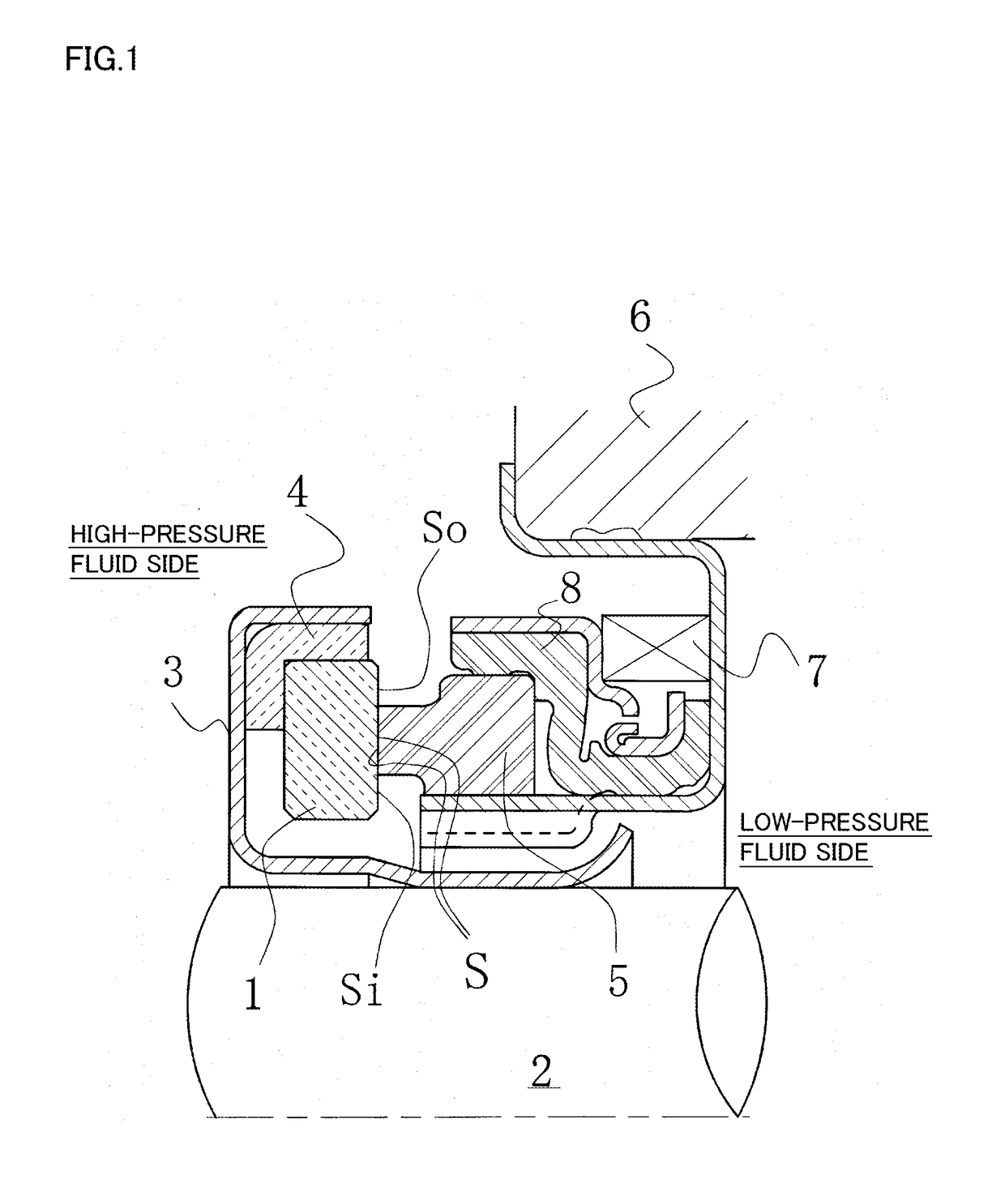

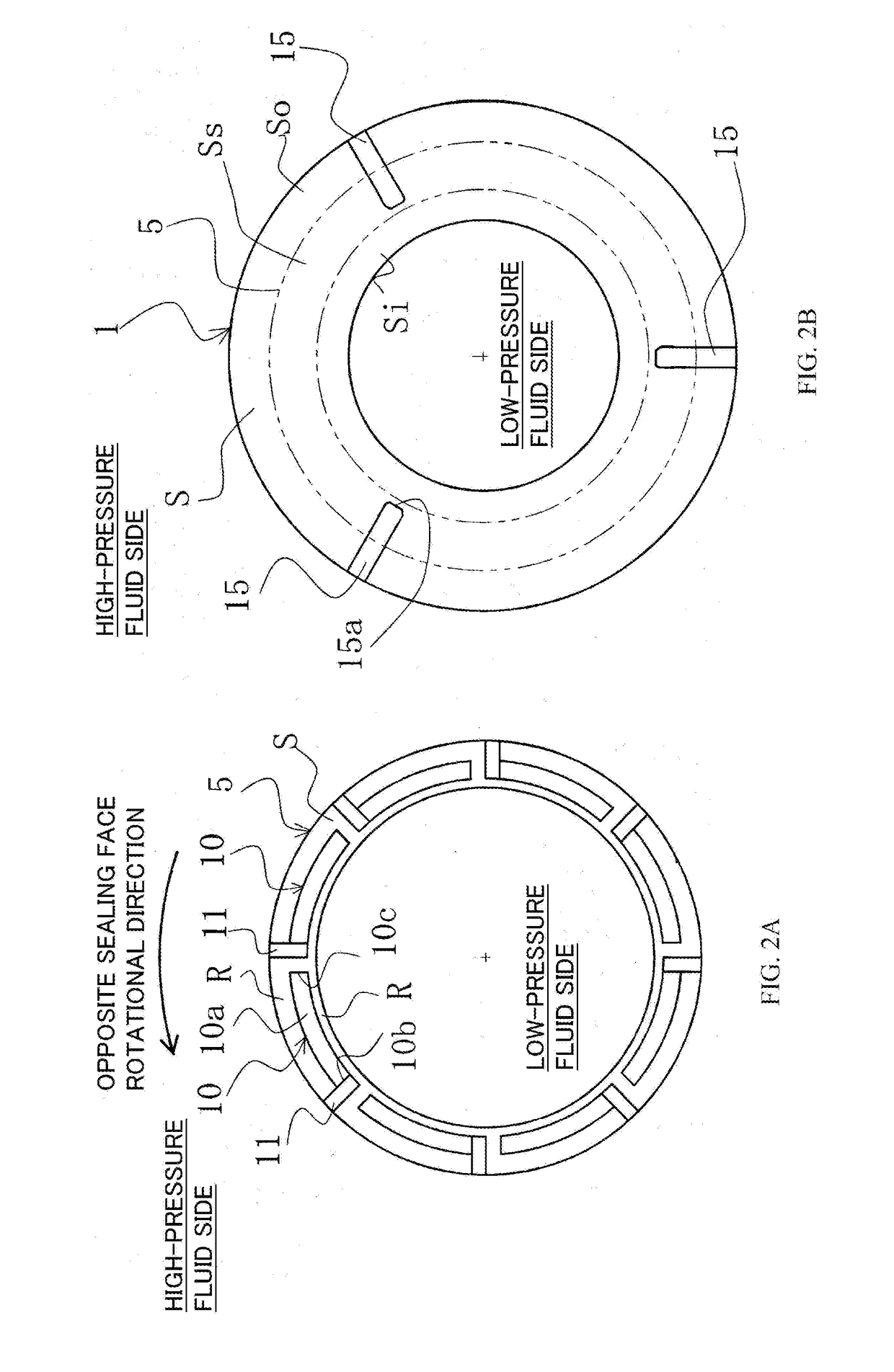

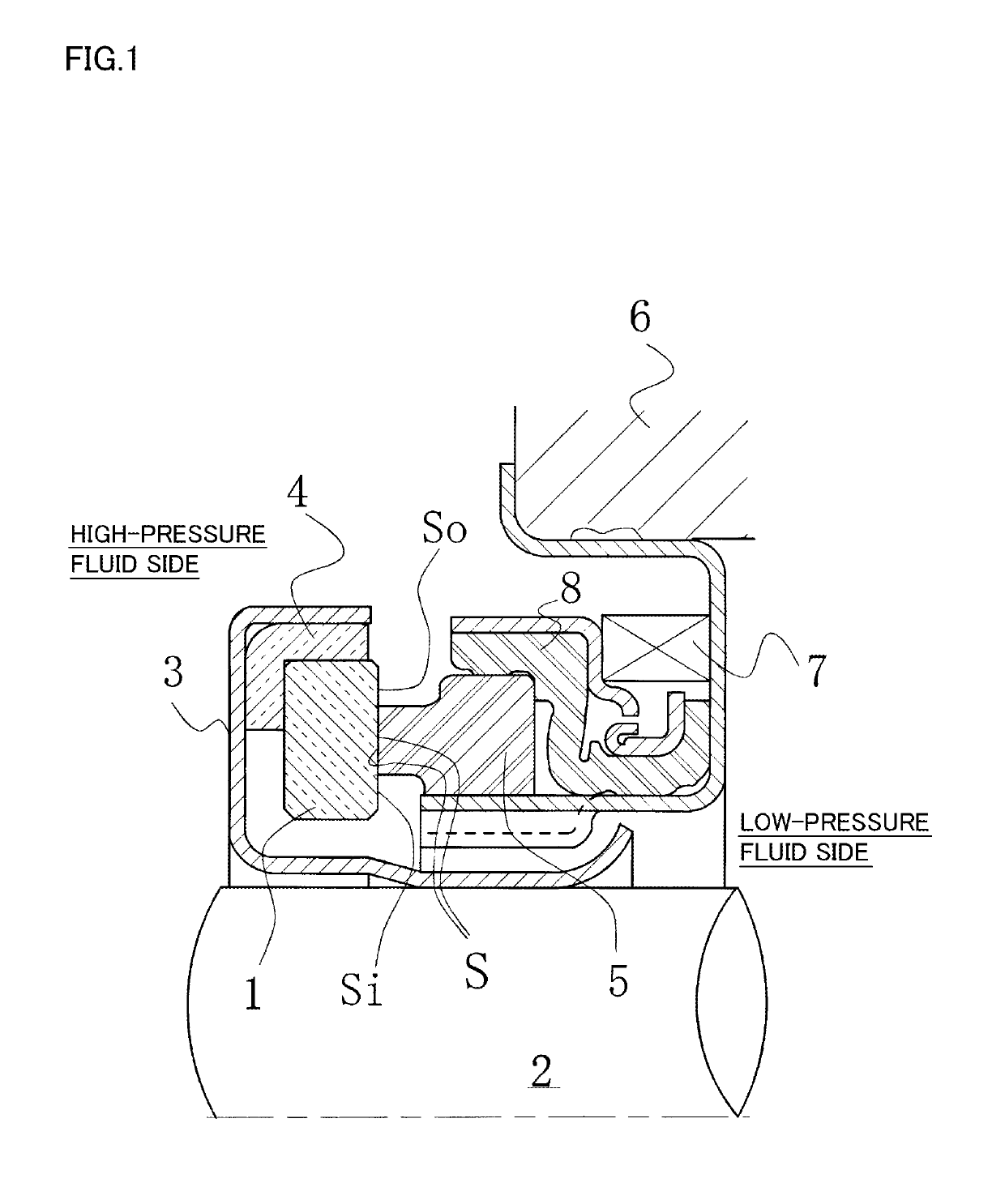

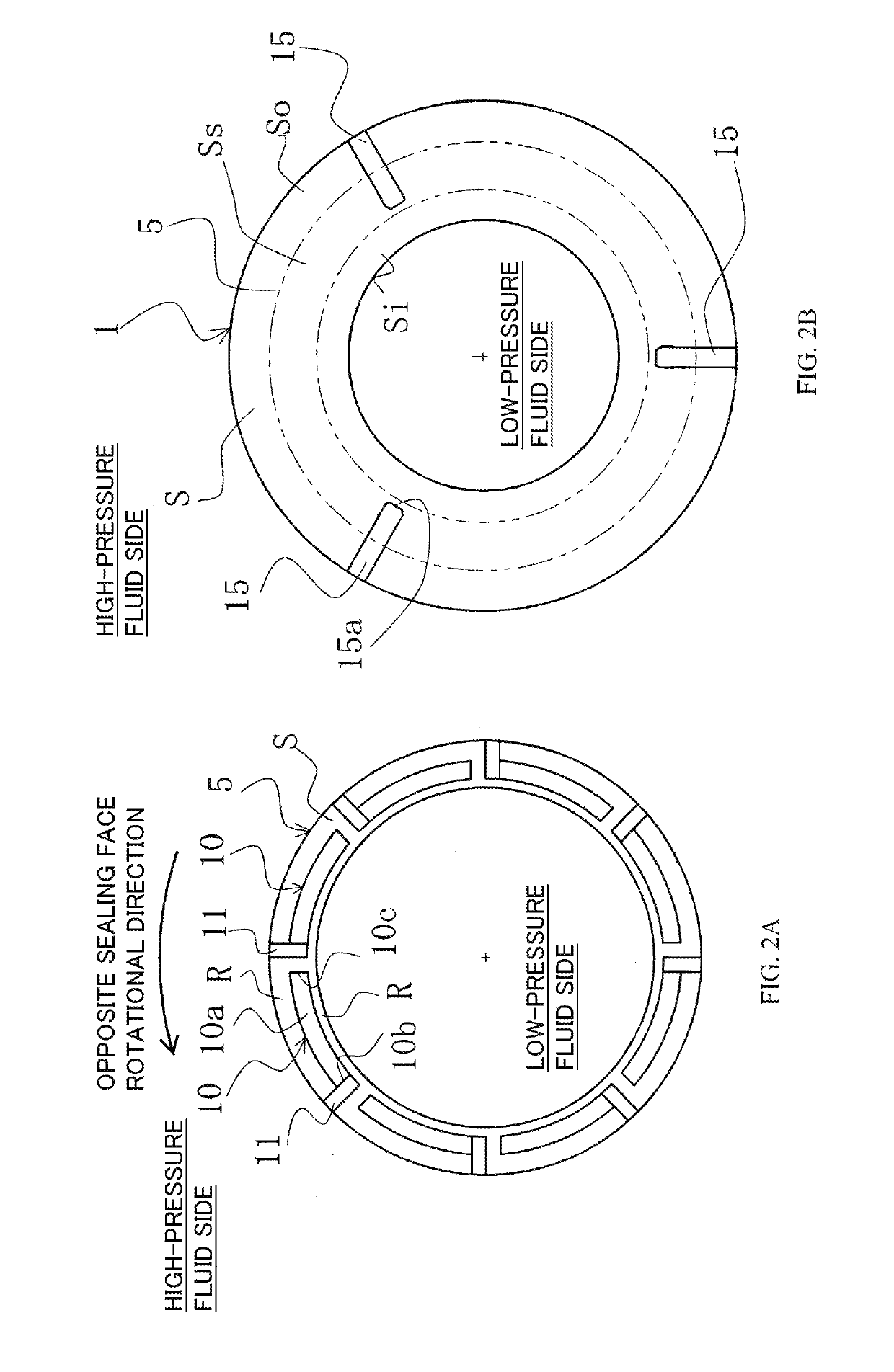

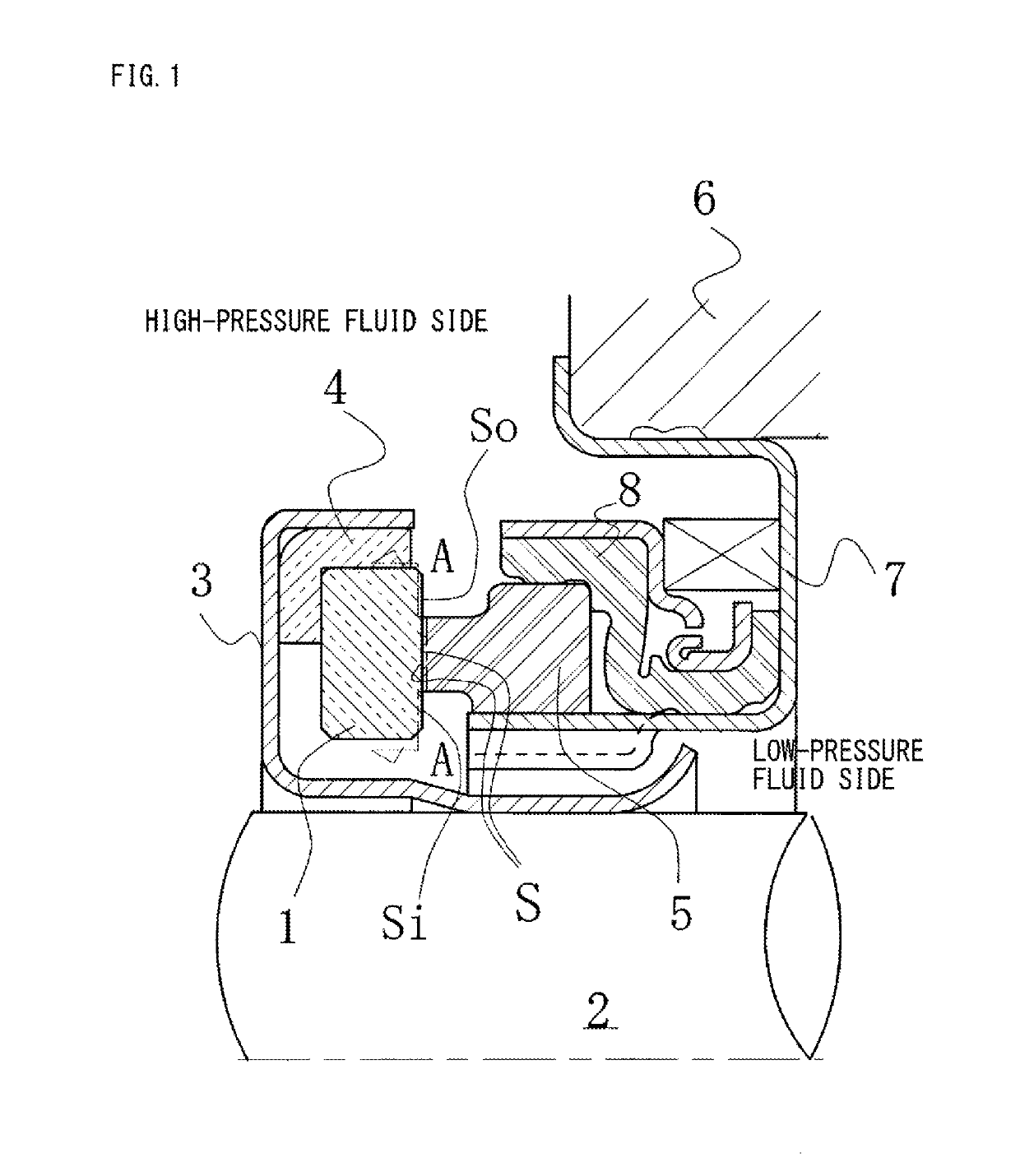

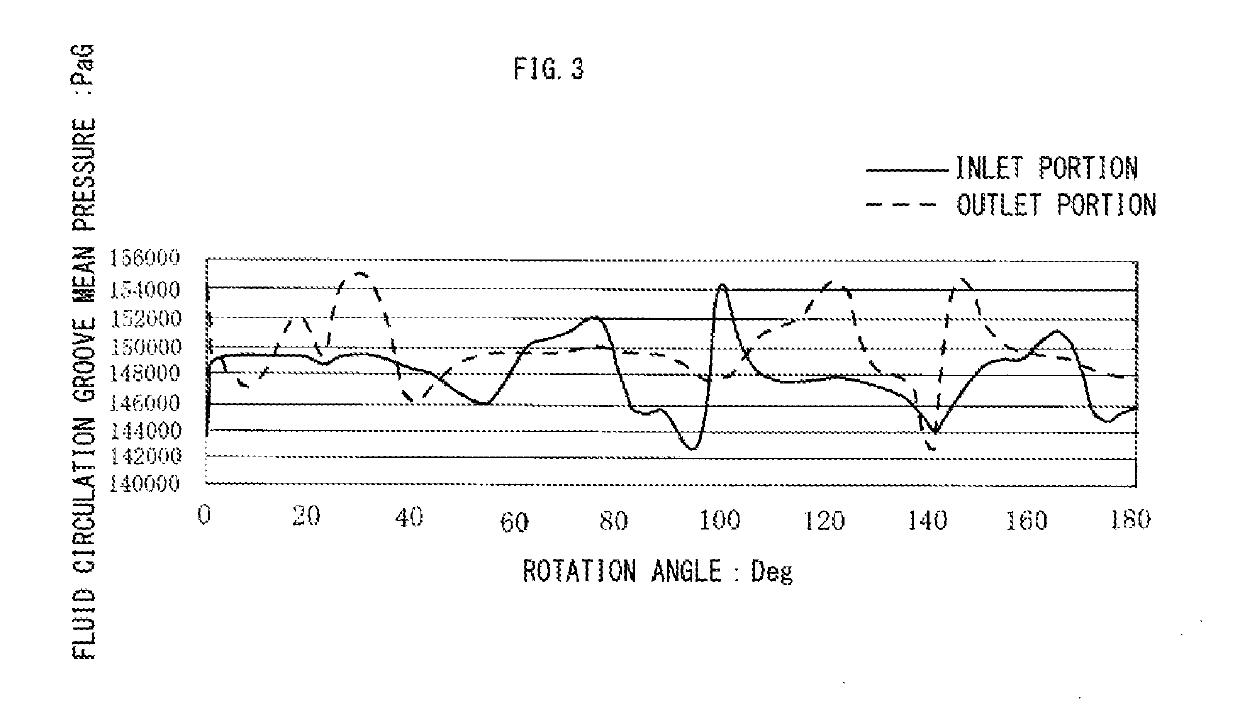

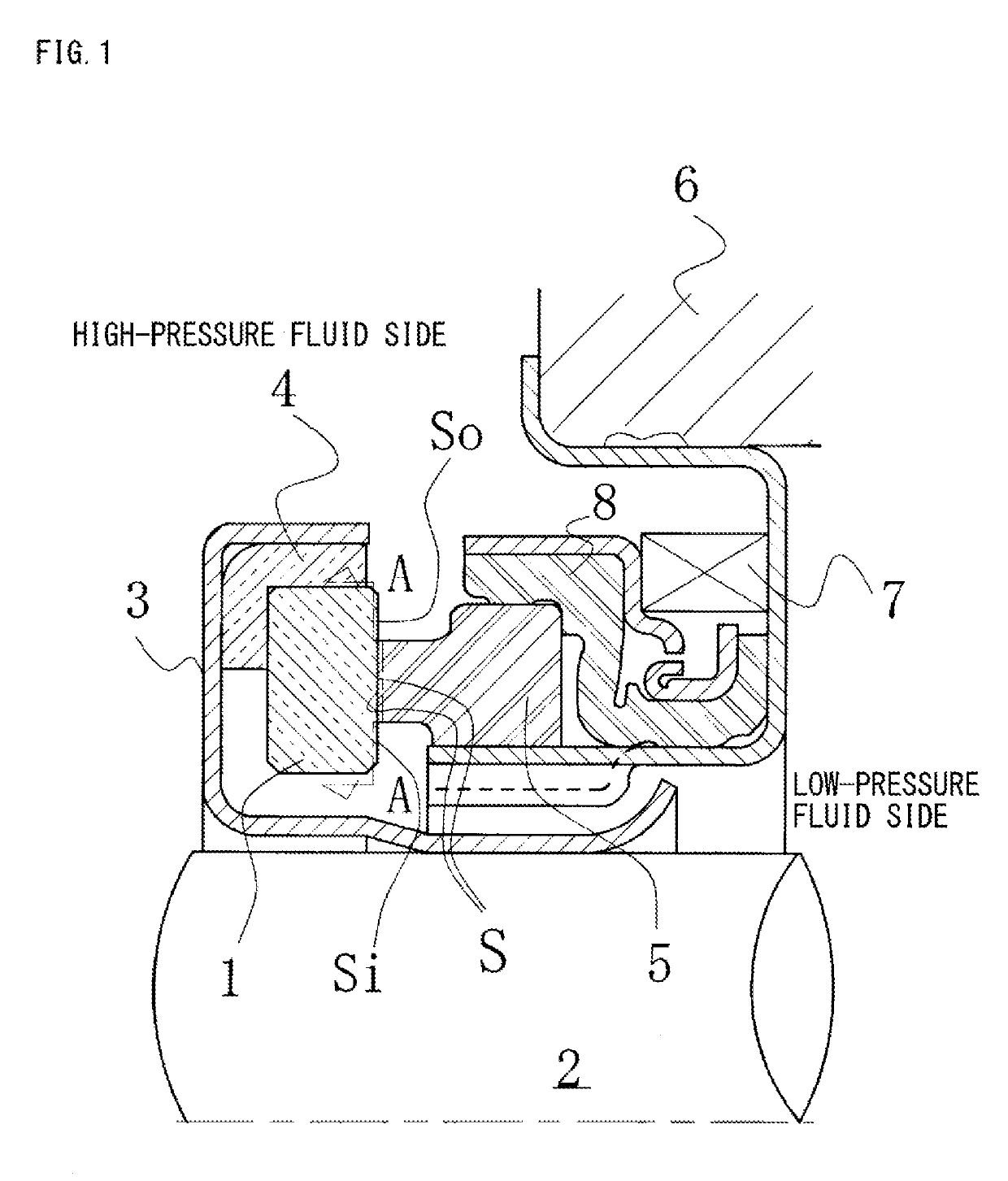

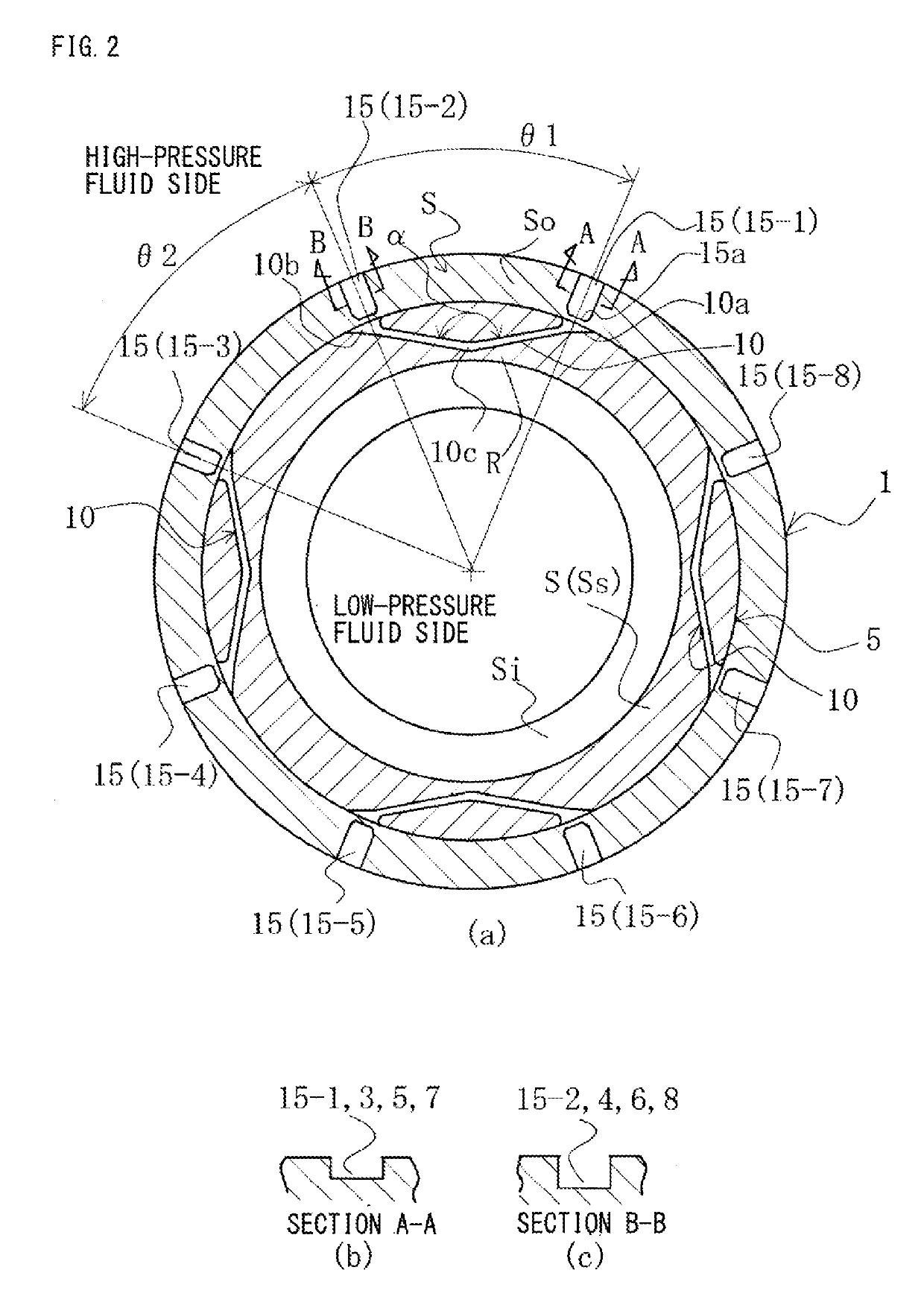

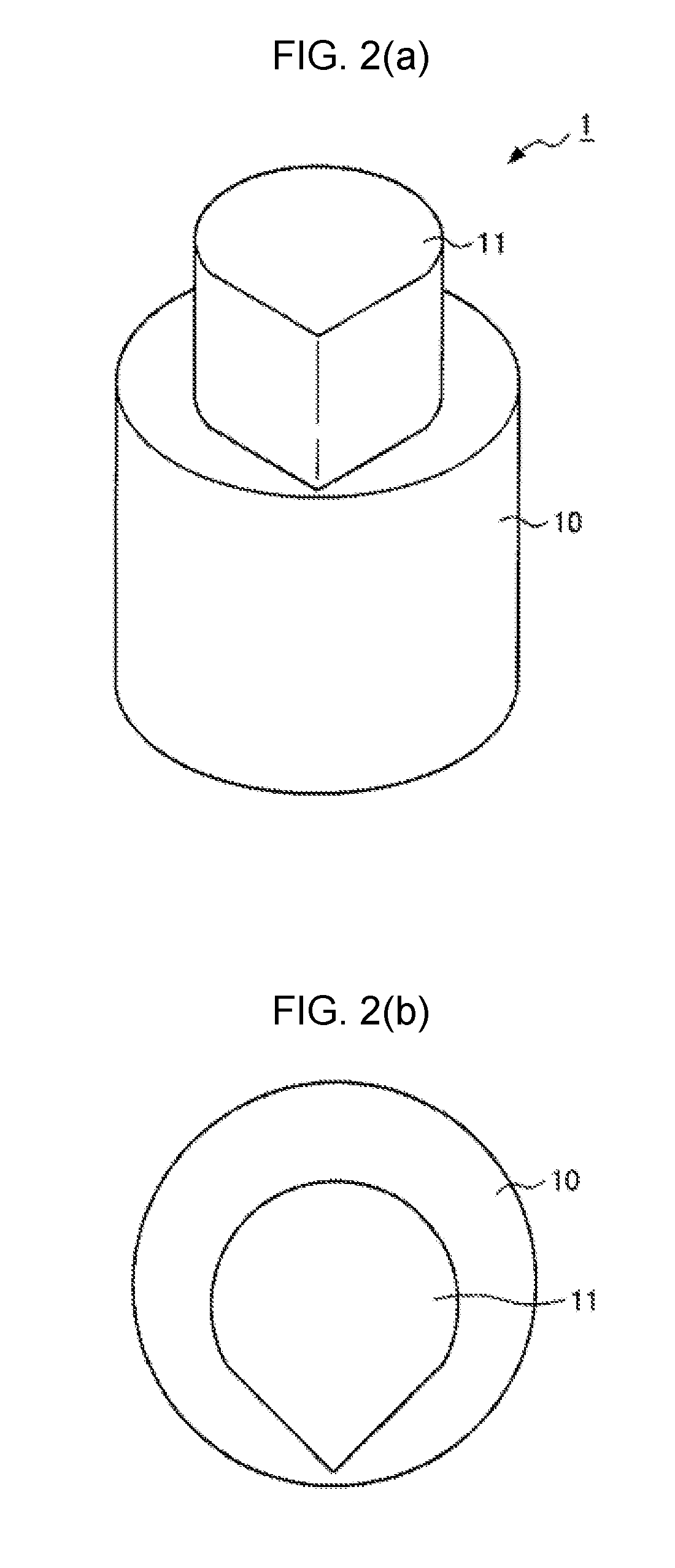

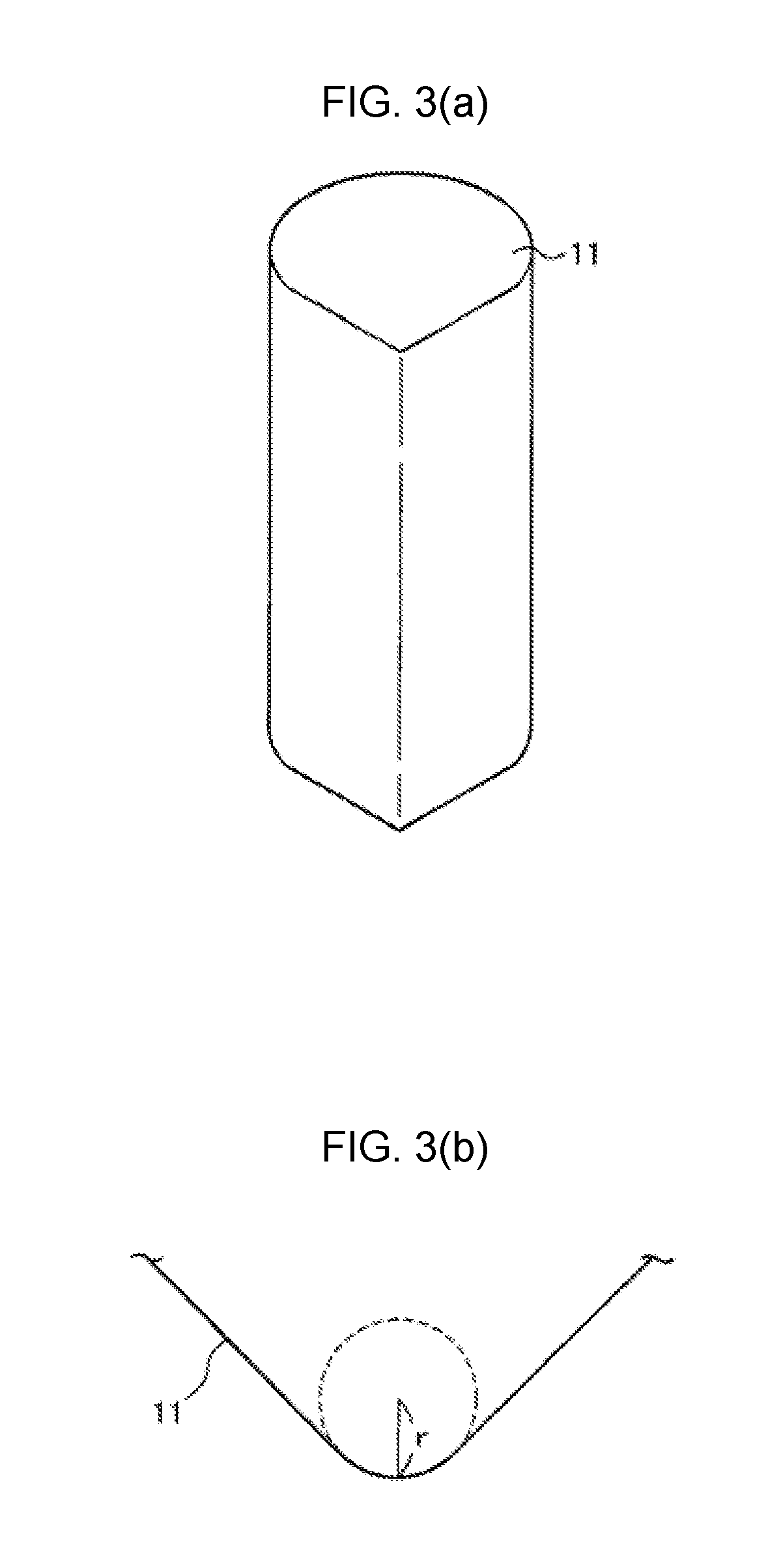

Slide component

ActiveUS20170241549A1Inhibits the formation of depositsInhibition formationEngine sealsPressure generationEngineering

In an embodiment, a slide component includes one slide part 5 provided, on a low-pressure side of a sealing face thereof, with a negative pressure generation mechanism 10 including a negative pressure generation groove 10. The negative pressure generation groove 10a communicates with a high-pressure fluid side and is separated from a low-pressure fluid side by a land portion R. Another slide part 1 is provided, in a sealing face thereof, with at least one interference groove 15 communicating with the high-pressure fluid side for producing pressure variations in a fluid in the negative pressure generation groove 10a. The at least one interference groove 15 has an end 15a on an inside-diameter side extending to a position to radially overlap the negative pressure generation groove 10a.

Owner:EAGLE INDS

Fuel supply apparatus for internal combustion engine

