Interconnected microchannel tube

a microchannel tube and interconnection technology, applied in the direction of tubular elements, lighting and heating apparatus, laminated elements, etc., can solve the problems of unfavorable heat transfer of the front edge of the tube, undetected large pressure drop, and create turbulent flow, so as to improve the heat transfer of the tube and minimize the effect of turbulen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

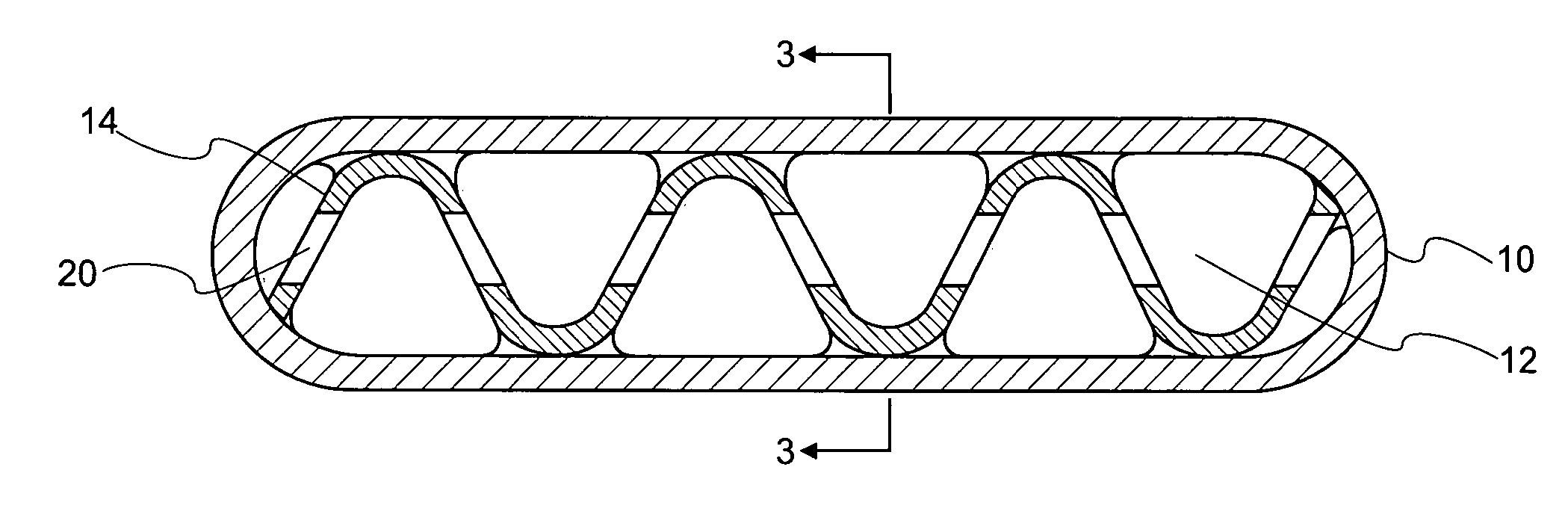

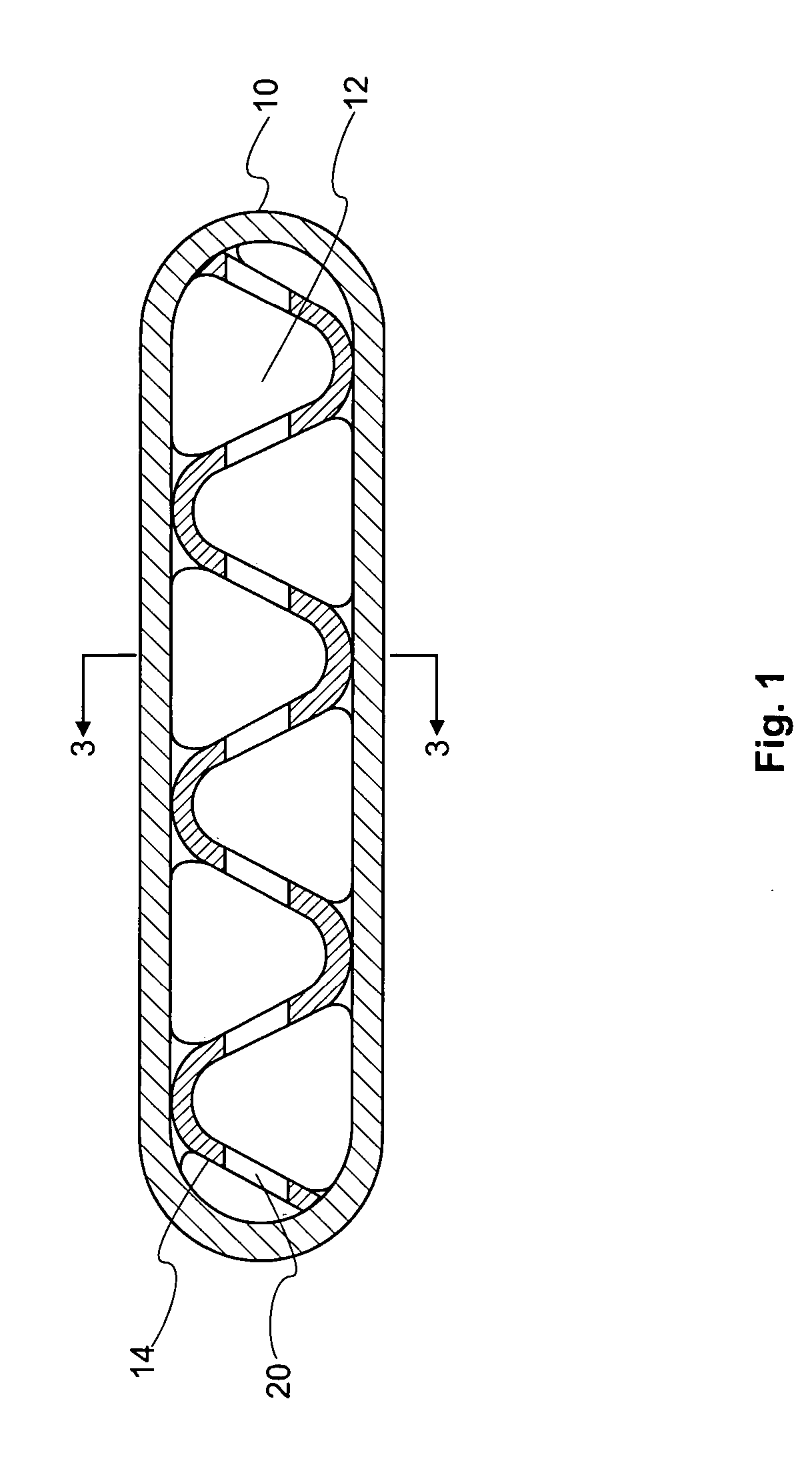

