Frames for supporting service cells

a technology for supporting structures and service cells, applied in the field of structures, can solve the problems of changes in site design or the needs of the site may exceed the existing capacity of the building, and it is difficult, time-consuming and/or expensive to reconfigure the slab support for a change in site design,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

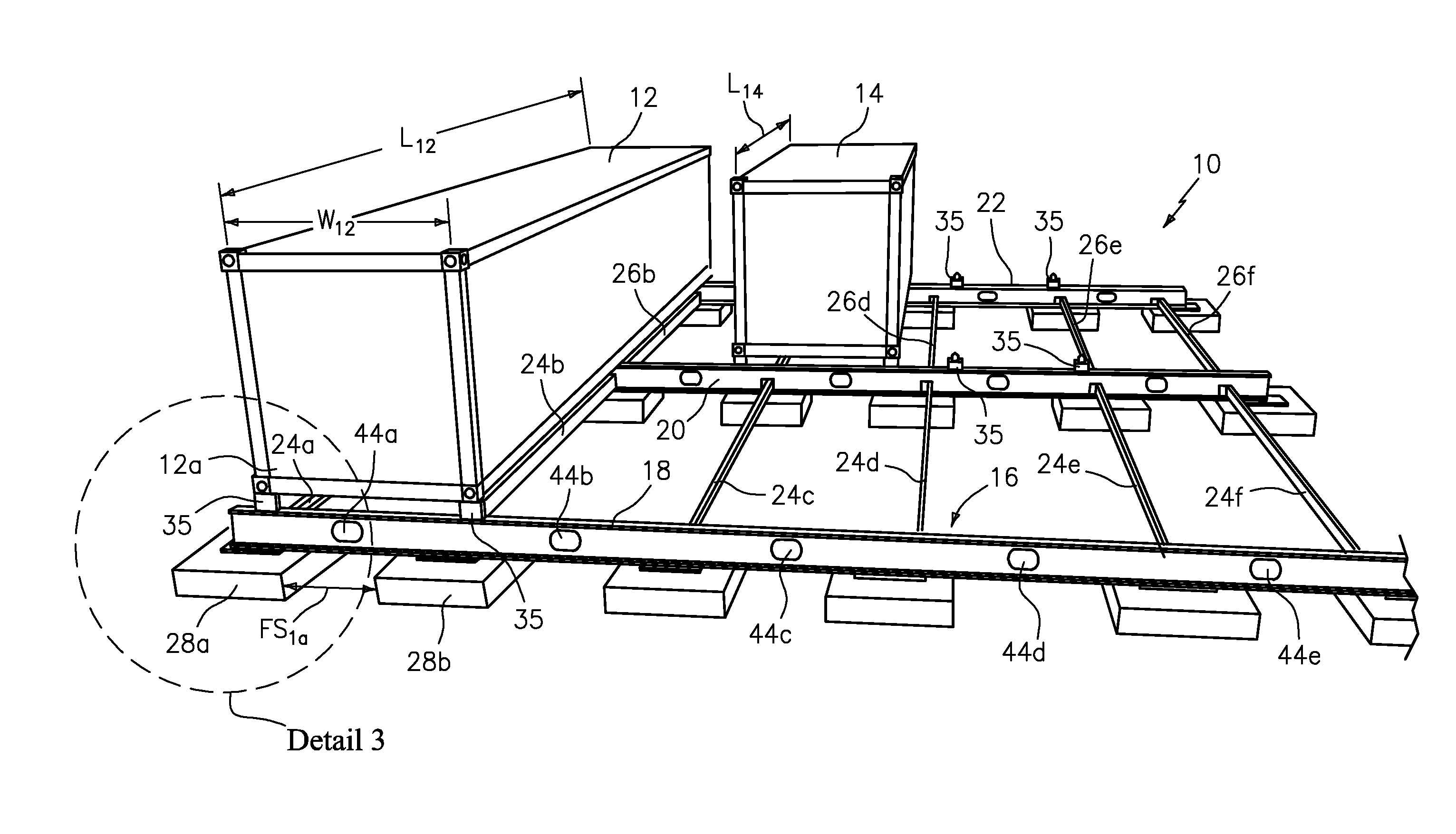

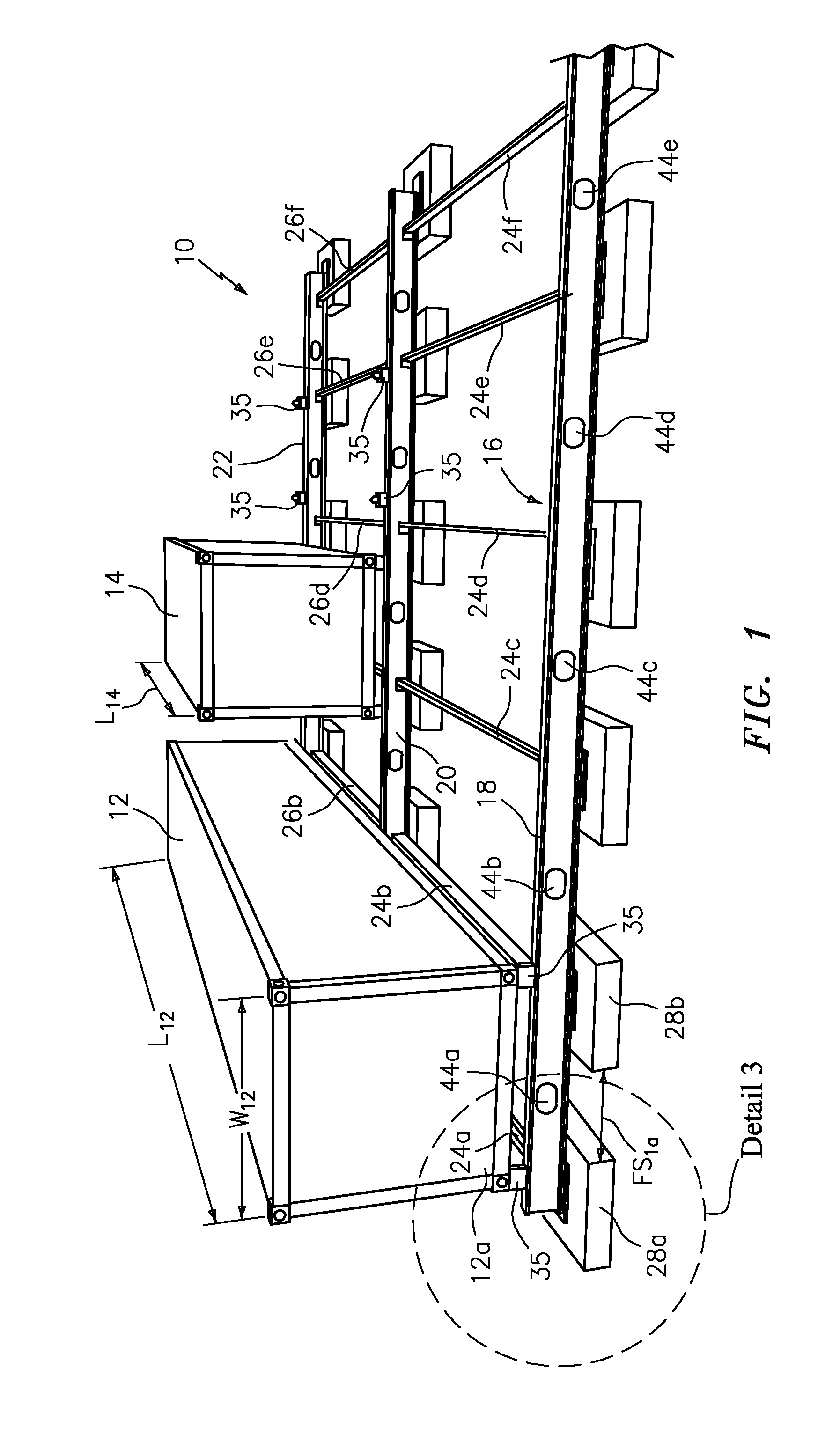

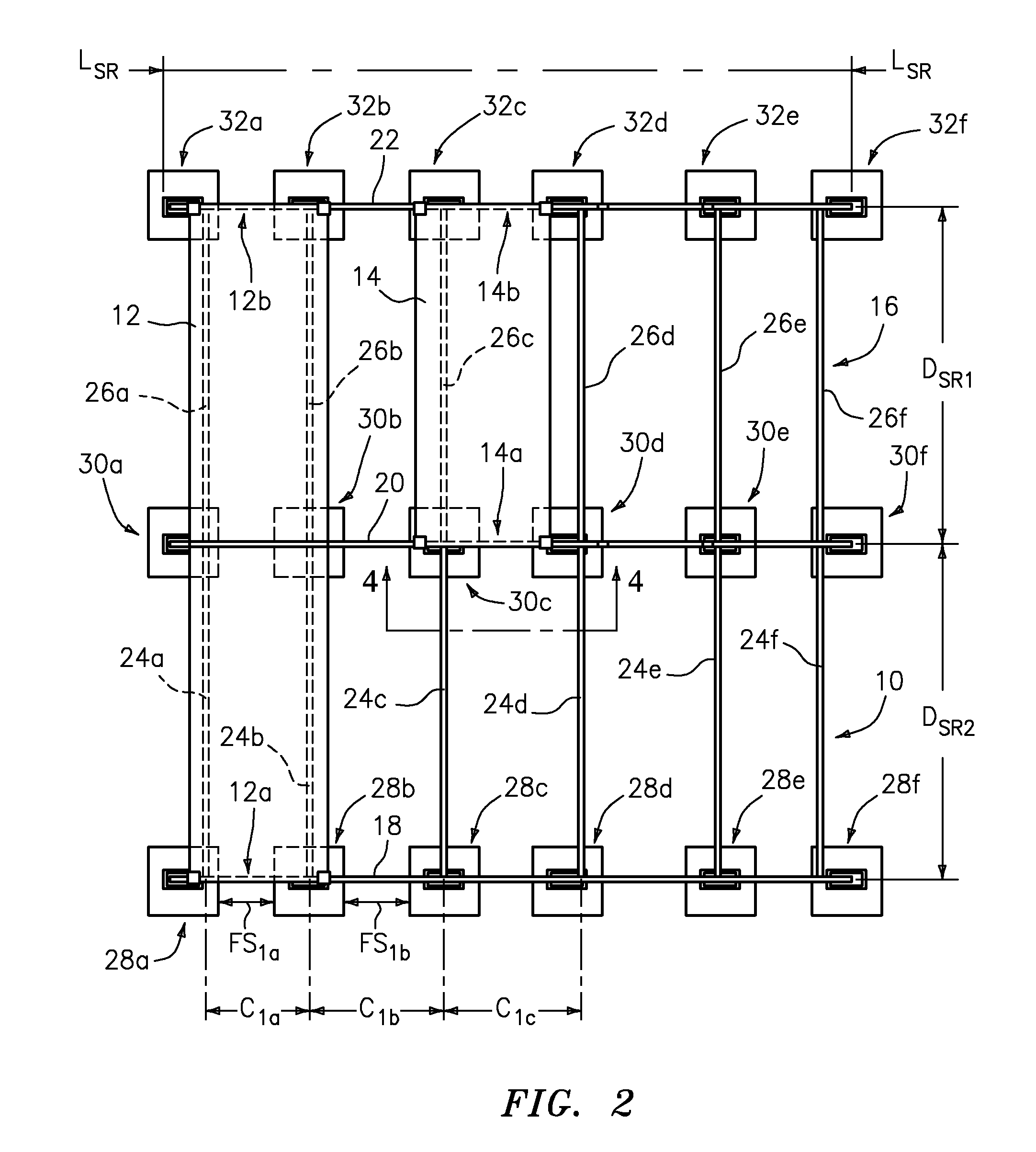

[0020]FIGS. 1 and 2 illustrate one embodiment of a frame, shown generally at 10, for supporting one or more modular cells such as, for example, two modular cells 12, 14, that provide one or more services to a building site. In one embodiment, the frame 10 includes a frame assembly 16 comprising a plurality of support rails, for example, three support rails 18, 20, and 22. In one embodiment, the frame assembly 16 also comprises a first plurality of connecting rails 24a, 24b, 24c, 24d, 24e, and 24f which extend between, and which are joined to, the support rails 18 and 20, and a second plurality of connecting rails 26a, 26b, 26c, 26d, 26e, and 26f, which extend between, and which are joined to, the support rails 20 and 22. In the embodiment shown, the frame assembly 16 rests on a plurality of footings that each support a portion of the support rails 18, 20 and 22. For example, in one embodiment, footings 28a, 28b, 28c, 28d, 28e, and 28f support the support rail 18; footings 30a, 30b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com