InactiveUS20070261674A1Suppress mutationImprove the state of combustionElectrical controlInternal combustion piston enginesHigh pressureCoolant temperature

The engine ECU executes a program including the step of detecting an engine coolant temperature, the step of detecting an engine speed and an engine load, the step of estimating a temperature at a tip end of an in-cylinder injector based on the engine coolant temperature, the engine speed and the engine load, and, when the temperature at the tip end is greater than a guaranteed temperature, the step of calculating a drive duty of a high-pressure fuel pump that ensures a decrease of the temperature at the tip end of the in-cylinder injector to the guaranteed temperature, and the step of controlling the high-pressure fuel pump using the drive duty.

Owner:TOYOTA JIDOSHA KK

Suction and filtering apparatus

InactiveUS20050115411A1Inhibition formationPromote absorptionCombination devicesSuction filtersMixing chamberWaste management

Air suction and filtering apparatus, comprising a dry filter (14) and a liquid bath filter (16), connected together in series, and suction means (21) able to create a flow of air between an inlet pipe (11), through the dry filter (14) and the liquid bath filter (16), and an outlet aperture (15), arranged downstream of the liquid bath filter (16). Between the dry filter (14) and the liquid bath filter (16) a mixing chamber (18) is arranged, independent of the two filters (14, 16), into which the air arriving from the dry filter (14) is able to be conveyed. The apparatus comprises a water introduction pipe (23), which is connected to the mixing chamber (18) in order to introduce water therein and obtain, in the mixing chamber (18), an air-water mixture able to be conveyed into the liquid bath filter (16).

Owner:DE LONGHI SPA

Control device and control method for internal combustion engine

ActiveUS9670866B2Inhibits the formation of depositsImprove cooling effectElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

A control device for an internal combustion engine includes: an EGR control unit executing open / close control over an EGR valve on the basis of an operating state of the engine; and a fuel injection control unit carrying out at least one of port injection and in-cylinder direct injection by operating at least one of a port injection injector and an in-cylinder direct injection injector on the basis of the engine operating state. The fuel injection control unit sets an EGR non-operation in-cylinder direct injection region, in which the port injection is stopped and the in-cylinder direct injection is carried out while the EGR valve is closed, within an operation range of the engine, and sets part of an EGR operation port injection permissible region, in which at least the port injection is carried out while the EGR valve is open, within the EGR non-operation in-cylinder direct injection region.