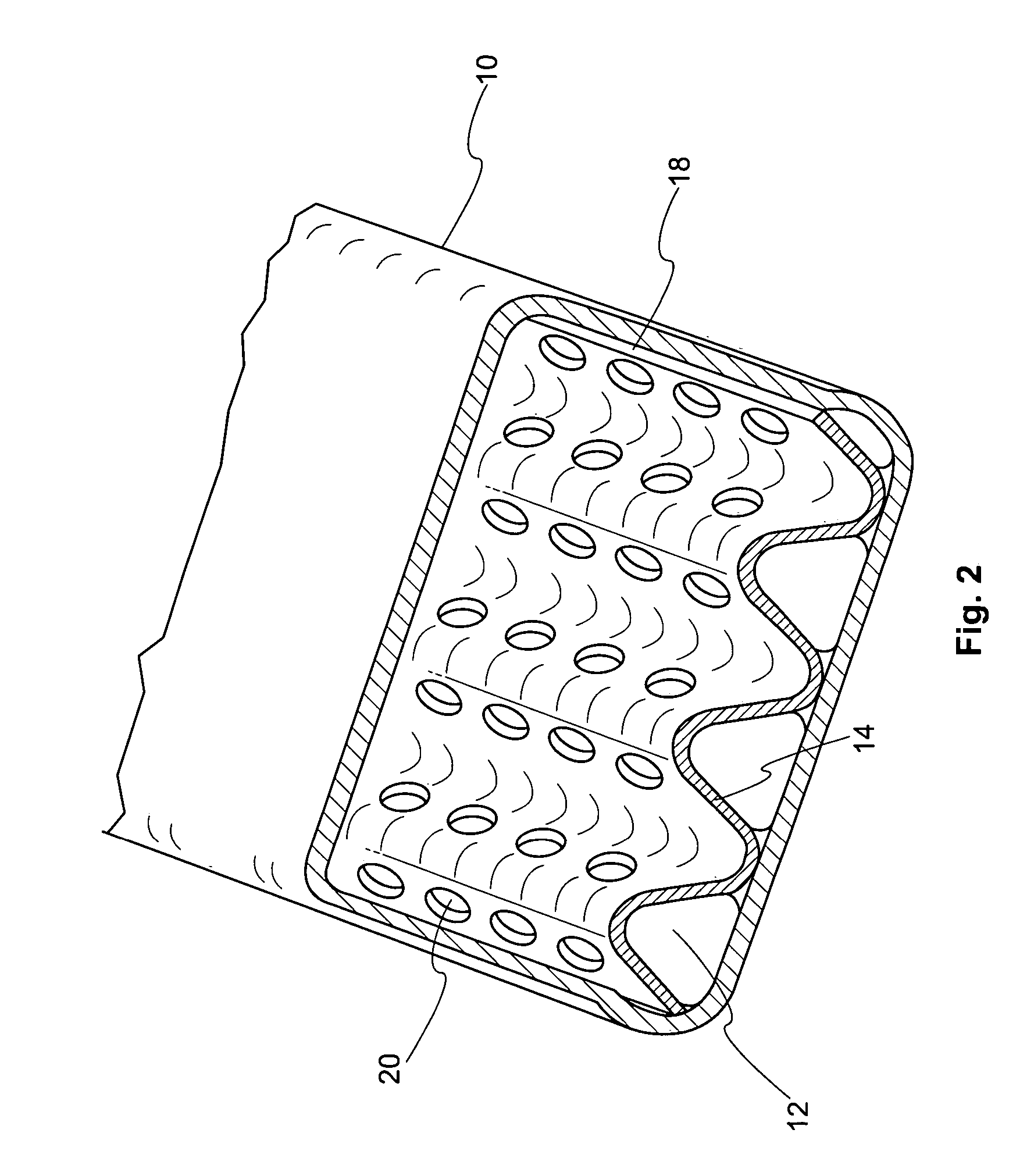

[0017] Referring to the drawings, the figures shows a heat exchange tube formed of a sheath 10 and microchannels 12 according to the present invention. The heat transfer tube is formed by a plurality of partitions 14 that form a plurality of microchannels 12. A heat transfer medium runs through the microchannels 12. In one embodiment, the invention includes at least about 2 to 12 partitions to form at least about 3 to 13 microchannels. In another preferred embodiment, at least about 4 to 8 partitions are present forming at least about 5 to 9 microchannels in the sheath.

[0018] The microchannels 12 define a path through which the heat transfer medium flows. As the heat transfer medium flows through a microchannel, it evaporates or condenses, thereby changing the vapor and liquid content of the composition. The microchannel at the front edge of the tube and the leeway edge of the tube may have different levels of heat transfer, due to external reasons. It is therefore possible that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com