Synchro motor of mixed exitation of tangential magnet steel possessing divided magnetic circuit

A hybrid excitation synchronous and synchronous motor technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of long axial magnetic circuit path, The magnetic circuit of the casing is saturated, and the volume and weight of the motor are reduced, so as to achieve the effect of small size, simple structure and shortening of the axial magnetic circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

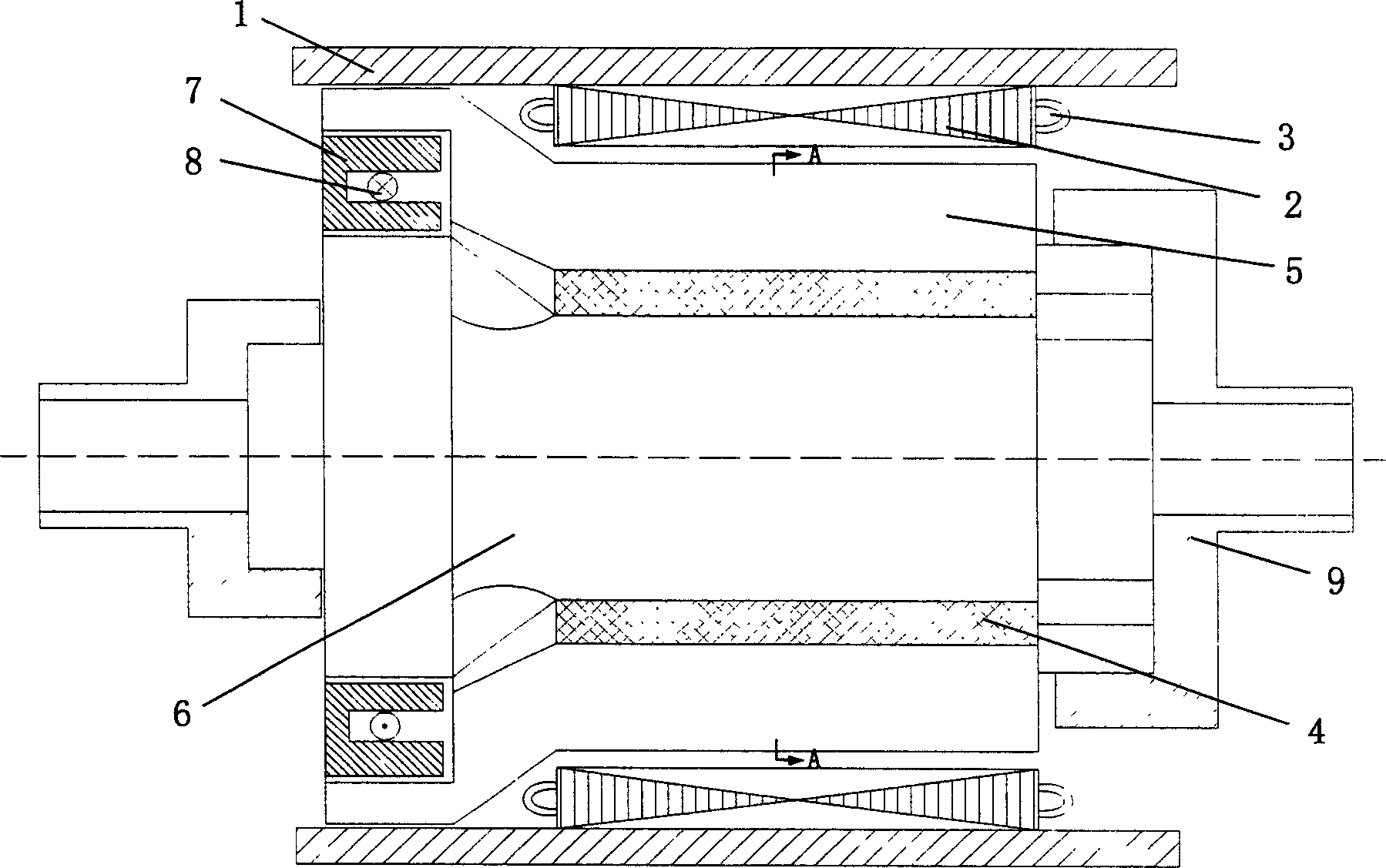

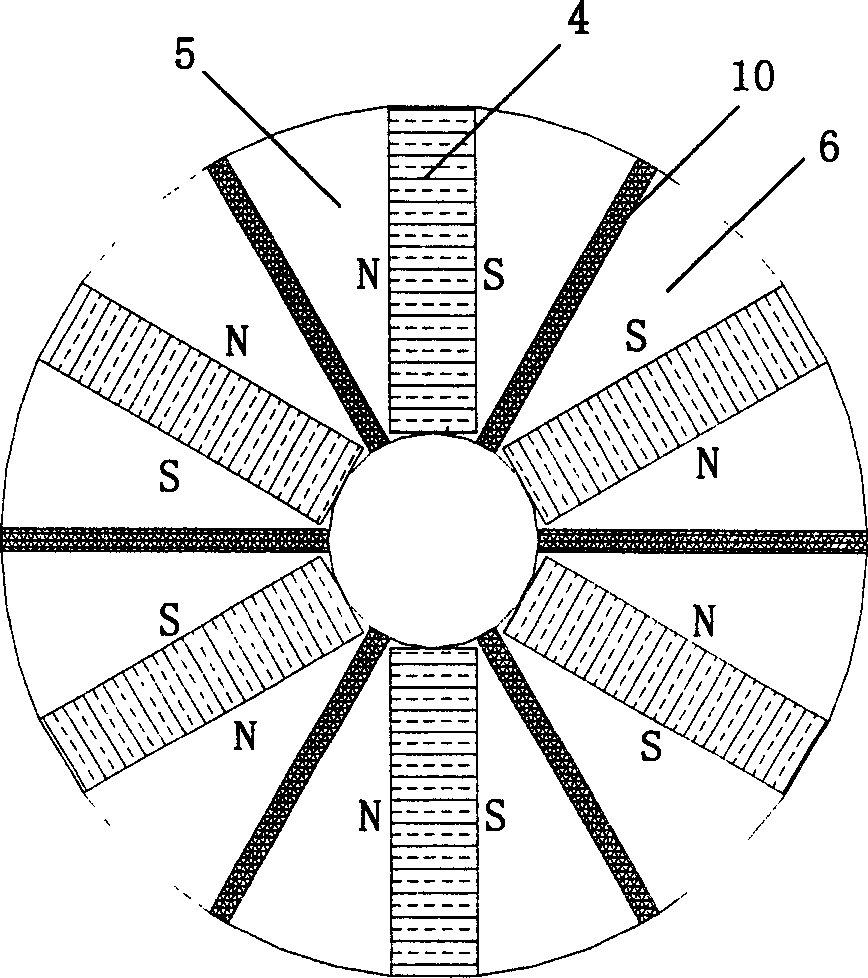

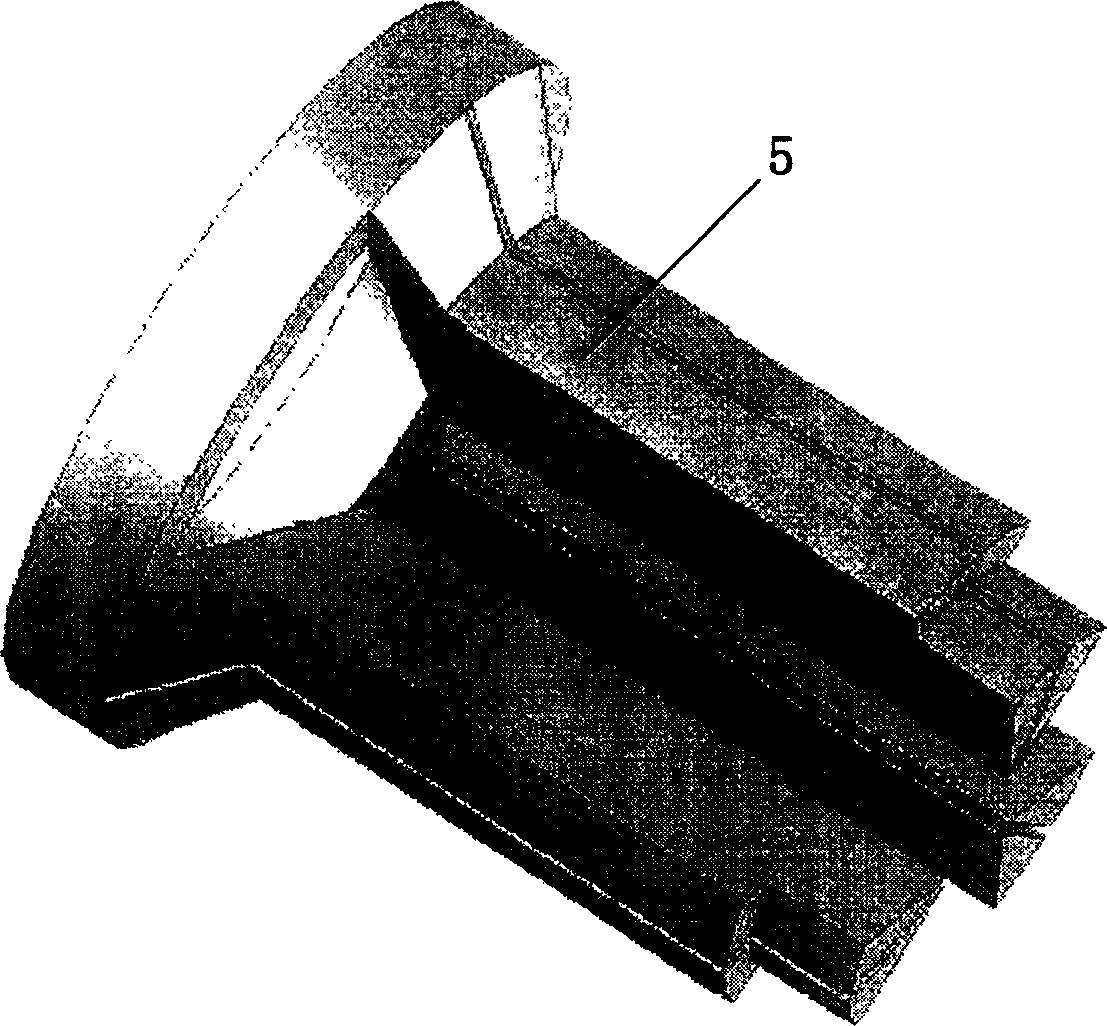

[0022] Depend on figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 It can be seen that the composition of the tangential magnet steel hybrid excitation synchronous motor of the present invention is composed of a tangential magnet steel permanent magnet synchronous motor on one side and an electric excitation part on the other side. That is, in the tangential structure permanent magnet synchronous motor composed of the stator composed of the armature core 2 and the armature winding 3 and the rotor equipped with the rotating shaft 9 and composed of the N-pole pole piece, the S-pole pole piece and the tangentially magnetized permanent magnet Basically, the N-pole shoe 5 and the S-pole shoe 6 of the rotor are directly extended to the same end respectively to form a image 3 structure. The N pole (or S pole) pole piece on the rotor expands in the shape of a trumpet. During the expansion process, it follows the principle of equal cross-section, and finally gathers into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com