Owner:TOYOTA JIDOSHA KK

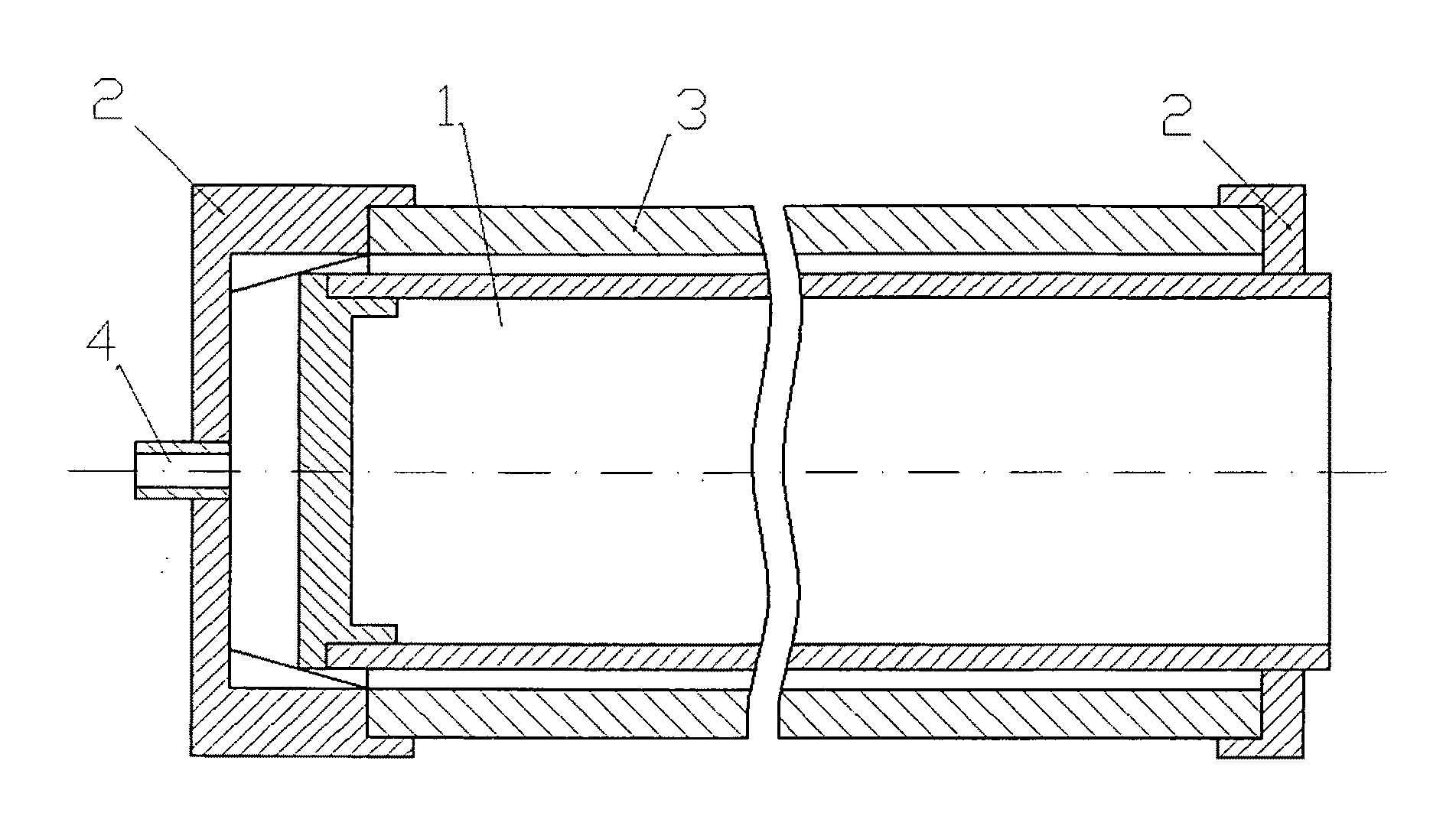

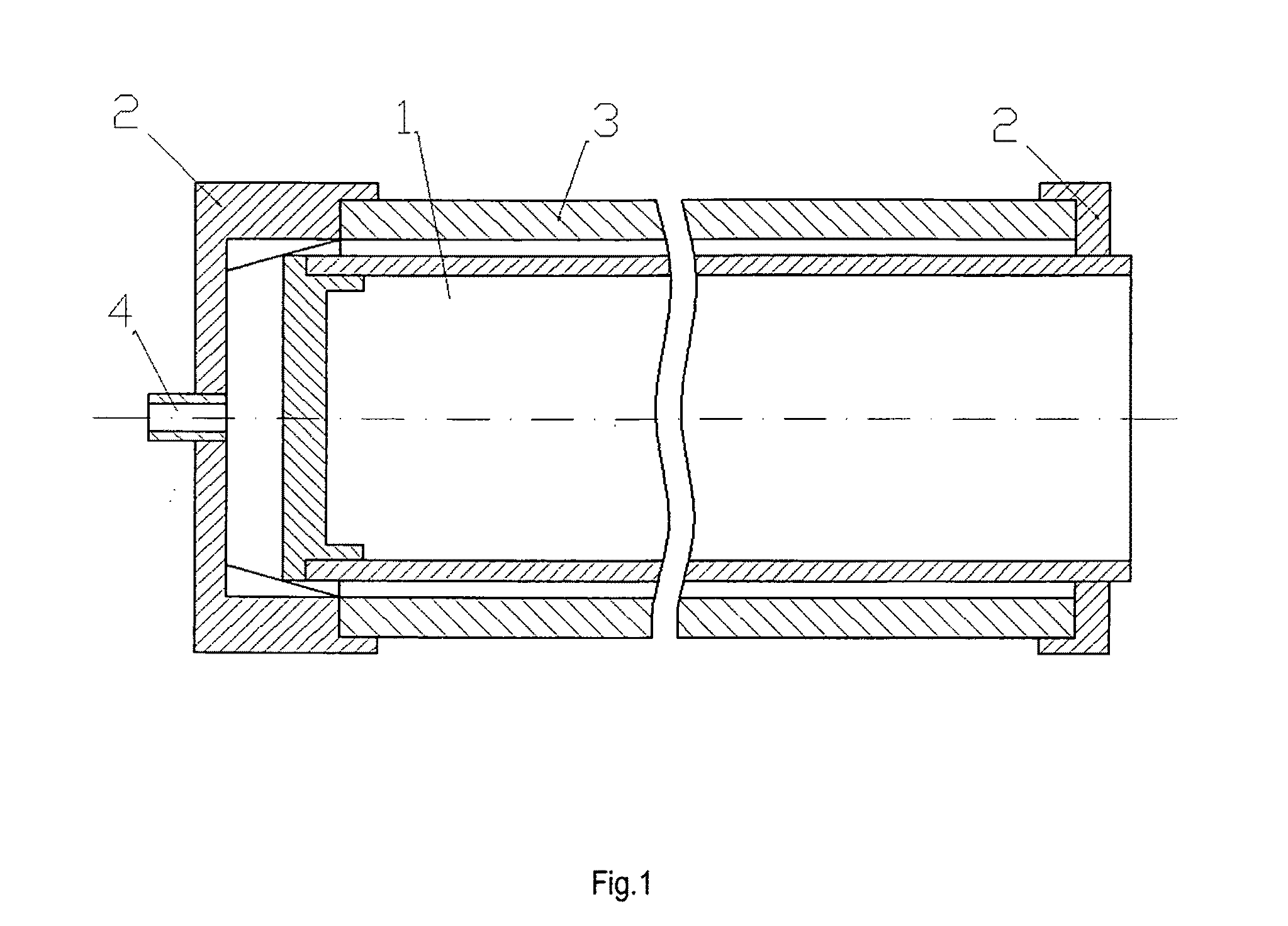

Tubing with an inner coating protecting it against deposits and a method for applying said coating

InactiveUS20100233365A1Inhibits the formation of depositsEasy to useLiquid surface applicatorsDrilling rodsInterior spaceEngineering

A method for applying a coating to a tubing is provided, wherein the tubing includes inner walls and end faces. A plug, having outer walls, is inserted into the tubing, so that the longitudinal axes of the plug and tubing coincide and internal space is provided between the inner and the outer walls. The inner walls are preferably heated up. Polyurethane is pumped into the internal space until it's filled up. Polyurethane is held to the full cure thereof. The plug is then extracted from the tubing, thereby producing the coating. The outer walls are preferably lubricated. Optionally, a reinforcement tube is inserted into the tubing. The tube is configured as a web made of perforated metal, and has a diameter equal to the inner diameter of tubing. Two mandrels are provided, so configured that can centering the plug during the insertion, and are fitted onto the end faces.

Owner:GAJSIN MALIK FAVZAVIERICH +2

Barrier catheter apparatus and method

ActiveUS7875008B2Inhibited DiffusionInhibits the formation of depositsCatheterPressure infusionCatheterBody fluid

Owner:MEDTRONIC MIMIMED INC

Slide component

ActiveUS10443737B2Inhibits the formation of depositsInhibition formationEngine sealsPressure generationEngineering

In an embodiment, a slide component includes one slide part 5 provided, on a low-pressure side of a sealing face thereof, with a negative pressure generation mechanism 10 including a negative pressure generation groove 10. The negative pressure generation groove 10a communicates with a high-pressure fluid side and is separated from a low-pressure fluid side by a land portion R. Another slide part 1 is provided, in a sealing face thereof, with at least one interference groove 15 communicating with the high-pressure fluid side for producing pressure variations in a fluid in the negative pressure generation groove 10a. The at least one interference groove 15 has an end 15a on an inside-diameter side extending to a position to radially overlap the negative pressure generation groove 10a.

Owner:EAGLE INDS

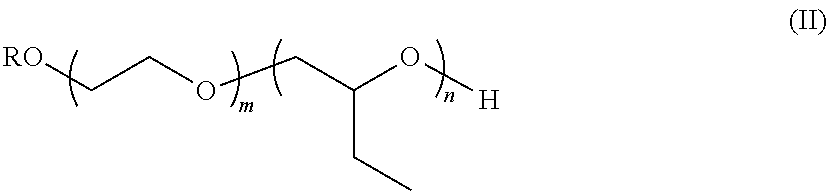

Use of peo-pbo block copolymers in ophthalmic compositions

InactiveUS20110059039A1Improve wettabilityEasy to cleanSenses disorderOrganic detergent compounding agentsOphthalmologyActive agent

The use of poly(oxyethylene)-poly(oxybutylene) block copolymers in pharmaceutical compositions useful for modifying the surfaces of contact lenses and other medical devices is disclosed. The present invention is based in-part on a discovery that this class of compounds is particularly efficient in wetting hydrophobic surfaces, such as the surfaces of silicone hydrogel contact lenses and other types of ophthalmic lenses. Such compounds are also useful for cleaning purposes. The use of the compounds as surfactants in various types of compositions for treating contact lenses therefore represents a preferred embodiment of the present invention.

Owner:ALCON INC

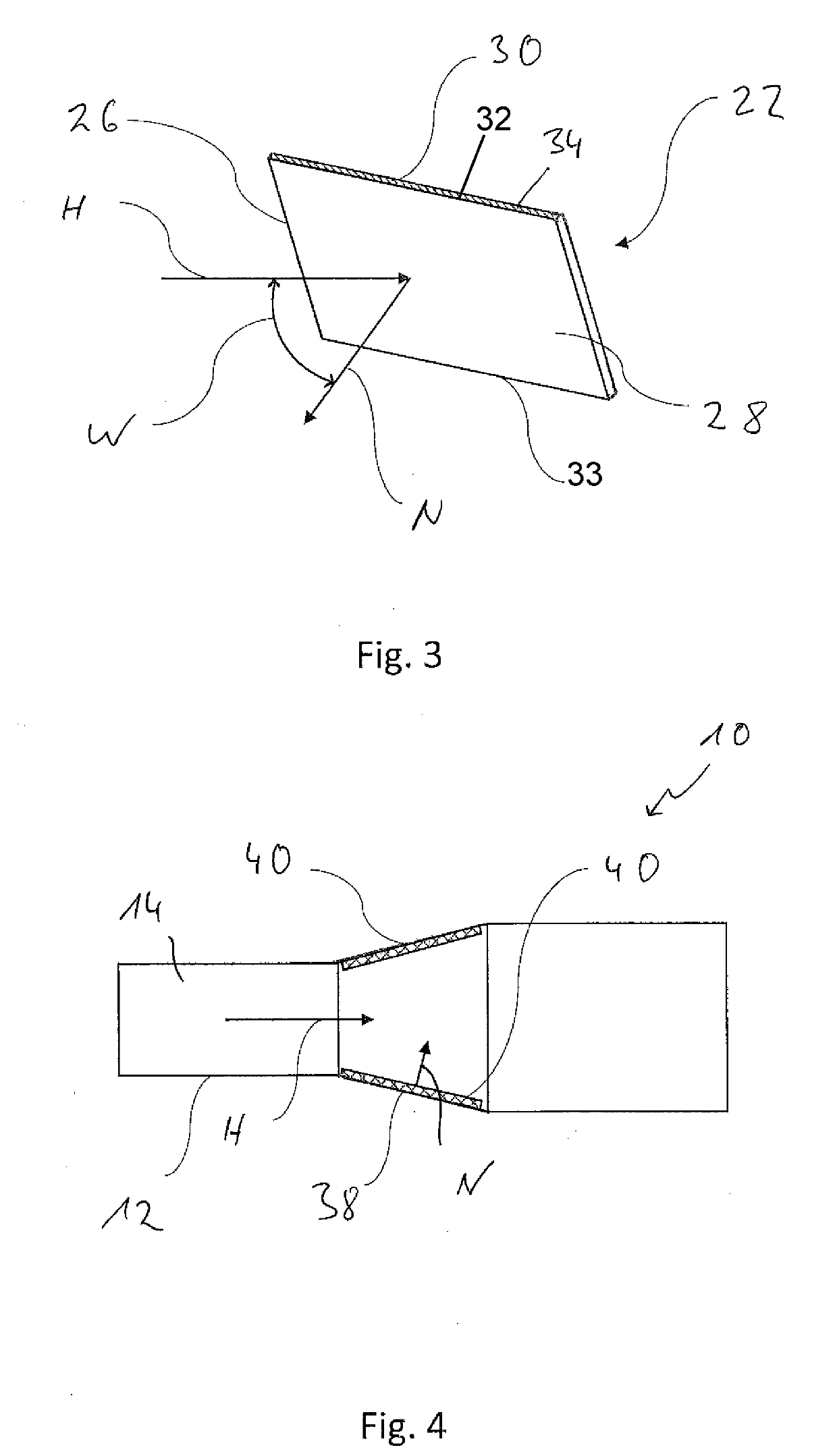

Exhaust system

ActiveUS20190107026A1Reduce riskPromote decompositionInternal combustion piston enginesFlow mixersEngineeringCatalytic converter

An exhaust system for an internal combustion engine, especially in a vehicle, includes an exhaust gas flow duct (14), a reactant release device (20) for the release of reactant (R) into the exhaust gas flow duct (14) and a catalytic converter device (16) downstream of the reactant release device (20). At least one part of a component surface is provided by a hydrophilic material (34) of at least one exhaust gas-carrying component (12, 22) positioned in the reactant flow path or / and defining this reactant flow path, or / and at least one part of the component surface is provided by a hydrophobic material (40) of at least one exhaust gas-carrying component (12, 18, 22) positioned in the reactant flow path.

