Brake gasket with bundle-type acrylic fibers and preparation method thereof

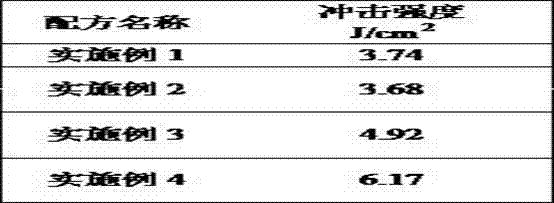

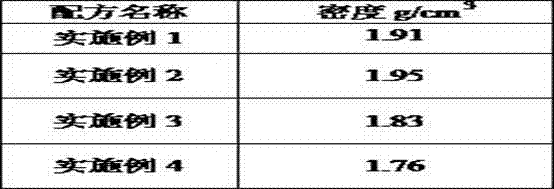

An acrylic fiber and brake technology, which is applied to chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems of easy rust, brake noise, and easy wear, and achieve stable friction performance, good wear resistance, and improved The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix the above components in the mixer, add 70 ° C of 70 ° C with the amount of feeding amount, and then mix and combine it to make a uniform particle size of 3mm granular plastic material, and then press this granular pressure pressureThe plastic is dried at 70 ° C and its moisture content is controlled at 3%.

[0019] Example 2: 15%of resin; short fiber of beam -shaped acrylic; 30%increase in muscler; 15%abrasive agent; 34%of the fillers;

Embodiment 2

[0020] Mix the above components in the mixer, add 50 ° C of 50 ° C with the amount of feeding amount, and then mix and combine it to make a uniform particle size of 5mm granular plastic material, and then press this granular pressure pressureThe plastic is dried at 75 ° C, and its moisture content is controlled at 2%.

[0021] Example 3: 15%of resin; 9%of the bundle acrylic short fiber; 30%increase in the increase agent; 15%abrasive agent; 31%of the fillers;

Embodiment 3

[0022] Mix the above components in the mixer, add 60 ° C of 60 ° C with the amount of feeding amount, and then mix it into a uniform particle size to 5mm granular plastic material, and then press this granular pressure pressureThe plastic is dried at 75 ° C, and its moisture content is controlled at 2%.

[0023] Example 4: 15%of resin; 12%fiber of beam -shaped acrylic; 30%increase agent; 15%abrasive agent; 28%fillers;

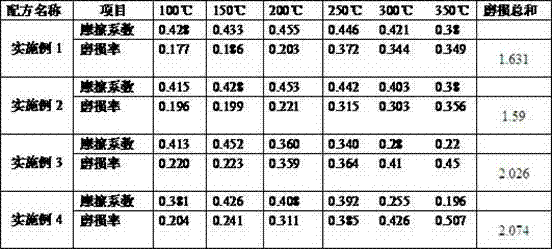

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com