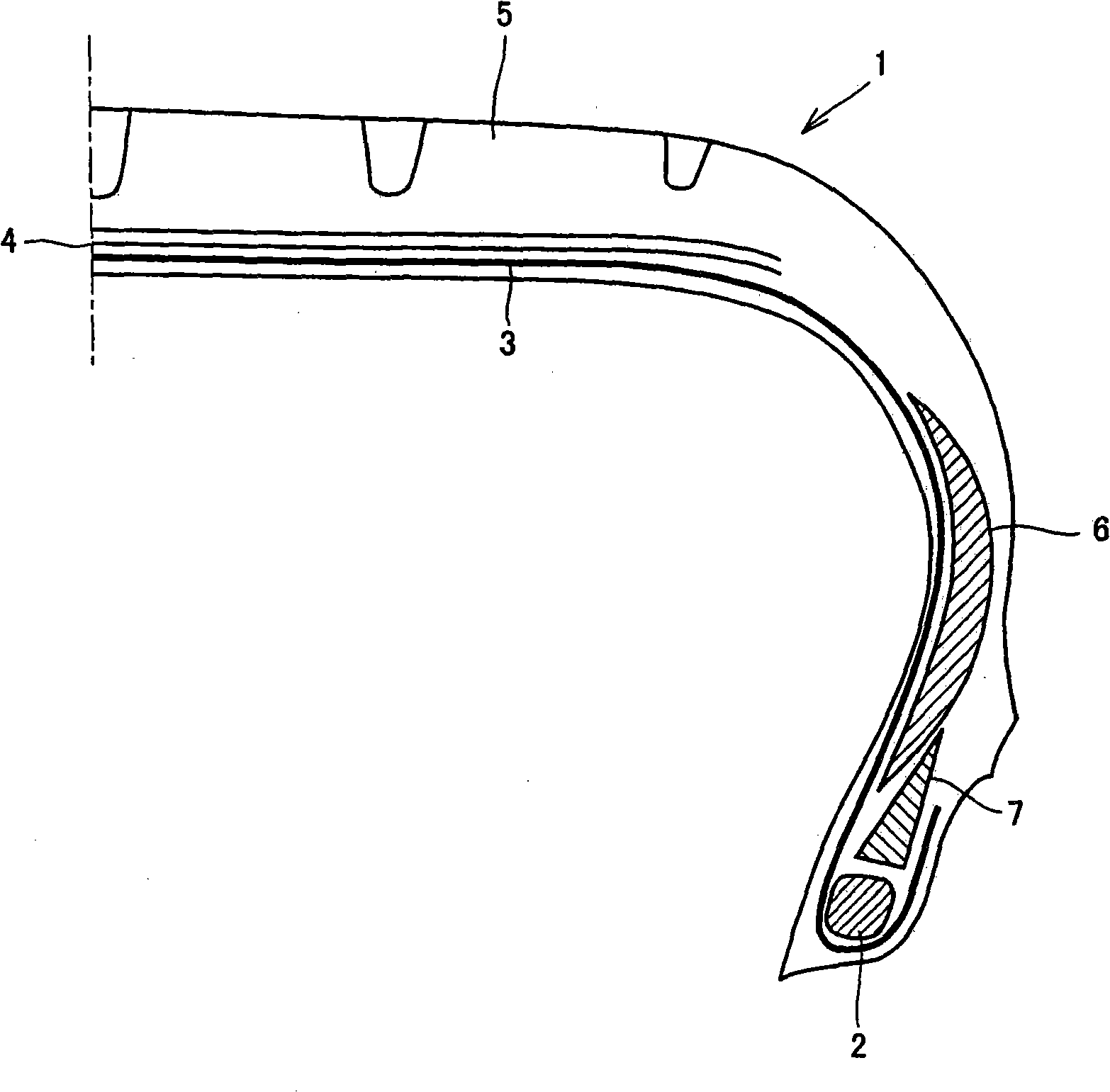

Rubber composition and run flat tire using the same

A rubber composition and run-flat technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of low hardness and insufficient load support, and achieve low heat generation and excellent run-flat performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

