Tangential rotor for rotating motor

A technology for rotating electrical machines and rotors, applied in the field of tangential rotors, which can solve problems such as low utilization of permanent magnets, increase of motor output, and influence on rotor applications, so as to improve the utilization of magnets, reduce production costs, and reduce magnetic flux leakage of magnets Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

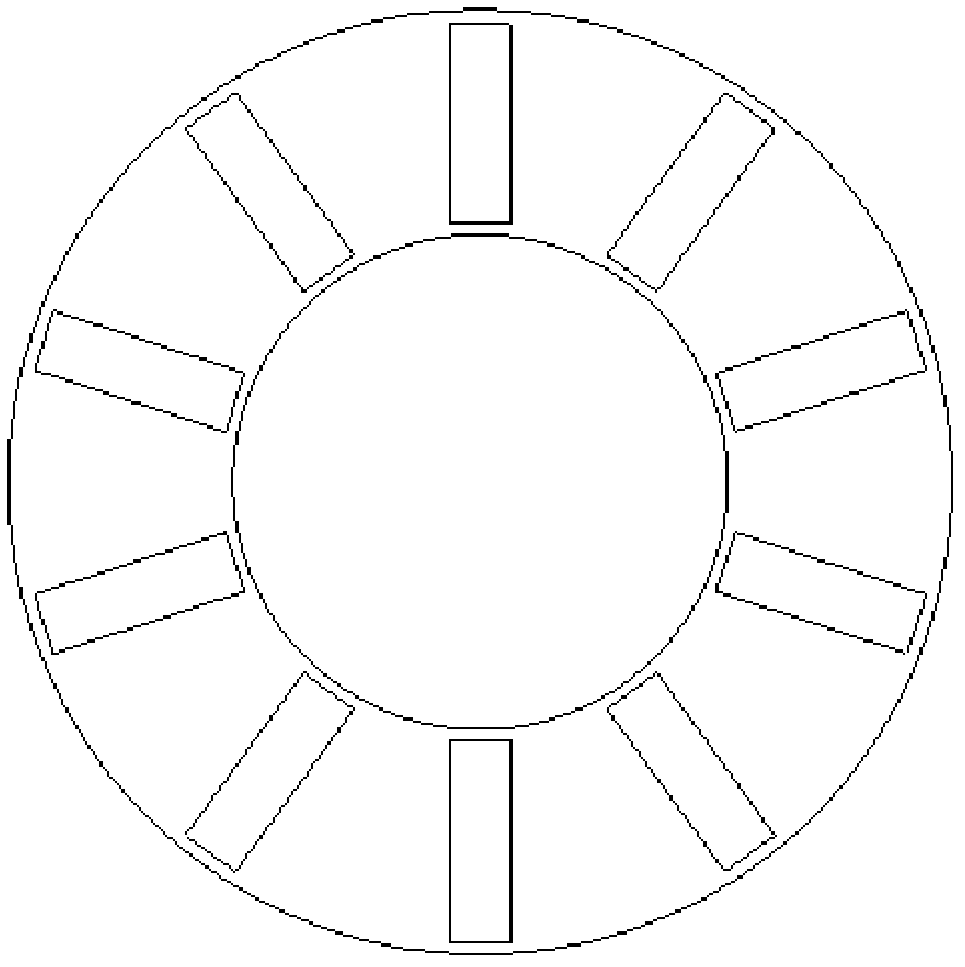

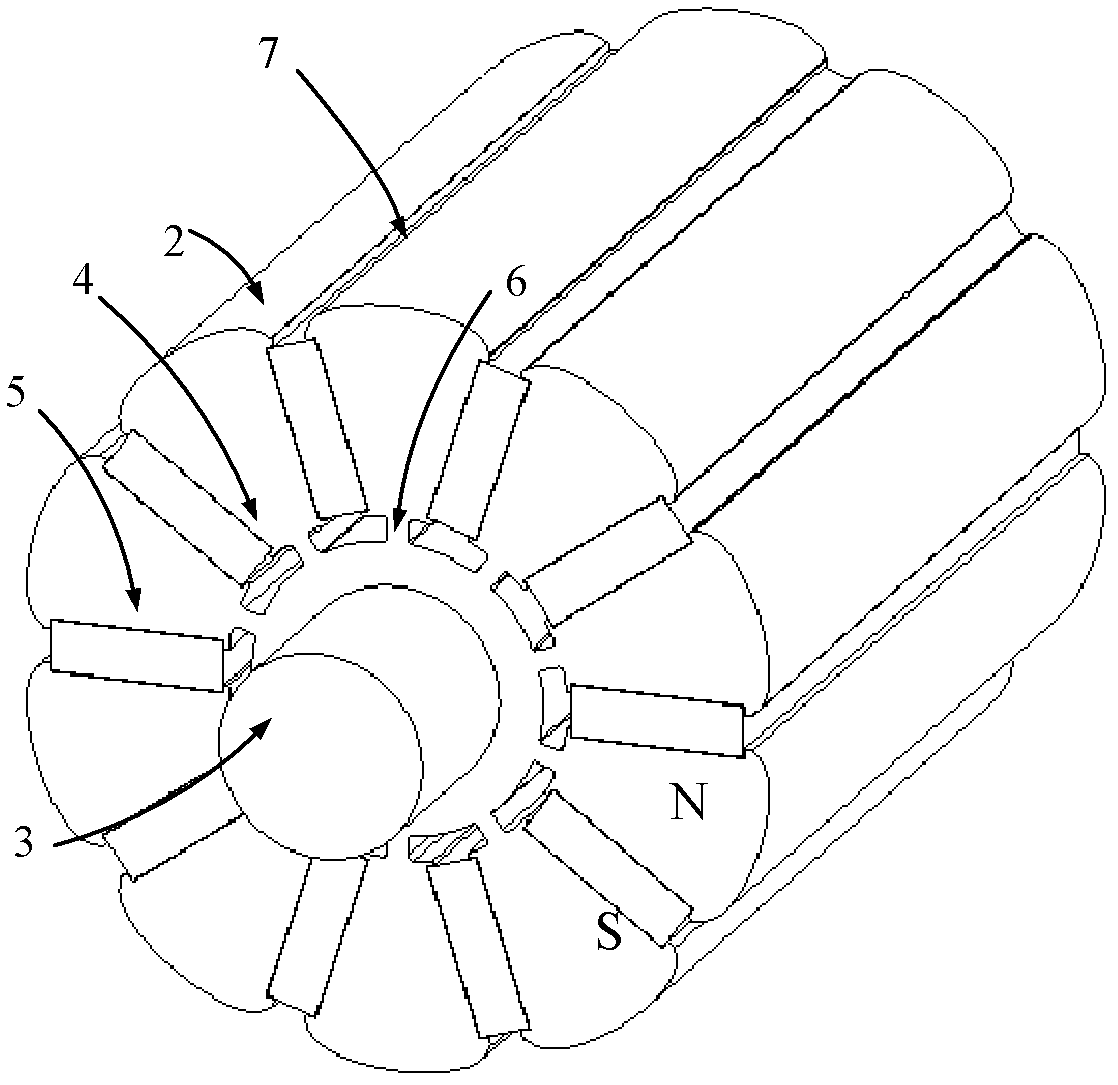

[0014] see image 3 , the tangential rotor of this rotating electrical machine includes a rotor composed of a rotating shaft 3 and a laminated iron core 2, and the laminated iron core 2 is provided with several permanent magnet poles that rotate along the axis of the rotating shaft 3 and are magnetized along the circumferential direction of the rotor relative to the axis 5. The permanent magnet pole part 5 is