Pumping filtration-based preparation method of paper-based friction material

A paper-based friction material and solution technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, paper, papermaking, etc., can solve the problems of uneven interface bonding, poor wear resistance, and easy settlement, etc. Achieve the effects of not easy to settle, not easy to flocculate, and improve friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

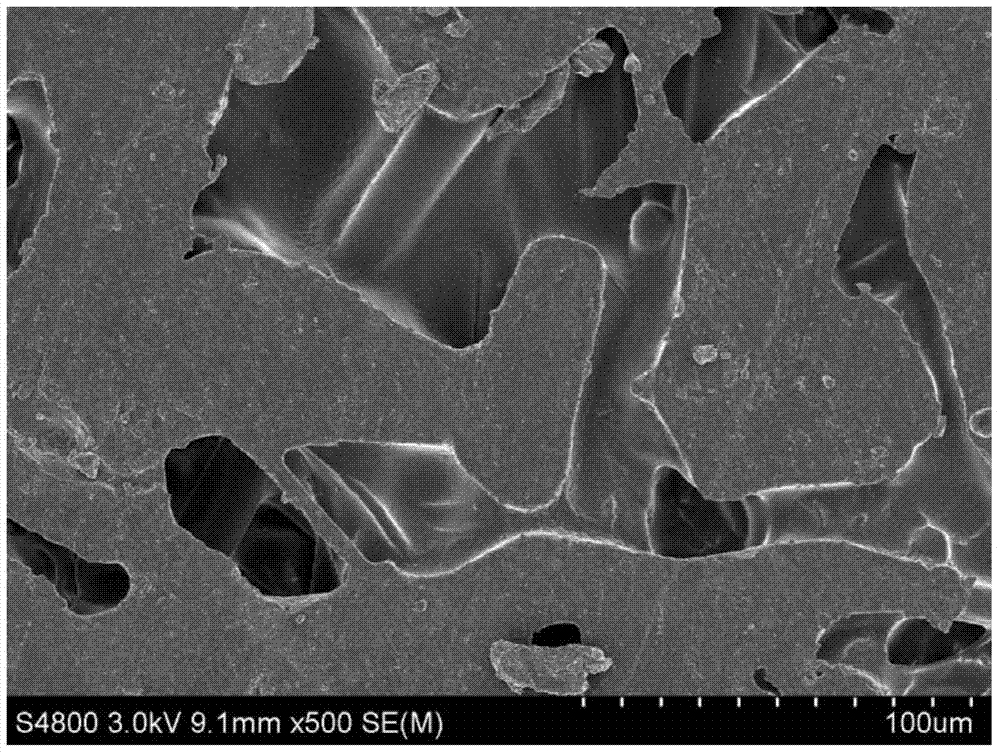

Image

Examples

Embodiment 1

[0026] Step 1: Take 1.0 g of cashew nut shell oil modified phenolic resin, dissolve it in 60 mL of absolute ethanol to obtain a phenolic resin solution, wait for the phenolic resin to be fully dissolved and let it stand for 20 hours, seal it and store it to obtain a solution;

[0027] Step 2: Disperse 3 g of multi-walled carbon nanotubes with a diameter of 30-50 nm in 100 mL of a 0.1% sodium dodecylsulfonate (SDS) aqueous solution, and stir magnetically for 4 hours until the multi-walled carbon nanotubes are uniformly dispersed. Obtain suspension B;

[0028] Step 3: Add 8 g of chopped carbon fibers with a diameter of 8 to 15 μm, 7 g of bamboo fibers with a beating degree of 60°SR, 1 g of diatomaceous earth, and 40 mL of A solution into 100 mL of absolute ethanol, and disperse evenly to obtain a mixed solution. Take 100g of suspension B and pour it into the mixed solution to obtain C solution;

[0029] Step 4: Pour the C solution into the decomposer and disperse for 1000r, tak...

Embodiment 2

[0032] Step 1: Take 2g of cashew nut shell oil modified phenolic resin, dissolve it in 70mL of absolute ethanol to obtain a phenolic resin solution, wait for the phenolic resin to fully dissolve and let it stand for 25 hours, seal it and store it to obtain A solution;

[0033] Step 2: Disperse 4 g of multi-walled carbon nanotubes with a diameter of 30 to 50 nm in 200 mL of an aqueous solution of sodium dodecylsulfonate (SDS) with a mass concentration of 0.2%, and stir magnetically for 5 hours until the multi-walled carbon nanotubes are uniformly dispersed. Obtain suspension B;

[0034] Step 3: Add 9 g of chopped carbon fibers with a diameter of 8 to 15 μm, 8 g of bamboo fibers with a beating degree of 70°SR, 2 g of diatomaceous earth, and 50 mL of A solution into 200 mL of absolute ethanol, and disperse evenly to obtain a mixed solution. Take 200g of suspension B and pour it into the mixed solution to obtain C solution;

[0035] Step 4: Pour the C solution into the decomposer...

Embodiment 3

[0038] Step 1: Take 3g of cashew nut shell oil-modified phenolic resin and dissolve it in 80mL of absolute ethanol to obtain a phenolic resin solution. After the phenolic resin is fully dissolved, let it stand for 30 hours, seal it and store it to obtain A solution;

[0039] Step 2: Disperse 5 g of multi-walled carbon nanotubes with a diameter of 30-50 nm in 300 mL of 0.3% sodium dodecylsulfonate (SDS) aqueous solution, and stir magnetically for 5.5 hours until the multi-walled carbon nanotubes are uniformly dispersed. Obtain suspension B;

[0040] Step 3: Add 10g of chopped carbon fibers with a diameter of 8 to 15 μm, 9g of bamboo fibers with a beating degree of 80°SR, 3g of diatomaceous earth and 60mL of A solution into 300mL of absolute ethanol, and disperse evenly to obtain a mixed solution. Take 300g of suspension B and pour it into the mixed solution to obtain C solution;

[0041] Step 4: Pour the C solution into the decomposer and disperse for 1400r, take out the decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com