Two-dimensional full-Stokes polarization imaging element and preparation method thereof

A polarization imaging and component technology, applied in polarization components, optical components, instruments, etc., can solve the problems of small extinction ratio, complex process, low transmittance, etc., and achieve the effect of simple steps, mature technology and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

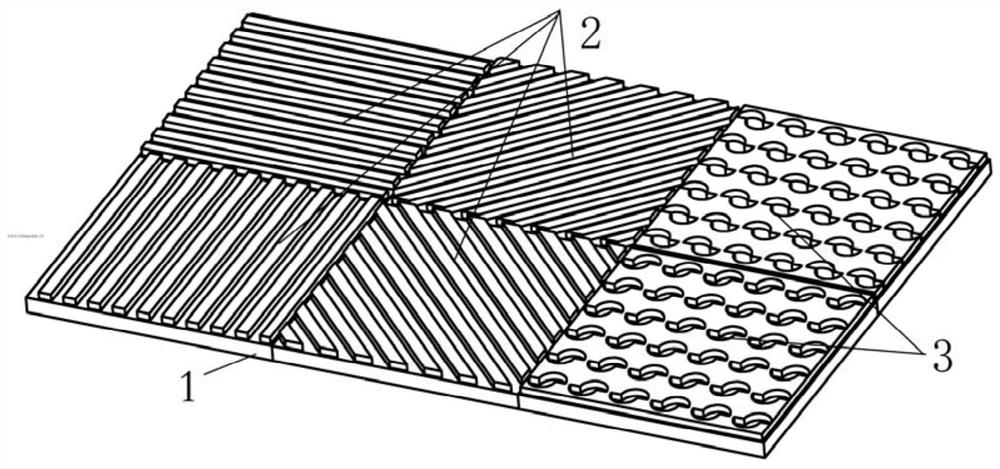

[0031] See figure 1 所示,本发明全斯托克斯偏振成像元件包括:1、透光基底;2、设置于透光基底上的四个不同方向的光栅介质结构;3、两个旋转对称手性介质结构。

[0032] 所述透光基底材料为二氧化硅,介质结构的材料为硅。

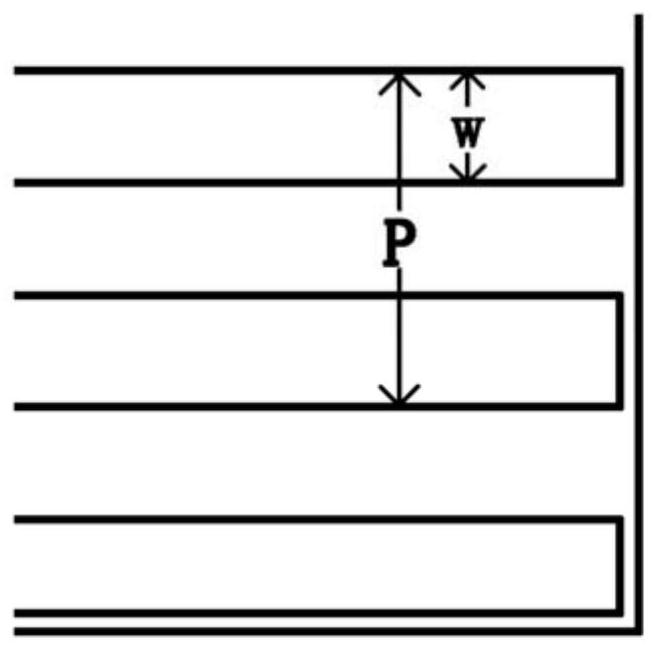

[0033] 所述的光栅结构俯视图如 figure 2 所示,周期0.77μm;介质结构的占空比0.88,所述的旋转对称手性介质结构的深度H为0.215μm。

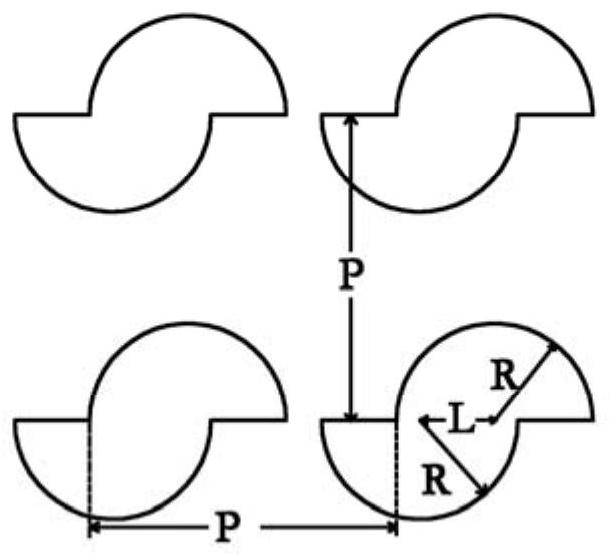

[0034] 所述的手性对称结构俯视图如 image 3 所示,周期0.92μm;所述的旋转对称手性介质结构的深度H为0.215μm,圆心距L为0.36μm,半径R 为0.23μm。

[0035] 该元件通过如下步骤制得:

[0036] (1)在二氧化硅表面利用电子束蒸发或者化学气相沉积法生长出一层硅;

[0037] (2)在硅层上使用匀胶机涂上一层电子束光刻胶负胶;

[0038] (3)利用电子束曝光和显影技术根据特定参数得到0°、45°、90°和135°不同取向的线栅和左右旋旋转对称手性结构的光刻胶结构图形;

[0039] (4)使用反应离子束刻蚀工艺刻蚀硅层,去除残余光刻胶得到全斯托克斯偏振成像元件。

[0040] attached Figure 4 , attached Figure 5 And attached Image 6 分别为线偏振光(TE,TM)由基底入射到介质线栅结构后的透过率曲线图、消光比曲线图以及二色性,其中 TE偏振光平行于光栅方向。在1.54μm波段,此元件对TM偏振光透过率达到92.5%。对两种偏振光的消光比达33.57db,偏振二色性超过92%。

[0041] attached Figure 7 , attached Figure 8 And attached Figure 9 分别为左右旋圆偏振光(RCP,LCP)由基底入射到附 image 3 所示的旋转对称手性结构后的透过率曲线图、圆偏振消光比以及圆偏振二色性曲线图。可以看出,在1.54μm波段此元件的对左旋圆偏振光的透过率达到95%。消光比达到45比1,偏振二色性达到94.3%。

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| degree of polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com