Permanent-magnet eddy current retarder based on Halbach array

A permanent magnet eddy current and retarder technology, which is applied in the direction of permanent magnet clutches/brakes, can solve the problems that have not been seen in the application of Halbach arrays, and achieve the effects of high magnet utilization efficiency, large braking torque, and convenient adjustment of the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

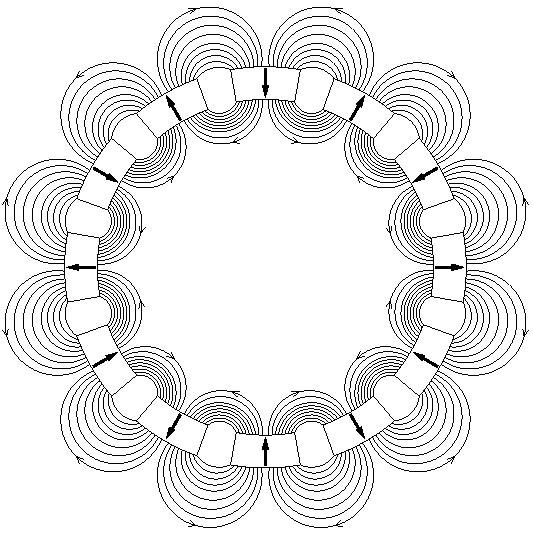

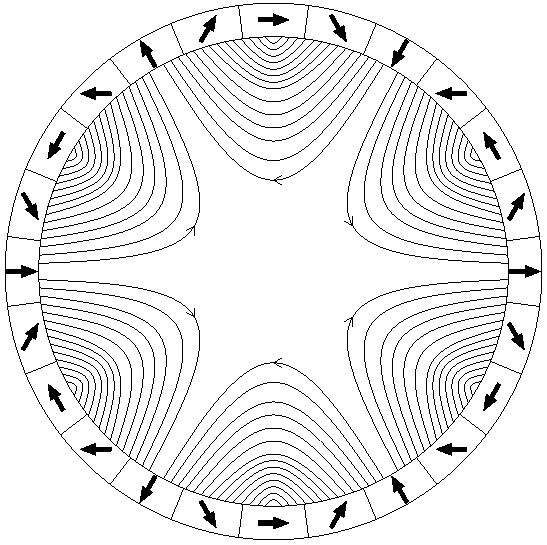

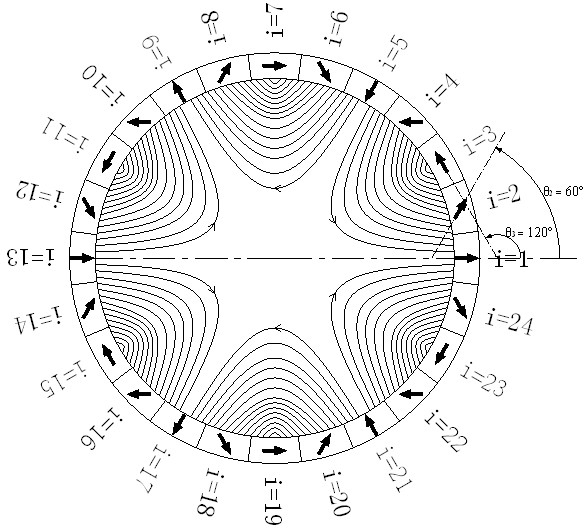

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

[0025] Such as Figure 4 , Figure 5 , Figure 6 Shown, the present invention comprises left fixed plate 15, right fixed plate 21, power transmission shaft 14, rotor 18, servo motor 1, shaft coupling 2, motor fixed frame 3, two-way lead screw shaft 6, the left and right sides of opposite direction of rotation Lead screw nuts 8, 11, three linear optical axes 16, and two stators with the same structure. The rotor 18 made of magnetically permeable material is mounted on the drive shaft 14 through a key. One end of the rotor 18 rests on the shaft shoulder, and the other end is fixed with a round nut 20. The web between the rotor hub and the rotor outer ring is processed into a fan blade shape. When the rotor 18 rotates with the transmission shaft 14, the generated axial airflow will take away the heat generated during braking. The two ends of transmission shaft 14 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com