System and method utilizing flue duct waste gas of hot air furnace to bake and preheat charging of blast furnace

A technology of flue exhaust gas and hot blast stove, which is applied to blast furnaces, preheating costs, and details of blast furnaces. It can solve problems such as single function, affecting normal production of blast furnaces, and high manufacturing costs, so as to enhance the screening effect and avoid gas explosion. Dangerous, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

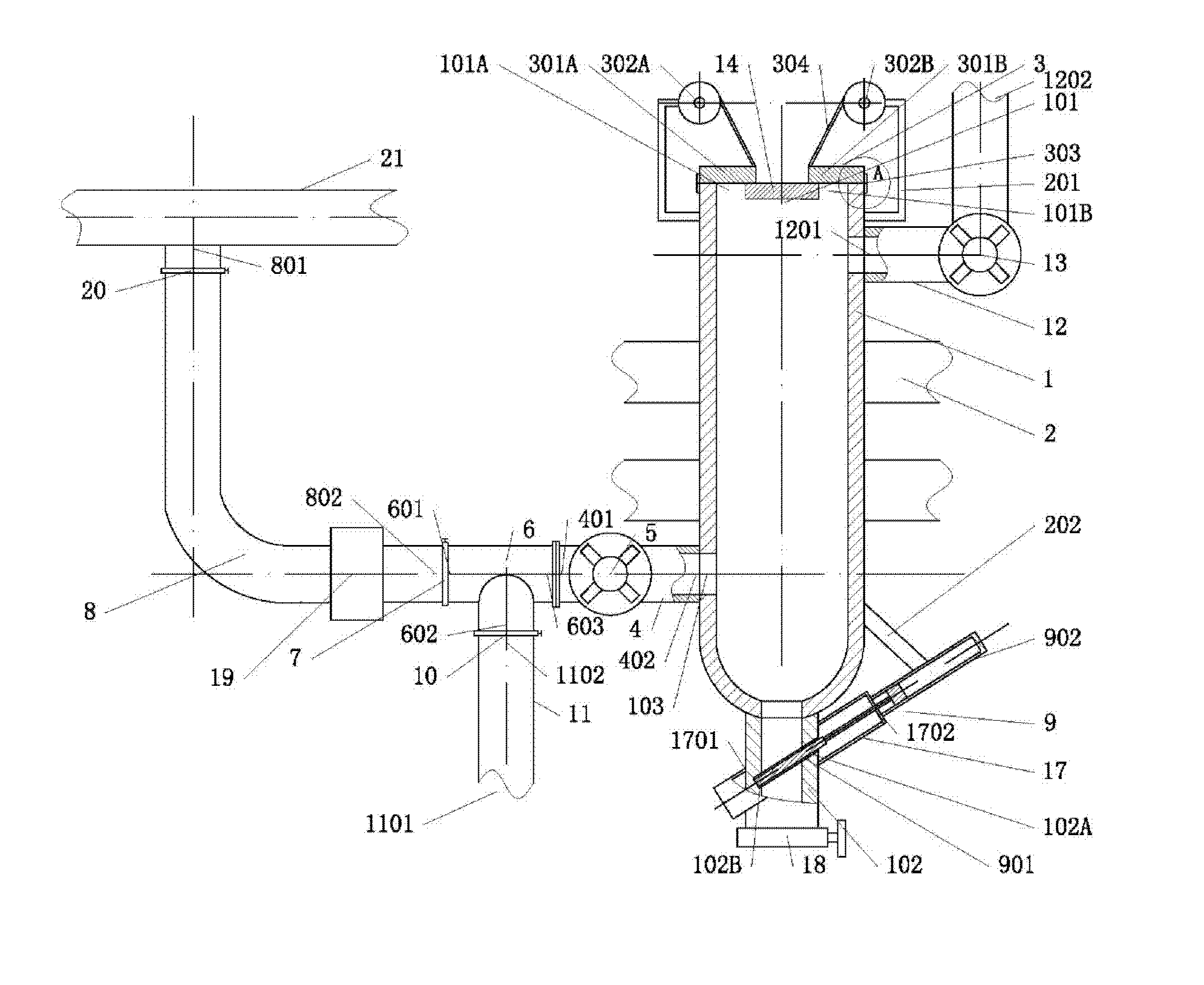

[0035] Such as figure 1As shown, the present invention utilizes the flue gas of the hot blast stove to bake and preheat the system of the blast furnace charge, which includes a silo 1, which is a vertical columnar shell (the present embodiment takes a square quadrangular prism shell as an example), and the silo 1 Supported in the air by the support 2, the bottom is a conical arc surface or a spherical conical arc surface ( figure 1 The bottom shown in is a spherical arc), such a bottom structure is easy to discharge; the feed bin 1 is provided with a feed port 101 and a discharge port 102, and the feed port 101 is arranged on the top of the feed bin 1, figure 1 The feed inlet 101 shown in is equivalent to the top of the silo 1, and is basically square, with its side length forming a ring-shaped end face. The middle part of the two inner walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com