Staggered continuous pole permanent magnet synchronous linear motor

A permanent magnet synchronous linear, interlaced and continuous technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of expensive rare earth permanent magnets, increased motor costs, etc., to facilitate installation and fixing, optimize thrust performance, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

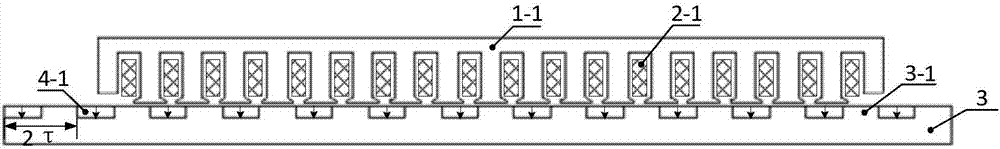

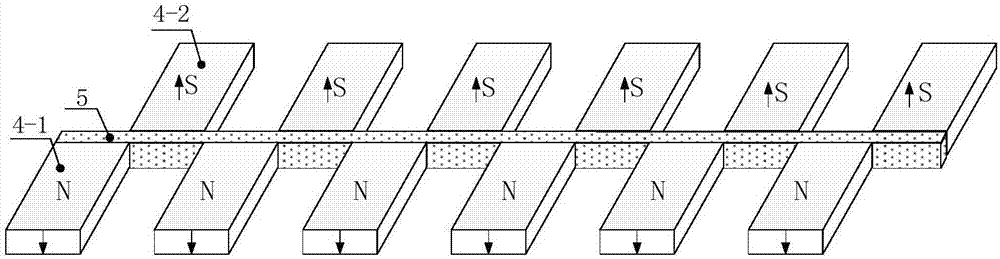

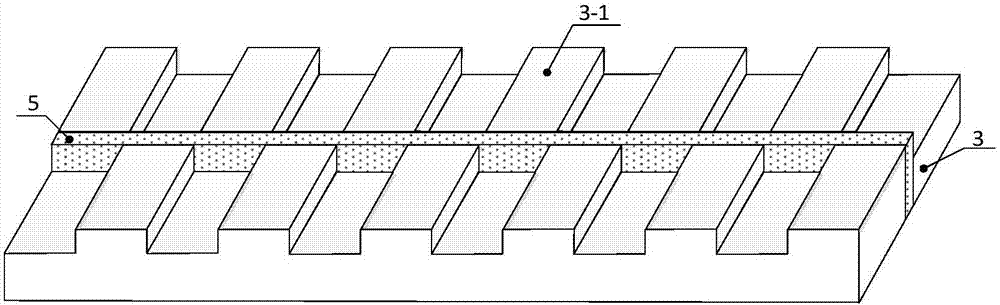

[0026] Such as figure 1 As shown, the interleaved continuous pole permanent magnet synchronous linear motor of the present invention includes primary, secondary and air gap. The primary is composed of a multi-tooth primary iron core 1-1 and a primary armature winding 2-1, every other primary iron core is wound with a primary armature winding, and the primary iron cores at both ends are not wound. The secondary is composed of a secondary back yoke core 3, a permanent magnet-iron pole array and a magnetic isolation material 5, and there is an air gap of 0.5 mm between the primary and secondary. In the permanent magnet-iron pole array, the permanent magnets 4-1, 4-2 and iron poles 3-1 are alternately arranged, and are divided into two groups of equal length along the transverse direction, and a magnetic isolation material 5 is arranged in the middle of the two groups, and the polarity of one group is according to N-iron poles-N are arranged alternately, and the other set of pola...

Embodiment 2

[0029] Such as Figure 5 As shown, the primary structure of Embodiment 2 is exactly the same as that of Embodiment 1, the difference is that the secondary permanent magnet-iron pole array of Embodiment 2 is expanded into multiple groups of combinations, that is, expanded from 2 groups to 3 groups, 4 groups, and 5 groups , ..., N groups of combinations, wherein the permanent magnet-iron pole arrays of the odd groups are all arranged in the same arrangement as the first group, and the permanent magnet-iron pole arrays of the even groups are all arranged in the same arrangement as the second group. The combination of multiple groups is suitable for large-thrust linear motors, which helps to reduce process difficulty, reduce material costs and improve thrust performance.

Embodiment 3

[0031] Such as Figure 6 As shown, the primary structure of the third embodiment is exactly the same as that of the first embodiment, the difference is that the two sides of the secondary side of the third embodiment can be formed by two primary structures with the same groove structure, and the upper primary is composed of a multi-tooth primary iron core 1-1 Composed of primary armature winding 2-1, the lower primary is composed of multi-tooth primary iron core 1-2 and primary armature winding 2-2, the upper and lower secondary primary are staggered by a certain distance, and the staggered tooth structure is used to effectively weaken the Positioning power. The upper and lower surfaces of the secondary back yoke iron core are provided with permanent magnet-iron pole arrays with opposite polarities.

[0032] Such as Figure 7 Shown is the interleaved permanent magnet array in the bilateral interleaved continuous pole permanent magnet synchronous linear motor. Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com