embedded in the laminated iron core 2 through the permanent magnet slot 4, the side of the permanent magnet slot 4 near the air gap is connected or disconnected from the laminated iron core 2, and the distance between the sides near the rotating shaft is 6 The circumferential width is 0.1-5 mm.

[0015] In this embodiment, the rotor is a 10-pole rotor, and there are 10 permanent magnet poles 5 in total. The side 7 of the permanent magnet slot 4 near the air gap is disconnected from the laminated core 2 , and the polarities of the adjacent permanent magnet poles 5 are oppo...

no. 2 example

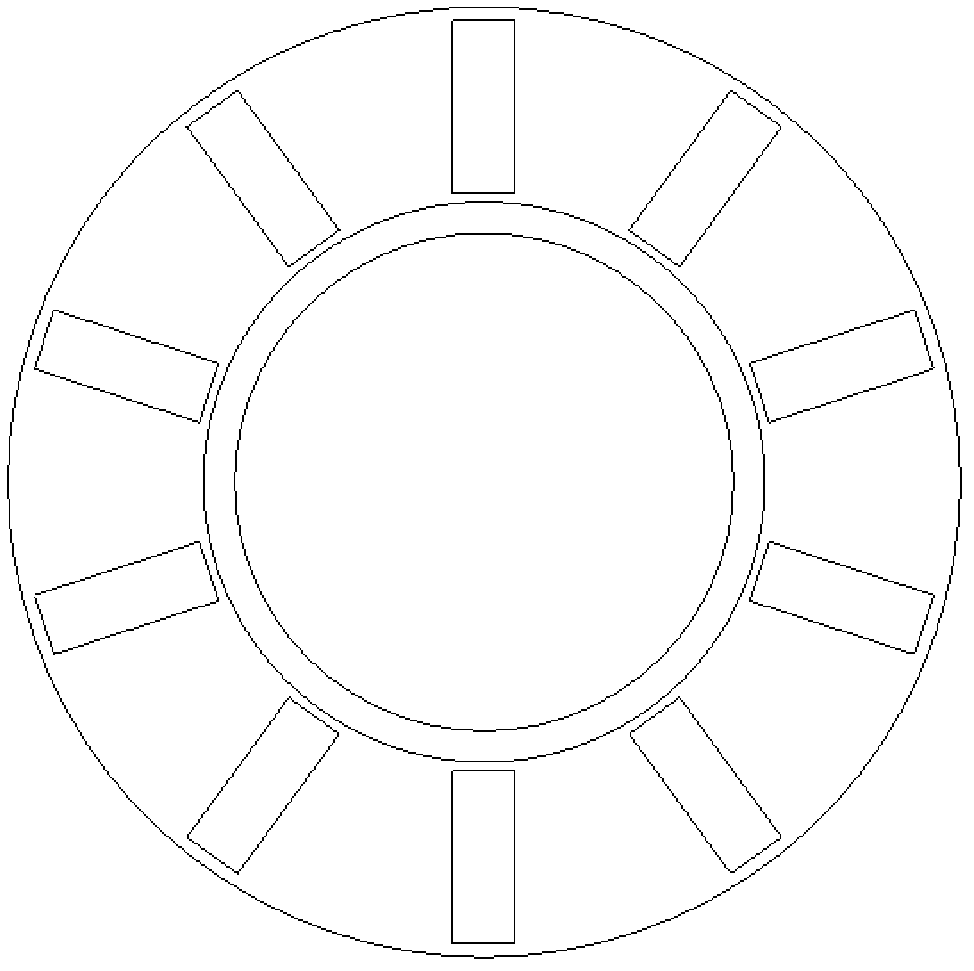

[0017] see Figure 4 The main difference between the tangential rotor of this rotating electrical machine and the first embodiment is that the side 7 of the permanent magnet slot 4 near the air gap is connected to the laminated iron core 2 . Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com