Powder material suspension heat exchange device and powder material heat exchange system

A powder material, heat exchange device technology, applied in the direction of preheating cost, lighting and heating equipment, furnace cooling, etc., to achieve the effect of reducing the loss of heat energy and transportation electric energy, reducing the height of the building and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

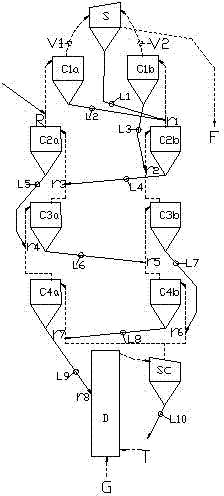

[0018] figure 1 An embodiment of the raw meal heat exchange device used in cement production equipment of the present invention, that is, the preheater system is given. The multiple cyclone heat exchangers of the preheater system are arranged in 2 rows and 4 stages, and 1-4 stages Two cyclone heat exchangers respectively, C1a, C1b and C2a, C2b and C3a, C3b and C4a, C4b.

[0019] Airflow Routes: The airflow routes are shown in dashed lines with arrows in the attached drawings. Such as figure 1 As shown, the kiln gas enters the general air inlet chamber (in this embodiment, the decomposition furnace D), and the insufficient heat source can be supplemented by supplementing the heat source T. The gas after the decomposition furnace enters the cyclone heat exchange collector Sc, and the Sc exits The tuyere is connected to the C4a and C4b air inlets in two ways, and then enters the C4a-C3a-C2a-C1a column and the C4b-C3b-C2b-C1b column respectively, and finally merges into the cycl...

Embodiment 2

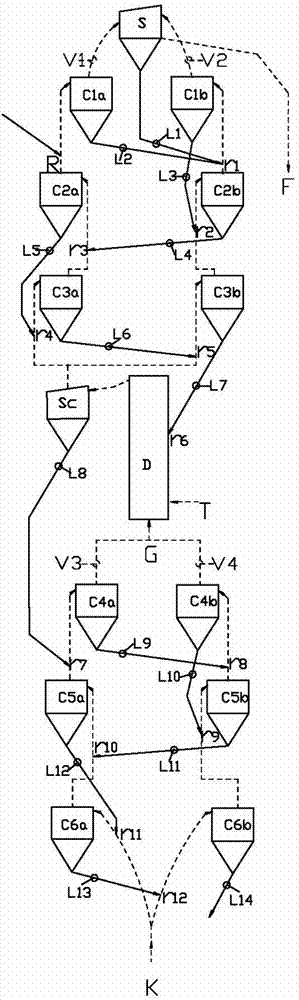

[0022] figure 2 A powder material heat exchange system including two powder material suspension heat exchange devices is given. Specifically, it is an embodiment of a calcined lime production process, in which the two powdery material suspension heat exchange devices are respectively a heating reaction device for raw meal and a cooling device for high-temperature lime products. The system recycles the waste heat of high-temperature lime products, and also saves the lime kiln compared with the traditional system.

[0023] Airflow route: eg figure 2 As shown, the air K enters the air inlet pipes of cyclone heat exchangers C6a and C6b in two ways, and enters the cooling device, and the air flow passes through C6a, C5a, C4a and C6b, C5b, C4b cyclone heat exchangers to cool the high-temperature lime respectively. , the high-temperature gas generated by cooling the lime flows into the calciner D to decompose the limestone powder through the C4a and C4b outlet pipes, and the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com