Modular primary permanent magnetic linear motor and motor module consisting of same

A permanent magnet linear motor, modular technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increased system manufacturing costs and maintenance costs, high costs of permanent magnets and armatures, and achieve simple structure and easy heat dissipation. , the effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention includes a primary 11, a secondary 10 and a concentrated winding 113, wherein both the primary 11 and the secondary 10 are salient pole structures with an air gap between them.

[0033] The primary 11 includes m or 2m primary modules (110), where m is the phase number of the motor; a magnetically permeable or non-magnetically permeable material 114 is filled between two adjacent primary modules (110).

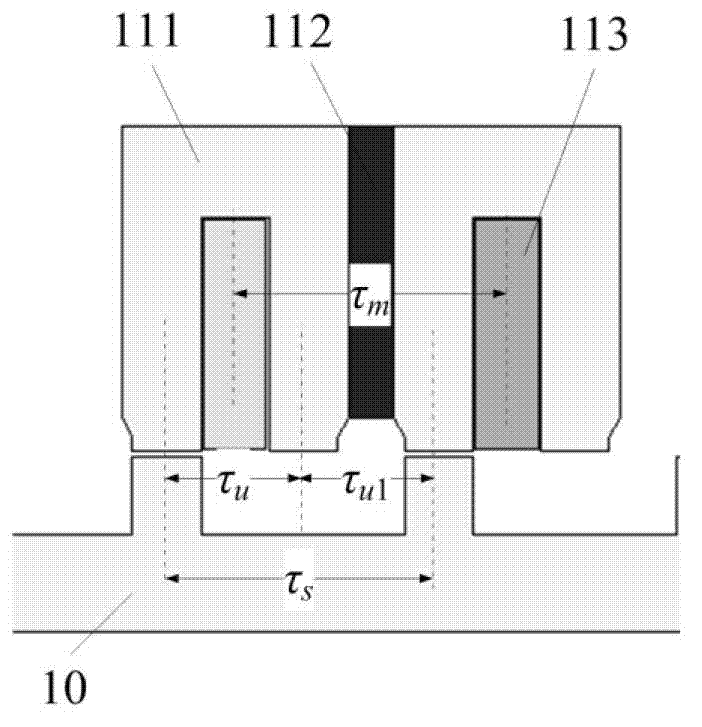

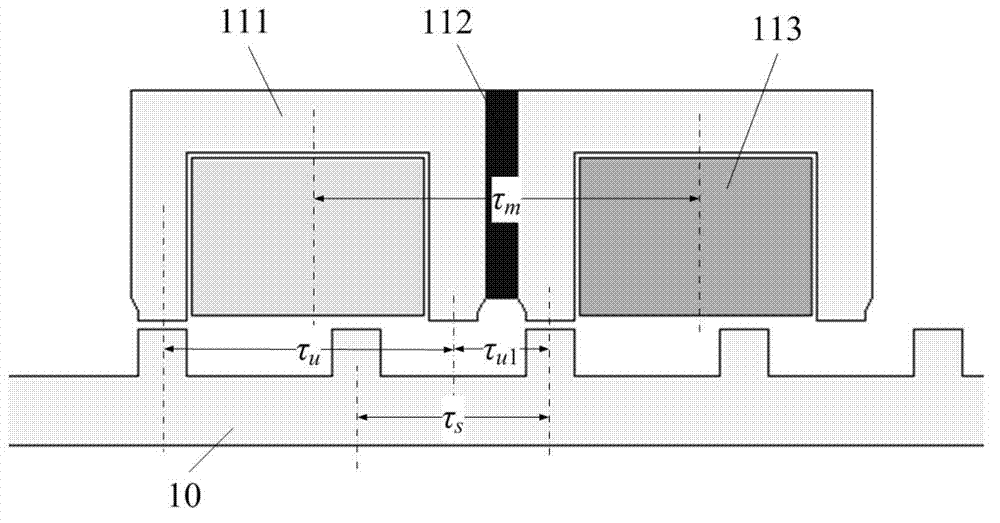

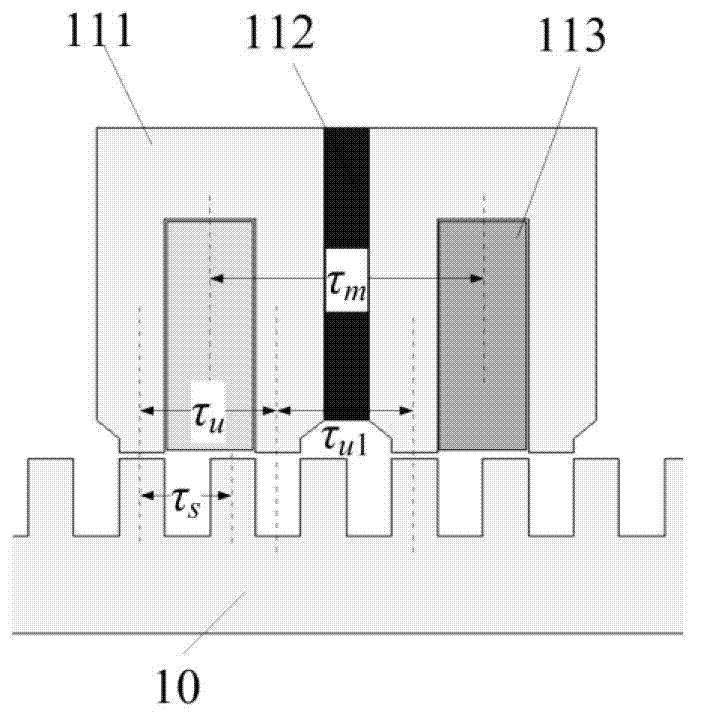

[0034] Each primary module 110 includes two U-shaped magnetically permeable materials 111 and a permanent magnet 112 disposed between the U-shaped magnetically permeable materials 111 . The concentrated winding 113 is disposed in the slot of the primary module 110 and covers the permanent magnet 112 .

[0035] The distance between the central axes of the two teeth of each U-shaped magnetically permeable material 111 is τ u , the distance between the central axes of the two U-shaped magnetic permeable materials 111 teeth on both sides of the permanen...

Embodiment 2

[0052] Such as Figure 6 and 7 As shown, the difference between the modularized primary permanent magnet linear motor in this embodiment and that in Embodiment 1 is that the relative displacement between the two primary modules 110 belonging to the same phase satisfies λ 1 =nτ s ,exist Figure 6 where n=19, in Figure 7 where n=6, so the two primary modules 110 belonging to the same phase do not have complementary characteristics. also in Figure 6 The two primary modules 110 belonging to the same phase are placed adjacent to each other, while in Figure 7 Two primary modules 110 belonging to adjacent phases are placed together. Therefore, for the sake of illustration, Figure 6 The structure in is called "ABCABC", Figure 7 The structure in is called "2A2B2C". Theoretically, in order to obtain an m-phase motor, the relative displacement between two primary modules 110 belonging to different phases needs to satisfy λ 2 =(i±1 / m)τ s or lambda 2 =[i±(0.5-1 / m)]τ s Tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com