Directly driving mixed excitation dual stator wind power dynamotor

A technology of wind power generator and mixed excitation, which is applied in wind power generation, synchronous motor with stationary armature and rotating magnet, electrical components, etc., which can solve the problems of low stator utilization rate, limited application, large stator space, etc., and achieve The effect of low manufacturing cost, high space utilization rate and large stator space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

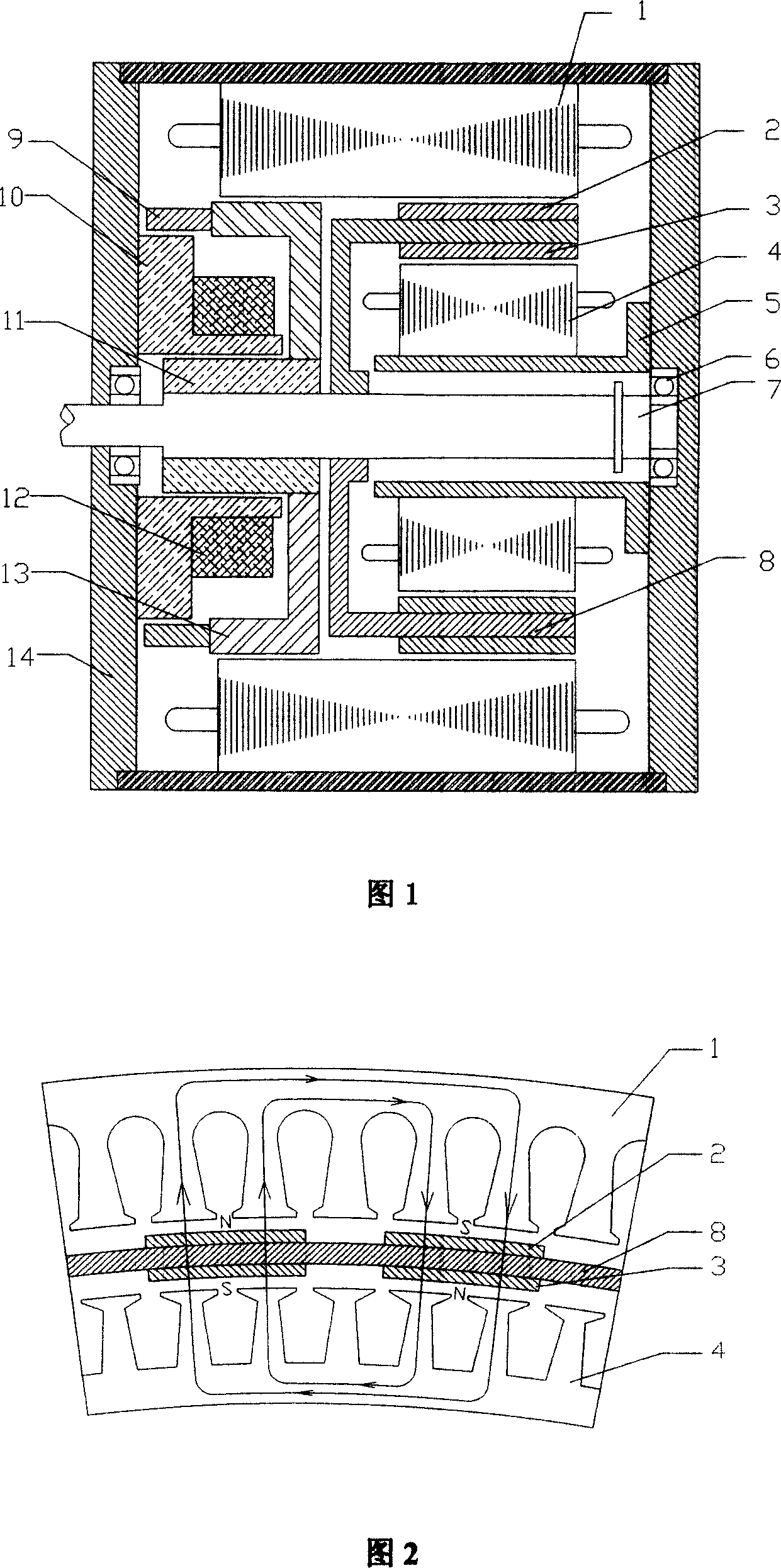

[0017] The present invention adopts a special motor structure, that is, two inner and outer stators are arranged in a large generator body space according to actual application requirements, and the stator structure is similar to that of an ordinary outer rotor inner rotor motor. The outer stator 1 is fixed on the casing of the motor; the outer permanent magnets 2 and inner permanent magnets 3 with different polarities are staggered and pasted on the inner and outer walls of the cup-shaped rotor 8; the inner stator 4 is fixed on the inner stator bracket 5; the inner stator bracket 5 is fixed on the end cover 14; the cup-shaped rotor 8 and the rotor back yoke 11 are fixed on the rotating shaft 7; the cantilever claw pole 9 and the claw pole 13 are fixed together by screws and the rotor ring; the electric excitation winding bracket 10 is fixed on the motor end On the cover 14; the electric excitation winding 12 is sleeved in the electric excitation winding support 10.

[0018] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com