Outer rotor magnetic flux collecting magnetic gear

A magnetic gear, outer rotor technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., to achieve the effect of improving torque transmission capacity, easy implementation, and reducing processing and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below with reference to the drawings.

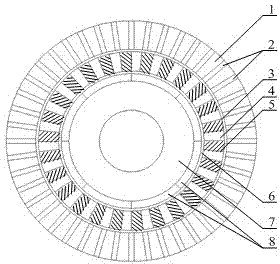

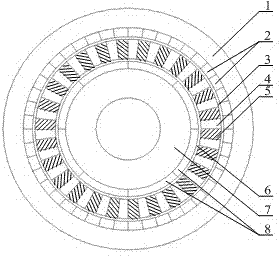

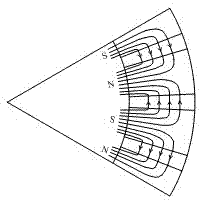

[0026] The outer rotor magnetization type magnetic gear provided by the present invention is a non-contact transmission device, which can be used in variable speed driving occasions and has the characteristics of high torque density. Its structure includes a magnetic gear outer rotor, a magnetic tuning ring and a magnetic gear inner rotor , The outer rotor of the magnetic gear includes the outer rotor core and the cuboid-shaped permanent magnets embedded in the core of the outer rotor; the magnetic ring includes the non-magnetic block of the magnetic ring and the magnetic block of the magnetic ring; the inner rotor of the magnetic gear includes the inner rotor core, which is attached to Permanent magnets on the surface of the inner rotor core; an outer air gap is provided between the outer rotor of the magnetic gear and the magnetic tuning ring; an inner air gap is provided between the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com