Battery separator and preparation method thereof

A technology for battery diaphragms and diaphragms, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of poor high temperature resistance and low mechanical strength, and achieve excellent mechanical properties, excellent high temperature performance, and easy hole forming methods line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

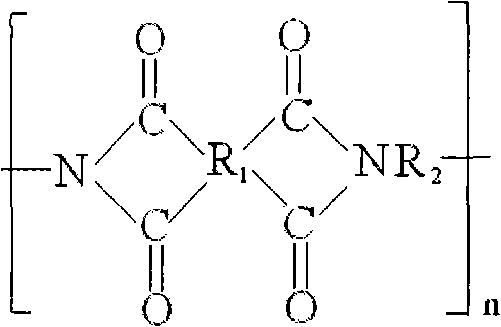

[0023] The preparation method of the battery separator of the present invention comprises mixing and contacting polyvalent organic carboxylic acid anhydride or its derivatives, organic diamine, pore-forming substances and additives with a solvent to obtain a mixture, coating the mixture into a mixture layer, and removing the pore-forming substances , and then imidize the mixture layer to obtain a separator containing polyimide, and the additive is inorganic whisker and / or orthosilicate. The types of the additives have been described in detail above and will not be repeated here. Based on the total amount of the separator, the content of the polyimide may be 60-98% by weight, and the content of the additive may be 2-40% by weight. Preferably, based on the total amount of the separator, the content of the polyimide is 75-95% by weight, and the content of the additive is 5-25% by weight.

[0024] The polybasic organic carboxylic acid anhydride or its derivatives can be selected ...

Embodiment 1

[0038] This example illustrates the battery separator of the present invention and its preparation method.

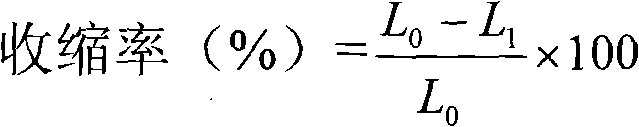

[0039] With 218 parts by weight of pyromellitic dianhydride (PMDA, Liyang Longsha Chemical Co., Ltd.), 200 parts by weight of diaminodiphenyl ether (ODA, Shanghai Reagent No. 3 Factory), dioctyl phthalate of 41.8 parts by weight Esters, 13 parts by weight of orthosilicate ethyl ester and 2100 parts by weight of N-methylpyrrolidone were stirred and mixed uniformly at 25°C to obtain a mixture, which was coated on a glass sheet with an I-shaped coating film applicator to form a mixture Floor. The mixture layer was immersed in 1000 ml of water for 5 minutes, taken out, air-dried, and heated in an oven at 320° C. for 60 minutes to obtain a polyimide diaphragm. Based on the total amount of the polyimide diaphragm, polyimide The content of the amine was 97% by weight, and the content of the additive tetraethyl orthosilicate was 3% by weight. The average degree of polymerizat...

Embodiment 2

[0041] This example illustrates the battery separator of the present invention and its preparation method.

[0042] With 218 parts by weight of pyromellitic dianhydride (PMDA, Liyang Longsha Chemical Co., Ltd.), 200 parts by weight of diaminodiphenyl ether (ODA, Shanghai Reagent No. 3 Factory), 83.6 parts by weight of polyvinylpyrrolidone (Hangzhou Shenhua Technology Development Co., Ltd., K30), 22 parts by weight of calcium sulfate whiskers (Hefei Jiankun Chemical Co., Ltd., average particle diameter 20nm) and 4000 parts by weight of N-methylpyrrolidone were stirred and mixed evenly at 25°C to obtain a mixture , the mixture was coated as a mixture layer on a glass sheet with an I-shaped coating film applicator. The mixture layer was immersed in 1000 ml of water for 3 minutes, taken out, air-dried, and heated in an oven at 320° C. for 60 minutes to obtain a polyimide diaphragm. Based on the total amount of the polyimide diaphragm, polyimide The content of the amine was 95% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com