Owner:PUREM GMBH

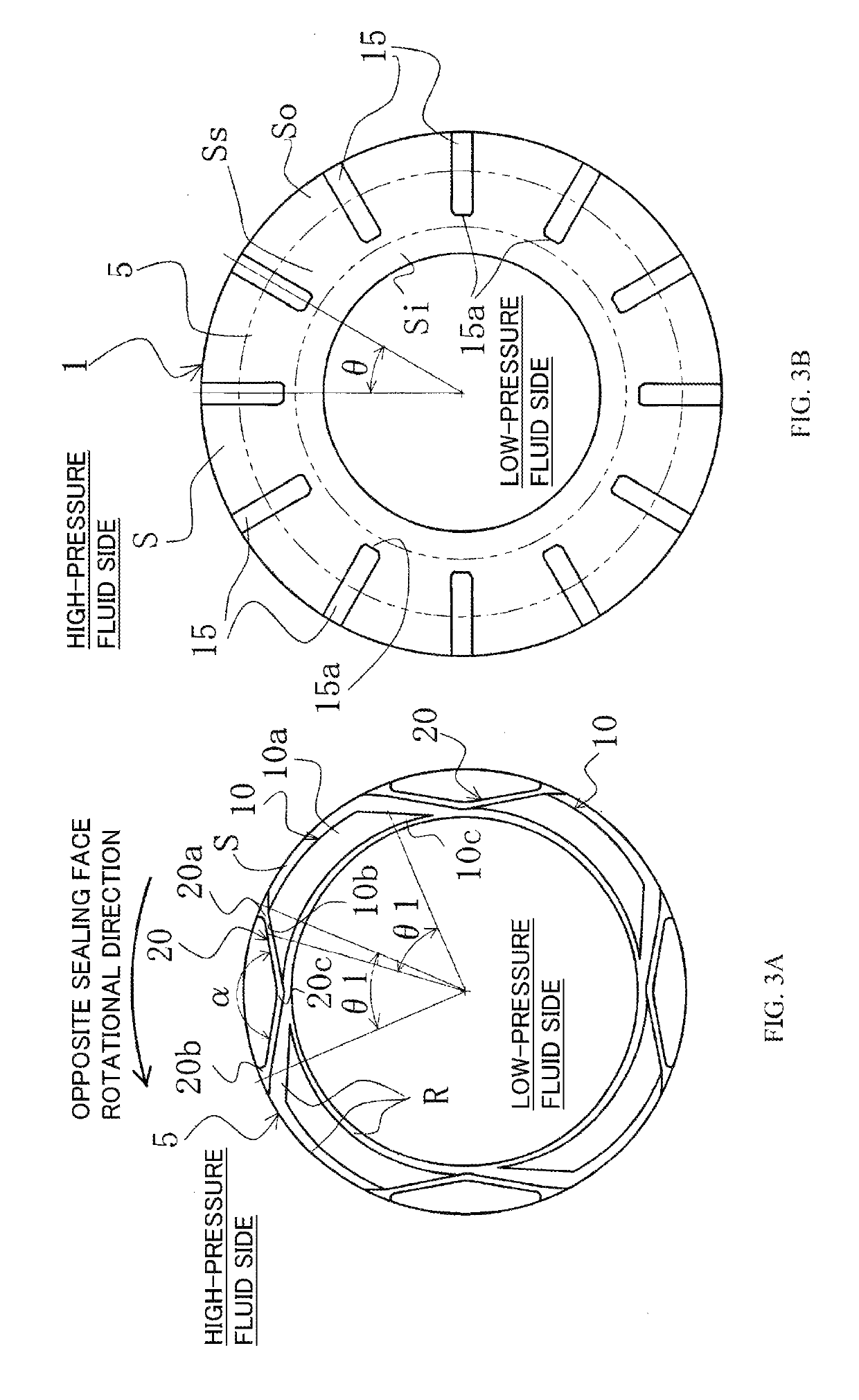

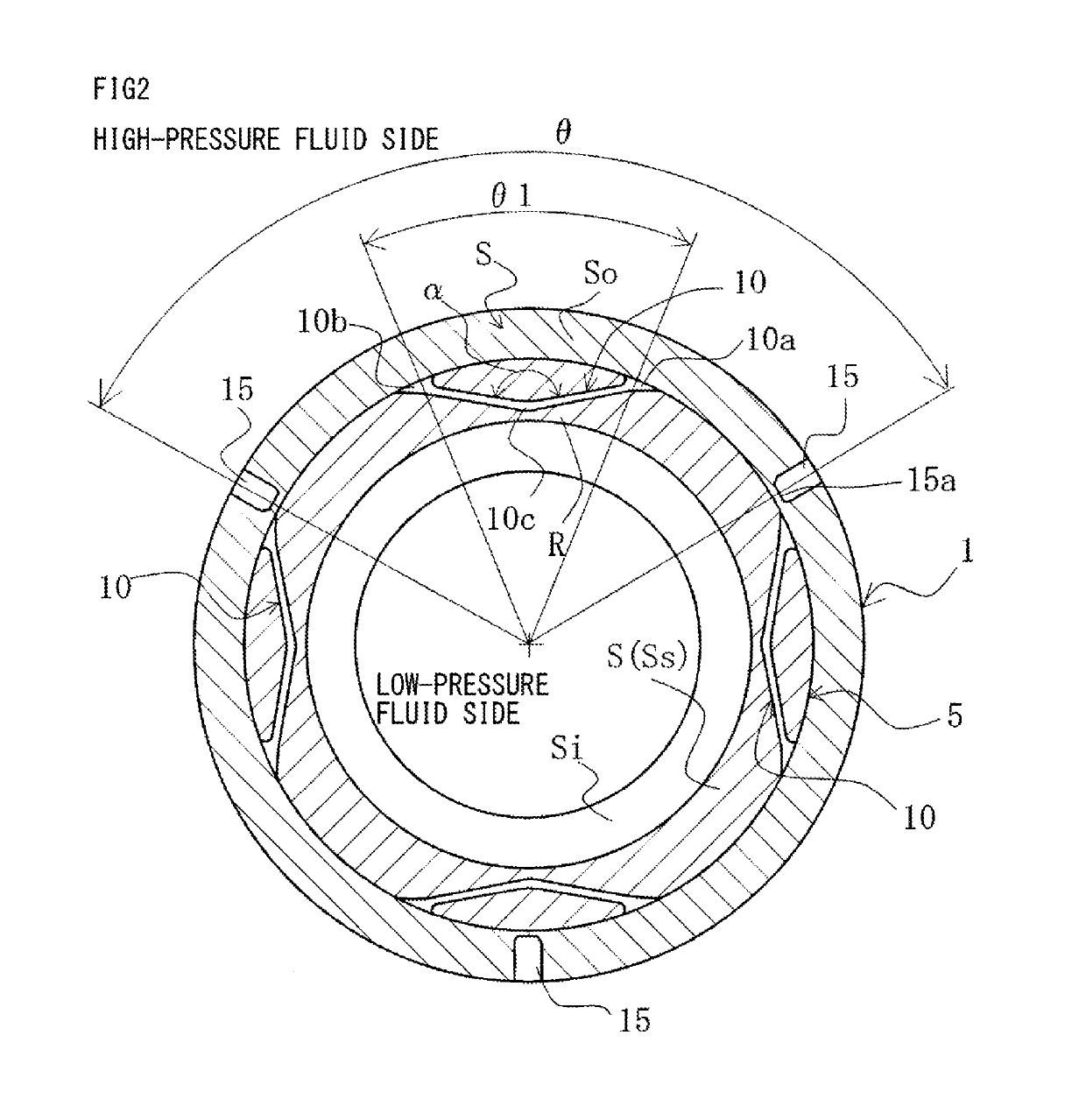

Sliding component

ActiveUS10274086B2Inhibits the formation of depositsMaintain sealing functionEngine sealsEngineeringHigh pressure

Owner:EAGLE INDS

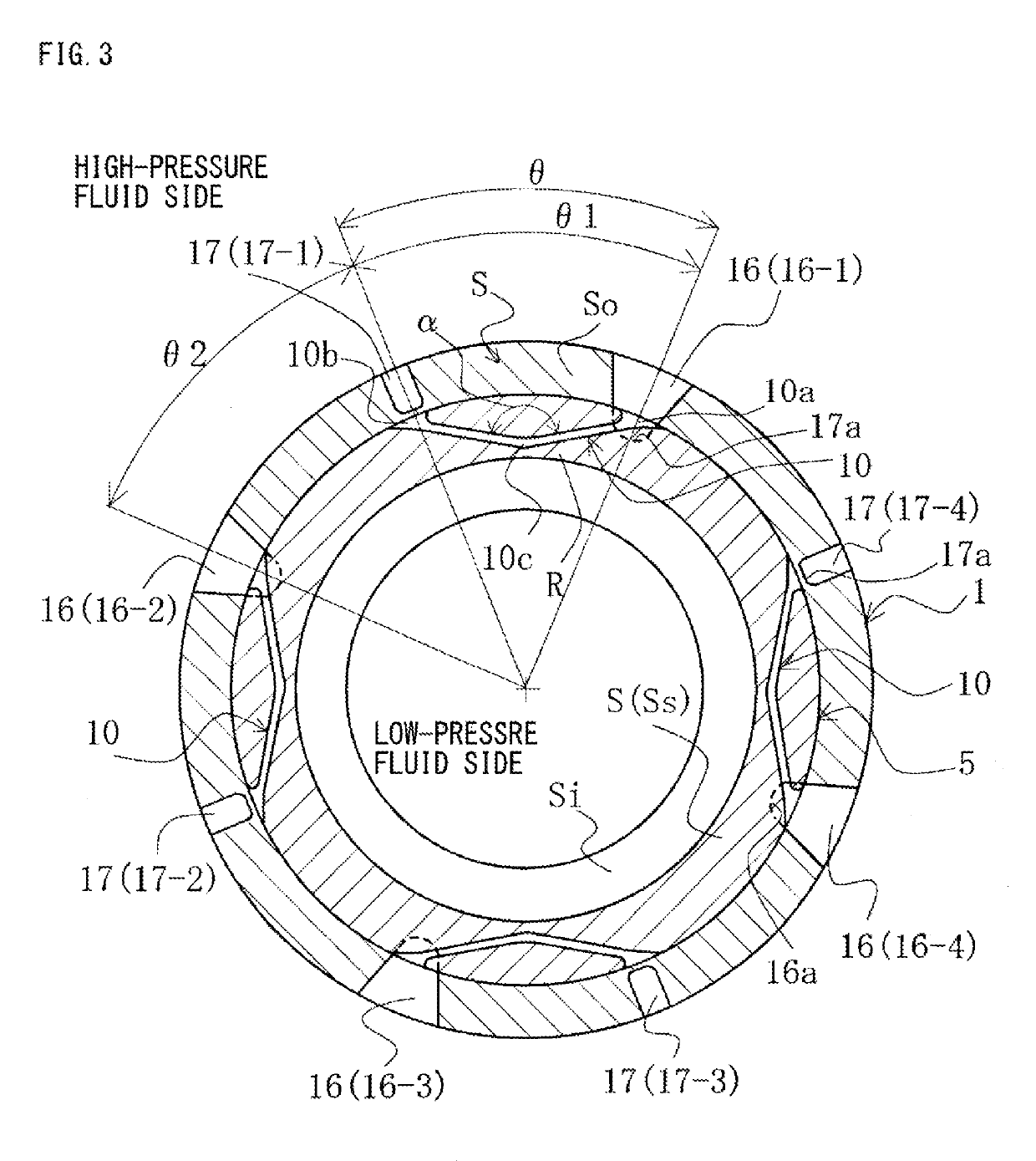

Sliding component

ActiveUS10344867B2Inhibits the formation of depositsMaintain sealing functionEngine sealsPump componentsHigh pressureMechanical engineering

In an embodiments, a slide component includes a pair of slide parts that relatively slide on each other, one of the slide parts being provided in a sealing face with fluid circulation grooves 10 that communicate with a high-pressure fluid side via inlet portions and outlet portions and are separated from a low-pressure fluid side by land portions, the other of the slide parts being circumferentially provided in a sealing face with a plurality of interference grooves 15, 16, 17, 20 for producing pressure variations in a fluid in the fluid circulation grooves 10, adjacent ones of the interference grooves 15, 16, 17, 20 being set to have different shapes.

Owner:EAGLE INDS

Tea extract and method for producing the same

InactiveUS20110274788A1Great tasteAdd flavorPre-extraction tea treatmentTea extractionPentagalacturonic acidFood flavor

To provide a tea extract more excellent in flavor, with formation of deposits inhibited, the present invention provides a method for producing a tea extract, comprising the step of treating a raw material tea by using raw tea leaves and an enzyme preparation having a polygalacturonase activity.

