Electric furnace charging and preheating device

A preheating device and electric furnace technology, applied in the field of metallurgy, can solve the problems of poor scrap preheating effect, increased height of electric furnace equipment, stagnation of popularization and use, etc., and achieves the effect of saving driving power, short overall length, and less equipment maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

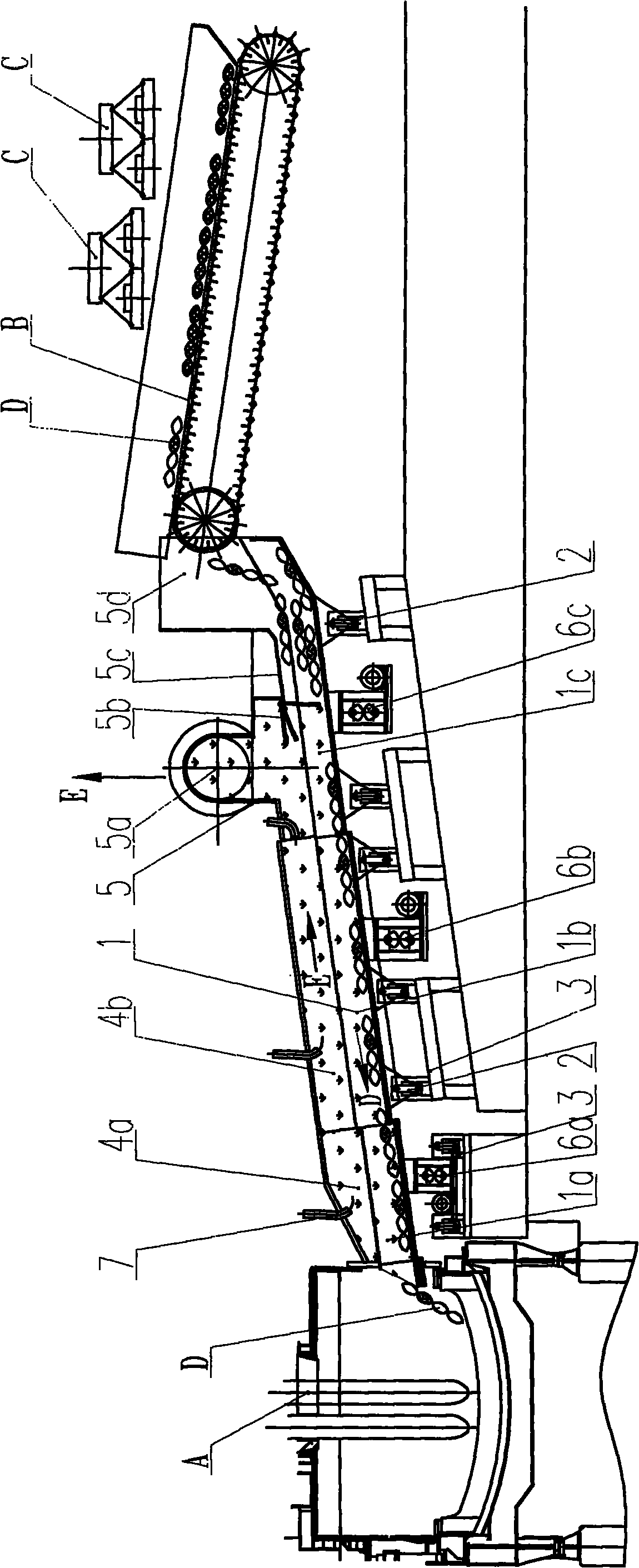

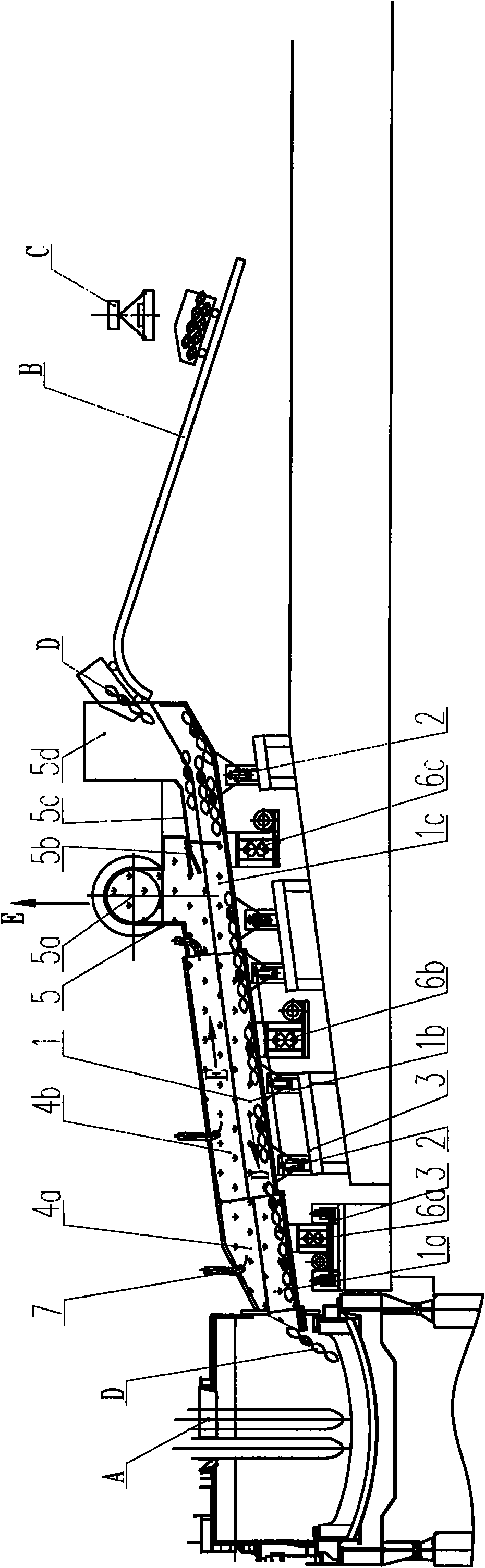

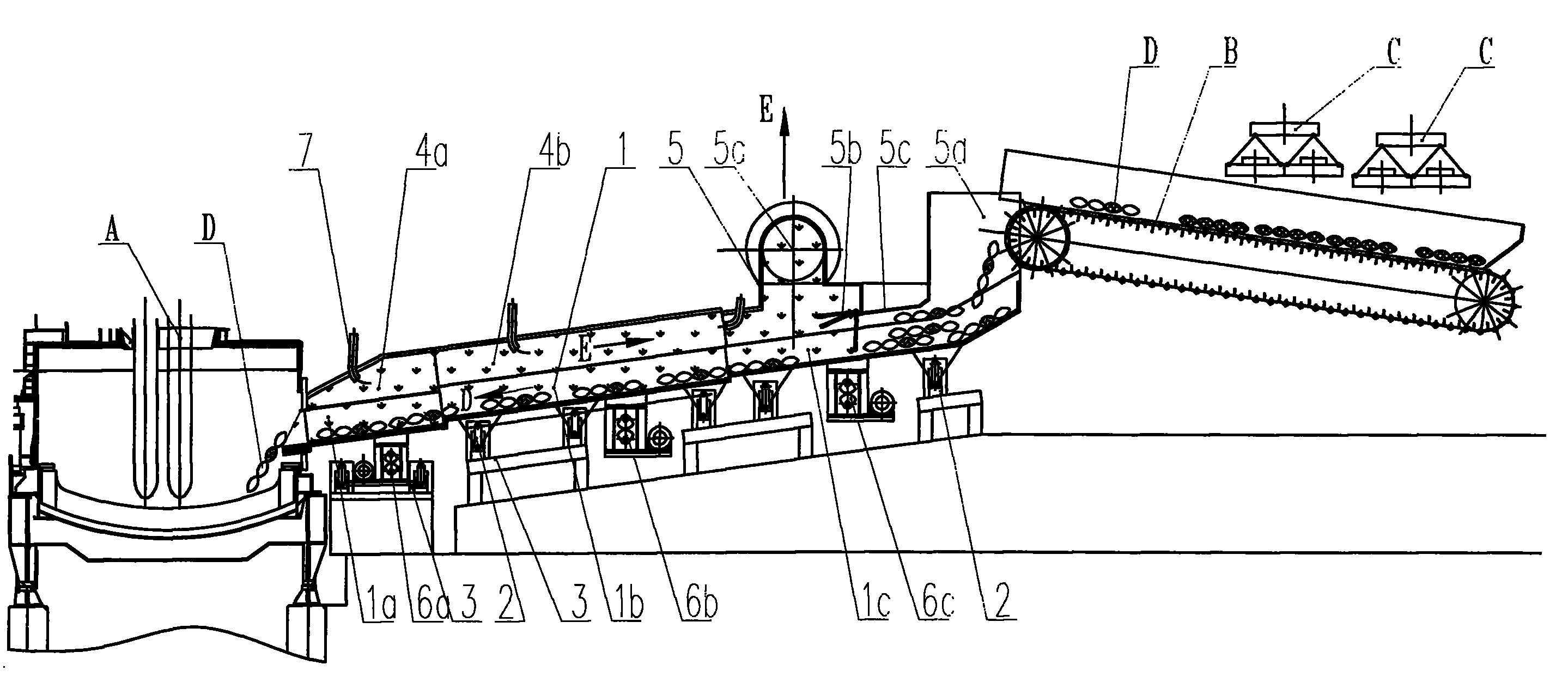

[0027] Embodiment 1: as figure 1 Shown:

[0028] Steel scrap D is loaded onto the plate chain receiving conveyor through the disk crane C (or other equipment). In order to ensure the flow rate of the feeding material, the plate chain receiving conveyor must have sufficient length. The receiving conveyor can be installed obliquely to reduce the hoisting height of the disk crane, and also increase the feeding length of the plate chain receiving conveyor. Of course, the plate chain receiving conveyor can also be set in a curved manner, which can also increase the feeding length. The plate chain receiving conveyor transports the scrap steel D into the high end of the scrap steel conveying chute 1. The bottom 1 of the scrap steel conveying chute is inclined about 10° from the horizontal plane. The plate chain receiving conveyor is set at an inclination angle of 15° from the horizontal plane. And it is arranged in an inverted V shape with the scrap steel conveying chute 1. The in...

Embodiment 2

[0034] Embodiment 2: The difference from Embodiment 1 is that piece B is a receiving machine with a ramp trolley, and the inclination angle can be larger. The transportation volume of the ramp trolley in this scheme is small, which is suitable for small electric furnaces.

[0035] The scrap steel conveying chute and the traction type receiving conveyor of the present invention form the conveying process of scrap steel to V shape, which is very similar to the skiing process, so the system is also called SKISTEEL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com