Mobile heating device having shell breaking function inside methane pool and shell breaking method

A heating device and biogas digester technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of no heating device installed, cannot be used normally, and cannot be provided, etc., and achieves convenient construction and operation. Simple and effective in improving gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

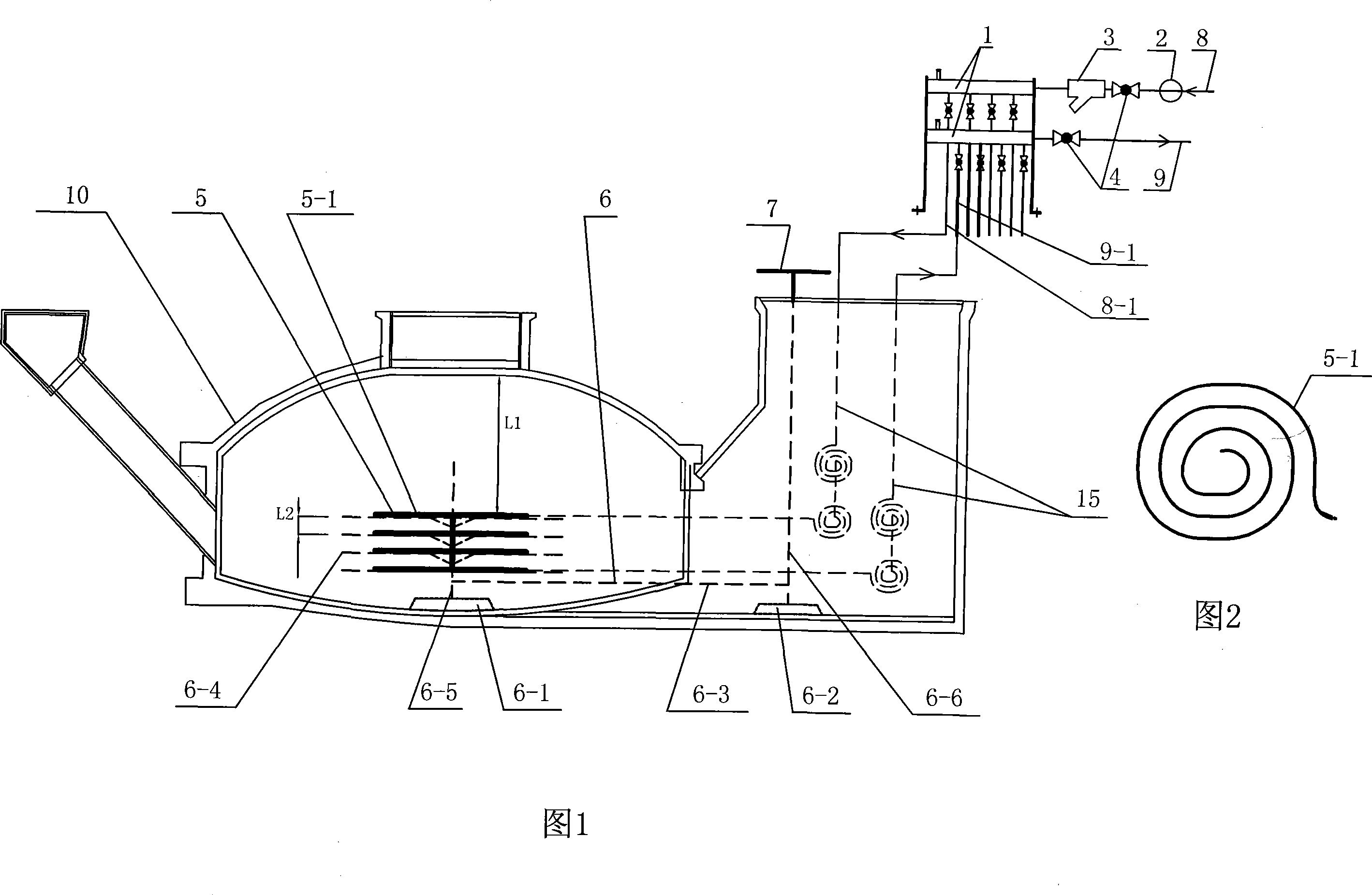

[0008] Specific Embodiment 1: As shown in Figure 1, the mobile heating device with shell breaking function in the biogas digester of this embodiment consists of a water separator / collector 1, a circulating pump 2, a control valve 4, a group of heating pipe bodies 5, and a heating pipe The base frame 6 and the control handle 7 are composed, the control valve 4 is respectively arranged on the water supply pipe 8 and the water return pipe 9 of the water distribution / collector 1, and the circulation pump 2 installed on the water supply pipe 8 of the water distribution / collector 1 is connected with the The inlet end of the control valve 4 on the water supply pipe 8 of the water distributor / collector 1 communicates; the heating pipe body 5 is installed on the heating pipe base frame 6, and the control handle 7 is fixedly connected with the heating pipe base frame 6, and the heating The pipe base 6 is placed on the bottom face in the digester 10 . Hot water flows into the heating pip...

specific Embodiment approach 2

[0010] Embodiment 2: As shown in FIG. 1 , the heating pipe body 5 in this embodiment is composed of four horizontal loop-winding tubes 5-1 arranged in parallel, and each horizontal loop-winding tube 5-1 is connected. The vertical distance L2 between every two horizontal loop winding pipes 5-1 is 10 to 100 cm. With such a structure, it is suitable for applications in the range of 8 to 50 m 3 In a small biogas digester, the effect of heating and cracking shells is better. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: As shown in FIG. 2 , the shape of the heating pipe body 5 in this embodiment is a spiral shape. The distance between two adjacent tubes is 5-50 cm, and this structure has good heating effect and is easy to process. Other compositions and connections are the same as in the first embodiment.

[0012] Specific Embodiment Four: As shown in Figure 1, the heating tube base frame 6 described in this embodiment consists of a first base 6-1, a second base 6-2, a horizontal bar 6-3, and several horizontal brackets 6- 4. The first vertical bar 6-5 and the second vertical bar 6-6 are composed, the upper end surface of the first base 6-1 is fixedly connected with the lower end of the first vertical bar 6-5, and the second base 6-2 The upper end surface of the upper end is fixedly connected with the lower end of the second vertical bar 6-6, and several horizontal brackets 6-4 are horizontally arranged on the first vertical bar 6-5 from top to bottom, the first vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com