Owner:TAKASAGO INTERNATIONAL CORPORATION

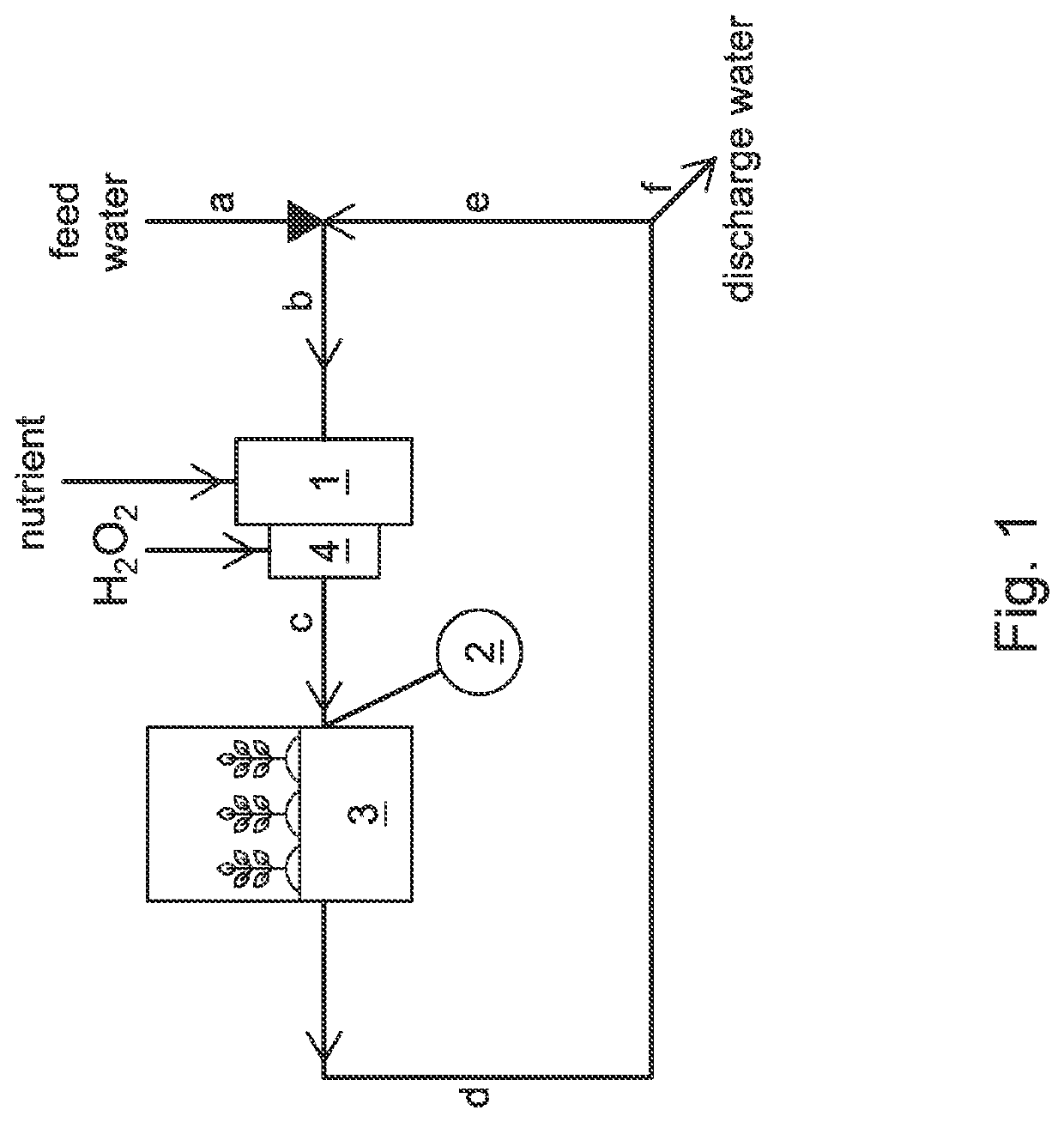

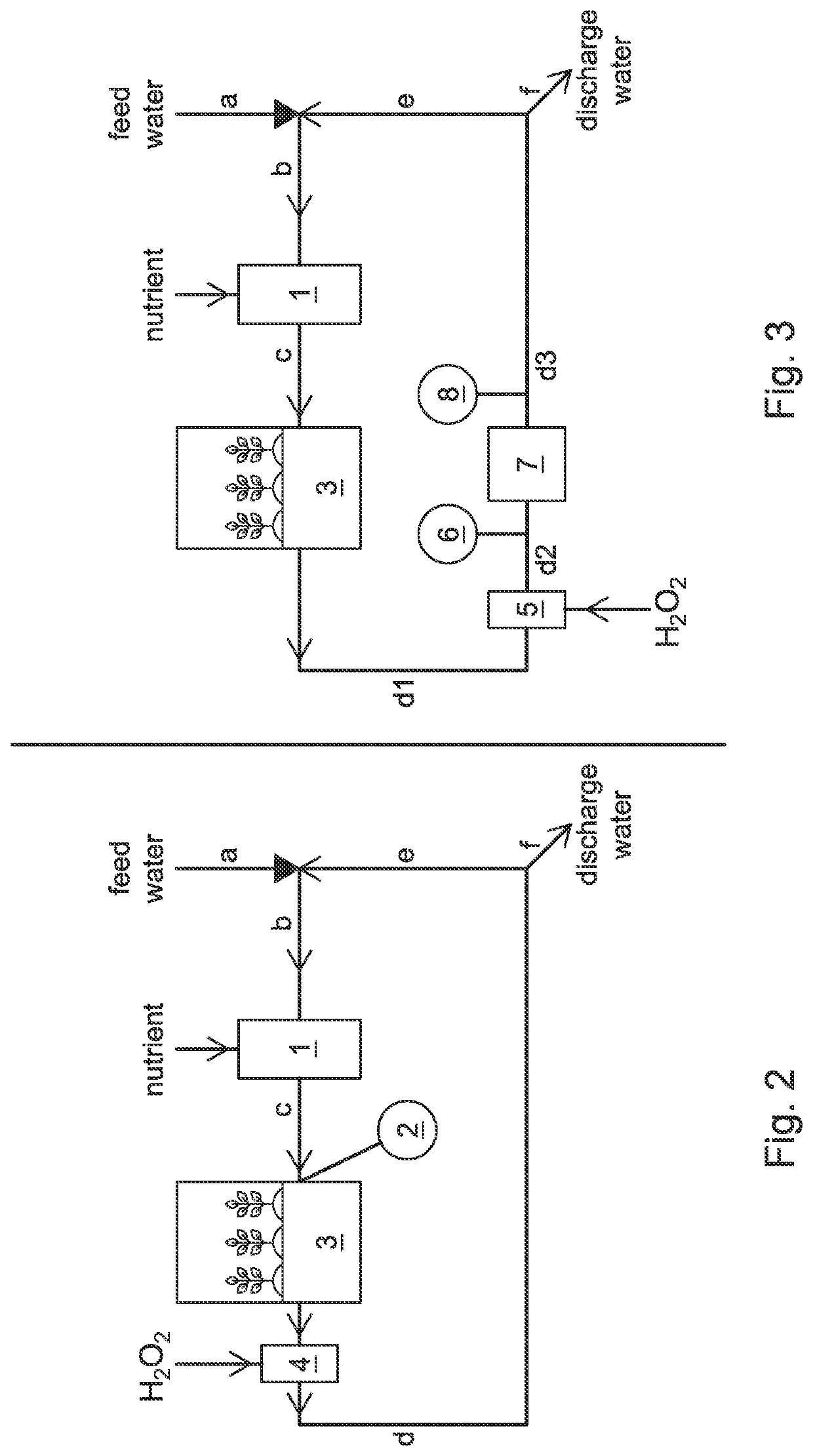

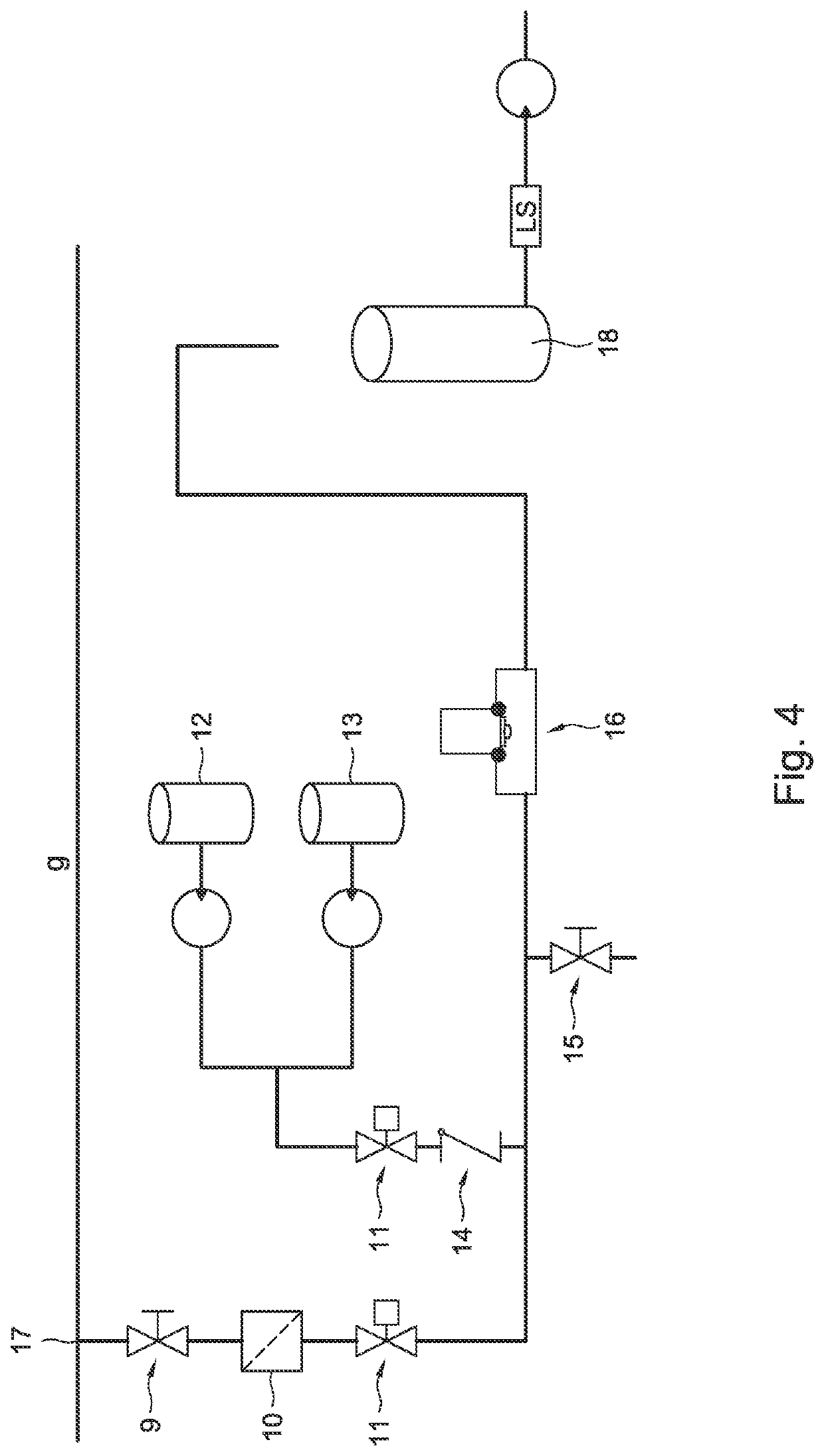

Horticulture Facility, Comprising a Water Loop

PendingUS20220312690A1Improve efficiencyAvoid unacceptable damageGrowth substratesCulture mediaEnvironmental engineeringH2O2 - Hydrogen peroxide

A horticulture facility, including a grow area, a water loop, a nutrient dosing unit configured to dose nutrients to the feed water for the growth area, a hydrogen peroxide dosing unit, configured to introduce a hydrogen peroxide solution into the water loop; a hydrogen peroxide measurement system configured to determine a hydrogen peroxide concentration in the water loop, the hydrogen peroxide measurement system including a sampling unit having a sampling point downstream of the hydrogen peroxide dosing unit, which hydrogen peroxide measurement system is configured to withdraw discrete liquid samples from liquid in the water loop at the sampling point configured to take samples from the water loop and configured to determine a hydrogen peroxide content of a liquid in the water loop; and wherein the horticulture facility includes a controller unit configured to control the hydrogen peroxide content.

