Axial additional airgap rotor magnetic-shunt type hybrid excitation synchronous motor

A hybrid excitation synchronous, additional air gap technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. The limited cross-sectional area of the magnetic bridge window and the long axial length of the motor can achieve the effect of realizing the integration of starting and power generation, eliminating the need for rotating rectifiers, and improving work reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

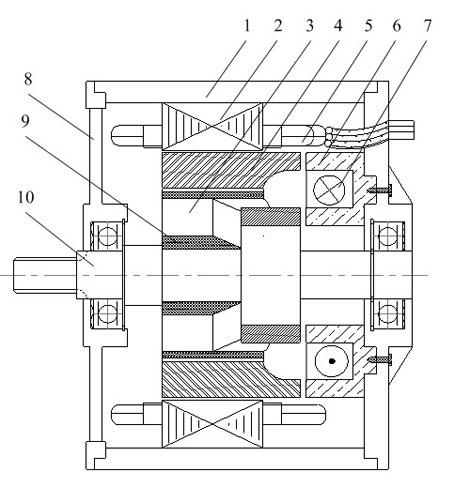

[0021] The technical scheme of the invention will be described in detail below in conjunction with the drawings:

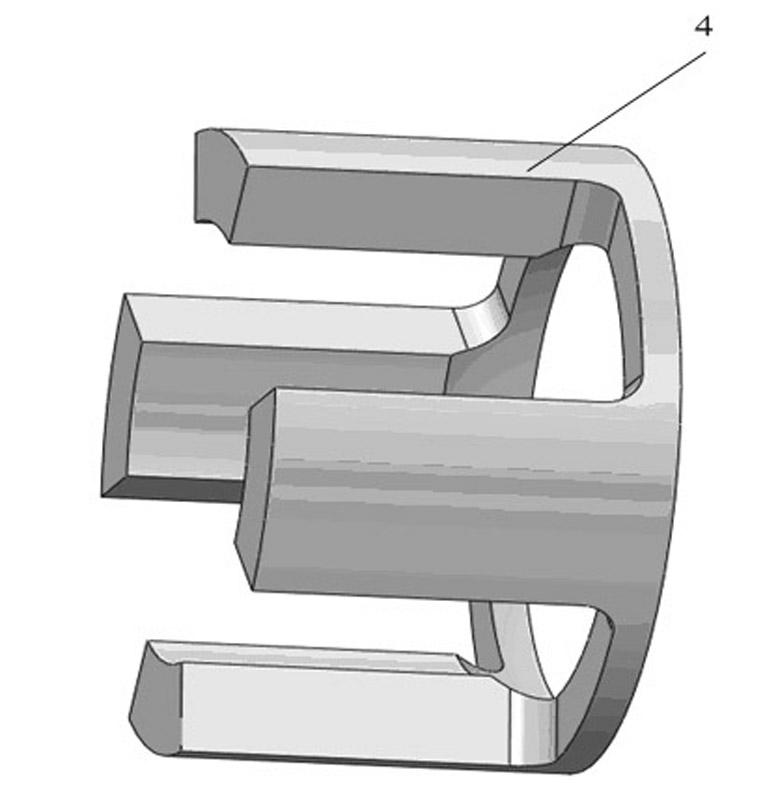

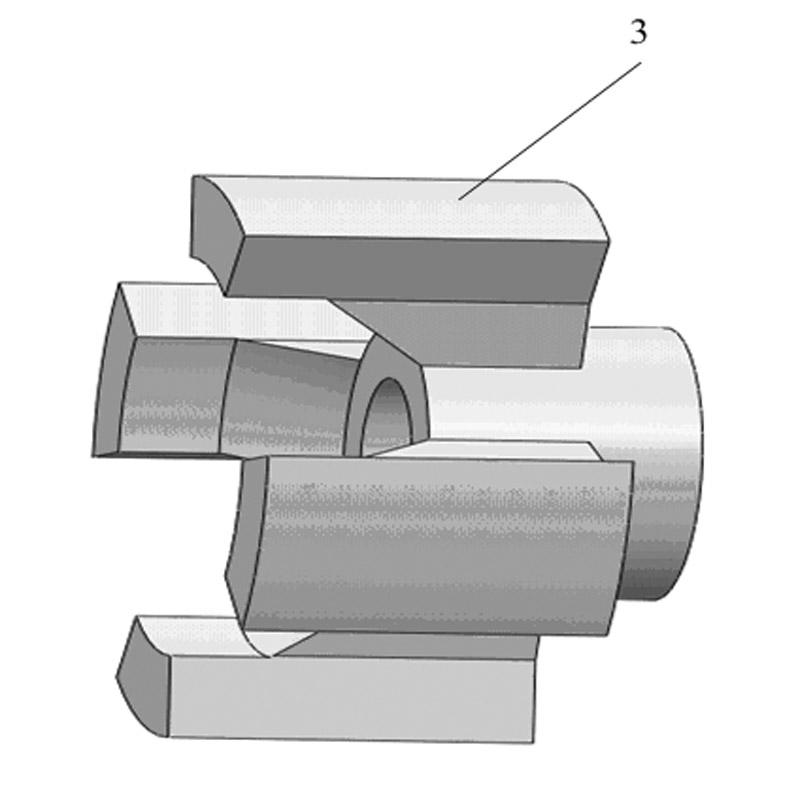

[0022] There are two implementation schemes for the magnetic shunt hybrid excitation synchronous motor with an axial additional air gap rotor involved in the present invention. The first scheme is: the N pole and the S pole shoe of the rotor extend in the same direction along the axial direction. The outer diameter of the pole piece is constantly extended, and it is assembled in the circular ring-shaped pole piece. At the same time, each S pole piece of the rotor stretches in the same direction and shrinks in a bottleneck shape, and is assembled on the hollow cylindrical pole piece, the circular ring-shaped pole piece The hollow cylindrical pole piece and the hollow cylindrical pole piece are respectively aligned with the outer wall and the inner wall of the annular magnetic bridge fixed on the back end cover of the motor, that is, the outer diameter of the circular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com