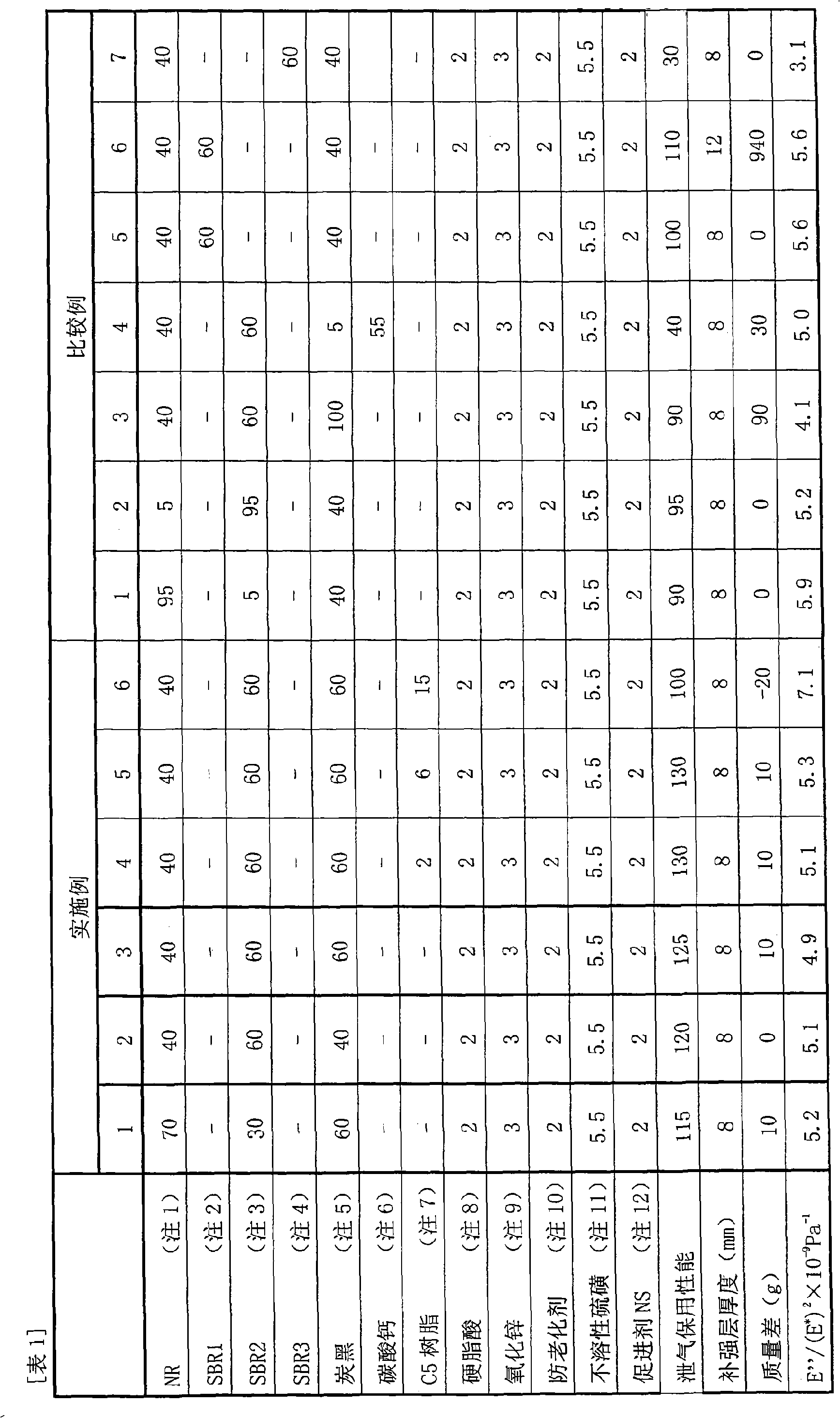

Embodiment 1~2 and comparative example 1~4

[0050]

[0051] (1) SPBd crystalline SBR-2

[0052] 250 g of 1,3-butadiene was dissolved in 8000 ml of a hexane solution, and 1000 g of SBR ("SL574" manufactured by JSR) was added to fully dissolve it. As a polymerization catalyst, 500 ml of 0.2M triisopropylaluminum, 20 ml of 0.042 M cobalt octoate solution, and 15 ml of carbon disulfide were added, reacted at 40°C for 8 hours, and dried under reduced pressure to obtain SPBd with an SPBd crystal content rate of 12% by mass. Crystalline SBR-2 was 1135 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com