Central refrigeration machine room modular prefabrication and assembled construction method

A refrigeration machine room and construction method technology, applied in industrial buildings, special data processing applications, instruments, etc., can solve problems such as low work efficiency, large space limitations, and harsh construction environments, so as to improve assembly efficiency, utilize labor resources, Control for uniform and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

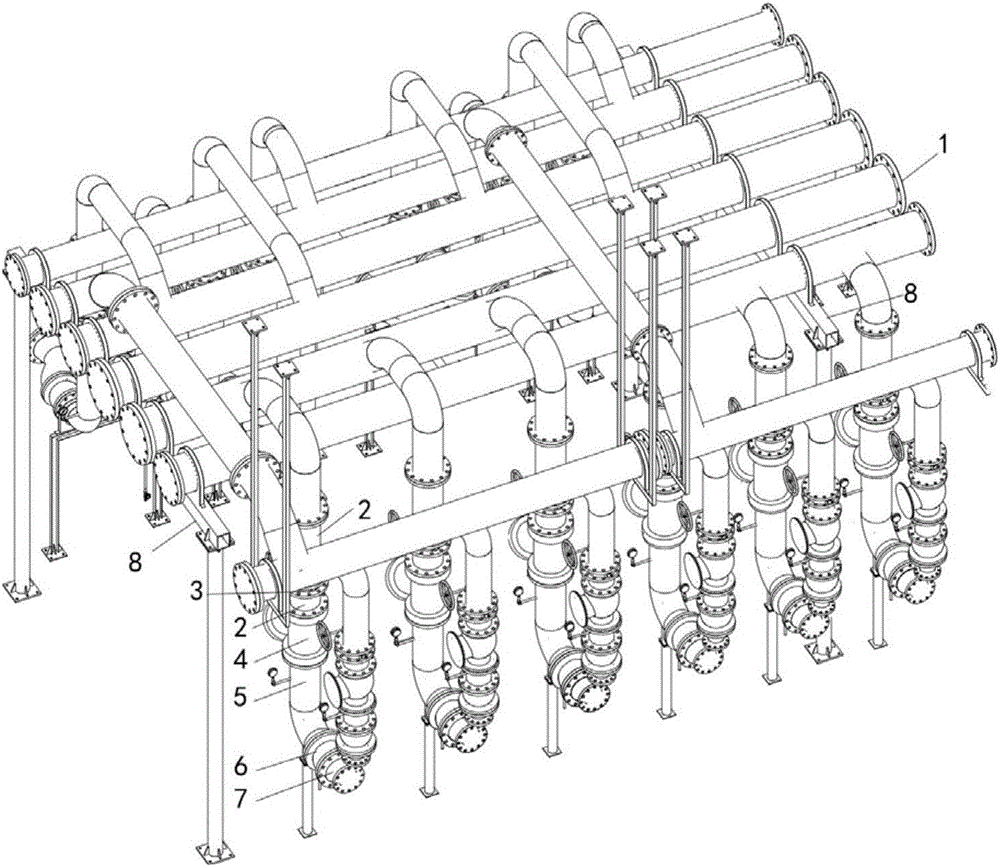

[0032] figure 2 Numbers in: 1. Main pipe; 2. Short pipe; 3. Butterfly valve; 4. Y-type filter; 5. Elbow section; 6. Stainless steel soft joint; 7. Eccentric head;

