Elastic joint body

An elastic connector, elastic technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve problems such as increasing the maximum torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

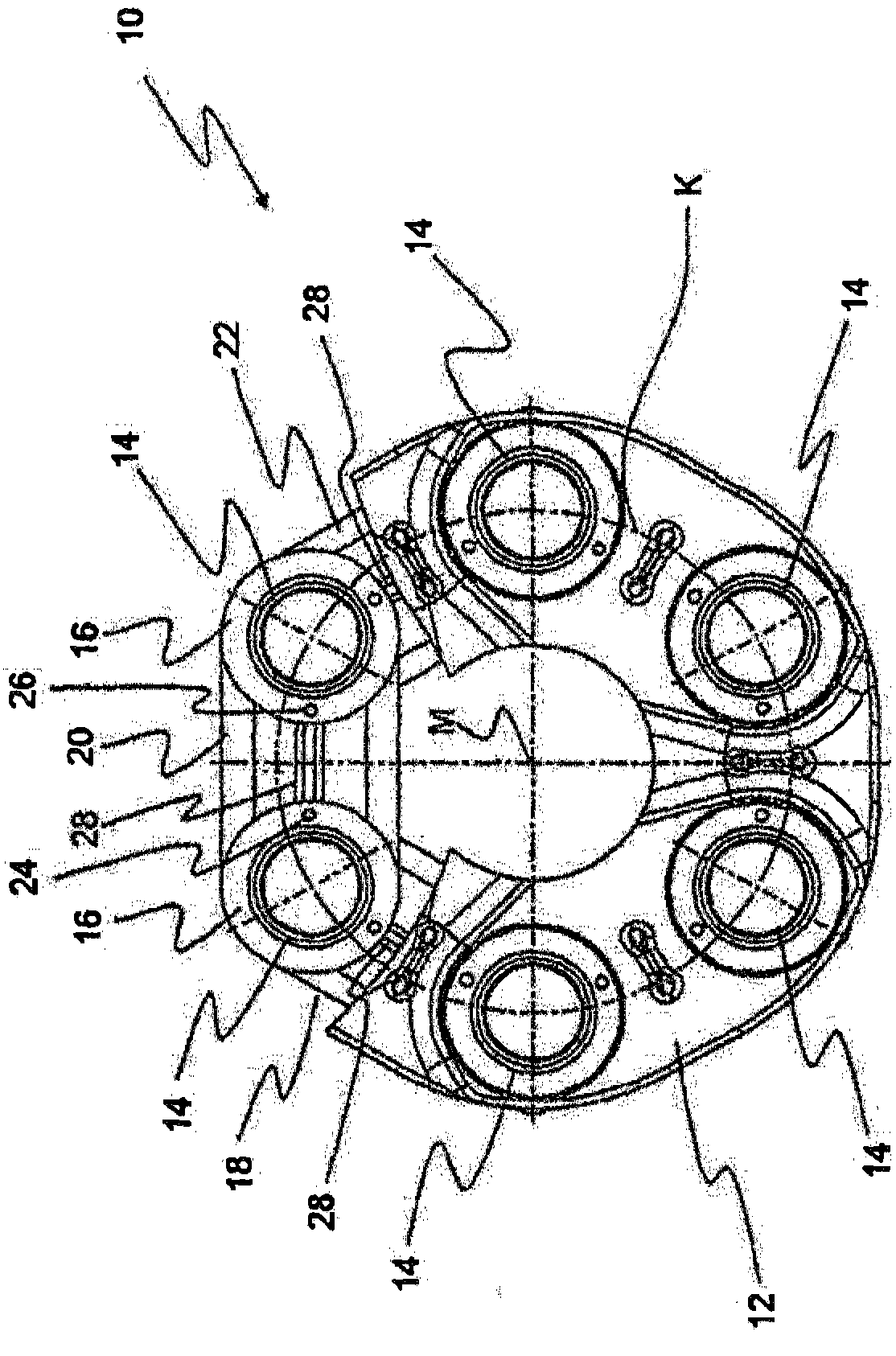

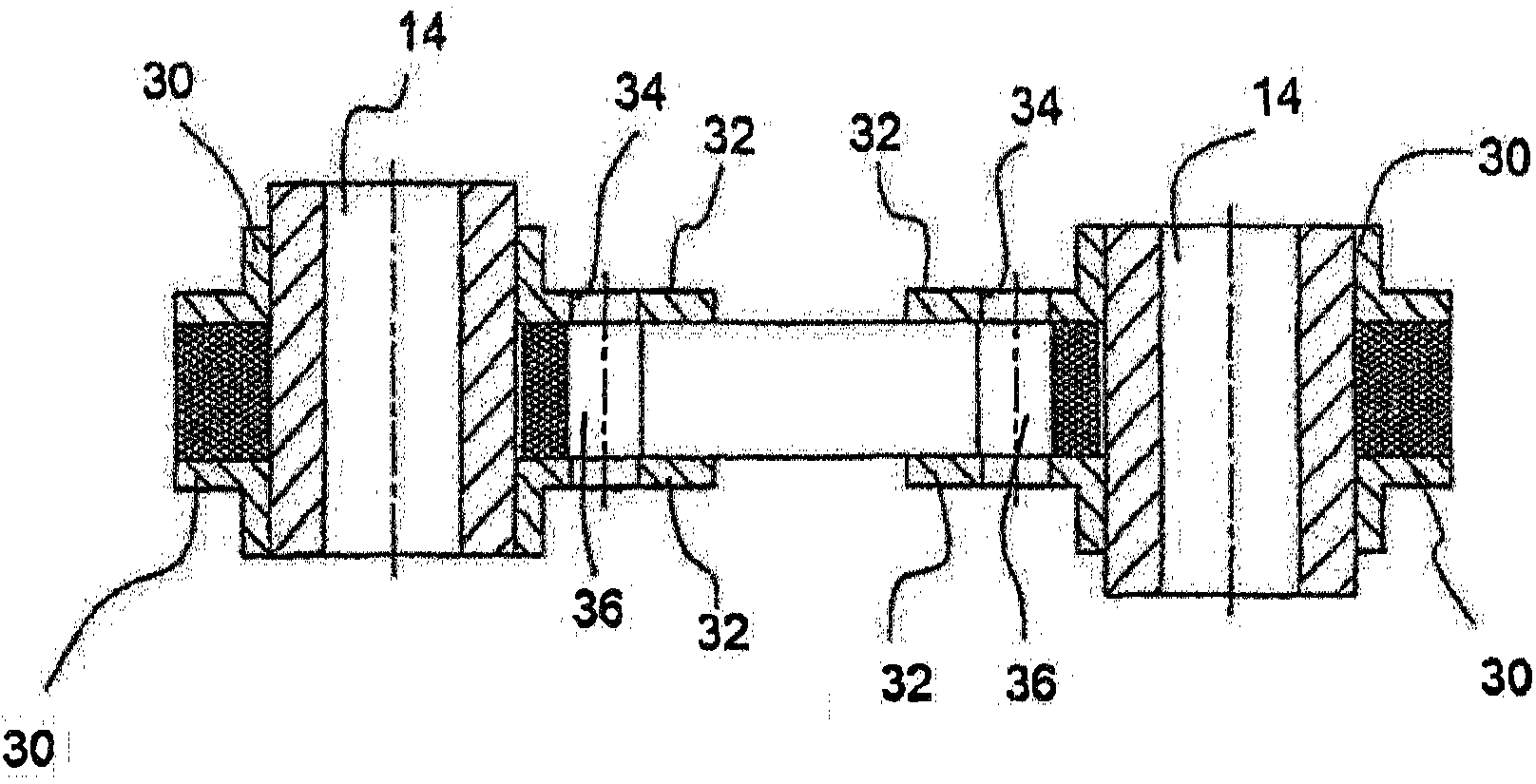

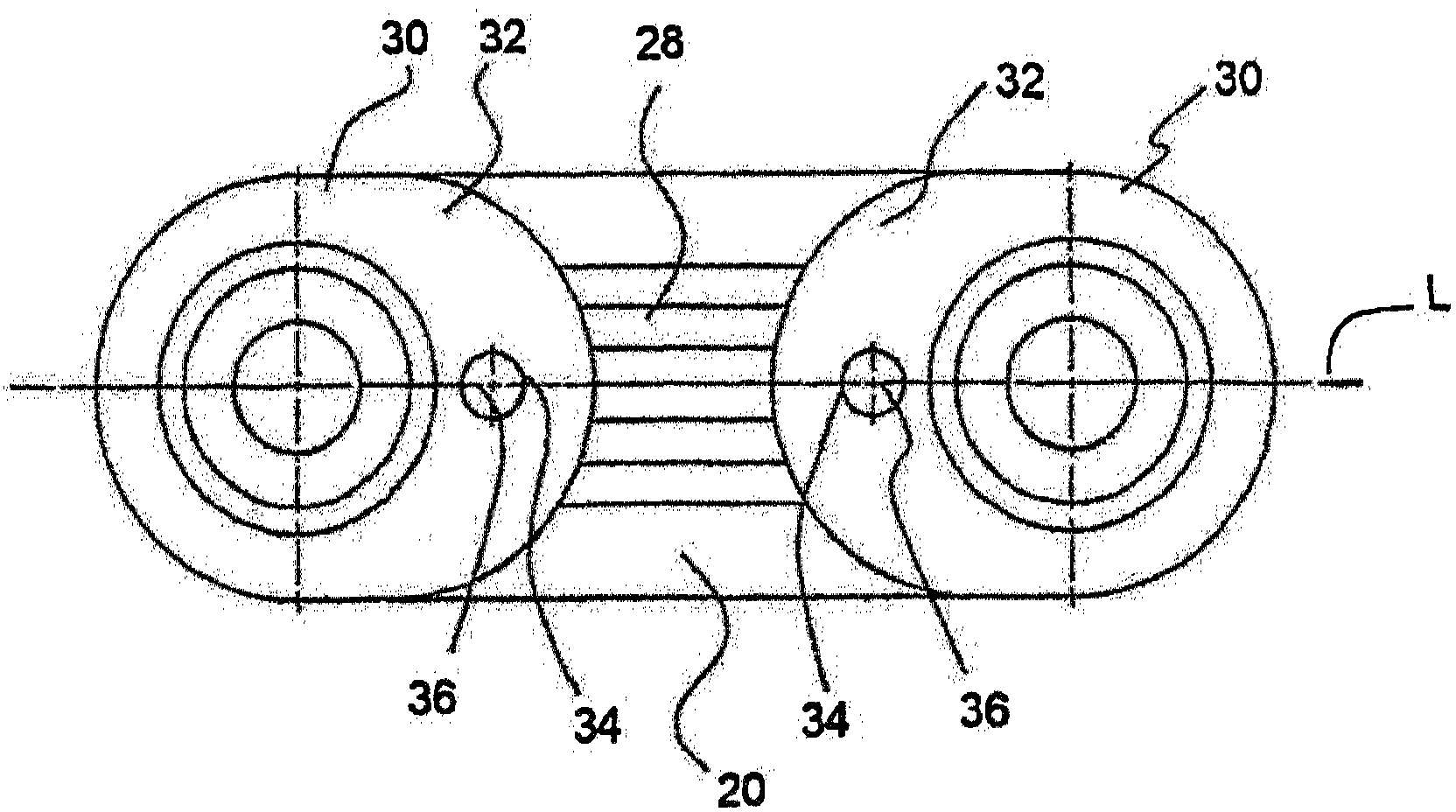

[0032] figure 1A partially cut-away plan view is shown of an elastic connecting body 10 according to the invention having six bushings 14 surrounded by a rubber elastic casing 12 . The bushings 14 are arranged in predetermined corners of the connecting body 10 in the circumferential direction with respect to the center axis M in such a way that their center points lie on the circular path K. As shown in FIG. in accordance with figure 1 In the portion of the connecting body of , which is shown cut away in the figure, the collar element 16 on the bushing 14 can be seen, which is arranged to axially support the ring bundles 18 , 20 and 22 . figure 1 It is also shown that on the collar element 16 two corresponding pegs 24 (or stakes) are received in receiving openings 26 in areas facing each other. A respective auxiliary loop 28 extending within the loops 18 , 20 , 22 is guided around each of these staples 24 .

[0033] figure 1 Also shown are a plurality of loop bundles 18 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com