Rotor with quasi-V-shaped magnetic steel structures and suitable for high-performance motor

A high-performance, magnetic steel technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the magnetic circuit, etc., can solve the problem of not attracting enough attention, and reduce the phenomenon of magnetic leakage, air-gap magnetic The effect of high density and low harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

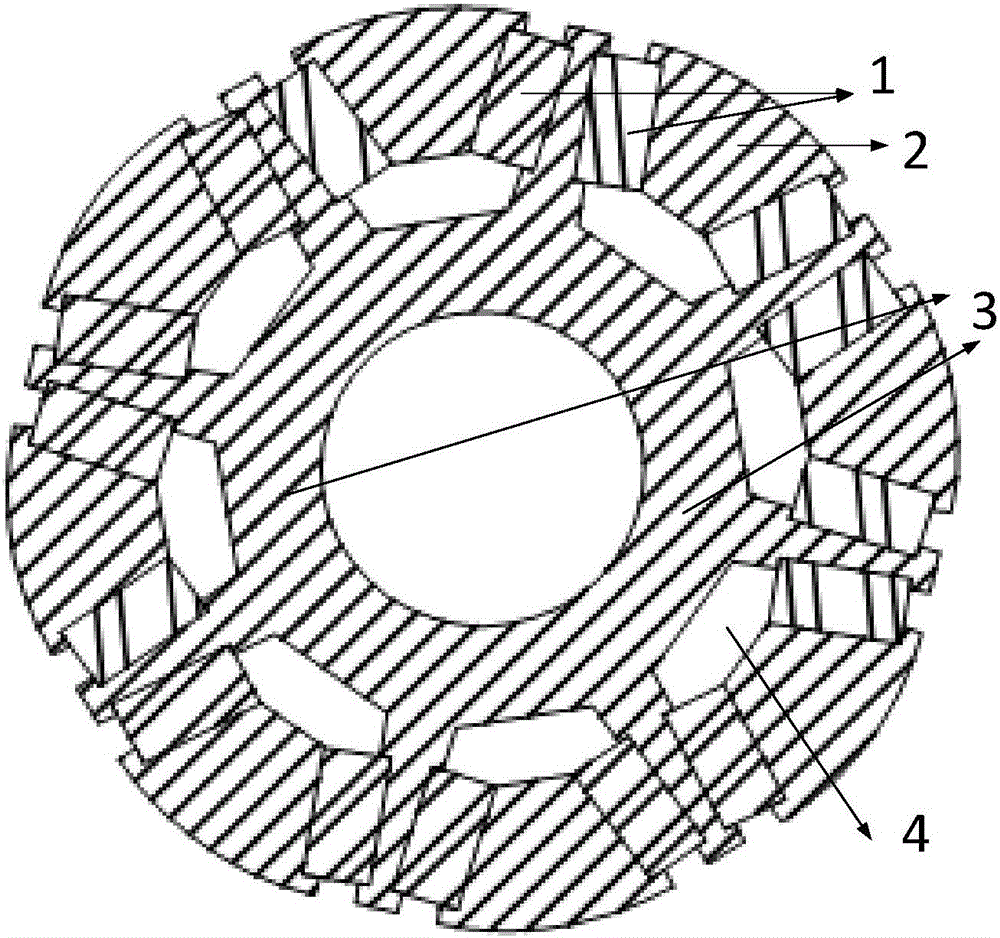

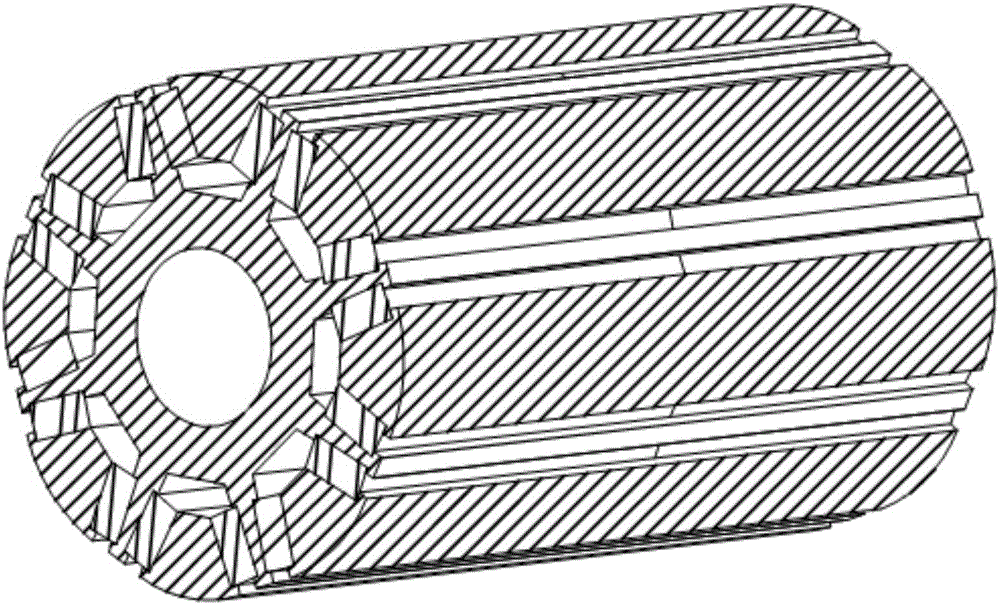

[0030] A quasi-V-shaped magnetic steel structure rotor suitable for high-performance motors mainly includes a quasi-V-shaped magnetic steel 1, an auxiliary rotor core 2, an active rotor core 3 and a cooling channel 4. Such as figure 1 shown.

