Method for dyeing all-zirconium tooth by using film

A technology of thin film and zirconium teeth, which is applied in the direction of dentures, etc., can solve the problems of complex process and large operation influence, and achieve the effect of simple operation, high safety factor and flexible coloring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The polyethylene used in the film of the present invention is linear low density polyethylene (LLDPE) as the main raw material.

[0027] The zirconia material has very good biocompatibility, very high flexural strength, good light transmittance, and the color after dyeing tends to be more natural teeth.

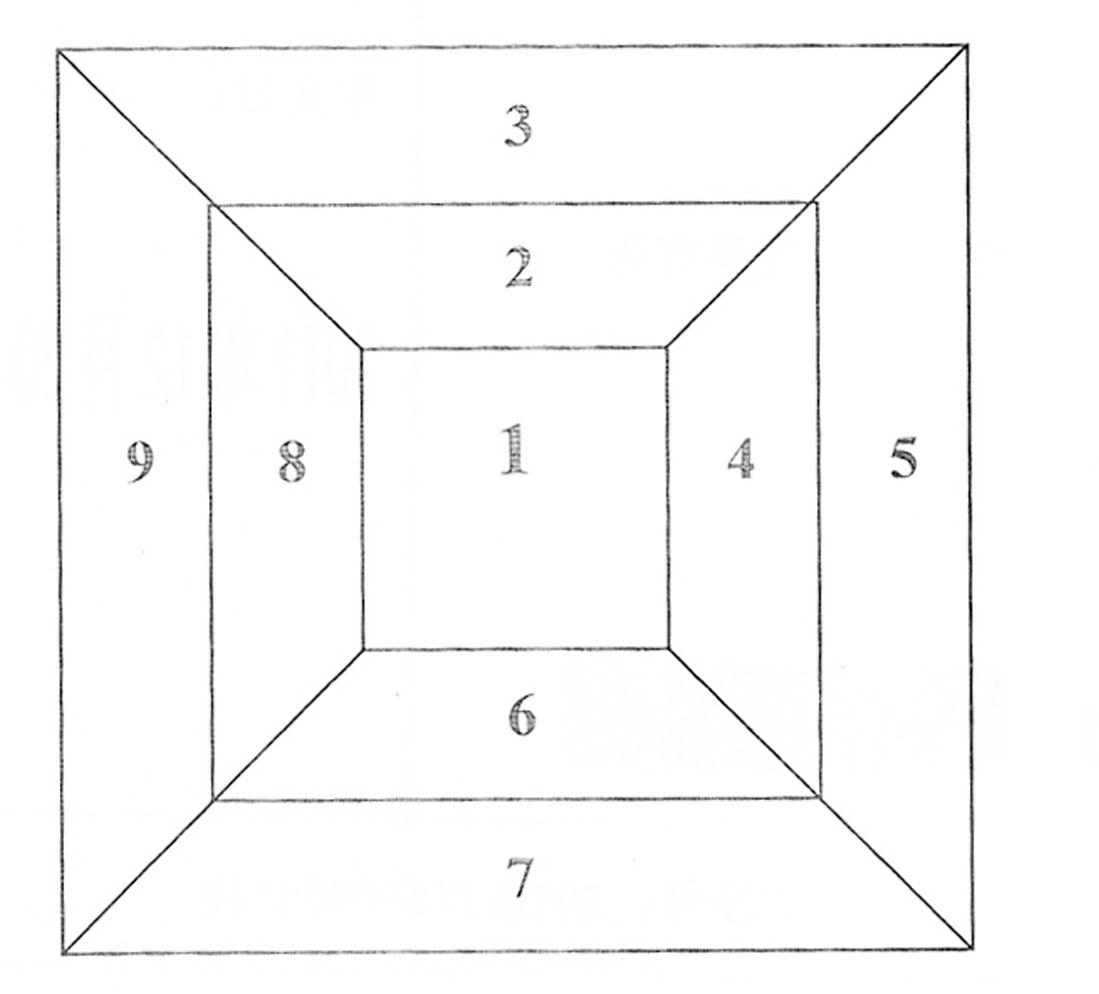

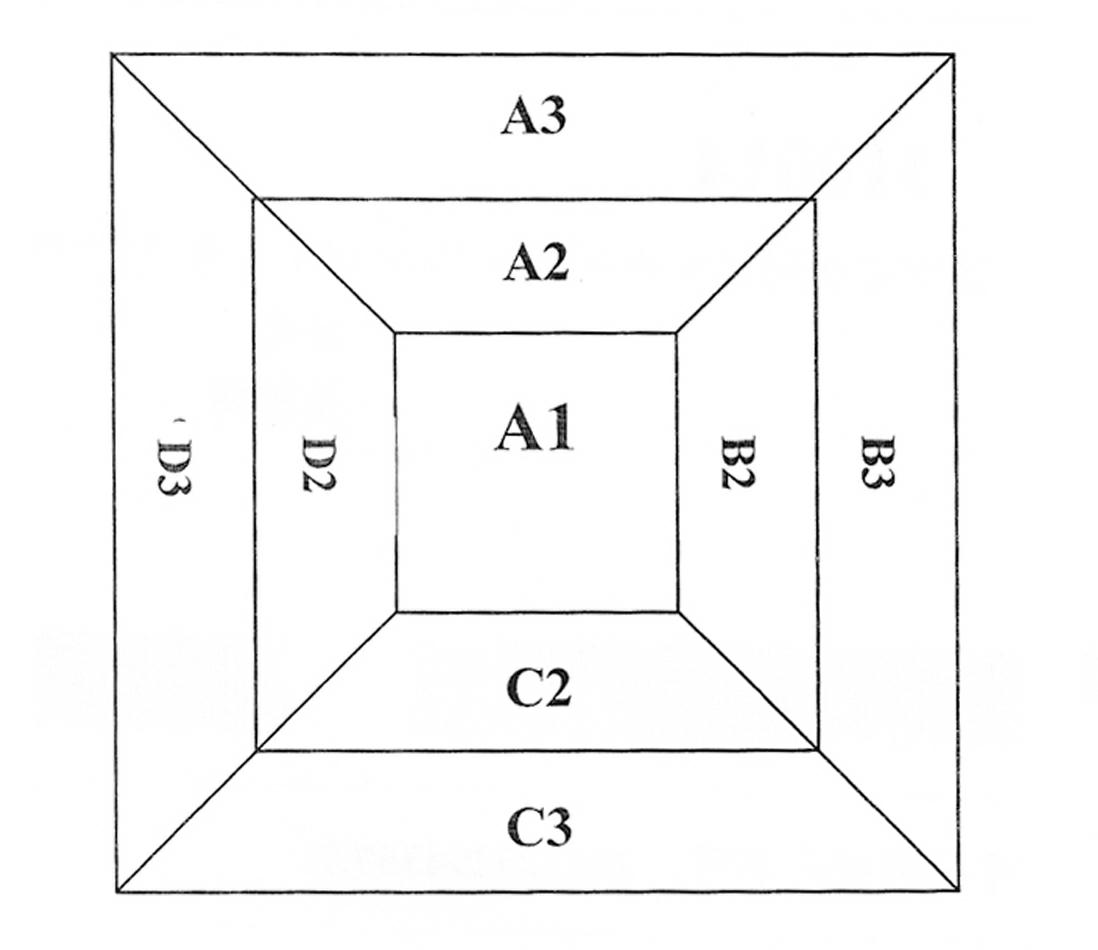

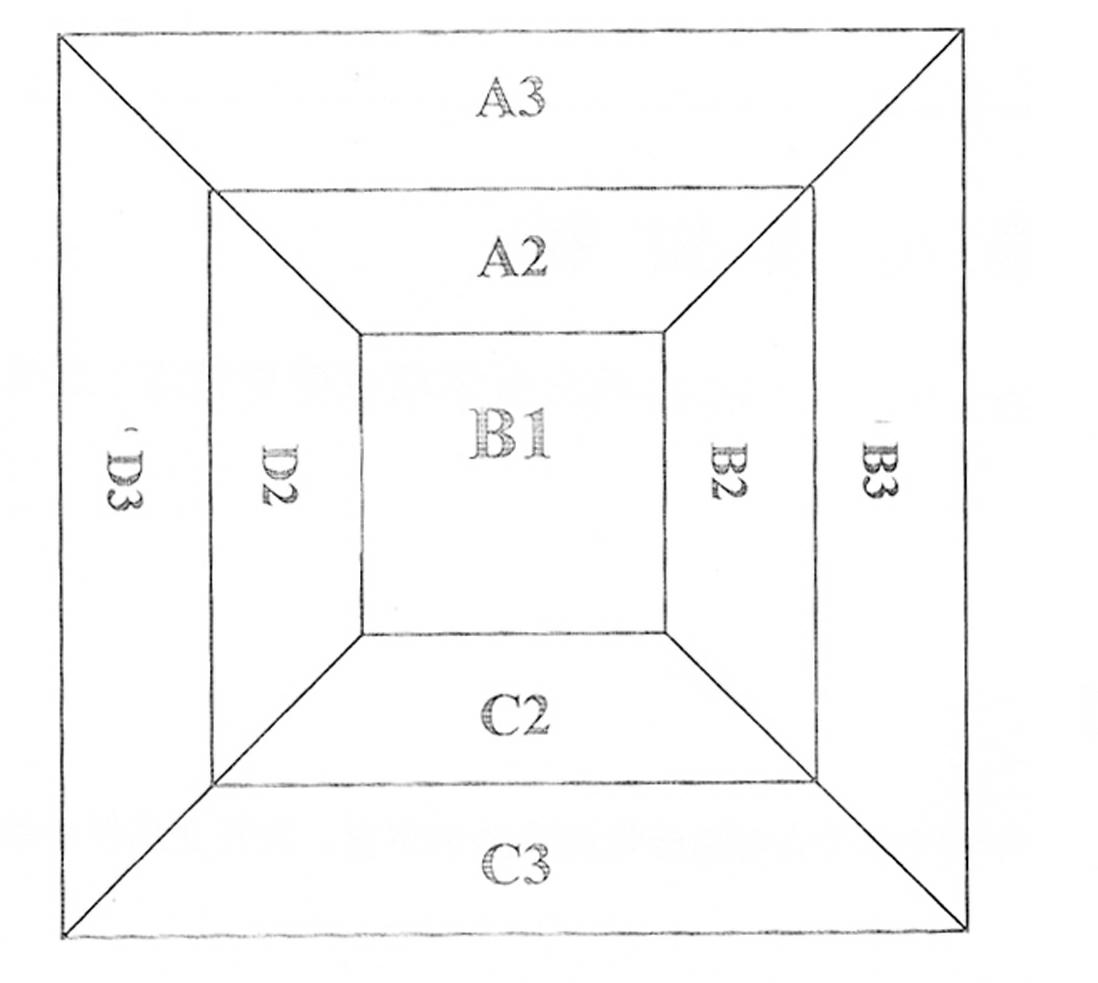