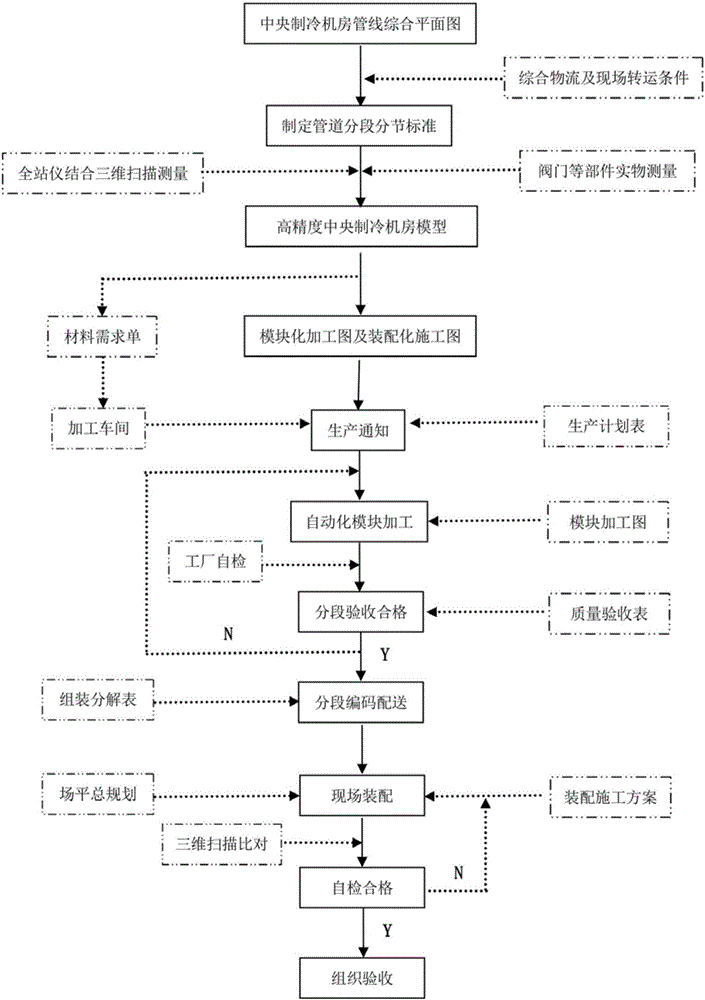

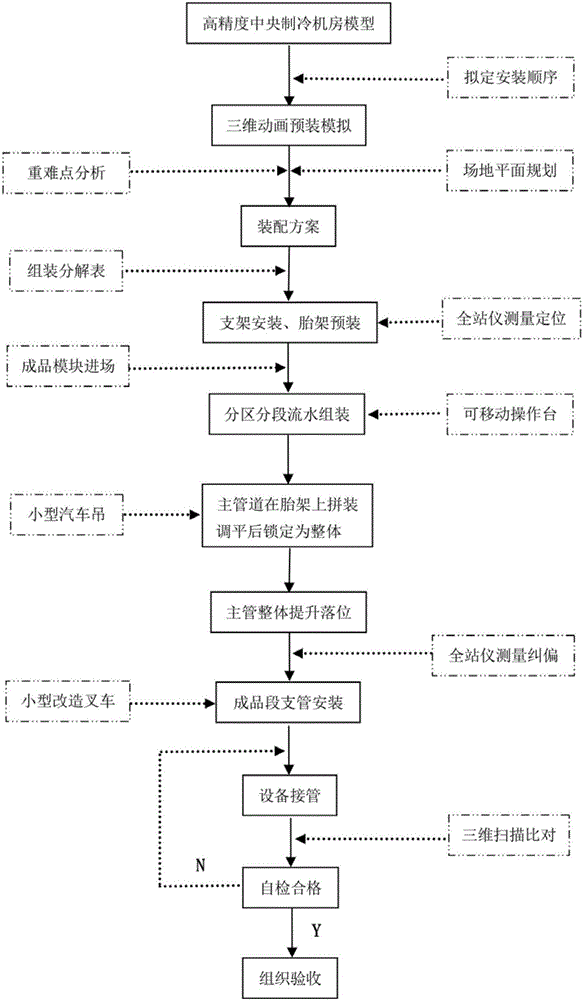

[0033] Below in conjunction with accompanying drawing, the present invention is further described, as figure 1 , figure 2 , image 3 shown

[0034] 1. Establish a BIM model of the central refrigeration room pipeline: use REVIT software, on the basis of building information modeling BIM, according to the design drawings of the central refrigeration room, combined with the requirements of assembly construction, create a standard BIM family library, and establish a central refrigeration based on physical size BIM model of equipment room pipeline;

[0035] 2. Review and measure the building structure of the central refrigeration room, feed back the measured actual size in the form of three-dimensional data to the BIM model of the pipeline of the central refrigeration room for comparison, and consider the impact o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com