High-power density permanent magnet motor

A high power density, permanent magnet motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low motor efficiency and thrust density, poor sine degree of air gap flux density waveform, high motor vibration and noise, etc. Achieve the effect of large electromagnetic thrust, good sine degree and small thrust fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

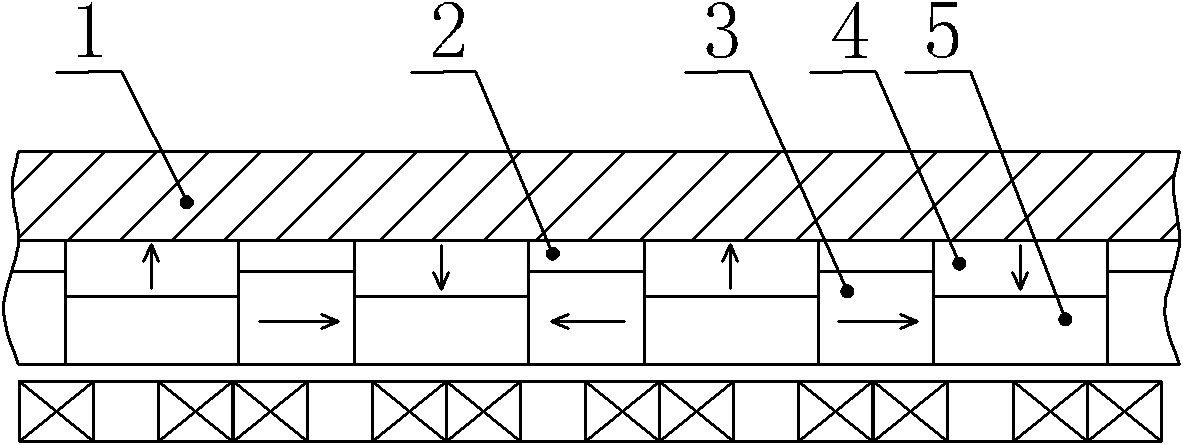

[0022] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the high power density permanent magnet motor of this embodiment, it is flat linear permanent magnet motor with unilateral structure: it includes primary and secondary, there is an air gap between primary and secondary, and secondary includes yoke plate 1. m spacer magnets 2, m auxiliary permanent magnets 3, m main permanent magnets 4 and m concentrating magnets 5, the yoke plate 1 is flat, and main Permanent magnet 4 and spacer magnet 2, the inboard of main permanent magnet 4 is provided with concentrating magnet 5, and concentrating magnet 5 is identical with main permanent magnet 4 along the moving direction width; The permanent magnets 3 have the same width along the moving direction; the outer surfaces of the m auxiliary permanent magnets 3 and the m collecting magnets 5 are on the same plane, and the main permanent magnets 4 are magnetized in parallel, and the magnetizi...

specific Embodiment approach 2

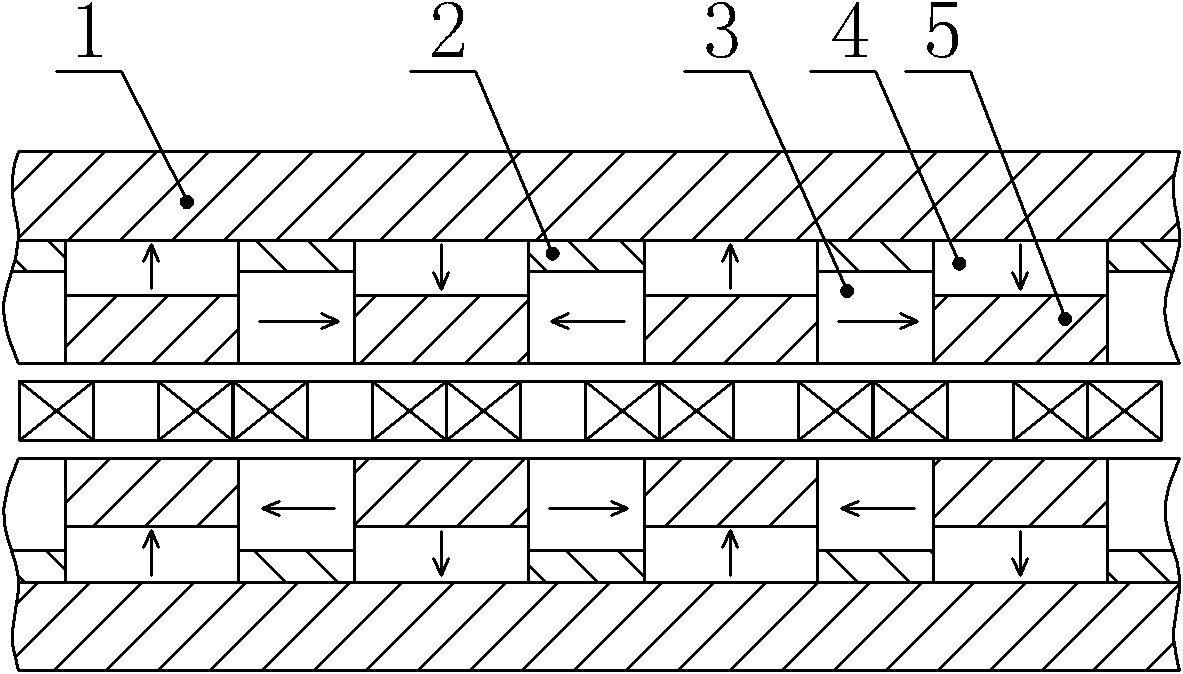

[0026] Specific implementation mode two: the following combination figure 2 Describe this embodiment, the high power density permanent magnet motor of this embodiment, it is the flat linear permanent magnet motor of double-sided structure:

