Investment casting process of metal product

A technology of metal products and casting technology, which is applied in the field of metal product manufacturing, can solve problems such as large tolerances and internal defects, and achieve the effects of controllable errors, high production efficiency, and avoiding excessive tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings, but it should be noted that these embodiments are not a limitation of the present invention, and those of ordinary skill in the art make functional, method, or structural improvements based on these embodiments. Equivalent changes or substitutions fall within the protection scope of the present invention.

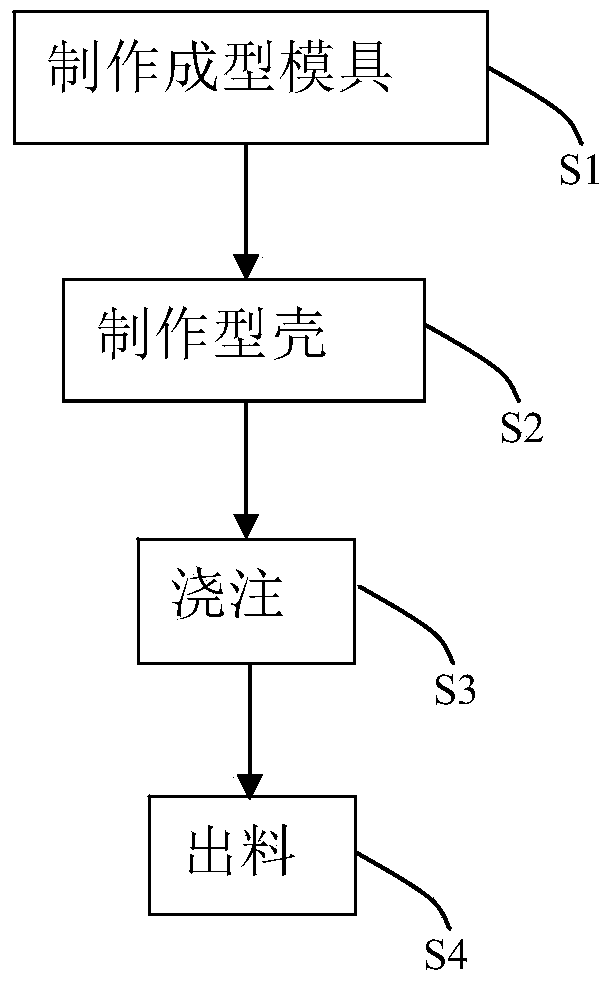

[0023] Such as figure 1 As shown, the investment casting process 100 for metal products of the present invention includes the following steps:

[0024] S1. Make a forming mold, and make a corresponding forming mold according to the size of the workpiece of the metal product;

[0025] S2. Making the shell, making the shell according to the forming mold in S1;

[0026] S3. Pouring, pouring metal solution into the cavity of the shell;

[0027] S4. Discharging, after the metal solution is solidified, remove the mold shell and take off the formed metal product.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com