Five-phase permanent magnet synchronous motor with high torque density

A permanent magnet synchronous motor, high torque technology, applied to synchronous motors with stationary armature and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of low third harmonic content , The improvement of torque density is not significant, etc., to achieve the effect of reducing magnetic leakage rate, increasing degree of freedom, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

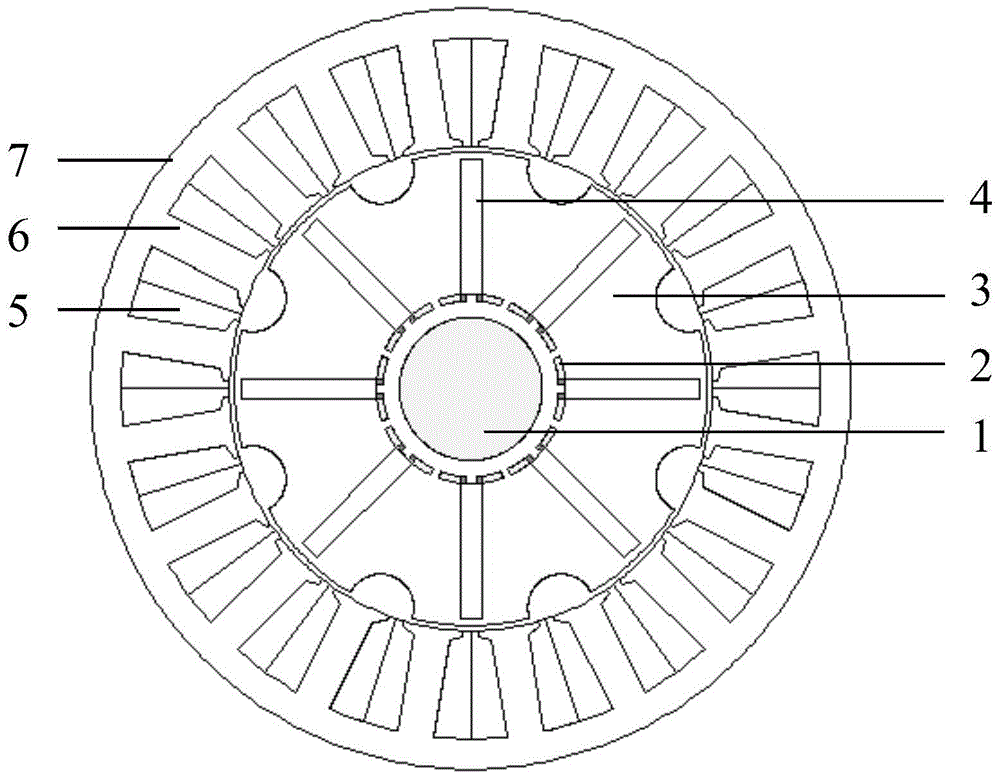

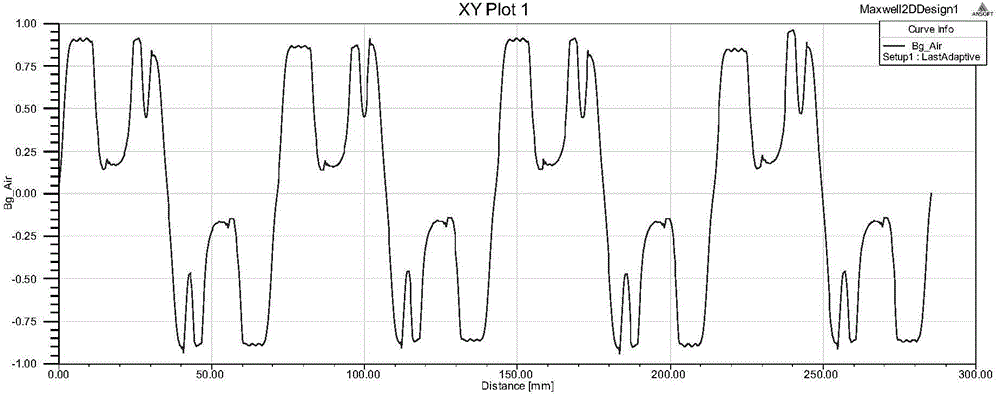

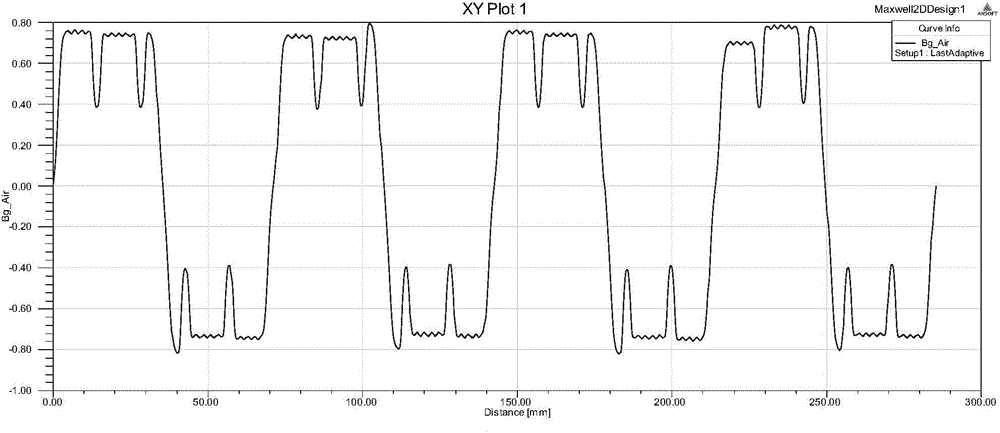

[0025] Such as figure 1 As shown, a five-phase permanent magnet synchronous motor with high torque density, the grooves arranged alternately along the outer circumference of the rotor, inject the fundamental wave and the third harmonic current at the same time, choose the appropriate groove radius, the appropriate fundamental wave and The amplitude and phase of the third harmonic current can significantly increase the output torque of the motor. The above methods have been verified by the finite element method.

[0026] The stator winding adopts five-phase symmetrical fractional slot concentrated winding; the appropriate number of pole slots is used to make the motor winding have a high third harmonic winding coefficient.

[0027] The built-in permanent magnet rotor is adopted, and the permanent magnet is made of high-performance permanent magnet mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com