Hemp fiber doped saloon car brake pad and preparation process thereof

A technology of hemp fiber and brake pad is applied in the field of asbestos-free organic-based car brake pad and its preparation process, which can solve the problems of poor friction performance, poor compatibility, and affecting the progress of replacing asbestos.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The hemp fiber used in the present invention should have the advantages of environmental protection, noise reduction, stable friction performance, and low cost. It also needs to be treated by physical methods to improve its shortcomings such as hardness and brittleness, low friction coefficient, and poor compatibility. Therefore, microwave-ultrasonic -Laser joint treatment is precisely to increase its flexibility, improve friction performance and heat resistance, and improve its cohesion on the basis of maintaining the advantages of hemp fiber.

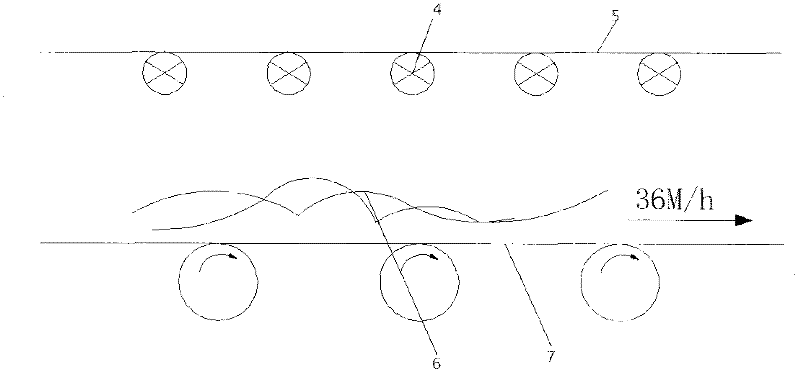

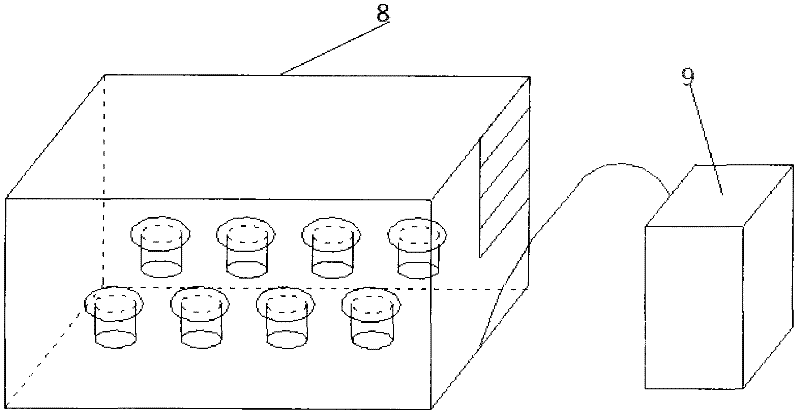

[0040] The process flow and parameters of the combined microwave-ultrasonic-laser treatment method are as follows:

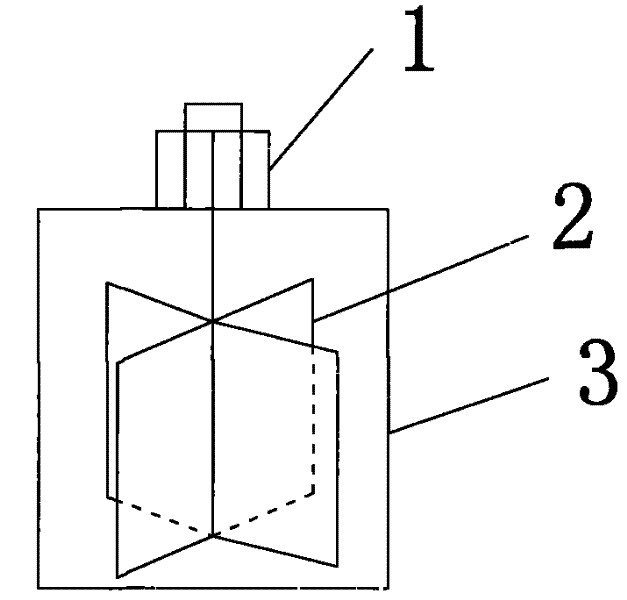

[0041] Alkali treatment: first place the hemp fiber in 6% NaOH solution, soak it at a constant temperature of 70°C for 3 hours, the bath ratio is 1:20, and stir it with a stirrer, and the stirrer changes the direction of rotation every 2s. Its device such as figure 1 shown. The stirring motor 1 is an AC motor w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com