Method for realizing low-frequency rotary constant high-intensity magnetic field

A realization method and technology of strong magnetic field, applied in the directions of magnetic therapy, using variable magnetic field generated by mechanical movement, electrotherapy, etc., can solve the problems of leakage of magnetic force lines and insufficient magnetic therapy effect, so as to prevent interference and reduce the amount of magnets. , good effect of magnetic therapy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

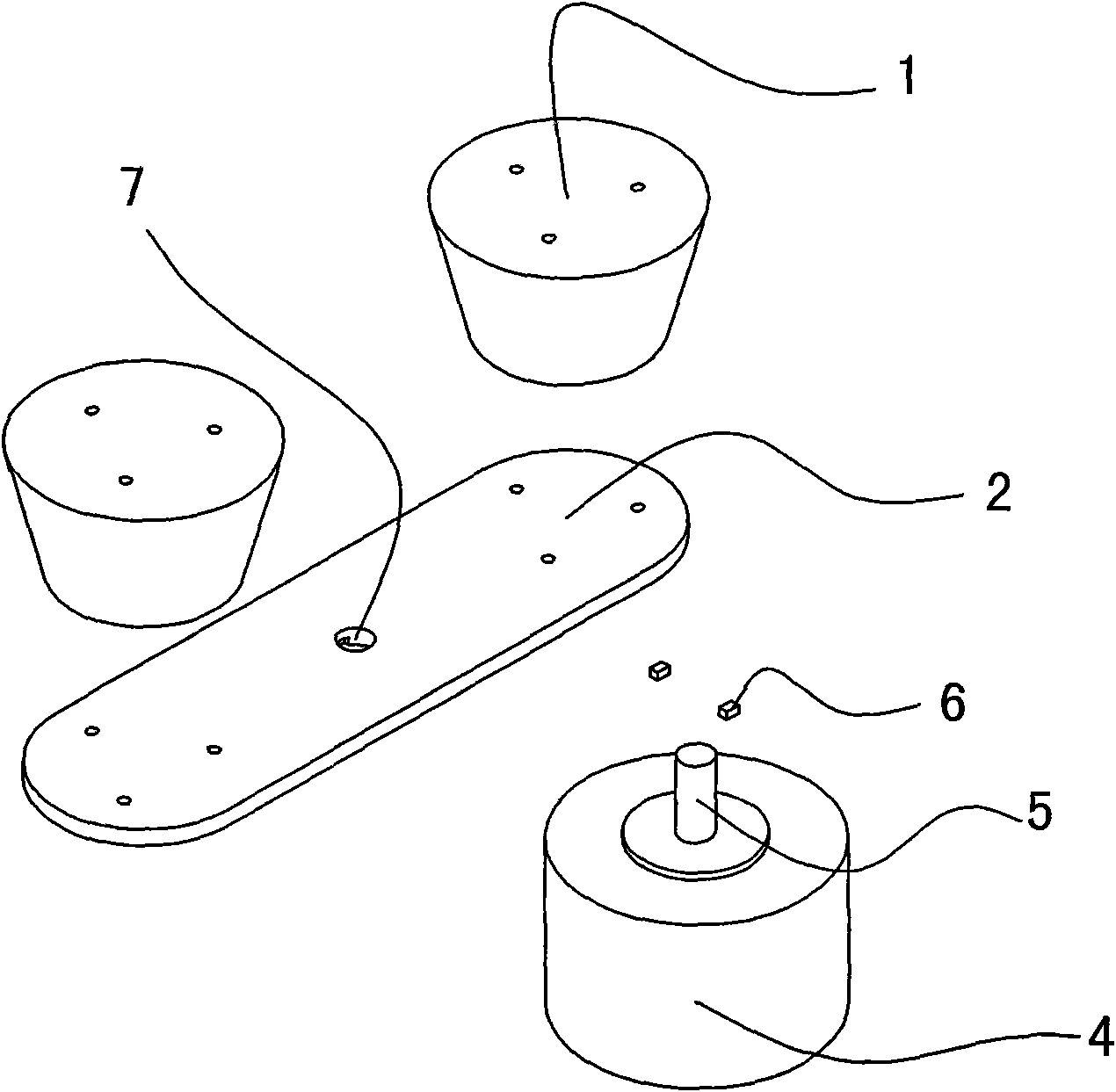

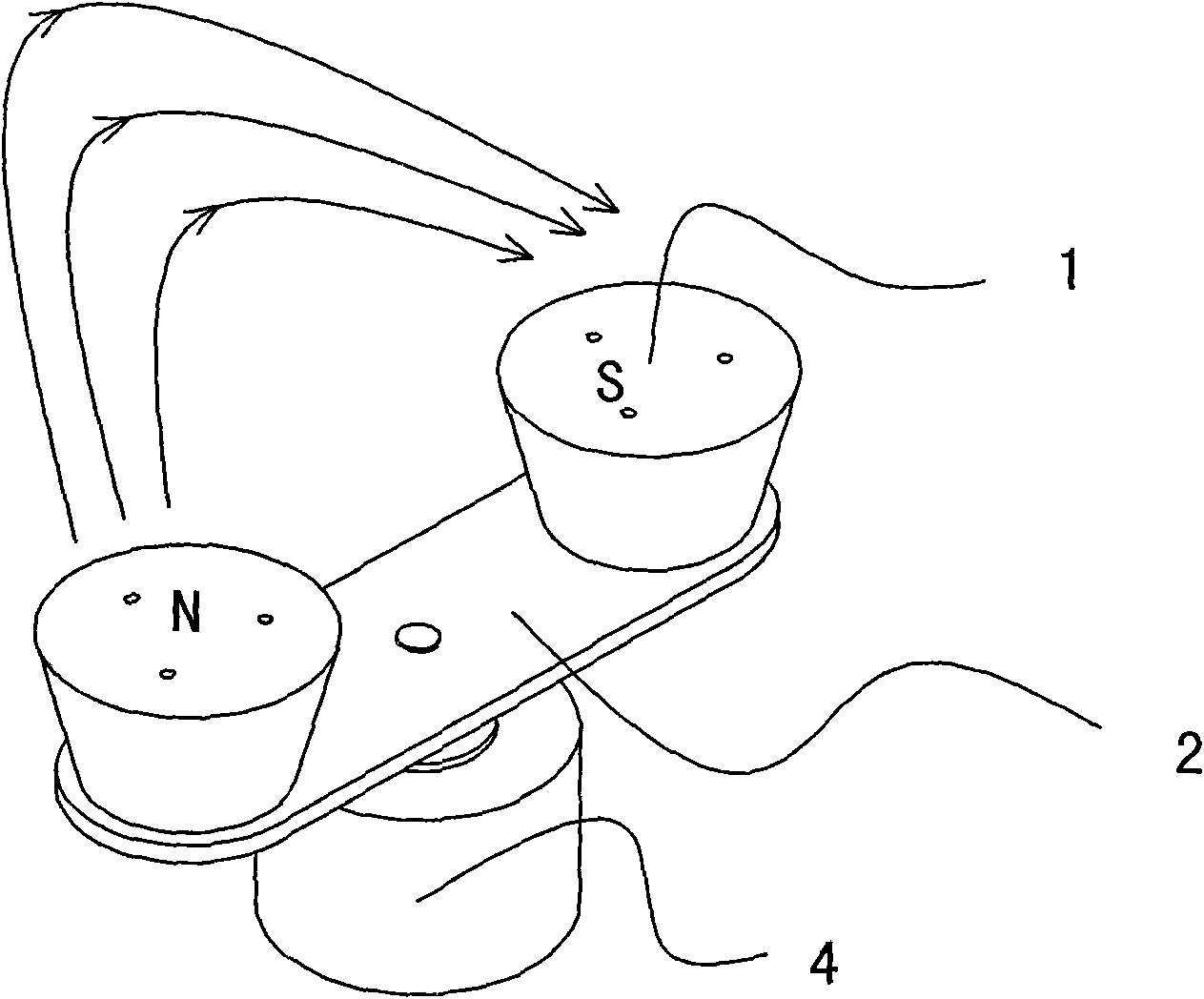

[0024] Embodiment 1: Please refer to the attached figure 1 And attached figure 2 , the present invention mainly includes a strong magnet 1, a magnetically conductive spiral arm 2 and a rotating motor 4. In the present embodiment, the magnetically conductive spiral arm 2 is made of A3 steel plate. During specific implementation, it can also be made of other magnetically conductive materials. The swing arm 2 is in the shape of a long strip, and a strong magnet 1 is fixedly installed at both ends respectively. In this embodiment, the strong magnet 1 is in the shape of a truncated cone. In the present embodiment, the smaller side (i.e. the lower surface) of the strong magnet 1 is fixedly mounted on the magnetically conductive spiral arm 2, and is defined as the connection surface of the magnet 1, and the larger side (i.e. the upper surface) is the action surface of the strong magnetic field. Defined as the free surface of magnet 1. In this embodiment, the strong magnet 1 is fix...