Owner:PRIVA HLDG

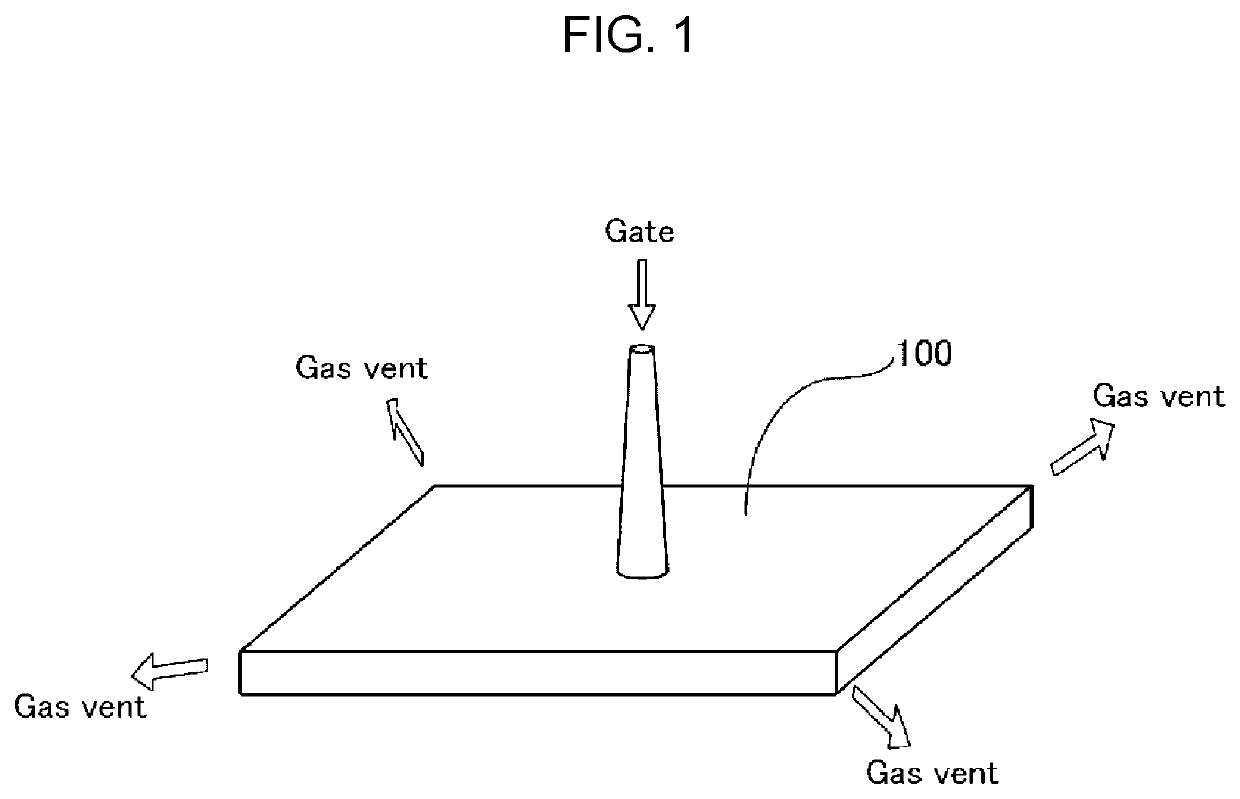

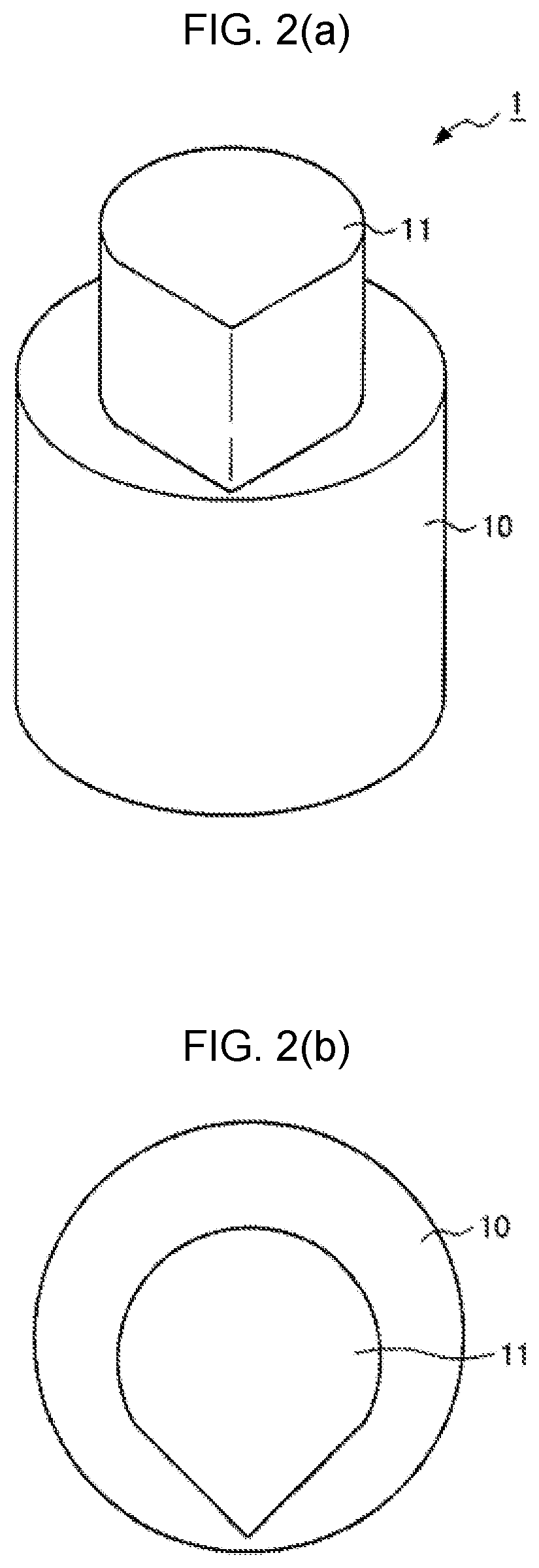

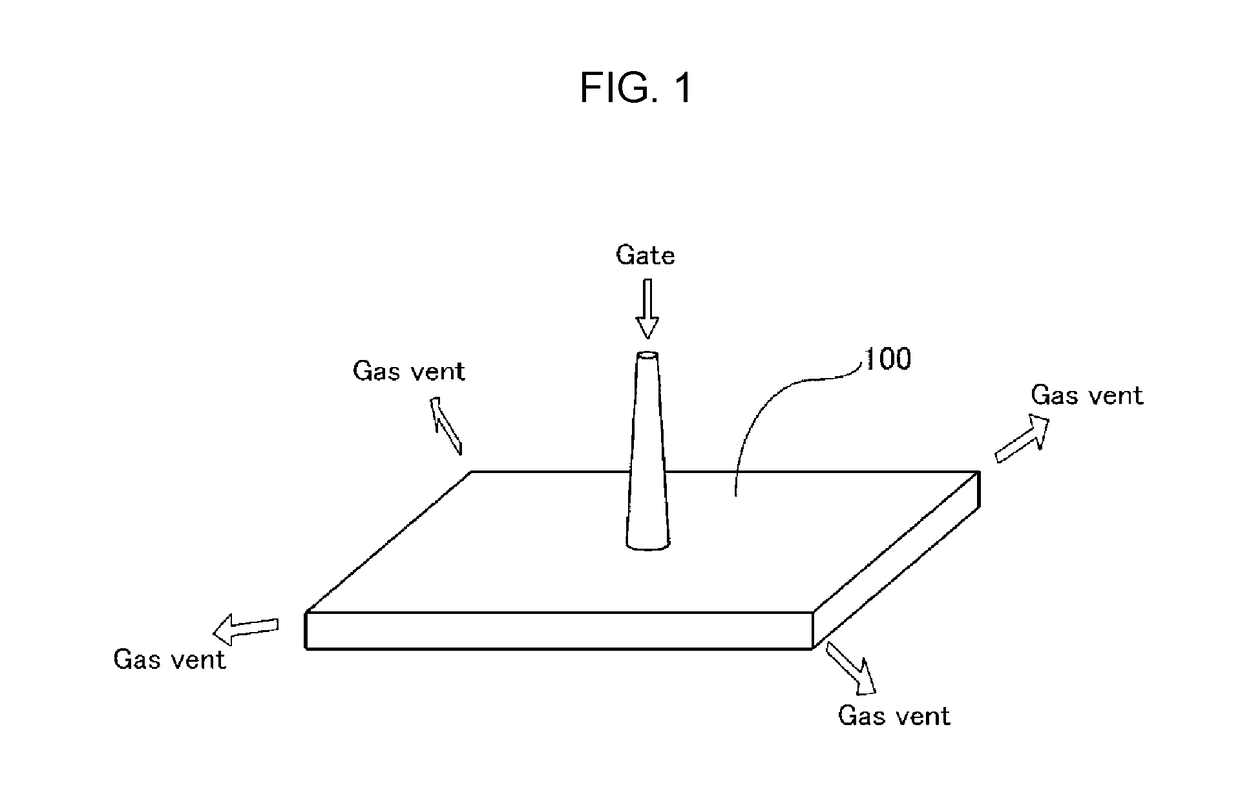

Polyarylene sulfide resin composition and insert molded article

ActiveUS10927255B2Enhanced inhibitory effectGood flowabilityCoatingsPolymer scienceOrganic chemistry

A polyarylene sulfide resin composition characterized by comprising a polyarylene sulfide resin, and an olefinic copolymer comprising an α-olefin-derived structural unit and an α,β-unsaturated acid glycidyl ester-derived structural unit, wherein the olefinic copolymer content is at least 1.0 parts by mass and less than 5.0 parts by mass with respect to 100 parts by mass of the polyarylene sulfide resin, a melt viscosity of the polyarylene sulfide resin measured at 310° C. and a shear rate of 1216 sec−1 is at least 70 Pa·s and at most 300 Pa·s, and a flow length for a width of 20 mm and a thickness of 1 mm, at a cylinder temperature of 320° C., an injection pressure of 100 MPa and a mold temperature of 150° C., is at least 80 mm and at most 200 mm.

