Rail wagon high-friction-coefficient brake shoe friction body and brake shoe

A high friction coefficient technology for railway wagons, applied in friction linings, other chemical processes, mechanical equipment, etc., can solve problems such as low compressive strength, low bending strength and impact strength, potential safety hazards for vehicles, and reduced wheel protection. Achieve low elastic modulus, less environmental pollution, and inhibit metal embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

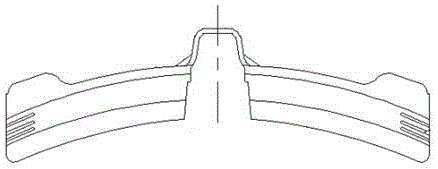

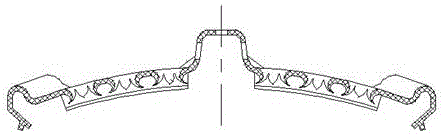

Image

Examples

Embodiment 1

[0041] 1) Prepare and weigh the components of the friction body according to the aforementioned mass ratio: 9% nitrile rubber, 7% cashew nut shell oil modified phenolic resin, 6% steel fiber, 15% sepiolite fiber, 25% barium sulfate, iron 20% powder, 6% graphite, 9.4% feldspar powder, 0.7% calcined bauxite, 0.4% accelerator, 0.4% stearic acid, 0.5% zinc oxide, 0.6% sulfur, satisfying the sum of the mass of each component to reach 100% requirements.

[0042] 2) Smelting: Preliminary mixing of phenolic resin, steel fiber, sepiolite fiber, barium sulfate, reduced iron powder, graphite, feldspar powder, calcined bauxite and zinc oxide; mastication of nitrile rubber, plastication Finally, adjust the stick distance and add the chaotic material, add accelerator and stearic acid for a certain period of refining time, and add sulfur in the last 1-3 minutes. Pay attention to the time and temperature of the refining.

[0043] A synthetic brake shoe for railway wagons, including a tile bac...

Embodiment 2

[0047] Prepare and weigh the components of the friction body according to the aforementioned mass ratio: 10% nitrile rubber, 10% cashew nut shell oil modified phenolic resin, 5% steel fiber, 16% sepiolite fiber, 23% barium sulfate, and 19% iron powder %, 5% graphite, 9% feldspar powder, 1.0% calcined bauxite, 0.35% accelerator, 0.45% stearic acid, 0.5% zinc oxide, and 0.7% sulfur, meeting the requirement that the sum of the mass of each component reach 100% .

[0048] 2) Smelting: Preliminarily mix phenolic resin, steel fiber, sepiolite fiber, barium sulfate, reduced iron powder, graphite, feldspar powder, and calcined bauxite, weigh a certain amount of nitrile rubber for plastication, and plasticize After refining, adjust the stick distance and add the chaotic material, add accelerator and stearic acid for a certain period of refining, and add a certain proportion of sulfur in the last 1-3 minutes. Pay attention to the time and temperature of the refining.

[0049] A synthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com