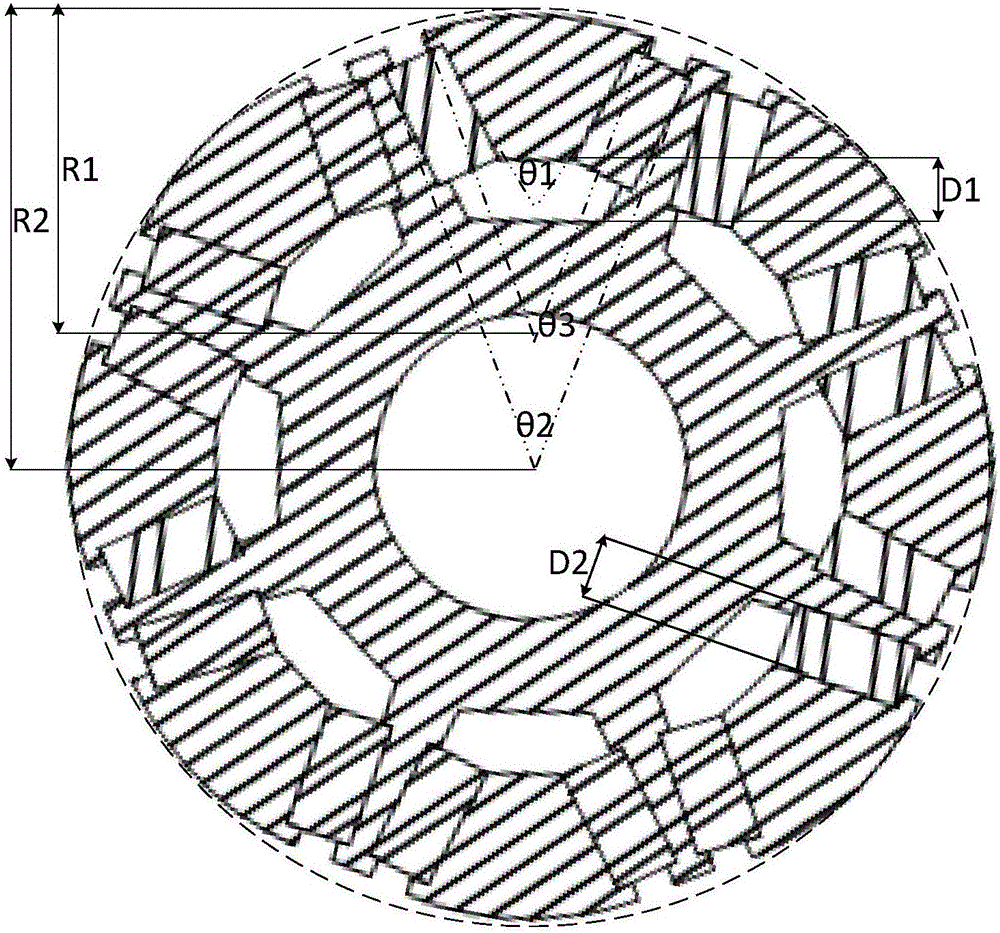

[0031] In the present invention, the quasi-V-shaped magnetic steel is a magnetic pole installation type. Specifically, a magnetic pole is equally divided into a quasi-V shape and embedded in the rotor core, including an auxiliary mover core 2 and a Two quasi-V-shaped magnets 1 on both sides of the mover core 2, the two quasi-V-shaped magnets 1 constitute a magnetic pole, and the shoulders of the two quasi-V-shaped magnets 1 of a quasi-V-shaped magnet structure The included angle θ2 between the line connecting the 3-axis center point of the active rotor core satisfies:

[0032]

[0033] where p is the number of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com