Owner:POLYPLASTICS CO LTD

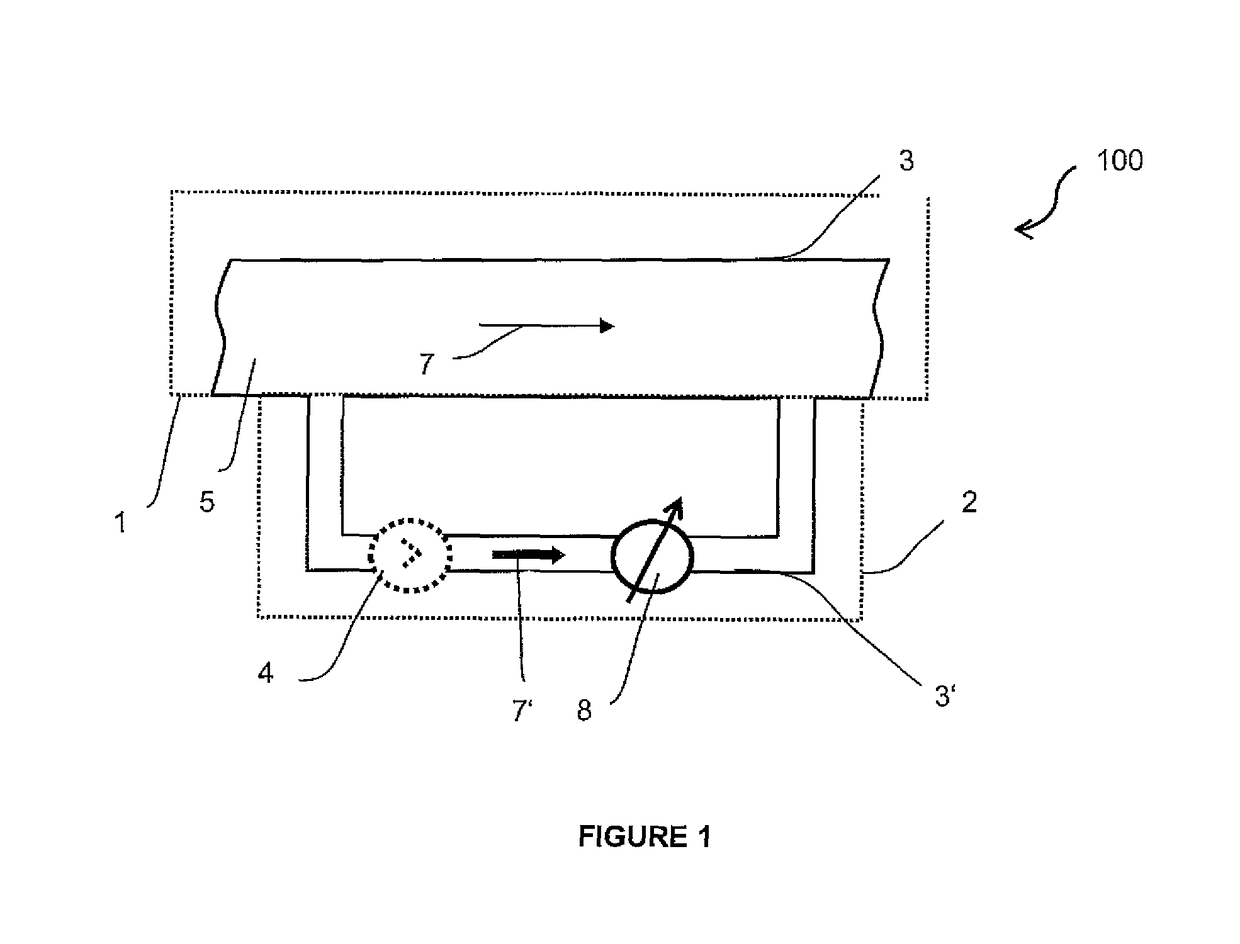

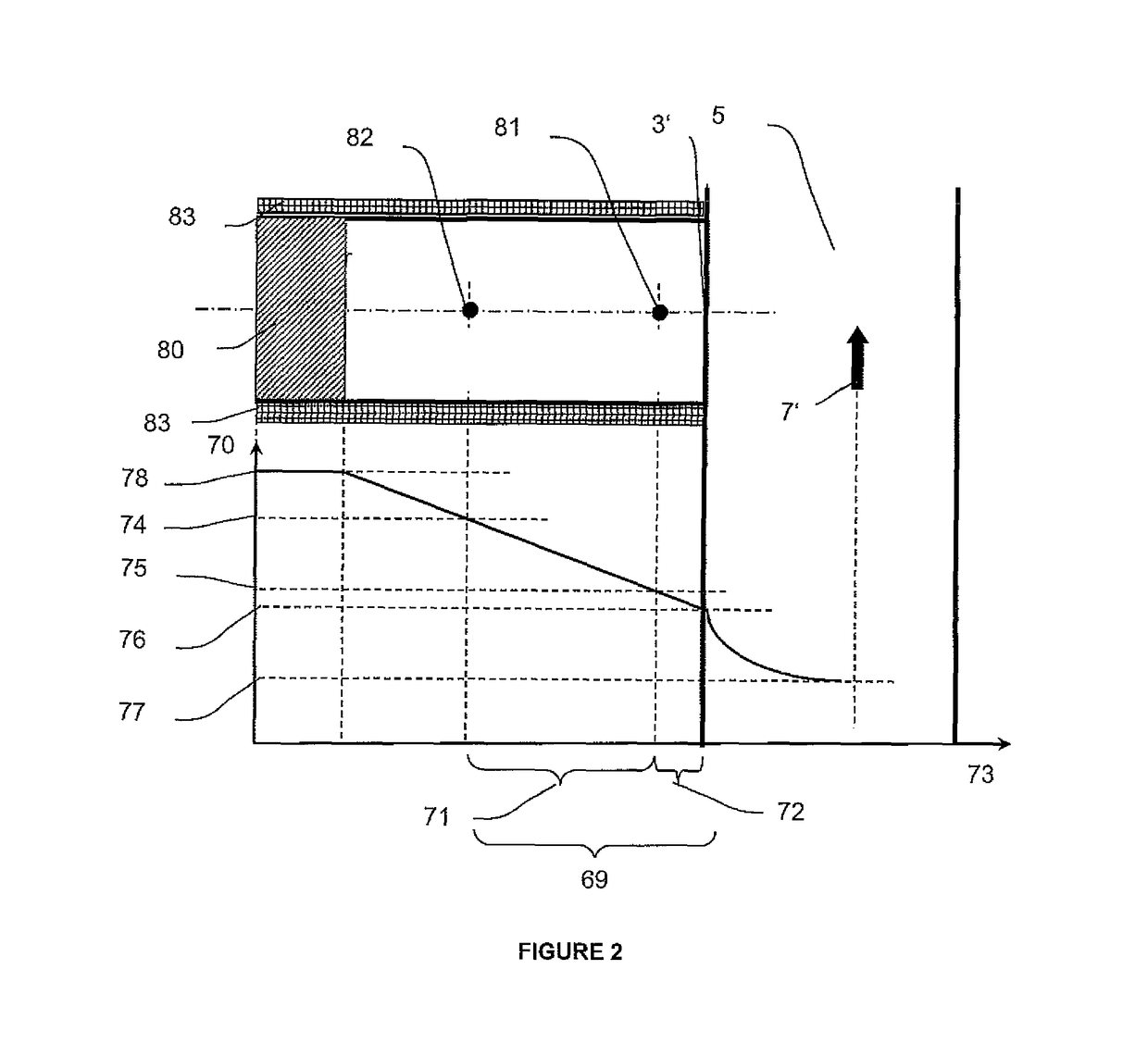

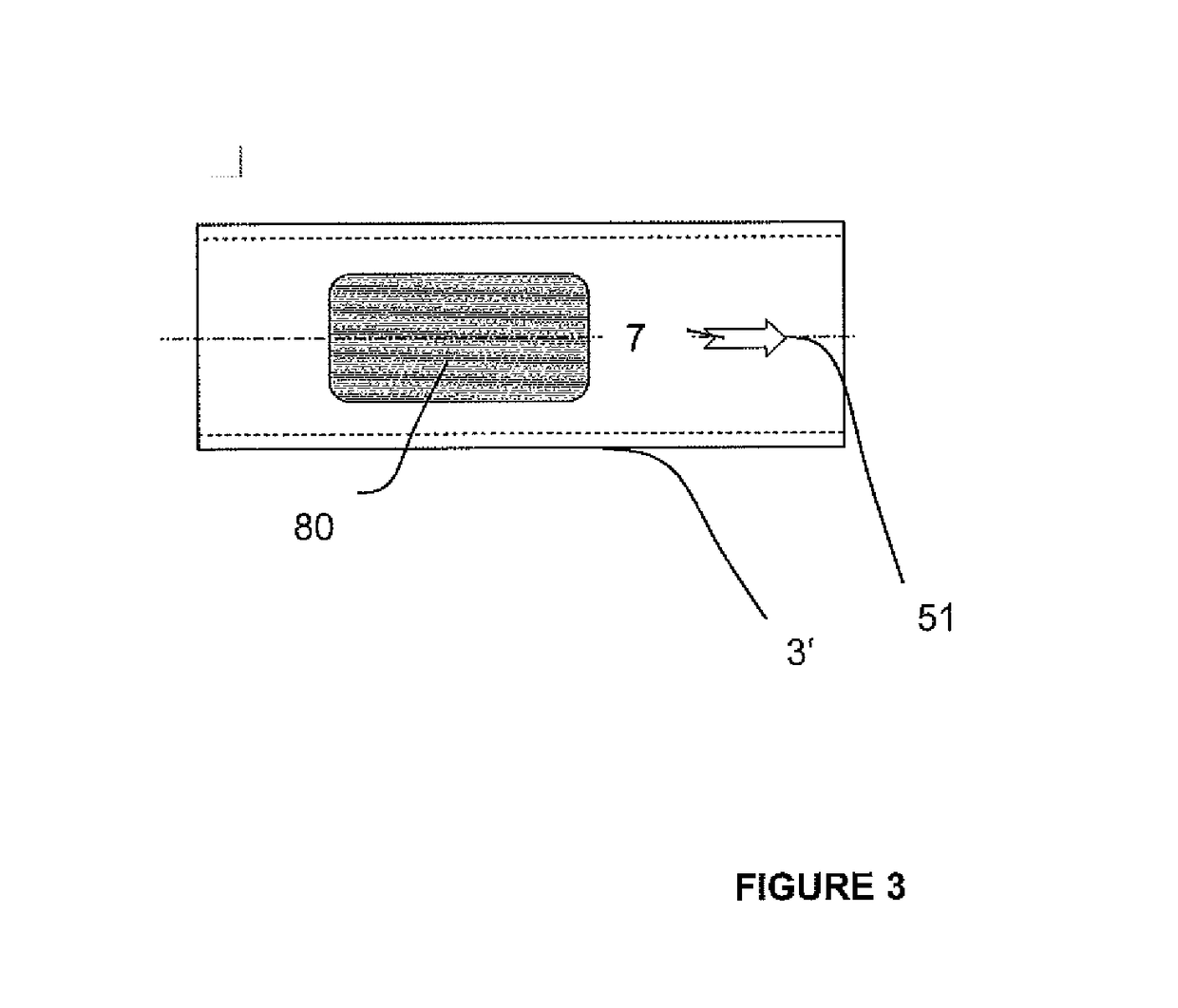

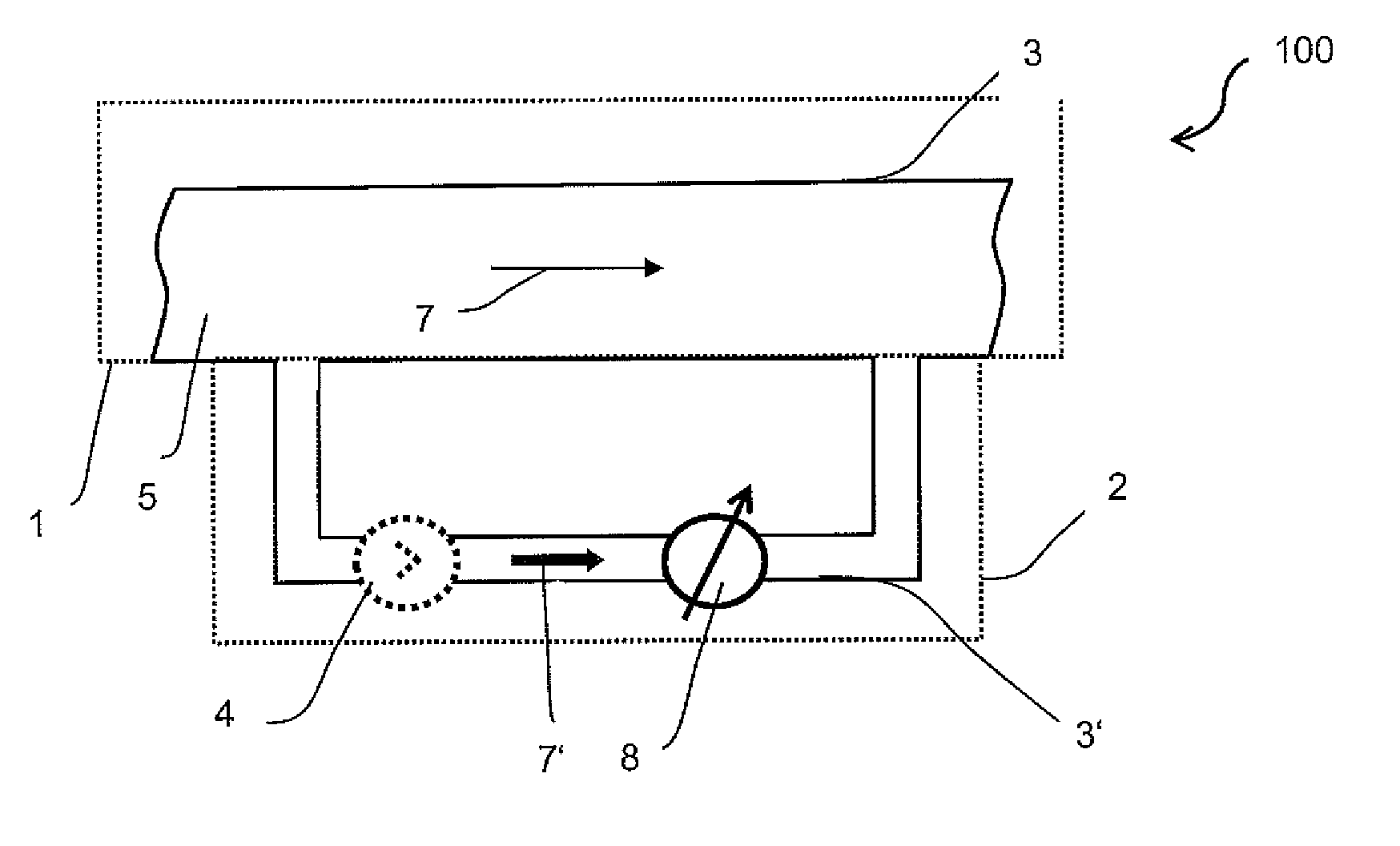

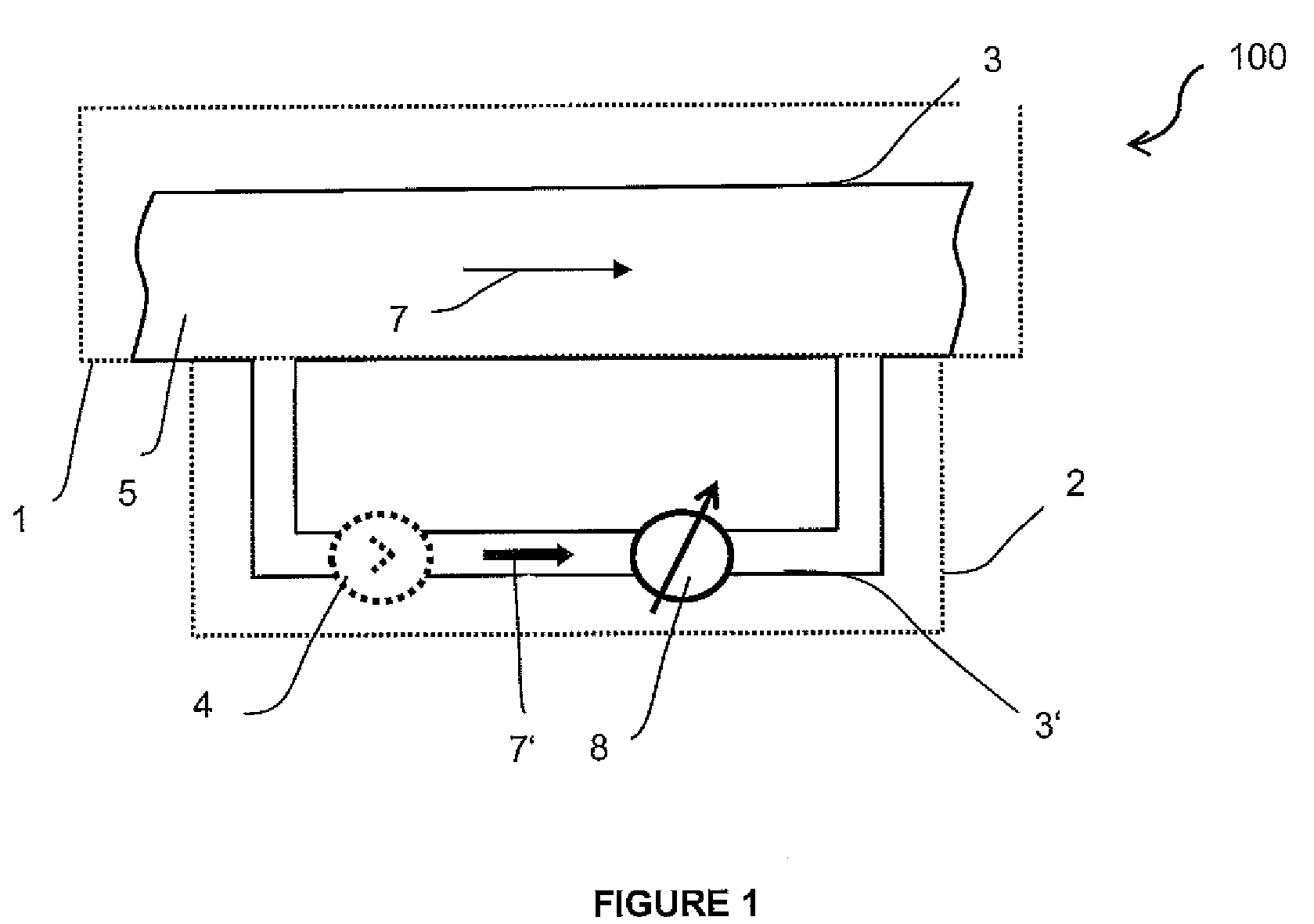

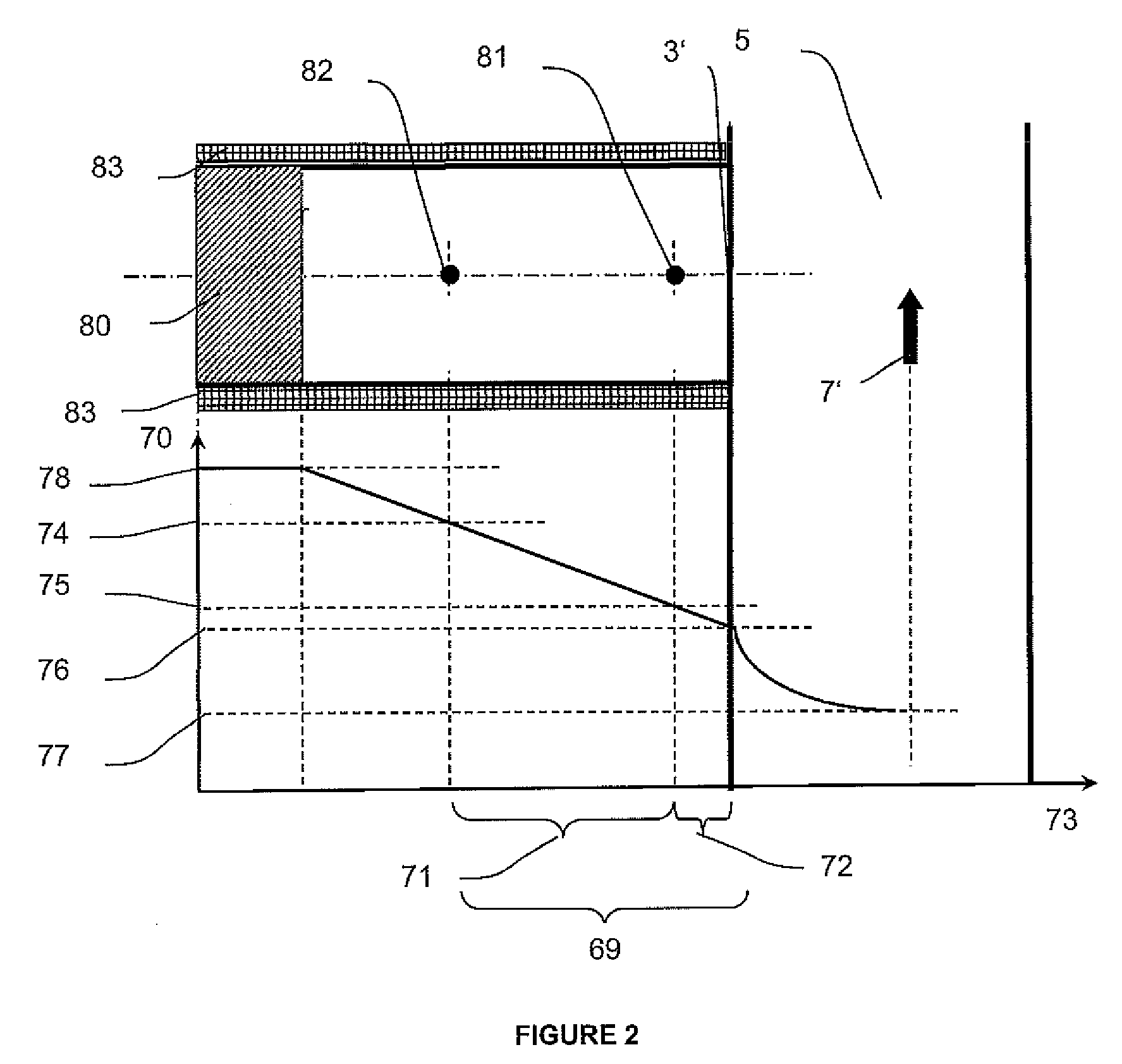

Device and method for controlling deposit formation

ActiveUS10233102B2Reduce detectionPromote formationWater treatment parameter controlMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineering

The invention suggests a method for controlling the deposit formation in a main system of a liquid bearing system, wherein a liquid is transported inside the liquid bearing system, wherein the liquid bearing system comprises a main system and a subsystem, wherein the subsystem is configured such that a tendency of deposit formation is promoted more inside the subsystem than inside the main system.

Owner:SOLENIS TECH CAYMAN

Device And Method For Controlling Deposit Formation

ActiveUS20160311714A1Promote deposit formationReduce detectionWater treatment parameter controlMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineering

The invention suggests a method for controlling the deposit formation in a main system of a liquid bearing system, wherein a liquid is transported inside the liquid bearing system, wherein the liquid bearing system comprises a main system and a subsystem, wherein the subsystem is configured such that a tendency of deposit formation is promoted more inside the subsystem than inside the main system.

Owner:SOLENIS TECH CAYMAN

Polyarylene sulfide resin composition and insert molded article

A polyarylene sulfide resin composition characterized by comprising a polyarylene sulfide resin, and an olefinic copolymer comprising an α-olefin-derived structural unit and an α,β-unsaturated acid glycidyl ester-derived structural unit, wherein the olefinic copolymer content is at least 1.0 parts by mass and less than 5.0 parts by mass with respect to 100 parts by mass of the polyarylene sulfide resin, a melt viscosity of the polyarylene sulfide resin measured at 310° C. and a shear rate of 1216 sec−1 is at least 70 Pa·s and at most 300 Pa·s, and a flow length for a width of 20 mm and a thickness of 1 mm, at a cylinder temperature of 320° C., an injection pressure of 100 MPa and a mold temperature of 150° C., is at least 80 mm and at most 200 mm.

Owner:POLYPLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com