Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

An ultra-high pressure, ultra-large technology, applied in the field of new ultra-large displacement ultra-high pressure cementing equipment, can solve the problems of difficult to meet the displacement and pressure requirements, complex pipeline connections, large floor space, etc., to meet the large displacement , Optimizing the piping of the mixing system, increasing the effect of pressure and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

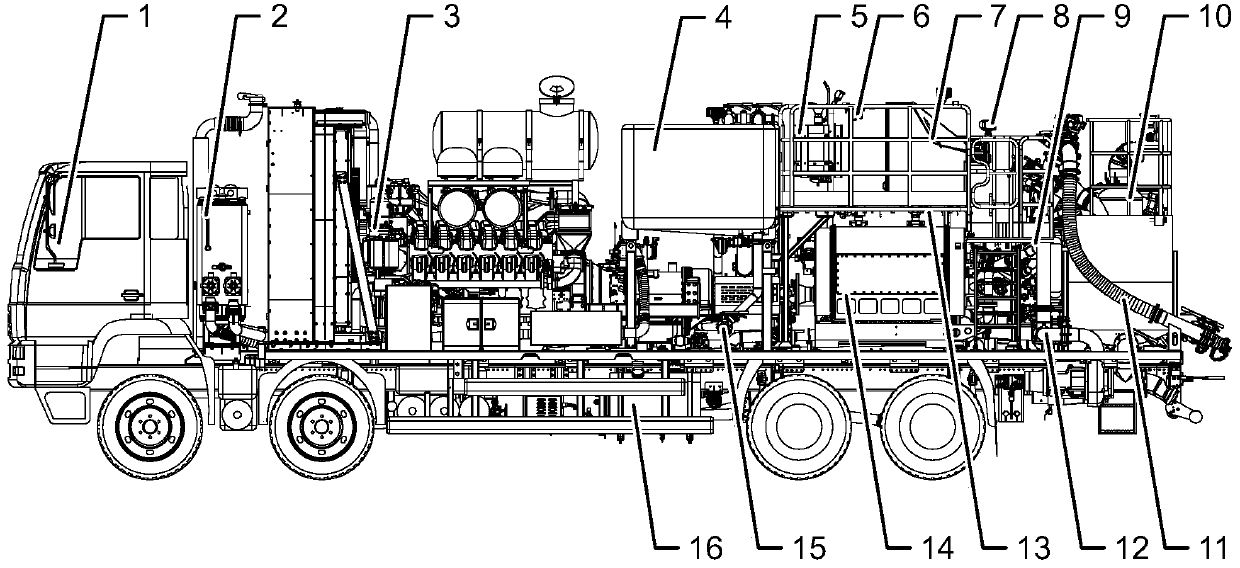

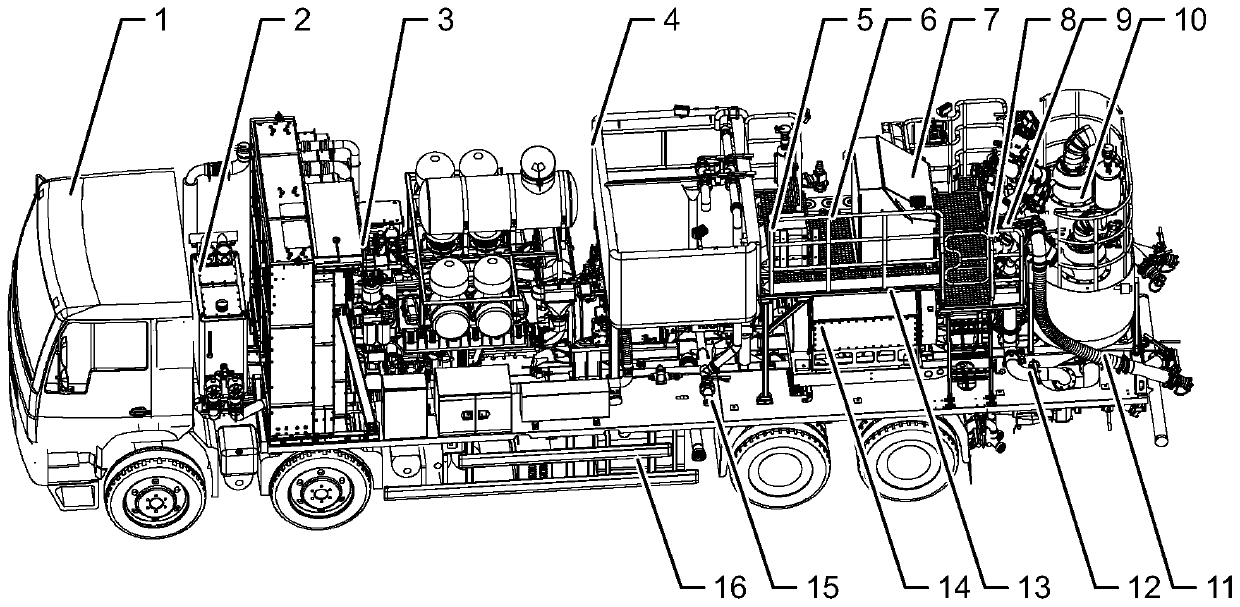

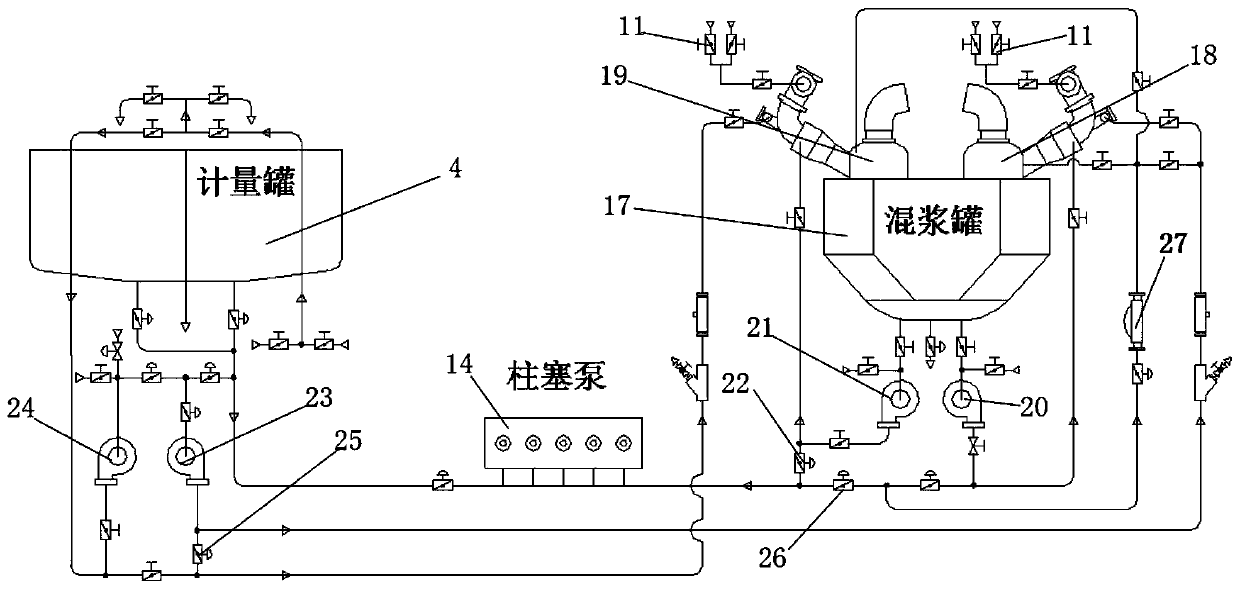

[0019] Such as Figures 1 to 3 As shown, a new type of ultra-large displacement and ultra-high pressure cementing equipment includes a loading body 1, a hydraulic system 2, a power transmission system 3, a metering tank 4, an electrical system 8, a gas system 6, a control system 7, and an operation platform 13 , plunger pump 14, clear water manifold 15, mud manifold 12, high pressure manifold 9, mixing system 10 and ash loading manifold 11, the hydraulic system 2, power transmission system 3, metering tank 4, operating platform 13, The mixing system 10 is sequentially installed on the loading body 1, the electrical system 8 is used to supply power to the electrical components on the cementing equipment, the gas circuit system 6 and the control system 7 are sequentially installed on the operating platform 13, The bottom of the metering tank 4 is connected to the inlet of the clean water manifold 15, and the outlet of the clean water manifold 15 is respectively connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com