[0028] The invention uses a film to dye the full anatomical zirconia all-ceramic teeth, uses linear low-density polyethylene (LLDPE) as the main raw material, and produces a PE film with strong self-adhesiveness through a multi-layer extrusion process. Printing or printing coloring of the film, cutting and wrapping the coloring film with the appropriate size of the pre-colored crown on the surface of the crown, after heat treatment to transfer the coloring particles to the surface of the crown to be stained, and then sintering, polishing and glazing , complete the entire staining process and get the final restoration. Taking the staining of the restoration of the uppe...

Embodiment 2

[0034] In Step 4, the colored particles are transferred to the surface of the crown to be stained through heat treatment. Two methods can be used in this link: the first one is to heat the wrapped crown in an oven at 60°C. After the colored particles on the film are transferred to the surface of the crown, the film can be removed and then sintered. In the second type, the crown covered with film is directly placed on the support column of the refractory plate and sintered at 1530° C. for 2 hours. Other steps are the same as in Example 1.

Embodiment 3

[0036] In Step 4, the colored particles are transferred to the surface of the crown to be stained through heat treatment. Two methods can be used in this link: the first one is to heat the wrapped crown in an oven at 70°C. After the colored particles on the film are transferred to the surface of the crown, the film can be removed and then sintered. In the second type, the film-wrapped crown is directly placed on the support column of the refractory plate and sintered at 1500°C for 2 hours. Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com