Embodiment 2

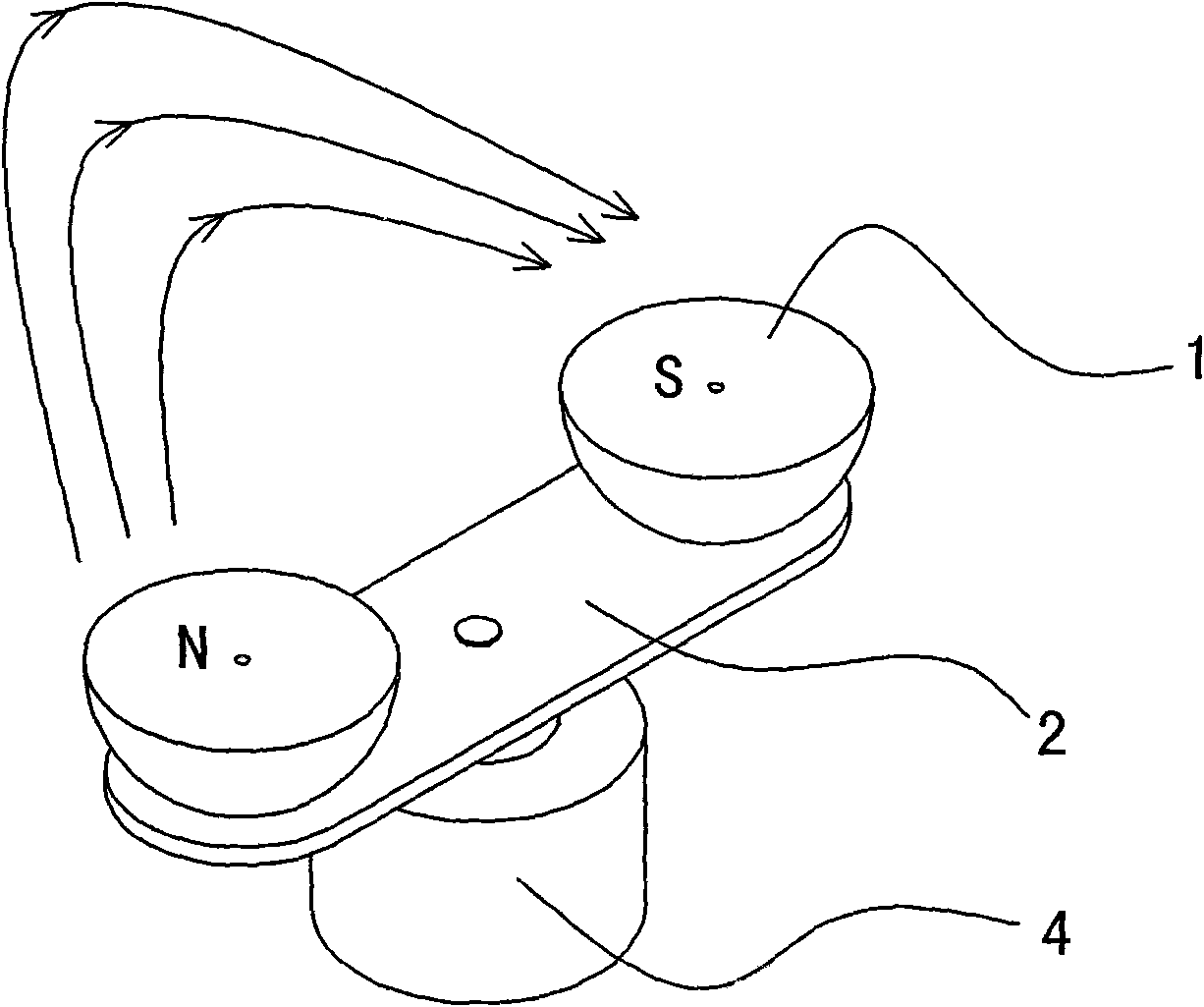

[0025] Embodiment two: Please refer to the attached image 3 , the present embodiment also includes a strong magnet 1, a magnetically conductive spiral arm 2 and a motor 4. In this embodiment, the strong magnet 1 is hemispherical, and the lower surface of the strong magnet 1 (that is, the point on the spherical cap corresponding to the center of the bottom surface) is fixed. Installed on the magnetically conductive spiral arm 2, the upper surface (that is, the bottom plane) is a strong magnetic field action surface. In this embodiment, the strong magnet 1 is fixed and installed on the magnetically conductive spiral arm 2 by screws, and other connection methods may also be used during specific implementation. In this embodiment, the motor 4 is also used to drive the magnetically conductive spiral arm 2 and the strong magnet 1 on the magnetically conductive spiral arm 2 to perform low-frequency rotational motion.

Embodiment 3

[0026] Embodiment three: Please refer to the attached Figure 4 , including strong magnet 1, magnetic conduction arm 2 and motor 4 equally in the present embodiment, in the present embodiment, strong magnet 1 is conical frustum shape, and the cross section of strong magnet 1 is oval, and strong magnet 1 lower surface (being relatively The small side) is fixedly installed on the magnetically conductive spiral arm 2, and the upper surface (that is, the larger side) is a strong magnetic field action surface. In this embodiment, the strong magnet 1 is fixed and installed on the magnetically conductive spiral arm 2 by screws, and other connection methods may also be used during specific implementation. In this embodiment, the rotating motor 4 is also used to drive the magnetically conductive spiral arm 2 and the strong magnet 1 on the magnetically conductive spiral arm 2 to perform low-frequency rotational motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com