[0027] It includes a primary and two secondary, with an air gap between the primary and each secondary, and each secondary includes a yoke plate 1, m spacer magnets 2, m auxiliary permanent magnets 3, and m main permanent magnets 4 And m pieces of concentrating magnets 5, yoke plate 1 is a flat plate, on the inner side wall of yoke plate 1, main permanent magnet 4 and spacer magnet 2 are successively arranged at intervals, the inboard of main permanent magnet 4 is provided with concentrating magnets 5, concentrating magnets 5 and The main permanent magnet 4 has the same width along the moving direction; the auxiliary permanent magnet 3 is set on the inner side of the spacer magnet 2, and the spacer magnet 2 and the auxiliary permanent mag...

specific Embodiment approach 3

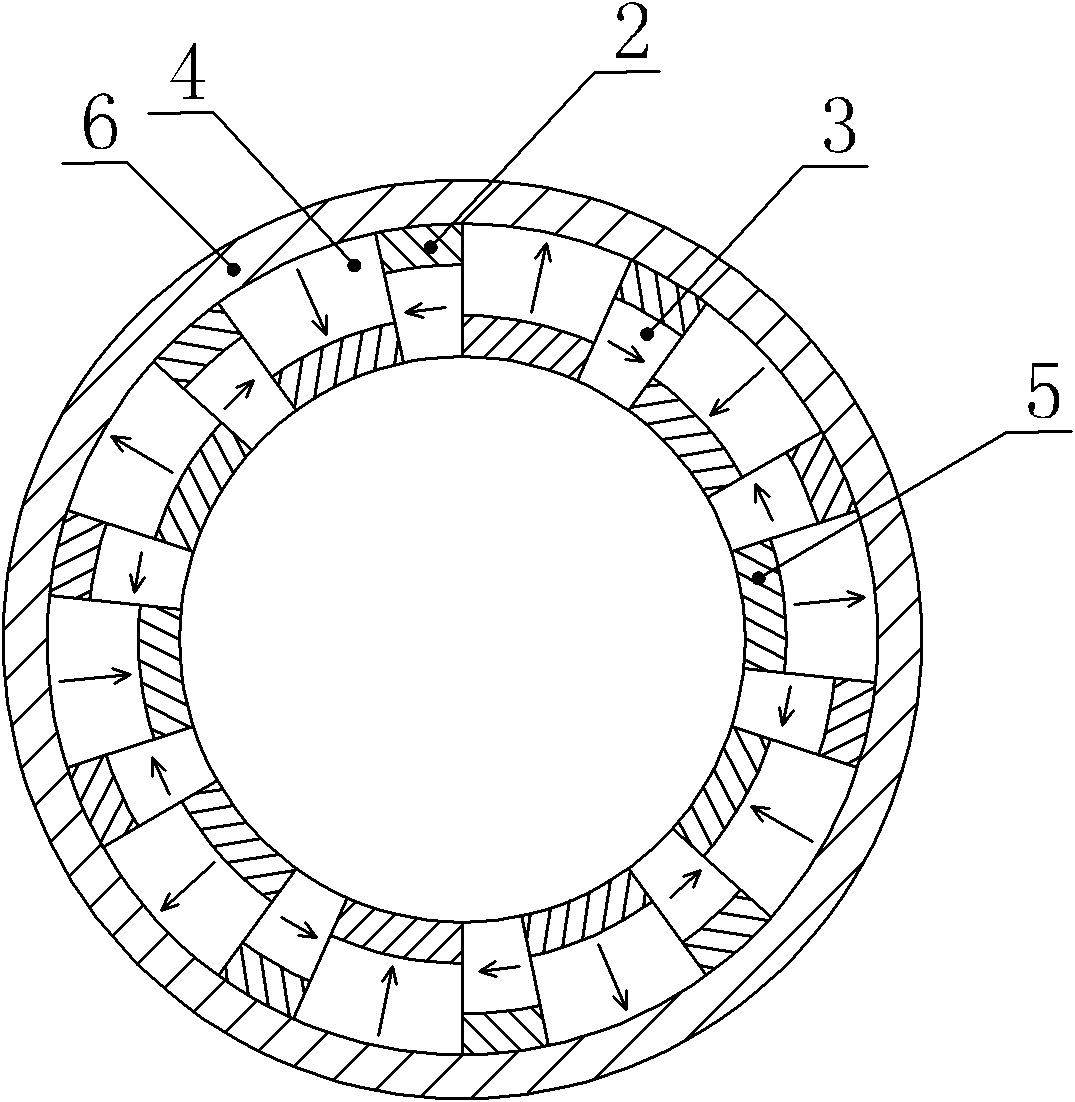

[0031] Specific implementation mode three: the following combination image 3 Describe this embodiment, the high power density permanent magnet motor of this embodiment, it is the cylindrical permanent magnet motor of outer rotor structure:

[0032] It includes a stator and a rotor. The rotor is located outside the stator. There is an air gap between the stator and the rotor. The rotor includes a yoke tube 6, m spacer magnets 2, m auxiliary permanent magnets 3, m main permanent magnets 4 and m concentrator magnets. 5. The yoke barrel 6 is cylindrical, and the main permanent magnet 4 and the spacer magnet 2 are arranged at intervals in sequence on the inner surface of the yoke barrel 6. The inner side of the main permanent magnet 4 is arranged with a concentrating magnet 5, and the concentrating magnet 5 and the main permanent magnet 4 The angle along the circumferential direction is the same; the auxiliary permanent magnet 3 is arranged inside the spacer magnet 2, and the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com